京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2

《中国塑料》编辑部 ©2008-2024 版权所有

地址:北京市海淀区阜成路11号 邮编:100048

编辑部:010-68985541 联系信箱:cp@plaschina.com.cn

广告部/发行部:010-68985253 本系统由北京玛格泰克科技发展有限公司设计开发

中国塑料 ›› 2022, Vol. 36 ›› Issue (3): 157-166.DOI: 10.19491/j.issn.1001-9278.2022.03.024

左志刚( ), 周帅, 田同金, 王强, 李瑞, 魏浩, 王国军(

), 周帅, 田同金, 王强, 李瑞, 魏浩, 王国军( )

)

收稿日期:2021-09-22

出版日期:2022-03-26

发布日期:2022-03-25

通讯作者:

王国军(1974—),男,副教授,主要研究方向为聚合物组成⁃结构⁃性能的关系,wang5347@hrbeu.edu.cn作者简介:左志刚(1998—),男,在读硕士,主要研究方向为光扩散剂的合成,zzg973510313@hrbeu.edu.cn

ZUO Zhigang( ), ZHOU Shuai, TIAN Tongjin, WANG Qiang, LI Rui, WEI Hao, WANG Guojun(

), ZHOU Shuai, TIAN Tongjin, WANG Qiang, LI Rui, WEI Hao, WANG Guojun( )

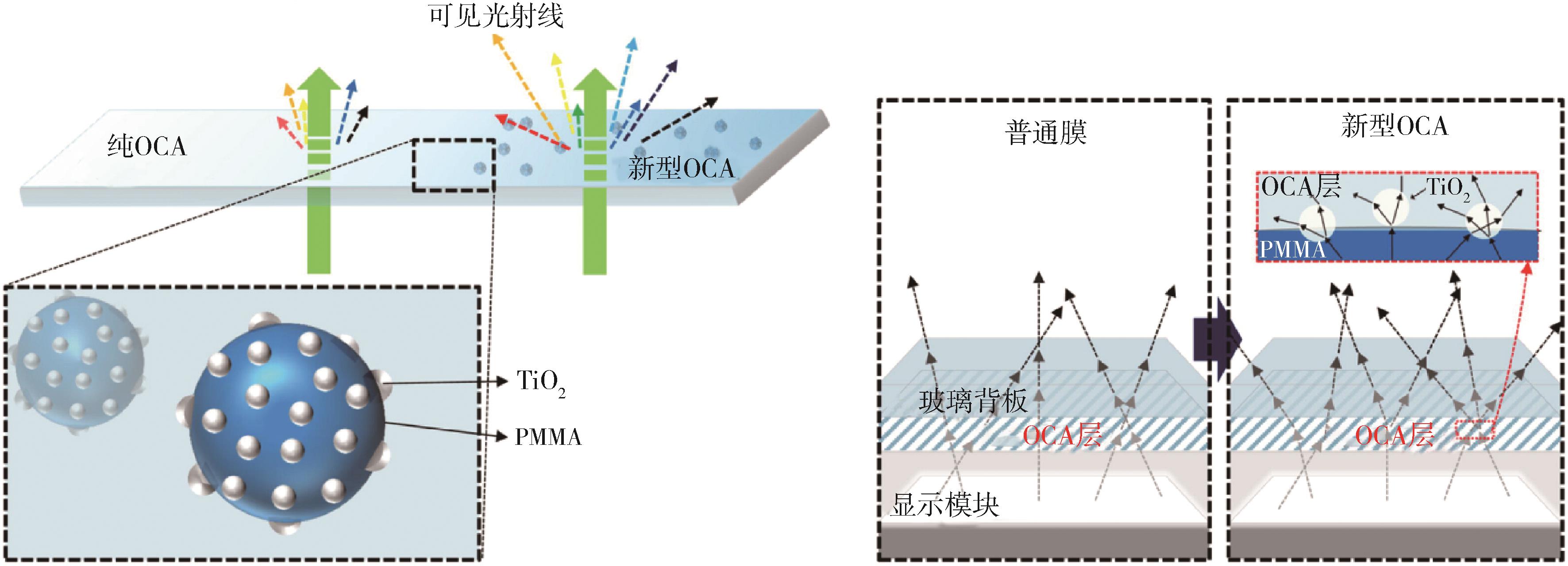

)

Received:2021-09-22

Online:2022-03-26

Published:2022-03-25

Contact:

WANG Guojun

E-mail:zzg973510313@hrbeu.edu.cn;wang5347@hrbeu.edu.cn

摘要:

首先对广泛应用于照明、生物材料、临床医学、化妆品和农业等领域的光扩散材料的类型和性能参数等方面进行了介绍,然后从光扩散原理以及通过结构设计提升光扩散性能等方面详细介绍了近几年国内外的研究进展。最后,总结了光扩散材料目前存在的问题,并展望了未来发展的方向。

中图分类号:

左志刚, 周帅, 田同金, 王强, 李瑞, 魏浩, 王国军. 高性能光扩散材料的研究进展[J]. 中国塑料, 2022, 36(3): 157-166.

ZUO Zhigang, ZHOU Shuai, TIAN Tongjin, WANG Qiang, LI Rui, WEI Hao, WANG Guojun. Research progress in high⁃performance light diffusion materials[J]. China Plastics, 2022, 36(3): 157-166.

材料 类型 | 结构 | 透光率/% | 雾度/% |

|---|---|---|---|

表面 浮雕型 | 粗糙微结构[ | 90 | 78 |

| 三维多孔薄膜[ | 94 | 40 | |

| 微透镜[ | 89 | 48.7 | |

体积 扩散型 | Mg⁃Al微球/PET[ | 81 | 86 |

| 勃姆石/PC[ | 81 | 86 | |

| AgCl纳米棒/PET[ | 93.6 | 88.6 | |

| 硅胶微球/PC[ | 78.1 | 99.9 | |

| PMMA/SiO2/PC[ | 94.6 | 84.2 | |

| SAN/SiO2/PC[ | 77.03 | 104.41 | |

| SiO2/TiO2/PMMA/丙烯酸树脂[ | 87 | 81 | |

| 复合型 | 有机硅微球/微透镜[ | 96.9 | 75 |

材料 类型 | 结构 | 透光率/% | 雾度/% |

|---|---|---|---|

表面 浮雕型 | 粗糙微结构[ | 90 | 78 |

| 三维多孔薄膜[ | 94 | 40 | |

| 微透镜[ | 89 | 48.7 | |

体积 扩散型 | Mg⁃Al微球/PET[ | 81 | 86 |

| 勃姆石/PC[ | 81 | 86 | |

| AgCl纳米棒/PET[ | 93.6 | 88.6 | |

| 硅胶微球/PC[ | 78.1 | 99.9 | |

| PMMA/SiO2/PC[ | 94.6 | 84.2 | |

| SAN/SiO2/PC[ | 77.03 | 104.41 | |

| SiO2/TiO2/PMMA/丙烯酸树脂[ | 87 | 81 | |

| 复合型 | 有机硅微球/微透镜[ | 96.9 | 75 |

| 1 | 任飞飞. 多孔聚苯乙烯微球制备及其光扩散剂应用研究[D]. 北京:北京化工大学, 2019. |

| 2 | 赵长松,贺建芸,谢鹏程,等. 微结构扩散膜光化学制备工艺[J].塑料, 2019, 48(5):111⁃113,127. |

| ZHAO C S, HE J Y, XIE P C, et al. Microstructure diffusion film photochemical preparation technology[J]. Plastics, 2019, 48(5):111⁃113,127. | |

| 3 | YOON J, LEE J H, LEE J B, et al. Highly scattering hierarchical porous polymer microspheres with a high⁃refractive index inorganic surface for a soft⁃focus effect[J]. Polymers, 2020, 12(10): 10.3390/polym12102418. |

| 4 | LUO H, YANG G, ZHU Q. Fiber endface illumination diffuser for endo⁃cavity photoacoustic imaging[J]. Optics Letters, 2020, 45(3):632⁃635. |

| 5 | JOHANNSMEIER S, TORRES⁃MAPA M L, DIPRESA D, et al. Hydrogels for targeted waveguiding and light diffusion[J]. Optical Materials Express, 2019, 9(10): 10.1364/OME.9.003925. |

| 6 | RAO A, NAGARAJAPPA G B, NAIR S, et al. Flexible transparent wood prepared from poplar veneer and polyvinyl alcohol[J]. Composites Science and Technology, 2019, 182: 10.1016/j.compscitech.2019.107719. |

| 7 | 张牙润,靳树伟,王明显,等. 高透光散光功能棚膜的开发[J].化工设计通讯, 2020, 46(5):162⁃163. |

| ZHANG Y R, JIN S W, WANG M X, et al. Development of functional shed film with high transmittance and astigmatism[J]. Chemical Engineering Design Communications, 2020, 46(5):162⁃163. | |

| 8 | GUO S, ZHOU S X, LI H J, YOU B. Light diffusing films fabricated by strawberry⁃like PMMA/SiO2 composite microspheres for LED application[J]. Journal of Colloid & Interface Science, 2015, 448:123⁃129. |

| 9 | LIM B W, SUH M C. Simple fabrication of a three⁃dimensional porous polymer film as a diffuser for organic light emitting diodes[J]. Nanoscale, 2014, 6(23):14 446⁃14 452. |

| 10 | JUNCHI, CHEN, BENJAMIN, et al. Microlens arrays with adjustable aspect ratio fabricated by electrowetting and their application to correlated color temperature tunable light⁃emitting diodes[J]. Optics Express, 2019, 27(4): 10.1364/OE.27.000A25. |

| 11 | OHZONO T, SUZUKI K, YAMAGUCHI T, et al. Tunable optical diffuser based on deformable wrinkles[J]. Advanced Optical Materials, 2013, 1(5):374⁃380. |

| 12 | HUANG J W, KAO Y M, CHIU P W, et al. Light diffusion film fabricated using colloidal lithography and embossing[J]. Journal of Nanoparticle Research, 2021, 23(1): 10.1007/s11051⁃020⁃05125⁃w. |

| 13 | KENTARO K, TAKAHIRO I, BAKU K, et al. Double⁃layer anisotropic light diffusion films fabricated using a two⁃step UV curing technique[J]. Japanese Journal of Applied Physics, 2016, 55(4):042601. |

| 14 | LIN F, ZHU L, YANG S. Effective optical diffuser based on interfacial hydrogen⁃bonding polymer complexation[J]. ACS Applied Polymer Materials, 2020, 2(9):3 805⁃3 812. |

| 15 | WU Y, ZHANG H, PAN A, et al. White⁃light⁃emitting melamine⁃formaldehyde microspheres through polymer⁃mediated aggregation and encapsulation of graphene quantum dots[J]. Advanced Science, 2019, 6(2): 1801432. |

| 16 | DING Y, XIONG Y, GUO S. The directional migration of SiO2 particles enhances the multiple scattering effect: new insights for improving the performance of light⁃scattering materials[J]. Composites Science and Technology, 2021, 212:108872. |

| 17 | ZHAO Z, QIU J, XIONG Y, et al. In⁃situ preparation of core⁃shell⁃like scatterers and their effects on optical and mechanical properties of PC⁃matrix light diffusing materials[J]. Materials & design, 2017, 115:355⁃363. |

| 18 | WU X, LIU M, HU J, et al. Light diffusing mechanism of new diffusion phenomena for diffusers with different diffu⁃sing patterns[J]. Optical Materials, 2020, 111(16):110599. |

| 19 | PARK Y, LEE J H. Wide viewing optically clear adhesives using PMMA/TiO2 core⁃shell micro/nanoparticles[J]. Molecular Crystals and Liquid Crystals, 2020, 705(1):135⁃140. |

| 20 | ZHONG X, HU S, WANG Y, et al. In situ hydrothermal synthesis of polysiloxane@3D flower⁃like hollow Mg⁃Al LDH microspheres with superior light diffusing properties for optical diffusers[J]. Applied clay science, 2019, 171:92⁃99. |

| 21 | SACHHIDANANDA S, NITHIN K S, KEERTHI K M, et al. Mixed Metal oxide Nanofillers Introduced Poly (vinyl alcohol) based Light⁃ Diffusing Nanocomposites: Optical Studies and Improving the Brightness Uniformity of LEDs[J]. Optik ⁃ International Journal for Light and Electron Optics, 2021, 241:166496. |

| 22 | 赵长松. 基于光固化微压印的扩散膜制备工艺设备及成型机理研究[D]. 北京:北京化工大学, 2019. |

| 23 | HOU H, GAN Y, YIN J,et al. Polymerization⁃Induced Groh of Microprotuberance on the Photocuring Coating[J]. Langmuir the Acs Journal of Surfaces & Colloids, 2017, 33(8):2027. |

| 24 | 钟熙. 水热法制备光扩散杂化微球及其在光扩散膜中的应用[D].南京:东南大学, 2018. |

| 25 | TAKAHIRO, ISHINABE, YUYA, et al. Light distribution control of layer⁃structured PDLC fabricated by using micro lens structure and anisotropically diffused UV light[J]. Optics Express, 2019, 27(9):13 416⁃13 429. |

| 26 | CHANG S I, YOON J B, KIM H, et al. Microlens array diffuser for a light⁃emitting diode backlight system[J]. Optics Letters, 2006, 31(20):3 016⁃3 018. |

| 27 | SHIH T K, CHEN C F, HO J R, et al. Fabrication of PDMS (polydimethylsiloxane) microlens and diffuser using replica molding[J]. Microelectronic Engineering, 2006, 83(11/12):2 499⁃2 503. |

| 28 | DENG Z, YANG Q, CHEN F, et al. High⁃performance laser beam homogenizer based on double⁃sided concave microlens[J]. IEEE Photonics Technology Letters, 2014, 26(20):2 086⁃2 089. |

| 29 | WEI W, TASSI N G, ZHU H, et al. Nanocellulose⁃based translucent diffuser for optoelectronic device applications with dramatic improvement of light coupling[J]. ACS Applied Materials & Interfaces, 2015, 7(48):26 860⁃26 864. |

| 30 | BUTT H, KNOWLES H, MONTELONGO K, et al. Devitrite⁃based optical diffusers[J]. Acs Nano, 2014, 8(3):2 929⁃2 935. |

| 31 | BUTT H, YETISEN A K, KHAN A A, et al. Electrically tunable scattering from devitrite–liquid crystal hybrid devices[J]. Advanced Optical Materials, 2016, 5(1):1600414. |

| 32 | ZHAO Y, SHI L, TANG A, et al. Enhanced blue light shielding property of light⁃diffusion polycarbonate compo⁃sites by CeO2⁃coated silicate microspheres[J]. Functional Materials Letters, 2015, 8(6):1550074. |

| 33 | BUNTEM R, SUTHABANDITPONG W, et al. Studies of optical properties of UV⁃cured acrylate films modified with spherical silica nanoparticles[J]. Advanced Powder Technology the Internation Journal of the Society of Powder Technology Japan, 2016, 27(2):411⁃416. |

| 34 | SUTHABANDITPONG W, TANI M, TAKAI C, et al. Facile fabrication of light diffuser films based on hollow silica nanoparticles as fillers[J]. Advanced Powder Technology, 2016, 27(2):454⁃460. |

| 35 | ZHONG X, HU J, ZHOU Y, et al. Template⁃free hydrothermal synthesis of 3D flower⁃like hollow Mg⁃Al layered double hydroxides microspheres for high⁃performance optical diffusers[J]. Materials Letters, 2017, 211:343⁃347. |

| 36 | FAYZULLIN I Z, GOLUBCHIKOVA K E, VOLFSON S I. Light⁃diffusing composite material based on polystyrene, polyethylene and hollow glass microspheres[J]. Plasticheskie Massy: Sintez Svojstva Pererabotka Primenenie, 2019, (7/8):62⁃66. |

| 37 | 佟伟,吴俊,岑茵,彭民乐,等. 矿物填充光扩散PC材料研究[J].广东化工, 2020, 47(3):36⁃37. |

| TONG W, WU J, CENG Y, et al. Study on mineral filled light diffusive polycarbonate[J]. Guangdong Chemical Industry, 2020, 47(3):36⁃37. | |

| 38 | SAMPATHGAMAGE, KANG E, CHRISTINAKERLIND, et al. Transparent nanocellulose metamaterial enables controlled optical diffusion and radiative cooling[J]. Journal of Materials Chemistry C, 2020, 8(34):11687⁃11694. |

| 39 | PARK J Y, CHO W S, CHOI C S, et al. Embedding scattering centers in polymer substrate to yield robust hazy film with high optical transmittance: application to virtual‐reality display[J]. Advanced Optical Materials, 2020, 8(8):1901866. |

| 40 | ZHOU L, HAN C, ZHANG C, et al. A novel optical diffuser based on polymer micro⁃balls⁃filled nematic liquid crystal composite film[J]. RSC Advances, 2018, 8(70):40 347⁃40 357. |

| 41 | ZHOU L, MA H, HAN C, et al. A novel light diffuser based on the combined morphology of polymer networks and polymer balls in a polymer dispersed liquid crystals film[J]. RSC Advances, 2018, 8(39):21 690⁃21 698. |

| 42 | ZHOU L, ZHANG LY, et al.Optical diffusers based on uniform nano⁃sized polymer balls/nematic liquid crystals composite films[J]. Liquid Crystals, 2019, 47(5):785⁃798. |

| 43 | MAHPEYKAR S M, ZHAO Y, LI X, et al. Cellulose nanocrystal:polymer hybrid optical diffusers for index⁃matching⁃free light management in optoelectronic devices[J]. Advanced Optical Materials, 2017, 5(21):1700430. |

| 44 | XU Q, MENG L, WANG X. Reducing shadowing losses in silicon solar cells using cellulose nanocrystal: polymer hybrid diffusers[J]. Applied Optics, 2019, 58(10):2 505⁃2 511. |

| 45 | CHEN Q, DING X, et al. Preparation and properties of porous P(St⁃MMA⁃AA) microsphere anti⁃glare film[J]. Progress in Organic Coatings, 2019, 137:105 287. |

| 46 | OUYANG X, LEI S, et al.Preparation of refractive⁃index⁃controlled silicone microspheres and their application in polycarbonate light diffusing materials[J]. Polymer Plastics Technology & Materials, 2019, 58(16):1 766⁃1 780. |

| 47 | 瞿鹏,郭惠铭,梁天,等. 硅橡胶微球光扩散剂的制备表征及应用[J].高分子材料科学与工程, 2018,34(1):143⁃147,153. |

| QU P, GUO H M, LIANG T,et al. Preparation,characterization and application of silicone rubber microsphere light scattering agent[J]. Polymer Materials Science & Engineering, 2018,34(1):143⁃147,153. | |

| 48 | ZHANG X, CAO Y, JIANG Q, et al. Preparation of cross⁃linked poly(methyl methacrylate) microspheres using an asymmetric cross⁃linker via dispersion polymerization and its application in light diffusers[J]. Colloid and Polymer Science, 2020, 298(4/5):495⁃504. |

| 49 | WU G, LI W, et al.Preparation of nonspherical fluorinated acrylate polymer particles by a "surface tension controlling" method and their applications in light⁃diffusing films[J]. Macromolecular Materials and Engineering, 2019, 304(8):1900174. |

| 50 | JIANG J, WEI A, LI J, et al. Preparation and characterization of polymethyl methacrylate light⁃scattering material[J]. Polymer Bulletin, 2019, 77(6): 3 223⁃3 235. |

| 51 | WU X, WANG X, QIN Z, et al. Polycarbonate composites with high light transmittance, haze, and flame retardancy based on a series of incomplete⁃cage oligomeric silsesquioxanes[J]. Journal of Materials Science, 2021, 56(1):428⁃441. |

| 52 | HWANG Y, CHO N J, et al. An intrinsically micro⁃/nanostructured pollen substrate with tunable optical properties for optoelectronic applications [J]. Advanced Materials, 2021, 33(32):2100566. |

| 53 | WU G, GUO S, YIN Y, et al. Hollow microspheres of SiO2/PMMA nanocomposites: preparation and their application in light diffusing films[J]. Journal of Inorganic and Organometallic Polymers and Materials, 2018, 28(6):2 701⁃2 713. |

| 54 | DING Y, ZHOU Q, LI X, et al. PC light⁃scattering material containing "pomegranate⁃like" SAN⁃SiO2 microspheres with excellent effective scattering range based the large⁃screen display[J]. Composites Science and Technology, 2021, 201(10):108532. |

| 55 | SON I, LEE J H. Highly transparent and wide viewing optical films using embedded hierarchical double⁃shell layered nanoparticles with gradient refractive index surface[J]. ACS Applied Materials And Interfaces, 2020, 12(27):30 862⁃30 870. |

| 56 | ZHONG X, ZHOU Y, HE M, et al. Synthesis of organosiloxane⁃coated SiO2/CeO2 with multilayered hierarchical structure and its application in optical diffusers[J]. Journal of Materials Science, 2017, 52(21):12 806⁃12 817. |

| 57 | HU J, ZHOU Y. The properties of nano(ZnO⁃CeO2)@polysiloxane core⁃shell microspheres and their application for fabricating optical diffusers[J]. Applied Surface Science, 2016, 365:166⁃170. |

| 58 | HU J, ZHOU Y, WANG M, et al. Optical diffusers based on the novel fillers of polysiloxane@boehmite core⁃shell microspheres[J]. Materials Letters, 2015, 165:107⁃110. |

| 59 | HU J, ZHOU Y, SHENG X. Hydrothermal synthesis of ZnO@polysiloxane microspheres and their application in preparing optical diffusers[J]. RSC Advances, 2015, 5(22):17 064⁃17 069. |

| 60 | ZHU J C, LIU Y H. Fabrication of engineered particle⁃doped light diffuser with a soft transparent mold of UV⁃curable polymer[J]. Optical Materials, 2017, 73:234⁃240. |

| 61 | YMA B, TONG G A, CF A, et al. Facile fabrication of biomimetic films with the microdome and tapered nanonipple hierarchical structure possessing high haze, high transmittance, anti⁃fouling and moisture self⁃cleaning functions[J]. Chemical Engineering Journal, 2021, 404:127101. |

| [1] | 沙金, 陈欣, 陈冬平, 马玉录, 谢林生. 基于EHD的PVA薄膜图案化及其在玻璃表面微结构制造中的应用[J]. 中国塑料, 2021, 35(6): 53-59. |

| [2] | 杨明山 朱宝 张万里 薛增增 孟豪宇 张军. 照明LED灯罩及灯管用光扩散聚碳酸酯的制备[J]. 中国塑料, 2019, 33(1): 72-77. |

| [3] | 李江洪 王影 曹瑞军 王晶 卢秉恒. 医用热压膜材料理化性能研究[J]. 中国塑料, 2018, 32(12): 56-60,117. |

| [4] | 王鑫;杜林芳;李寒琪. 薄壁制品微结构充填注射压缩成型中关键因素分析[J]. 中国塑料, 2017, 31(6): 90-94 . |

| [5] | 胡凌骁;康维嘉;贺建芸;杨卫民;谢鹏程. 微流控芯片的紫外光固化注射成型工艺对微结构的影响[J]. 中国塑料, 2016, 30(11): 57-62 . |

| [6] | 任小龙;韩艳霞;蒋耿杰. 黑色聚酰亚胺薄膜研究进展[J]. 中国塑料, 2016, 30(03): 1-9 . |

| [7] | 常乐;蔡天泽;丁玉梅;杨卫民;谢同维;谢鹏程;. 紫外光固化注射成型制品微结构复制度的研究[J]. 中国塑料, 2014, 28(10): 0-64 . |

| [8] | 张勤星 李倩 赵娜 赵建 申长雨. 注塑制品微结构的三维数值模拟分析[J]. 中国塑料, 2011, 25(11): 61-65 . |

| [9] | 于越 张明耀. 基体的组成对透明ABS树脂性能的影响[J]. 中国塑料, 2009, 23(04): 20-23 . |

| [10] | 刘旭红;欧笛声. 基于SUMP优化理论的注塑机固定模板拓扑优化[J]. 中国塑料, 2008, 22(2): 90-92 . |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2