京ICP备13020181号-2

© 《China Plastics》

© 《China Plastics》

China Plastics ›› 2023, Vol. 37 ›› Issue (12): 101-108.DOI: 10.19491/j.issn.1001-9278.2023.12.015

• Machinery and Mould • Previous Articles Next Articles

WANG Congxiao, ZHENG Jiaxin, ZHAO Yuyin, SU Zhenqian, REN Feng( )

)

Received:2023-06-25

Online:2023-12-26

Published:2023-12-26

CLC Number:

WANG Congxiao, ZHENG Jiaxin, ZHAO Yuyin, SU Zhenqian, REN Feng. Effect of screw configuration on properties of PBAT/Talc composites[J]. China Plastics, 2023, 37(12): 101-108.

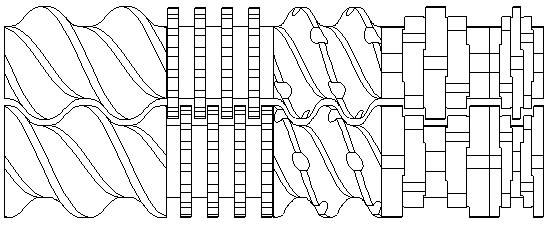

| 实验编号 | 实验类型 | 螺杆构型 | 编码 |

|---|---|---|---|

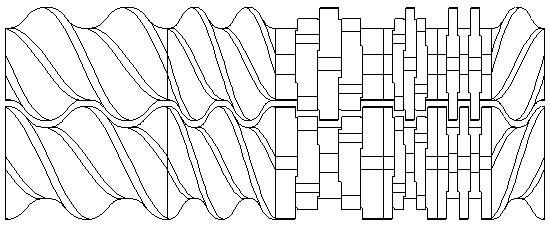

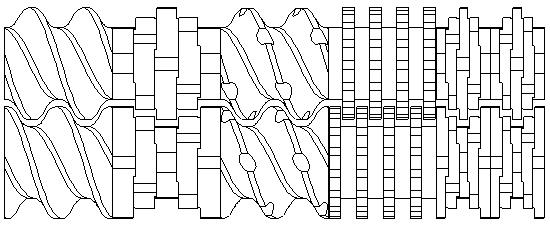

| 1# | 对照组 |  | SE/36/36+SE/36/36+ SE/24/24+SE/24/24 |

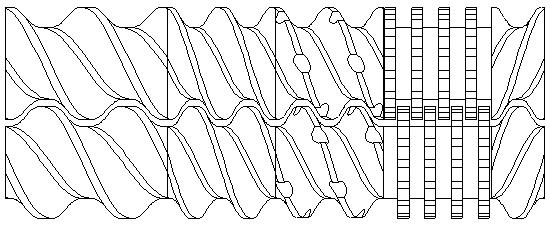

| 2# | 分散混合 |  | SE/36/36+SE/24/24+K45/5/24+K45/5/12+ K90/5/12+SE/24/12L |

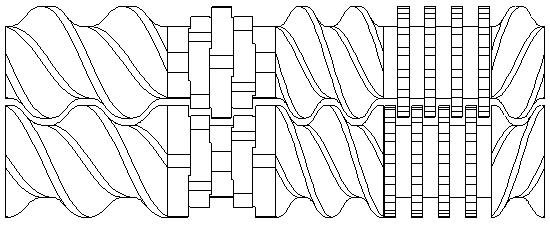

| 3# | 分布混合 |  | SE/36/36+SE/24/24+SME+TME+SE/24/12L |

| 4# | 先分散 后分布 |  | SE/36/36+K45/5/24+SE/24/24+TME+SE/24/12L |

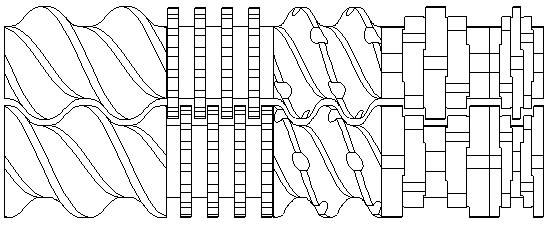

| 5# | 先分布 后分散 |  | SE/36/36+TME+SME+K45/5/24+K45/5/12L |

| 6# | 分散分布 交错布置 |  | SE/24/24+K45/5/24+SME+TME+ K45/5/12+ K45/5/12 |

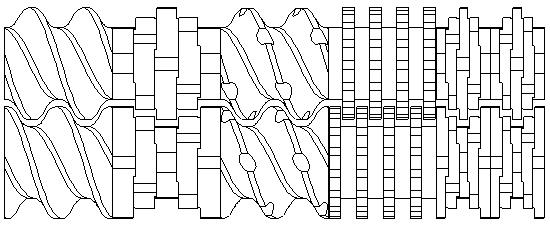

| 实验编号 | 实验类型 | 螺杆构型 | 编码 |

|---|---|---|---|

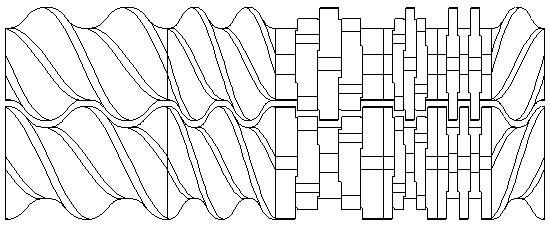

| 1# | 对照组 |  | SE/36/36+SE/36/36+ SE/24/24+SE/24/24 |

| 2# | 分散混合 |  | SE/36/36+SE/24/24+K45/5/24+K45/5/12+ K90/5/12+SE/24/12L |

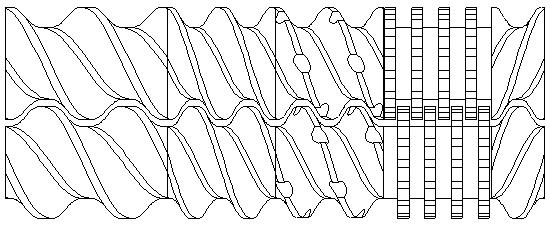

| 3# | 分布混合 |  | SE/36/36+SE/24/24+SME+TME+SE/24/12L |

| 4# | 先分散 后分布 |  | SE/36/36+K45/5/24+SE/24/24+TME+SE/24/12L |

| 5# | 先分布 后分散 |  | SE/36/36+TME+SME+K45/5/24+K45/5/12L |

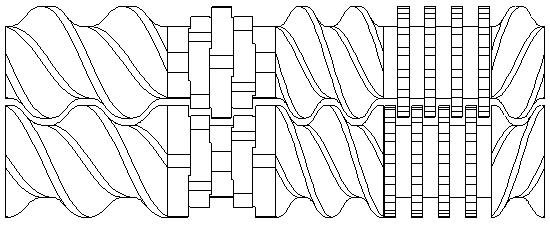

| 6# | 分散分布 交错布置 |  | SE/24/24+K45/5/24+SME+TME+ K45/5/12+ K45/5/12 |

| 样品 | 平均剪切 应力/MPa | 平均停留 时间/s | 回流量/ cm3·s-1 | 拉伸强度/ MPa | 断裂 伸长率/% |

|---|---|---|---|---|---|

| 1# | 0.216 | 39.7 | 4.34 | 33.8 | 426 |

| 2# | 0.218 | 49.0 | 5.20 | 34.3 | 527 |

| 3# | 0.232 | 45.3 | 4.98 | 34.2 | 457 |

| 4# | 0.234 | 46.9 | 4.71 | 32.7 | 410 |

| 5# | 0.230 | 49.6 | 5.61 | 35.4 | 489 |

| 6# | 0.228 | 47.9 | 6.07 | 34.5 | 507 |

| 样品 | 平均剪切 应力/MPa | 平均停留 时间/s | 回流量/ cm3·s-1 | 拉伸强度/ MPa | 断裂 伸长率/% |

|---|---|---|---|---|---|

| 1# | 0.216 | 39.7 | 4.34 | 33.8 | 426 |

| 2# | 0.218 | 49.0 | 5.20 | 34.3 | 527 |

| 3# | 0.232 | 45.3 | 4.98 | 34.2 | 457 |

| 4# | 0.234 | 46.9 | 4.71 | 32.7 | 410 |

| 5# | 0.230 | 49.6 | 5.61 | 35.4 | 489 |

| 6# | 0.228 | 47.9 | 6.07 | 34.5 | 507 |

| 1 | 张 婷,张彩丽,宋鑫宇,翁云宣. PBAT薄膜的制备及应用研究进展[J]. 中国塑料, 2021, 35(7): 115⁃125. |

| ZHANG T, ZHANG C L, SONG X Y, WENG Y X. Research progress in preparation and applications of PBAT films[J]. China Plastics, 2021, 35(7): 115⁃125. | |

| 2 | CHEN J H, CHEN C C, YANG M C. Characterization of nanocomposites of poly(butylene adipate⁃co⁃terephthalate) blending with organoclay[J]. Journal of Polymer Research, 2011, 18(6): 2 151⁃2 159. |

| 3 | YESMINE F, QUIM T, PERé M, et al. PBAT/thermoplastic starch blends: Effect of compatibilizers on the rheological, mechanical and morphological properties[J]. Carbohydrate Polymers, 2018, 199: 51⁃57. |

| 4 | JEAN MARIE R, YOGARAJ N, RAMANI N, et al. Novel high⁃performance talc/poly[(butylene adipate)⁃co⁃terephthalate] hybrid materials[J]. Macromolecular Materials and Engineering, 2008, 293(4): 310⁃320. |

| 5 | 孙 静,黄安荣,罗珊珊,等. 扩链剂对PBAT/Talc复合材料性能影响研究[J]. 塑料科技, 2021, 49(8): 1⁃6. |

| SUN J, HUANG A R, LUO S S, SHI M, LUO H. Effect of chain extender on the properties of PBAT/talc composites[J]. Plastics Science and Technology, 2021, 49(8): 1⁃6. | |

| 6 | ZHANG X X, ZHANG W, SU J S, et al. Preparation, characterization, and properties of polyethylene composites highly filled with calcium carbonate through co⁃rotating conical twin⁃screw extrusion(Article)[J]. Journal of Vinyl and Additive Technology, 2014, 20(2): 108⁃115. |

| 7 | 耿孝正. 双螺杆挤出机及其应用[M]. 2003. |

| 8 | 黄 丽,郑旖旎,吕亚非,等. 不同混合方式对超高分子量聚乙烯复合材料中填料粒子分散性的影响[J]. 北京化工大学学报(自然科学版), 2006, (1): 105⁃107,111. |

| HUANG L, ZHENG Y N, LV Y F, et al. Effects of different mixing methods on properties of UHMWPE⁃based composites[J]. Journal of Beijing University of Chemical T Echnology, 2006, (1): 105⁃107,111. | |

| 9 | 李彦辉,马秀清,武学伟,等. 啮合异向双螺杆挤出机中捏合块元件对PE⁃HD/PS不相容体系混合效果的研究[J]. 中国塑料, 2010, 24(9): 94⁃98. |

| LI Y H, MA X Q, WU X W, TIAN J. Influence of kneading blocks on the mixing effect of PE⁃HD/PS immiscible blend in intermeshing counter⁃rotating twin screw extruder[J]. China Plastics, 2010, 24(9): 94⁃98. | |

| 10 | BERNARDO F, COVAS J, EACUTE, et al. On⁃line optical monitoring of the mixing performance in co⁃rotating twin⁃screw extruders[J]. Polymers, 2022, 14(6): 1 152. |

| 11 | KOKI M, TATSUYA T. A modified blister mixing element for generating extensional flow in a twin⁃screw extruder: Process characterization and dispersion state of carbon nanotubes in cyclo⁃olefin polymer[J]. Polymer Engineering & Science, 2022, 62(4): 1 223⁃1 238. |

| 12 | 赵 勃. 挤出工艺条件对玻纤增强聚丙烯复合材料中玻纤保留长度的影响[J]. 上海塑料, 2021, 49(4): 51⁃54. |

| ZHAO B. Effect of extrusion conditions on glass fiber retention length of glass fiber reinforced polypropylene composites[J]. Shanghai Plastics, 2021, 49(4): 51⁃54. | |

| 13 | 张俊义,马秀清. 斜齿齿形盘与直齿齿形盘混合性能的对比研究[J]. 中国塑料, 2004, 18(3): 83⁃87. |

| ZHANG J Y, MA X Q. Contrast of mixing results of TME and ZME in co⁃rotating twin screw extruders[J].China Plastics,2004,18(3):83⁃87. | |

| 14 | 岳进峰. 基于含能材料的同向双螺杆挤出大型机的研究[D]. 北京:北京化工大学, 2020. |

| 15 | CHAO Z, LING Z, NICOLIN G, et al. DEM analysis of residence time distribution during twin screw granulation[J]. Powder Technology, 2021, 377: 924⁃938. |

| 16 | MOHAMMADI M, M⁃C HEUZEY, CARREAU P J, et al. Interfacial localization of CNCs in PLA/PBAT blends and its effect on rheological, thermal, and mechanical properties[J]. Polymer, 2021, 233. |

| 17 | STEENE S V D, RENTERGHEM J V, VANHOORNE V, et al. Identification of continuous twin⁃screw melt granulation mechanisms for different screw configurations, process settings and formulation[J]. International Journal of Pharmaceutics, 2022, 630: 122322. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||