京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2

《中国塑料》编辑部 ©2008-2024 版权所有

地址:北京市海淀区阜成路11号 邮编:100048

编辑部:010-68985541 联系信箱:cp@plaschina.com.cn

广告部/发行部:010-68985253 本系统由北京玛格泰克科技发展有限公司设计开发

中国塑料 ›› 2024, Vol. 38 ›› Issue (12): 105-114.DOI: 10.19491/j.issn.1001-9278.2024.12.017

刘鑫1, 费怀宇2, 左红梅1,3, 苏永生4, 胡侨乐1,3, 杨莉1,3, 阮芳涛1,3( )

)

收稿日期:2024-03-13

出版日期:2024-12-26

发布日期:2024-12-25

通讯作者:

阮芳涛,工学博士,纤维增强复合材料方向,ruanfangtao @ahpu.edu.cn作者简介:第一联系人:地址:北京市海淀区阜成路11号《中国塑料》杂志社基金资助:

LIU Xin1, FEI Huaiyu2, ZUO Hongmei1,3, SU Yongsheng4, HU Qiaole1,3, YANG Li1,3, RUAN Fangtao1,3( )

)

Received:2024-03-13

Online:2024-12-26

Published:2024-12-25

Contact:

RUAN Fangtao

E-mail:ruanfangtao @ahpu.edu.cn

摘要:

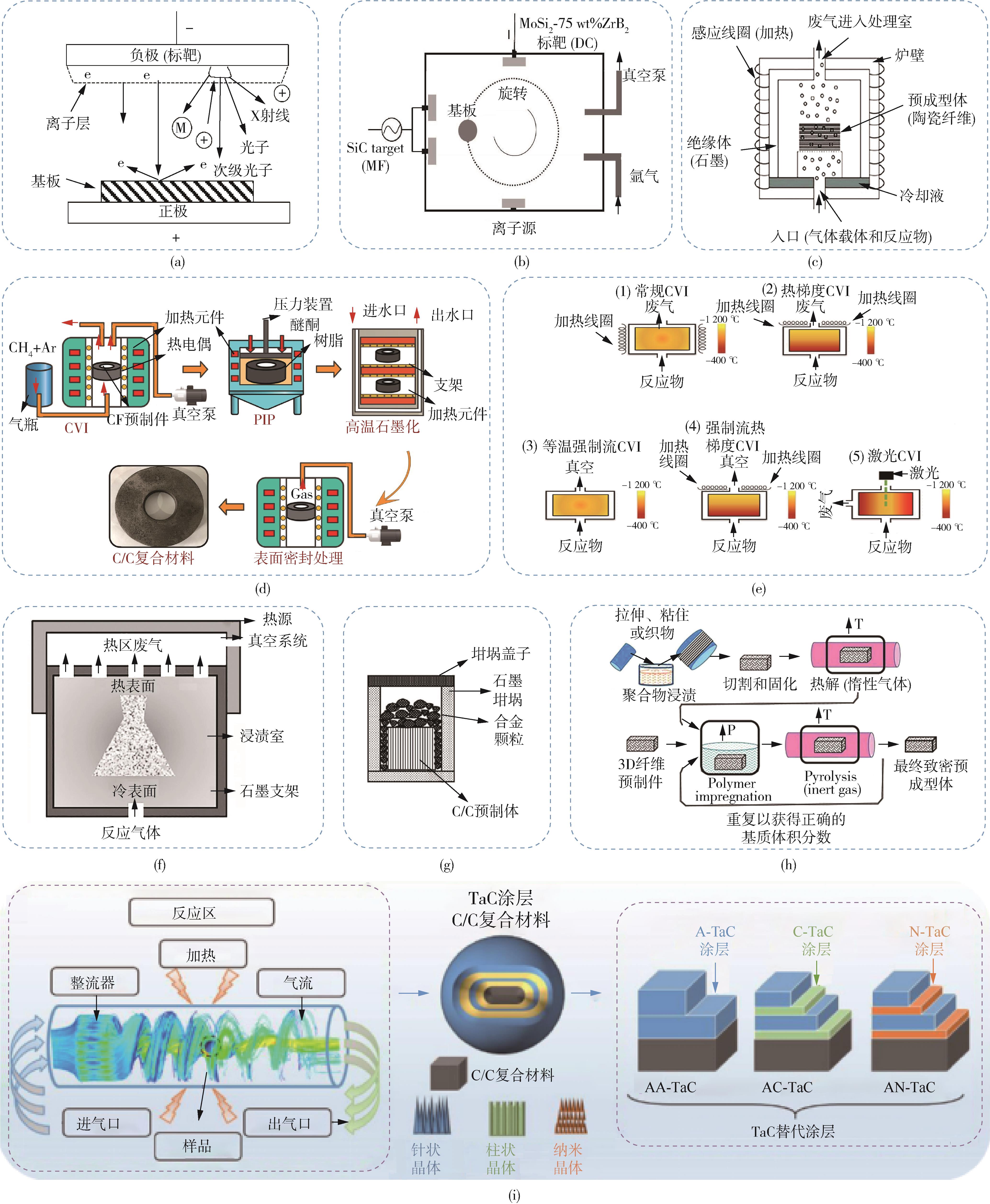

从陶瓷先驱体、SiC、过渡金属涂层材料和磁控溅射、化学气相渗透、化学气相沉积、反应熔渗法、先驱体转化法、包埋法等涂层工艺角度,回顾了C/C复合材料近期的表面涂层处理技术的制备原理及工艺过程的研究现状。探讨了表面改性C/C复合材料在提高材料性能、拓展应用领域等方面的最新进展和发展前景。

中图分类号:

刘鑫, 费怀宇, 左红梅, 苏永生, 胡侨乐, 杨莉, 阮芳涛. 碳/碳复合材料表面涂层工艺研究进展[J]. 中国塑料, 2024, 38(12): 105-114.

LIU Xin, FEI Huaiyu, ZUO Hongmei, SU Yongsheng, HU Qiaole, YANG Li, RUAN Fangtao. Research progress in surface coating process for carbon/carbon composites[J]. China Plastics, 2024, 38(12): 105-114.

| 材料 | 制备工艺 | 密度/g·cm-3 | 测试参数 | 线烧蚀率/μm·s-1 | 参考文献 |

|---|---|---|---|---|---|

| C/C | LPI | 1.98 | 3 200 ℃/60 s | 26.10 | [ |

| C/C⁃ZrC | PIP | 1.80 | 3 000 ℃/120 s | 7.02 | [ |

| RMI | 1.12 | 3 100 ℃/20 s | 1.2 | [ | |

| RMI | 20s | 2 | [ | ||

| C/C⁃ZrB2 | SI | 3 000 ℃/30 s | 4.33 | [ | |

| C/C⁃SiC⁃ZrC | PIP | 2.22 | 2 300 ℃/60 s | 2.48 | [ |

| RMI | 2.64 | 3 000 ℃/60 s | 0.29 | [ | |

| RMI | 2 610 ℃/60 s | 0.4 | [ | ||

| CLVD | 1.97 | 90 s | 0.67 | [ | |

| ICVI | 2.37 | 2.38 MW·m-2/60 s | 7.5 | [ | |

| C/C⁃SiC⁃ZrB2 | PC | 1 727 ℃/40 s | 4.40 | [ | |

| LSI | 2.366 | 300 s | 0.217 | [ | |

| PIP | 4.2 MW·m-2/120 s | 12.74 | [ | ||

| C/C⁃SiC⁃ZrC⁃ZrB2 | PIP | 1.87 | 2.38 MW·m-2 /60 s | 4.05 | [ |

| RMI | 2.23 | 20 s | 2 | [ | |

| SI⁃RMI | 4.18 MW·m-2/60 s | 2.5 | [ | ||

| C/C⁃HfC | PIP | 2.01 | 2 300 ℃/240 s | 5.31 | [ |

| RMI | 60 s | 8 | [ | ||

| C/C⁃SiC⁃HfC | PIP | 2.38 | 4.18 MW·m-2/60 s | 1.06 | [ |

| RMI | 3.42 | 4.18 MW·m-2/120 s | 2.33 | [ | |

| C/C⁃HfB2 | PIP | 1.84 | 3 000 ℃/90 s | 6.56 | [ |

| C/C⁃SiC⁃HfB2 | PIP | 1.94 | 2.38 MW·m-2/60 s | 14.7 | [ |

| C/C⁃ | PC | 4.38 W·m-2/30 s | 4.2 | [ | |

| C/C⁃SiC⁃HfC⁃TaC | PC⁃SAPS | 2.38 MW·m-2/60 s | 0.32 | [ | |

| C/C⁃ZrB2⁃ MoSi2 | PS | 1 600 ℃/600 s | 0.48 | [ | |

| C/C⁃SiC⁃MoSi2 | RMI | 3.20 | [ | ||

| C/C⁃HfB2⁃MoSi2⁃SiC | PC⁃SP | 2 500 ℃/90 s | 18.60 | [ | |

| C/C⁃Mo⁃Si⁃Cr | RMI | 2.66 | 2 500 ℃/600 s | 4.00 | [ |

| C/C⁃ZrB2⁃MoSi2 | APS | 1 500 ℃/9 h | [ |

| 材料 | 制备工艺 | 密度/g·cm-3 | 测试参数 | 线烧蚀率/μm·s-1 | 参考文献 |

|---|---|---|---|---|---|

| C/C | LPI | 1.98 | 3 200 ℃/60 s | 26.10 | [ |

| C/C⁃ZrC | PIP | 1.80 | 3 000 ℃/120 s | 7.02 | [ |

| RMI | 1.12 | 3 100 ℃/20 s | 1.2 | [ | |

| RMI | 20s | 2 | [ | ||

| C/C⁃ZrB2 | SI | 3 000 ℃/30 s | 4.33 | [ | |

| C/C⁃SiC⁃ZrC | PIP | 2.22 | 2 300 ℃/60 s | 2.48 | [ |

| RMI | 2.64 | 3 000 ℃/60 s | 0.29 | [ | |

| RMI | 2 610 ℃/60 s | 0.4 | [ | ||

| CLVD | 1.97 | 90 s | 0.67 | [ | |

| ICVI | 2.37 | 2.38 MW·m-2/60 s | 7.5 | [ | |

| C/C⁃SiC⁃ZrB2 | PC | 1 727 ℃/40 s | 4.40 | [ | |

| LSI | 2.366 | 300 s | 0.217 | [ | |

| PIP | 4.2 MW·m-2/120 s | 12.74 | [ | ||

| C/C⁃SiC⁃ZrC⁃ZrB2 | PIP | 1.87 | 2.38 MW·m-2 /60 s | 4.05 | [ |

| RMI | 2.23 | 20 s | 2 | [ | |

| SI⁃RMI | 4.18 MW·m-2/60 s | 2.5 | [ | ||

| C/C⁃HfC | PIP | 2.01 | 2 300 ℃/240 s | 5.31 | [ |

| RMI | 60 s | 8 | [ | ||

| C/C⁃SiC⁃HfC | PIP | 2.38 | 4.18 MW·m-2/60 s | 1.06 | [ |

| RMI | 3.42 | 4.18 MW·m-2/120 s | 2.33 | [ | |

| C/C⁃HfB2 | PIP | 1.84 | 3 000 ℃/90 s | 6.56 | [ |

| C/C⁃SiC⁃HfB2 | PIP | 1.94 | 2.38 MW·m-2/60 s | 14.7 | [ |

| C/C⁃ | PC | 4.38 W·m-2/30 s | 4.2 | [ | |

| C/C⁃SiC⁃HfC⁃TaC | PC⁃SAPS | 2.38 MW·m-2/60 s | 0.32 | [ | |

| C/C⁃ZrB2⁃ MoSi2 | PS | 1 600 ℃/600 s | 0.48 | [ | |

| C/C⁃SiC⁃MoSi2 | RMI | 3.20 | [ | ||

| C/C⁃HfB2⁃MoSi2⁃SiC | PC⁃SP | 2 500 ℃/90 s | 18.60 | [ | |

| C/C⁃Mo⁃Si⁃Cr | RMI | 2.66 | 2 500 ℃/600 s | 4.00 | [ |

| C/C⁃ZrB2⁃MoSi2 | APS | 1 500 ℃/9 h | [ |

| 分类 | 特征 | 优点 | 缺点 |

|---|---|---|---|

| 平衡磁控溅射 | 磁场紧密,磁力线在靶材表面保持闭合 | 结构简单,应用广泛 | 膜基结合程度差,易形成多孔粗糙的柱状晶薄膜 |

| 非平衡磁控溅射 | 磁场较弱,部分磁力线可延伸至基底表面,常用于多靶系统 | 可沉积出大面积均匀致密的高质量薄膜 | 结构复杂 |

| 直流磁控溅射 | 采用直流电源,可溅射导体或半导体材料 | 工艺设备简单,已大量应用在工业上 | 溅射时易产生电弧,不稳定,靶材利用率低,成膜质量较差 |

| 射频磁控溅射 | 采用射频电源,能对任何材料进行溅射 | 溅射电流大,溅射速率高,膜基结合力强 | 电源结构复杂,设备昂贵 |

| 中频磁控溅射 | 采用交流中频电源(13.56 MHz),常用于孪生靶溅射系统 | 靶材利用率高,溅射速度快,可杜绝“靶中毒”现象 | 电源结构复杂,设备昂贵 |

| 脉冲磁控溅射 | 采用脉冲电源,输出电压波形是非对称的双极性脉冲 | 溅射功率高,防止打弧,降低基底温度,提高沉积速率,成膜质量最好 | 电源结构复杂,设备昂贵 |

| 反应磁控溅射 | 通入反应气体,靶材与反应气体反应形成化合物 | 丰富了膜的种类,可沉积多元复合膜 | 易出现“靶中毒”,阳极消失现象 |

| 分类 | 特征 | 优点 | 缺点 |

|---|---|---|---|

| 平衡磁控溅射 | 磁场紧密,磁力线在靶材表面保持闭合 | 结构简单,应用广泛 | 膜基结合程度差,易形成多孔粗糙的柱状晶薄膜 |

| 非平衡磁控溅射 | 磁场较弱,部分磁力线可延伸至基底表面,常用于多靶系统 | 可沉积出大面积均匀致密的高质量薄膜 | 结构复杂 |

| 直流磁控溅射 | 采用直流电源,可溅射导体或半导体材料 | 工艺设备简单,已大量应用在工业上 | 溅射时易产生电弧,不稳定,靶材利用率低,成膜质量较差 |

| 射频磁控溅射 | 采用射频电源,能对任何材料进行溅射 | 溅射电流大,溅射速率高,膜基结合力强 | 电源结构复杂,设备昂贵 |

| 中频磁控溅射 | 采用交流中频电源(13.56 MHz),常用于孪生靶溅射系统 | 靶材利用率高,溅射速度快,可杜绝“靶中毒”现象 | 电源结构复杂,设备昂贵 |

| 脉冲磁控溅射 | 采用脉冲电源,输出电压波形是非对称的双极性脉冲 | 溅射功率高,防止打弧,降低基底温度,提高沉积速率,成膜质量最好 | 电源结构复杂,设备昂贵 |

| 反应磁控溅射 | 通入反应气体,靶材与反应气体反应形成化合物 | 丰富了膜的种类,可沉积多元复合膜 | 易出现“靶中毒”,阳极消失现象 |

| 1 | WANG Y, XIAO L, ZENG C, et al. Structural and mechanical changes by adding graphene to C/C composites[J]. Ceramics International, 2022, 48(20): 30 927⁃30 937. |

| 2 | LI F, MA Y, XU W, et al. Study on the mechanical and tribological properties of C/C composites by CVI and PIP[J]. Emerging Materials Research, 2022, 11(4): 438⁃446. |

| 3 | NI D, CHENG Y, ZHANG J, et al. Advances in ultra⁃high temperature ceramics, composites, and coatings[J]. Journal of Advanced Ceramics, 2021, 11(1): 1⁃56. |

| 4 | 孙翔宇, 李瑞珍, 谢 栋. HfC、ZrC改性碳/碳复合材料研究进展[J]. 材料导报, 2023, 37(S1): 117⁃122. |

| SUN X Y, LI R Z, XIE D.Research Progress of HfC or ZrC Modified Carbon/Carbon Composites[J]. Materials Reporst, 2023, 37(S1): 117⁃122. | |

| 5 | 王志永, 赵宇辉, 赵吉宾, 等. 陶瓷增材制造的研究现状与发展趋势[J]. 真空, 2020, 57(01): 67⁃75. |

| WANG Z Y, ZHAO Y H, ZHAO J B, et al.Research Status and Development Trend of Ceramic Precursors[J]. Vaccum, 2020, 57(01): 67⁃75. | |

| 6 | 高 波, 王 浩, 王小宙. 聚甲基硅烷的研究进展 [J]. 化工进展, 2011, 30(8): 1 772⁃1 777. |

| GAO B, WANG H, WANG X Z.Research progress of polymethylsilane[J]. Chemical Industry and Engineering Progress, 2011, 30(8): 1 772⁃1 777. | |

| 7 | FU S, ZHU M, ZHU Y. Organosilicon polymer⁃derived ceramics: An overview [J]. Journal of Advanced Ceramics, 2019, 8(4): 457⁃478. |

| 8 | XIAOHUI XU Y M, CHEN FEN, RONGQIAN YAO, et al. Effects of oxidation cross⁃linking and sintering additives (TiN, B) on the formation and heat⁃resistant performance of polymer⁃derived SiC(Ti, B) films [J]. Ceramics International, 2016, 42(7): 8 636⁃8 644. |

| 9 | GUO W, YE Y, BAI S, et al. Preparation and formation mechanism of C/C–SiC composites using polymer⁃Si slurry reactive melt infiltration [J]. Ceramics International, 2020, 46(5): 5 586⁃5 593. |

| 10 | ZHU Y, WEI H, YAN L, et al. Morphology and anti⁃ablation properties of PIP Cf/C–SiC composites with different CVI carbon content under 4.2 MW/m2 heat flux oxy⁃acetylene test [J]. Ceramics International, 2021, 47(2): 2 194⁃2 201. |

| 11 | 滕雅娣, 张大伟, 管国生. 陶瓷前驱体聚硅氮烷的应用研究进展(二) [J]. 有机硅材料, 2013, 27 (6): 457⁃461. |

| TENG Y D, ZHANG D W, GUAN G S.Progress in Application of Polysilazanes as Ceramic Precursors (II)[J]. Silicone Maerial, 2013, 27 (6): 457⁃461. | |

| 12 | 滕雅娣, 孙晓龙, 黄鑫龙, 等. 不同组成的陶瓷前驱体聚硅氮烷的结构与性能的研究[J]. 功能材料, 2015, 46: 7 019⁃7 024. |

| TENG Y D, SUN X L, HUANG X L, et al.Research of chemical structures and properties of | |

| pre⁃ceramic polymer polysilazanes with different composition[J]. Journal of Functional Materials,2015, 46: 7 019⁃7 024. | |

| 13 | 黄 健, 高利珍, 付俊杰, 等. 聚硅氮烷合成方法与应用研究进展[J].化工新型材料, 2016, 44: 9⁃10. |

| HUANG J, GAO L Z, FU J J, et al.Progress of synthesis method of polysilazane and its application[J]. New Chemical Materials, 2016, 44: 9⁃10. | |

| 14 | 邓紫怡, 赵新星, 张 建, 等. 聚硅氮烷原位功能化碳纤维设计及其高温抗氧化性能[J].复合材料学报, 2023, 40(11): 6 119⁃6129. |

| DENG Z Y, ZHAO X X, ZHANG J, et al.In⁃situ polysilazane modified carbon fiber for high temperature anti⁃oxidation[J]. Acta Materiae Compositae Sinica,, 2023, 40(11): 6 119⁃6 129. | |

| 15 | JIA Y, AJAYI T D, RAMAKRISHNAN K R, et al. A skin layer made of cured polysilazane and yttria stabilized zirconia for enhanced thermal protection of carbon fiber reinforced polymers (CFRPs) [J]. Surface and Coatings Technology, 2020, 404.DOI:10.1016/j.surfcoat.2020.126481 . |

| 16 | FAN Z, XIONG C, YIN J, et al. Preparation and characterization of polysilazane⁃based thermal protective coating for CFRP [J]. Journal of Polymer Research, 2023, 30(11).DOI:10.1007/s10965-023-03814-3 . |

| 17 | 雷永鹏, 王应德, 宋永才, 等. 氮化硼纤维先驱体聚硼氮烷的研究进展[J].高分子材料科学与工程, 2010, 26(12): 164⁃167+72. |

| LEI Y P, WANG Y D, SONG Y C, et al.Progress of Polyborazine in Precursor of Boron Nitride Fibers[J].Polymer Materials Science and Engineering, 2010, 26(12): 164⁃167+72. | |

| 18 | 邓 橙, 宋永才, 王应德, 等. 先驱体转化法制备氮化硼陶瓷及表征[C]//中国空间科学学会空间材料专业委员会.湖南:中国空间科学学会空间材料专业委员会2009学术交流会,2009:6. |

| 19 | BRODU E, BALAT⁃PICHELIN M, DE SOUSA MENESES D, et al. Reducing the temperature of a C/C composite heat shield for solar probe missions with an optically selective semi⁃transparent pyrolytic boron nitride (pBN) coating [J]. Carbon, 2015, 82: 39⁃50. |

| 20 | 马青松. 聚硅氧烷先驱体转化制备陶瓷基复合材料研究[D].湖南;国防科学技术大学, 2003. |

| 21 | 夏立建, 卢 伟, 吴连锋, 等. 离子液体基聚硅氧烷的应用研究进展[J]. 有机硅材料, 2023, 37(02): 58⁃67. |

| XIA L J, LU W, WU L F, et al.Research Progress on the Application of Ionic Liquid⁃Based Polysiloxane[J]. Silicone Maerial, 2023, 37(02): 58⁃67. | |

| 22 | GUMULA T. Improved lifetime of new fibrous carbon/ceramic composites [J]. Applied Physics A, 2018, 124(3).DOI:10.1007/s00339-018-1669-3 . |

| 23 | 邢 欣, 刘 琳, 苟燕子, 等. 碳化硅陶瓷先驱体聚甲基硅烷的研究进展[J]. 硅酸盐学报, 2009, 37(5): 898⁃904. |

| XING X, LIU L, GOU Y Z,et al. Research progress of polymethylsilane in precursor of silicon carbide ceramics[J]. Jounel of the Chinese Ceramic Society, 2009, 37(5): 898⁃904. | |

| 24 | 黄能武, 刘 沙, 赵倩倩. 一种SiC涂层的制备方法: 中国,202011453458.4[P]. 20210323. |

| 25 | KRENKEL W. Carbon Fiber Reinforced CMC for High⁃Performance Structures [J]. International Journal of Applied Ceramic Technology, 2004, 1(2): 188⁃200. |

| 26 | CHEN Z, CHEN Y, DONG D, et al. Tribological performance of SiC coating for carbon/carbon composites at elevated temperatures [J]. Ceramics International, 2018, 44(10): 11 233⁃11 238. |

| 27 | FENG T, LI H, HU M, et al. Oxidation and ablation resistance of the ZrB2–CrSi2–Si/SiC coating for C/C composites at high temperature [J]. Journal of Alloys and Compounds, 2016, 662: 302⁃307. |

| 28 | ZISHAN C, HEJUN L, QIANGANG F. SiC wear resistance coating with added Ni, for carbon/carbon composites [J]. Surface and Coatings Technology, 2012, 213: 207⁃215. |

| 29 | 刘昌鹏, 雷 伟, 冉旭东, 等. TaSi2改性ZrB2/SiC复合粉末制备及涂层抗氧化性能研究[J]. 表面技术, 2023, 52(10): 350⁃359. |

| LIU C P, LEI W, RAN X D,et al.Preparation of ZrB2 /SiC Composite Powder Modified by TaS2and the Antioxidant Property of Its Coating[J]. Surface Technology, 2023, 52(10): 350⁃359. | |

| 30 | 周海军, 董绍明, 何 平, 等. 碳/碳碳化硅复合材料的摩擦磨损行为与机理[J]. 无机材料学报, 2013, 28(10): 1 057⁃1 061. |

| ZHOU H J, DONG S M, HE P.et al. Tribological Behaviors and Anti⁃wear Mechanisms of Carbon/Carbon⁃silicon Carbide Composites[J]. Jornal of Inorganic Materials, 2013, 28(10): 1 057⁃1 061. | |

| 31 | LI G, YAN Q. Comparison of Friction and Wear Behavior Between C/C, C/C⁃SiC and Metallic Composite Materials [J]. Tribology Letters, 2015, 60(1).DOI:10.1007/s11249-015-0591-5 . |

| 32 | ZHAO Z, LI K, LI W, et al. Preparation, ablation behavior and mechanism of C/C⁃ZrC⁃SiC and C/C⁃SiC composites [J]. Ceramics International, 2018, 44(7): 7 481⁃7 490. |

| 33 | Yang J, AI Y, LV X, et al. Fabrication of C/C‐SiC composites using high‐char‐yield resin [J]. International Journal of Applied Ceramic Technology, 2020, 18(2): 449⁃456. |

| 34 | 孙楚函, 王洪磊, 周新贵. 前驱体转化法制备超高温陶瓷粉体研究进展[J]. 硅酸盐通报, 2023, 42(08): 2 865⁃2 880. |

| SUN C H, WANG H L, ZHOU X G. Research Progress on Ultra⁃High Temperature Ceramics Powder Prepared by Precursor⁃Derived Method[J].Bulletin of the Chinese Ceramic Society, 2023, 42(08): 2 865⁃2 880. | |

| 35 | Cao J, Chen J, Wang X, et al. Tribology and Anti⁃Ablation Properties of SiC⁃VN⁃MoS2/Ta Composite Coatings on Carbon/Carbon Composites from 25 to 800 ℃ [J]. Materials, 2021, 14(22).DOI:10.3390/ma14226772 . |

| 36 | FU Q⁃G, JING J⁃Y, LI H⁃J, et al. Design of an inlaid interface structure to improve the oxidation protective ability of SiC–MoSi2–ZrB2 coating for C/C composites [J]. Ceramics International, 2016, 42(3): 4 212⁃4 220. |

| 37 | 孙丹羽, 朱世步, 刘泰山, 等. 超高温陶瓷改性C/C复合材料抗氧化烧蚀性能研究进展[J]. 材料导报, 2024: 1⁃27. |

| SUN D Y, ZHU S B, LIU T S,et al.Research Progress on Antioxidant Ablation Properties of Ultra⁃high Temperature Ceramic Modified Carbon/Carbon Composite[J]. Materials Reports, 2024: 1⁃27. | |

| 38 | WANG Y⁃L, XIONG X, LI G⁃D, et al. Preparation and ablation properties of Hf(Ta)C co⁃deposition coating for carbon/carbon composites [J]. Corrosion Science, 2013, 66: 177⁃182. |

| 39 | 韩雅芳, 郑运荣. 航空发动机用高温材料的应用与发展[J]. 世界科技研究与发展, 1998, (06): 67⁃71. |

| HAN Y F, ZHENG Y R. Development and Application of High Temperature Structural Materials for Aero⁃Engines[J]. World Sci⁃Tech R&D, 1998, (06): 67⁃71. | |

| 40 | 王洪金, 孙顺平, 潘 强, 等. MoSi2涂层制备工艺与腐蚀性能研究[J]. 山东化工, 2023, 52(01): 37⁃39. |

| WANG H J, SUN S P, PAN Q,et al.Study on Preparation and Corrosion Properties of MoSi2 Coating[J]. Shandong Chemical Industry, 2023, 52(01): 37⁃39. | |

| 41 | 查柏林, 高 勇, 王金金, 等. C/C复合材料在超声速富氧烧蚀环境下的烧蚀试验方法研究[J]. 固体火箭技术, 2023: 1⁃12. |

| ZHA B L, GAO Y, WANG J J,et al.Ablation test method for C/C composites in supersonic | |

| Oxygen⁃enriched ablation environment[J]. Journal of Solid Rocket Technology, 2023: 1⁃12. | |

| 42 | XIE J, LI K, SUN G, et al. Effects of precursor concentration on the microstructure and properties of ZrC modified C/C composites prepared by precursor infiltration and pyrolysis [J]. Ceramics International, 2017, 43(17): 14 642⁃14 651. |

| 43 | CHEN S A, ZHANG C, ZHANG Y, et al. Influence of pyrocarbon amount in C/C preform on the microstructure and properties of C/ZrC composites prepared via reactive melt infiltration [J]. Materials & Design, 2014, 58: 570⁃576. |

| 44 | WANG Y, ZHU X, ZHANG L, et al. Reaction kinetics and ablation properties of C/C–ZrC composites fabricated by reactive melt infiltration [J]. Ceramics International, 2011, 37(4): 1 277⁃1 283. |

| 45 | SUN H⁃H, LI H⁃J, SHEN X⁃T, et al. Microstructure and Ablation Behavior of C/C Composites Doped with ZrB2 [J]. Journal of Inorganic Materials, 2011, 26(6): 669⁃672. |

| 46 | XIE J, LI K, LI H, et al. Ablation behavior and mechanism of C/C–ZrC–SiC composites under an oxyacetylene torch at 3000 ℃ [J]. Ceramics International, 2013, 39(4): 4 171⁃4 178. |

| 47 | CHEN B⁃W, NI D⁃W, WANG J⁃X, et al. Ablation behavior of Cf/ZrC⁃SiC⁃based composites fabricated by an improved reactive melt infiltration [J]. Journal of the European Ceramic Society, 2019, 39(15): 4 617⁃4 624. |

| 48 | TIAN T, SUN W, XIONG X, et al. Novel one⁃step formed composite reinforcement of "Spider web like" SiCnw networks and "Z⁃pins like" SiC rods for ablation resistance improvement of C/C⁃ZrC⁃SiC [J]. Journal of the European Ceramic Society, 2022, 42(3): 786⁃800. |

| 49 | HE Q, LI H, TAN Q, et al. Effects of ZrC particle size on ablation behavior of C/C⁃SiC⁃ZrC composites prepared by chemical liquid vapor deposition [J]. Corrosion Science, 2022, 205.DOI:10.1016/j.corsci.2022.110469 . |

| 50 | FENG T, SHI X, HOU W, et al. The ablation and mechanical behaviors of C/(SiC⁃ZrC)n multi⁃layer structure matrix composites by chemical vapor infiltration [J]. Journal of the European Ceramic Society, 2022, 42(10): 4 133⁃4 143. |

| 51 | ZOU X, FU Q, LIU L, et al. ZrB2–SiC coating to protect carbon/carbon composites against ablation [J]. Surface and Coatings Technology, 2013, 226: 17⁃21. |

| 52 | KONG J H, LEE S Y, SON Y I, et al. Synergistic reinforcement effects of ZrB2 on the ultra⁃high temperature stability of Cf/SiC composite fabricated by liquid silicon infiltration [J]. Journal of the European Ceramic Society, 2023, 43(8): 3 062⁃3 069. |

| 53 | LI H⁃J, YAO X⁃Y, ZHANG Y⁃L, et al. Effect of heat flux on ablation behaviour and mechanism of C/C–ZrB2–SiC composite under oxyacetylene torch flame [J]. Corrosion Science, 2013, 74: 265⁃270. |

| 54 | LIU L, LI H, FENG W, et al. Ablation in different heat fluxes of C/C composites modified by ZrB2–ZrC and ZrB2–ZrC–SiC particles [J]. Corrosion Science, 2013, 74: 159⁃167. |

| 55 | PI H, FAN S, WANG Y. C/SiC–ZrB2–ZrC composites fabricated by reactive melt infiltration with ZrSi2 alloy [J]. Ceramics International, 2012, 38(8): 6 541⁃6 548. |

| 56 | ZHAO Z, LI K, LI W, et al. Cyclic ablation behavior of C/C⁃ZrC⁃SiC⁃ZrB2 composites under oxyacetylene torch with two heat fluxes at the temperatures above 2000 ºC [J]. Corrosion Science, 2021, 181.DOI:10.1016/j.corsci.2020.109202 . |

| 57 | XUE L, SU Z⁃A, YANG X, et al. Microstructure and ablation behavior of C/C–HfC composites prepared by precursor infiltration and pyrolysis [J]. Corrosion Science, 2015, 94: 165⁃170. |

| 58 | 张 鹏. 合金反应熔渗法制备C/C⁃HfC复合材料微观结构及抗烧蚀性能 [J]. 中国陶瓷, 2015, 51(01): 14⁃17+23. |

| ZHANG P.Microstructure and Ablation Resistance of C/C⁃HfC Composite Prepared by Alloyed Reactive Melt Infiltration[J]. China Ceramic, 2015, 51(01): 14⁃17+23. | |

| 59 | LI K⁃Z, DUAN T, ZHANG J⁃P, et al. Ablation Mechanism of Carbon/Carbon Composites Modified by HfC–SiC in Two Conditions Under Oxyacetylene Torch [J]. Journal of Materials Science & Technology, 2017, 33(1): 71⁃78. |

| 60 | KOU S, FAN S, MA X, et al. Ablation performance of C/HfC⁃SiC composites with in⁃situ HfSi2/HfC/SiC multi⁃phase coatings under 3000 ℃ oxyacetylene torch [J]. Corrosion Science, 2022, 200.DOI:10.1016/j.corsci.2022.110218 . |

| 61 | ZHANG J⁃P, FU Q⁃G, TONG M⁃D, et al. Microstructure, ablation behavior and thermal retardant ability of C/C⁃HfB2 composites prepared by precursor infiltration pyrolysis combined with chemical vapor infiltration [J]. Journal of Alloys and Compounds, 2018, 742: 123⁃129. |

| 62 | ZHANG J⁃P, QU J⁃L, FU Q⁃G. Ablation behavior of nose⁃shaped HfB2⁃SiC modified carbon/carbon composites exposed to oxyacetylene torch [J]. Corrosion Science, 2019, 151: 87⁃96. |

| 63 | QU J⁃L, FU Q⁃G, ZHANG J⁃P, et al. Ablation behavior of TaB2⁃SiC coating for carbon/carbon composites under oxyacetylene torch [J]. Vacuum, 2016, 131: 223⁃230. |

| 64 | FENG G, LI H, YAO X, et al. Ablation resistance of TaC⁃modified HfC coating prepared by supersonic plasma spraying for SiC⁃coated carbon/carbon composites [J]. Ceramics International, 2019, 45(14): 17 936⁃17 945. |

| 65 | LIU X, DENG C, DENG C, et al. Mullite⁃modified ZrB2⁃MoSi2 coating for carbon/carbon composites to withstand long term ablation [J]. Ceramics International, 2018, 44(4): 4 330⁃4 337. |

| 66 | 易 君, 张 贝, 汤振霄, 等. 熔渗法制备MoSi2改性C/C复合材料的组织结构与力学性能[J]. 粉末冶金材料科学与工程, 2019, 24(06): 529⁃535. |

| YI J, ZHANG B, TANG Z X,et al.Microstructure and mechanical properties of MoSi2 modified C/C composites prepared by infiltration[J]. Materials Science and Engineering of Powder Metallurgy, 2019, 24(06): 529⁃535. | |

| 67 | ZHANG P, FU Q, CHENG C, et al. Comparing oxidation behaviors at 1773 K and 1973 K of HfB2⁃MoSi2/SiC⁃Si coating prepared by a combination method of pack cementation, slurry painting and in⁃situ synthesis [J]. Surface and Coatings Technology, 2020, 403.DOI:10.1016/j.surfcoat.2020.126418 . |

| 68 | 郝安林, 郝振华, 孙 威, 等. Si⁃Mo⁃Zr反应熔渗改性C/C 复合材料的微观结构与烧蚀性能[J]. 中国有色金属学报, 2018, 28(02): 285⁃293. |

| HAO A L, HAO Z H, SUN W,et al.Microstructure and ablation properties of | |

| Si⁃Mo⁃Zr modified C/C composites by reactive melt infiltration[J]. The Chinese Journal of Nonferrous Metals, 2018, 28(02): 285⁃293. | |

| 69 | 毛金元. C/C复合材料表面ZrB2⁃MoSi2涂层的制备与抗高温氧化性能[D].广东:华南理工大学, 2015. |

| 70 | 乔阳阳, 刘明雪, 刘琼溪, 等. 磁控溅射技术在纺织领域的应用研究进展[J]. 现代纺织技术, 2023, 31(02): 204⁃207. |

| QIAO Y Y, LIU M X, LIU Q X,et al.Research progress of magnetron sputtering applied in the textile field[J]. Advanced Textile Technology, 2023, 31(02): 204⁃207. | |

| 71 | YANG L, JIANG S, CHEN Y, et al. Effect of carbon/tantalum hybrid film on the properties of carbon fiber and its composites based on magnetron sputtering [J]. Composites Science and Technology, 2023, 243.DOI:10.1016/j.compscitech.2023.110224 . |

| 72 | 杨艳姣, 代明江, 韦春贝, 等. 磁控溅射法制备碳/碳复合材料SiC/MoSi2⁃ZrB2涂层的结构及抗氧化性能研究(英文)[J]. 稀有金属材料与工程, 2017, 46(12): 3 663⁃3 668. |

| YANG Y J, DAI M J, WEI C B,et al.Microstructure and Anti⁃oxidation Properties of SiC/MoSi2⁃ZrB2 Coating for Carbon/Carbon Composites Prepared by Magnetron Sputtering Method[J]. Rare Metal Materials and Engineering, 2017, 46(12): 3 663⁃3 668. | |

| 73 | LIU M, YANG Y, MAO Q, et al. Influence of radio frequency magnetron sputtering parameters on the structure and performance of SiC films [J]. Ceramics International, 2021, 47(17): 24098⁃105. |

| 74 | 李昌恒, 刘奎仁, 魏世丞, 等. 磁控溅射技术制备氮化钛薄膜的研究进展[J]. 材料保护, 2023, 56(02): 111⁃119. |

| LI C H, LIU K R, WEI S C,et al.Research Progress of Titanium Nitride Thin Films Prepared by Magnetron Sputtering Technology[J]. Materials Protection, 2023, 56(02): 111⁃119. | |

| 75 | 李 芬, 朱 颖, 李刘合, 等. 磁控溅射技术及其发展[J]. 真空电子技术, 2011(03): 49⁃54. |

| LI F, ZHU Y, LI L H,et al.Review on Magnetron Sputtering Technology and Its Development[J]. Vacuum Electeonics, 2011(03): 49⁃54. | |

| 76 | MALE S B G. Infiltration of zirconium diboride by ICVI in porous materials [J]. Composites Science and Technology, 1997, 57(02): 217⁃227. |

| 77 | LI J, CHENG L, YE F, et al. Microstructure and Dielectric Property of 3D BNf/Si3N4 Fabricated by CVI Process [J]. Journal of Wuhan University of Technology⁃Mater Sci Ed, 2019, 34(4): 818⁃823. |

| 78 | 肖 鹏, 徐永东, 黄伯云. CSCVI法快速制备C纤维增韧SiC基复合材料及其微观结构[J]. 机械科学与技术, 2002, 21(04): 612⁃614. |

| XIAO P, XU Y D, HUANG B Y.Fabrication of SiC Matrix Composites Reinforced by Carbon Tows Using CSCVI Method and its Microstructure[J]. Mechanical Science and Technology, 2002, 21(04): 612⁃614. | |

| 79 | 肖 鹏, 熊 翔, 张红波, 等. C/C⁃SiC陶瓷制动材料的研究现状与应用[J]. 中国有色金属学报, 2005, 15(5): 667⁃674. |

| XIAO P, XIONG X, ZHANG H B, et al.Progress and application of C/ C⁃SiC ceramic braking materials[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(5): 667⁃674. | |

| 80 | BINNER J, PORTER M, BAKER B, et al. Selection, processing, properties and applications of ultra⁃high temperature ceramic matrix composites, UHTCMCs—a review [J]. International Materials Reviews, 2019, 65(7): 389⁃444. |

| 81 | 关洪达, 张 涛, 何新波. C/SiC陶瓷基复合材料研究与应用现状[J].材料导报, 2023, 37(16): 70⁃79. |

| GUAN H D, ZHANG T, HE X B.Current Status of the Research and Applications of C/SiC Ceramic Matrix Composites[J].Materials Reports, 2023, 37(16): 70⁃79. | |

| 82 | 丁思源, 刘贵民, 刘 振, 等. 化学气相渗透法制备C/C⁃SiC复合材料及其抗冲击性能研究[J]. 材料保护, 2023, 56(11): 30⁃35. |

| DING S Y, LIU G M, LIU Z,et al.Preparation of C/C⁃SiC Composites by Chemical Vapor Infiltration and Its Impact Resistance Properties[J]. Materials Protection, 2023, 56(11): 30⁃35. | |

| 83 | JIA L⁃T, WANG M⁃Q, GUO X⁃F, et al. Effect of chemical vapor infiltration on the flexural properties of C/C⁃SiC composites prepared by the precursor infiltration pyrolysis method [J]. New Carbon Materials, 2023, 38(6): 1 127⁃1 134. |

| 84 | 王少龙. 化学气相沉积SiC和ZrC涂层的制备及抗烧蚀性能[D].西北工业大学, 2015. |

| 85 | 杨 西, 杨玉华. 化学气相沉积技术的研究与应用进展[J]. 甘肃水利水电技术, 2008(03): 211⁃213. |

| YANG X, YANG Y H.Advances in Research and Application of Chemical Vapor Deposition Technology[J]. Gansu Water Resources and Hydropower Technology, 2008(03): 211⁃213. | |

| 86 | 黎宪宽, 陈 力, 蔡宏中, 等. 化学气相沉积技术及在难熔金属材料中的应用[J]. 稀有金属材料与工程, 2010, 39(S1): 438⁃443. |

| LI X K, CHEN L, CAI H Z,et al.Development of Chemical Vapor Deposition and Refractory Metal Materials[J]. Rare Metal Materials and Engineering, 2010, 39(S1): 438⁃443. | |

| 87 | KONG J A, ZHANG Y, WANG H, et al. Sublayer design and ablation resistance of CVD⁃TaC alternate coatings with different crystallite morphologies for C/C composites [J]. Journal of Materials Science & Technology, 2023, 141: 1⁃10. |

| 88 | ZHOU Z, TAO C, CHEN B, et al. Oxidative Ablation Behavior of W‐Coated C/C Composites Prepared by Chemical Vapor Deposition with Heat Treatment [J]. Advanced Engineering Materials, 2023, 25(12). |

| 89 | 秦明升, 肖 鹏, 熊 翔. C/C⁃SiC制动材料的研究进展[J]. 材料导报, 2008, 22: 36⁃38+52. |

| QIN M S, XIAO P, XIONG X.Research Progress in C/C⁃SiC Braking Materials[J]. Materials Reports, 2008, 22: 36⁃38+52. | |

| 90 | 吴小军, 刘明强, 张兆甫, 等. RMI法制备穿刺C/C⁃SiC复合材料的微结构及烧蚀性能[J]. 稀有金属材料与工程, 2021, 50(11): 4 023⁃4 030. |

| WU X J, LIU M Q, ZHANG Z P,et al.Microstructure and Ablation Properties of the Pierced C/C⁃SiC Composites Prepared by Reactive Melt Infiltration[J]. Rare Metal Materials and Engineering, 2021, 50(11): 4 023⁃4 030. | |

| 91 | TANG H, LI P, LI Z, et al. Braking behaviours of C/C–SiC mated with iron/copper⁃based PM in dry, wet and salt fog conditions [J]. Ceramics International, 2022, 48(3): 3261⁃3273. |

| 92 | 耿广仁, 周明星, 周长灵, 等. 高温陶瓷纤维/高温陶瓷基复合材料研究进展[J]. 佛山陶瓷, 2019, 29(11): 9⁃21. |

| GEN G R, ZHOU M X, ZHOU C L,et al.The Research Progress of High Temperature Ceramic Fiber / High Temperature Ceramic Matrix Composites[J]. Foshan Ceramics, 2019, 29(11): 9⁃21. | |

| 93 | 刘嘉琦. 先驱体转化法制备SiC涂层的C/C复合材料的氧化及烧蚀性能研究[D].湖南;中南大学, 2022. |

| 94 | YU M, LI H, XUE K, et al. Effect of microstructure evaluation during the PIP process on macroscopic properties of C/C composites [J]. Composite Structures, 2023, 308. |

| 95 | 孙国栋, 李贺军, 付前刚, 等. 带有SiC涂层的C/C复合材料的氧化行为[J].固体火箭技术, 2010, 33(01): 91⁃94. |

| SUN G D, LI H J, FU Q G,et al.Oxidation behavior of C/C composites with SiC coating[J].Journal of Solid Rocket Technology, 2010, 33(01): 91⁃94. | |

| 96 | 周华杉, 史耀君, 孙 华, 等. C/C⁃SiC复合材料表面处理技术的探讨与展望[J]. 轨道交通材料, 2023, 2: 8⁃11. |

| ZHOU H S, SHI Y J, SUN H,et al.Discussion and outlook on surface treatment technology for C/C ⁃ SiC composite[J]. Materials for Rail Transportation System, 2023, 2: 8⁃11. | |

| 97 | 杨 鑫, 黄启忠, 苏哲安, 等. C/C复合材料的高温抗氧化防护研究进展[J]. 宇航材料工艺, 2014, 44(01): 1⁃15. |

| YANG X, HUANG Q Z, SU Z A,et al.Review of Recent Progress on Oxidation Protection for C/C Composites at High Temperature[J]. Aerospace Materials & Technology, 2014, 44(01): 1⁃15. | |

| 98 | 朱双星. C/C复合材料Zr、Ta系陶瓷改性SiC涂层的研究[D].中南大学, 2022. |

| 99 | ZHANG R, SONG Q, LI J, et al. Study on the ablation performance of SiC⁃coated high thermal conductivity three⁃dimensional C/C composites [J]. Journal of the European Ceramic Society, 2024, 44(6): 3 797⁃3 808. |

| [1] | 刘鑫 费怀宇 左红梅 苏永生 胡侨乐 杨莉 阮芳涛. 碳/碳复合材料表面涂层工艺研究进展[J]. , 2024, (12): 0-0. |

| [2] | 朱瑞霞, 甘露, 武芷萱. 几种常见给水PVC工程管道的对比分析[J]. 中国塑料, 2021, 35(3): 50-58. |

| [3] | 曹俭. 高性能、功能化高分子材料在军民融合深度发展中释放强国强军新动能[J]. 中国塑料, 2019, 33(1): 109-110. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2