京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2

《中国塑料》编辑部 ©2008-2024 版权所有

地址:北京市海淀区阜成路11号 邮编:100048

编辑部:010-68985541 联系信箱:cp@plaschina.com.cn

广告部/发行部:010-68985253 本系统由北京玛格泰克科技发展有限公司设计开发

中国塑料 ›› 2022, Vol. 36 ›› Issue (6): 60-68.DOI: 10.19491/j.issn.1001-9278.2022.06.010

收稿日期:2022-01-25

出版日期:2022-06-26

发布日期:2022-06-27

通讯作者:

林志丹(1977—),男,教授,从事高分子材料改性研究,linzd@jnu.edu.cn基金资助:

HUANG Suyuan, CAO Lin, LI Wei, LIN Zhidan( ), ZHANG Peng(

), ZHANG Peng( )

)

Received:2022-01-25

Online:2022-06-26

Published:2022-06-27

Contact:

LIN Zhidan, ZHANG Peng

E-mail:linzd@jnu.edu.cn;tzhangpeng@jnu.edu.cn

摘要:

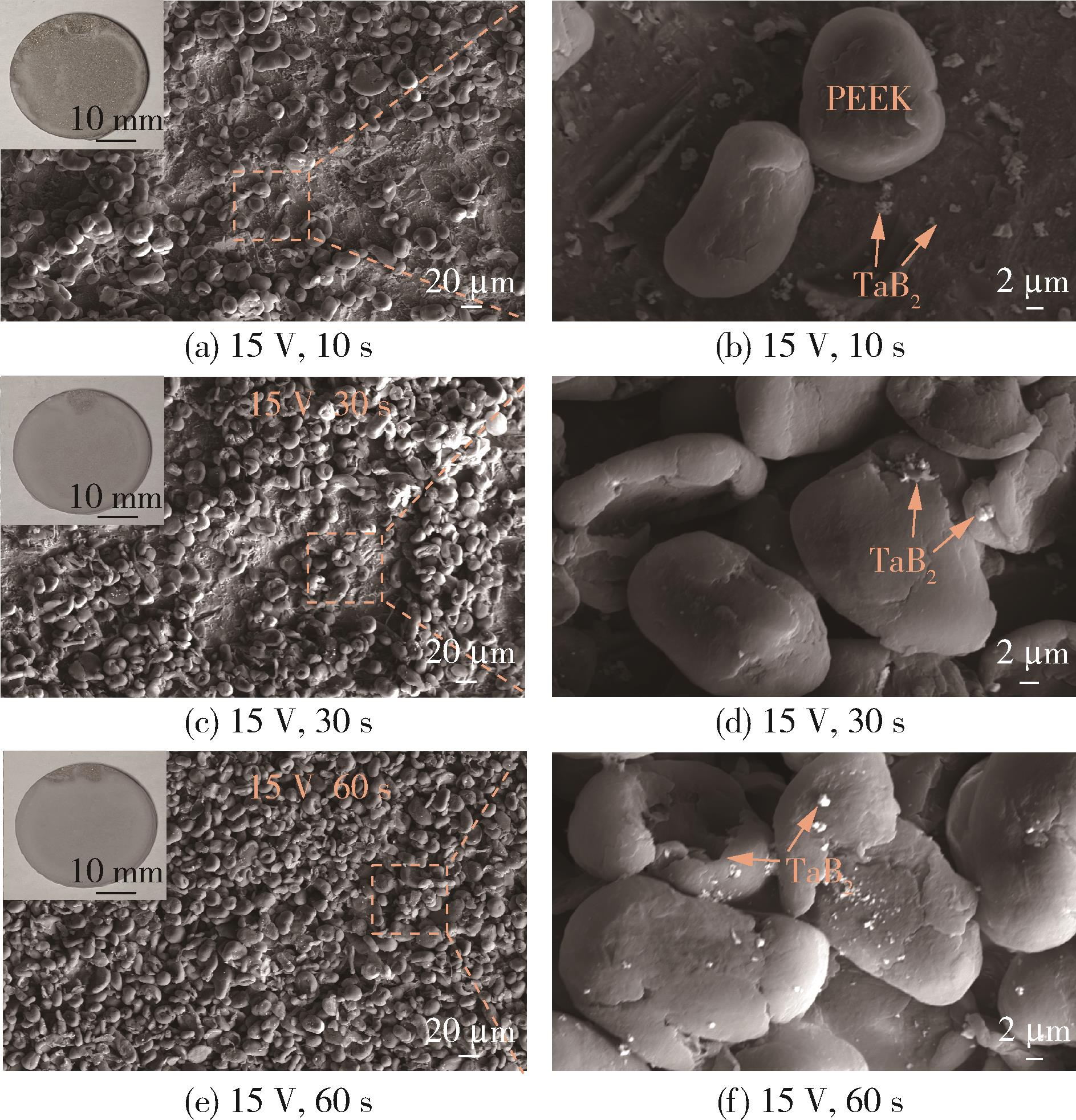

采用阴极电泳沉积技术在纯钛基板表面沉积聚醚醚酮(PEEK)/硼化钽(TaB2)复合涂层。采用透射电子显微镜、扫描电子显微镜、X射线衍射仪和摩擦磨损试验机等方式对电泳沉积液分散性、PEEK/TaB2复合涂层表面形貌、微观结构、结晶行为、摩擦学性能和生物学性能进行表征。结果表明,通过调节电泳沉积参数可以制备形貌均匀、具有一定厚度的PEEK/TaB2复合涂层,在390 ℃热处理后,涂层均匀致密无孔隙;热处理可以提高PEEK/TaB2涂层的结晶性能,TaB2颗粒的加入使PEEK涂层获得更高的结晶度;添加较低含量的TaB2颗粒时,复合涂层在小牛血清(fetal bovine serum,FBS)介质中表现出良好的摩擦学性能,与纯PEEK涂层相比,磨损率分别下降了48.1 %,69.1 %;但过量TaB2颗粒在PEEK基质中出现明显的团聚现象, 摩擦系数和磨损率呈现上升趋势;细胞实验表明,TaB2良好的生物活性促进了样品表面细胞增殖。

中图分类号:

黄素媛, 曹琳, 李卫, 林志丹, 张鹏. 硼化钽增强聚醚醚酮复合涂层的制备及性能评价[J]. 中国塑料, 2022, 36(6): 60-68.

HUANG Suyuan, CAO Lin, LI Wei, LIN Zhidan, ZHANG Peng. Preparation and performance evaluation of tantalum boride⁃reinforced polyether ether ketone composite coatings[J]. China Plastics, 2022, 36(6): 60-68.

| 1 | PUTRA N E, MIRZAALI M J, APACHITEI I, et al. Multi⁃material additive manufacturing technologies for Ti⁃, Mg⁃, and Fe⁃based biomaterials for bone substitution [J]. Acta Biomaterialia, 2020, 109: 1⁃20. |

| 2 | ZHANG J K, LIU J Q, WANG C T, et al. A comparative study of the osteogenic performance between the hierarchical micro/submicro⁃textured 3D⁃printed Ti6Al4V surface and the SLA surface [J]. Bioact Mater, 2020, 5(1): 9⁃16. |

| 3 | MA H Y, SUONAN A X, ZHOU J Y, et al. PEEK(Polyether⁃ether⁃ketone)and its composite materials in orthopedic implantation [J]. Arab J Chem, 2021, 14(3). |

| 4 | HALLMANN L, MEHL A, SERENO N, et al. The improvement of adhesive properties of PEEK through different pre⁃treatments [J]. Applied Surface Science, 2012, 258(18): 7 213⁃7 218. |

| 5 | KURTZ S M. PEEK biomaterials handbook [M]. William Andrew, 2019. |

| 6 | ABDULLAH M R, GOHARIAN A, KADIR M R A, et al. Biomechanical and bioactivity concepts of polyetheretherketone composites for use in orthopedic implantsa review [J]. J Biomed Mater Res Part A, 2015, 103(11): 3 689⁃3 702. |

| 7 | OLADAPO B I, ZAHEDI S A, ISMAIL S O, et al. Recent advances in biopolymeric composite materials: Future sustainability of bone⁃implant [J]. Renewable & Sustainable Energy Reviews, 2021, 150. |

| 8 | RIBEIRO R, INGOLE S, USTA M, et al. Tribological investigation of tantalum boride coating under dry and simulated body fluid conditions [J]. Wear, 2007, 262(11⁃12): 1 380⁃1 386. |

| 9 | HUNT C D, IDSO J P. Dietary boron as a physiological regulator of the normal inflammatory response: A review and current research progress [J]. 1999, 12(3): 221⁃233. |

| 10 | ARMSTRONG T A, SPEARS J W, LLOYD K E. Inflammatory response, growth, and thyroid hormone concentrations are affected by long⁃term boron supplementation in gilts [J]. Journal of Animal Science, 2001, 79(6): 1 549⁃1 556. |

| 11 | ESMAEILI M M, MAHMOODI M, IMANI R. Tantalum carbide coating on Ti⁃6Al⁃4V by electron beam physical vapor deposition method: Study of corrosion and biocompatibility behavior [J]. International Journal of Applied Ceramic Technology, 2017, 14(3): 374⁃382. |

| 12 | LEE S W, KIM Y W, CHEN H D. Electrical properties of Ta⁃doped SnO2 thin films prepared by the metal⁃organic chemical⁃vapor deposition method [J]. Applied Physics Letters, 2001, 78(3): 350⁃352. |

| 13 | LI R, LIU G, YANG L, et al. Tantalum boride as a biocompatible coating to improve osteogenesis of the bionano interface [J]. J Biomed Mater Res Part A, 2020, 108(8): 1 726⁃1 735. |

| 14 | KUSMIERCZYK F, ZIMOWSKI S, LUKASZCZYK A, et al. Development of Microstructure and Properties of Multicomponent MoS2/HA/PEEK Coatings on a Titanium Alloy Via Electrophoretic Deposition and Heat Treatment [J]. Metallurgical and Materials Transactions a⁃Physical Metallurgy and Materials Science, 2021, 52(9): 3 880⁃3 895. |

| 15 | FIOLEK A, ZIMOWSKI S, KOPIA A, et al. Electrophoretic co⁃deposition of polyetheretherketone and graphite particles: microstructure, electrochemical corrosion resistance, and coating adhesion to a titanium alloy [J]. Materials, 2020, 13(15). |

| 16 | MOSKALEWICZ T, WARCABA M, CIENIEK L, et al. Hydroxyapatite/sodium alginate coatings electrophoretically deposited on titanium substrates: microstructure and properties [J]. Applied Surface Science, 2021, 540. |

| 17 | SEUSS S, SUBHANI T, KANG M Y, et al. Electrophoretic deposition of PEEK⁃TiO2 composite coatings on stainless steel [J]. Electrophoretic Deposition: Fundamentals and Applications Iv, 2012, 507: 127. |

| 18 | MOSKALEWICZ T, ZIMOWSKI S, ZYCH A, et al. Electrophoretic deposition, microstructure and selected properties of composite alumina/polyetheretherketone coatings on the Ti⁃13Nb⁃13Zr alloy [J]. Journal of the Electrochemical Society, 2018, 165(3): D116⁃D28. |

| 19 | BESRA L, LIU M. A review on fundamentals and applications of electrophoretic deposition(EPD)[J]. Progress in Materials Science, 2007, 52(1): 1⁃61. |

| 20 | AMMAM M. Electrophoretic deposition under modulated electric fields: a review [J]. Rsc Advances, 2012, 2(20): 7 633⁃7 646. |

| 21 | BASTAN F E, REHMAN M A U, AVCU Y Y, et al. Electrophoretic co⁃deposition of PEEK⁃hydroxyapatite composite coatings for biomedical applications [J]. Colloids and Surfaces B⁃Biointerfaces, 2018, 169: 176⁃182. |

| 22 | MOSKALEWICZ T, ZYCH A, KRUK A, et al. Electrophoretic deposition and microstructure development of Si3N4/polyetheretherketone coatings on titanium alloy [J]. Surface & Coatings Technology, 2018, 350: 633⁃647. |

| 23 | IVEKOVIC A, NOVAK S, LUKEK M, et al. Aqueous electrophoretic deposition of bulk polyether ether ketone(PEEK)[J]. Journal of Materials Processing Technology, 2015, 223: 58⁃64. |

| 24 | SUN F, PANG X, ZHITOMIRSKY I. Electrophoretic deposition of composite hydroxyapatite⁃chitosan⁃heparin coatings [J]. Journal of Materials Processing Technology, 2009, 209(3): 1 597⁃1 606. |

| 25 | MENG X, T⁃YKWON, YANG Y, et al. Effects of applied voltages on hydroxyapatite coating of titanium by electrophoretic deposition [J]. Journal of Biomedical Materials Research Part B⁃Applied Biomaterials, 2006, 78B(2): 373⁃377. |

| 26 | MONDRAGON⁃CORTEZ P, VARGAS⁃GUTIERREZ G. Selective deposition of hydroxyapatite nanoparticles by electrophoretic deposition [J]. Advanced Engineering Materials, 2003, 5(11): 812⁃815. |

| 27 | ARRIGHI V, MCEWEN I J, QIAN H, et al. The glass transition and interfacial layer in styrene⁃butadiene rubber containing silica nanofiller [J]. Polymer, 2003, 44(20): 6 259⁃8 266. |

| 28 | GOYAL R K, NEGI Y S, TIWARI A N. Preparation of high performance composites based on aluminum nitride/poly(ether⁃ether⁃ketone)and their properties [J]. European Polymer Journal, 2005, 41(9): 2 034⁃2 044. |

| 29 | GHOSH S, CHOUDHURY D, ROY T, et al. Tribological performance of the biological components of synovial fluid in artificial joint implants [J]. Science and Technology of Advanced Materials, 2015, 16(4). |

| 30 | HUANG S Y, CAO L, LI W, et al. Evaluation of tribological and biological properties of PEEK/TaB2 composite coatings prepared by electrodeposition [J]. J Appl Polym Sci. |

| 31 | GHOSH S, CHOUDHURY D, DAS N S, et al. Tribological role of synovial fluid compositions on artificial joints ⁃ a systematic review of the last 10 years [J]. Lubr Sci, 2014, 26(6): 387⁃410. |

| [1] | 王轲, 龙春光. PE⁃UHMW/海泡石纤维复合材料的力学性能与摩擦学性能研究[J]. 中国塑料, 2022, 36(5): 19-23. |

| [2] | 黎帅, 龙春光, 闵建新, 周卓. 基于改性PET的极限PV值测试及摩擦学性能比较研究[J]. 中国塑料, 2021, 35(9): 87-94. |

| [3] | 彭鑫, 龙春光, 彭鹰. PEEK/ZA8复合材料的制备及力学与摩擦学性能研究[J]. 中国塑料, 2020, 34(5): 26-31. |

| [4] | 田仁杰, 朱光明, 吕玉伟, 吴涛涛, 任天宁, 马志亮, 张爽. 炭黑对聚醚醚酮激光吸收影响的实验研究及数值模拟[J]. 中国塑料, 2020, 34(10): 44-50. |

| [5] | 付扬威 龙春光 董佩冉. 聚甲醛/海泡石纤维复合材料的制备与性能研究[J]. 中国塑料, 2019, 33(2): 24-28. |

| [6] | 李长林 黄志刚 翁云宣. PEEK特种工程塑料耐磨改性研究进展及其应用展望[J]. 中国塑料, 2018, 32(04): 18-23. |

| [7] | 刘俊鹏;龙春光;谌磊;付扬威;许可可;董佩冉. 漆籽壳纤维含量对聚甲醛/玄武岩纤维复合材料的力学及摩擦学性能的影响[J]. 中国塑料, 2017, 31(4): 40-44 . |

| [8] | 刘焕萍;孙辉. 聚醚醚酮表面接枝O羧甲基壳聚糖及其血液相容性研究[J]. 中国塑料, 2016, 30(02): 39-42 . |

| [9] | 王志;雷卓研;张晓玲;杨甜甜;徐艳英. 聚醚醚酮/多壁碳纳米管复合材料力学及阻燃性能研究[J]. 中国塑料, 2014, 28(11): 42-46 . |

| [10] | . 聚醚醚酮表面壳聚糖的固定[J]. 中国塑料, 2014, 28(06): 52-56 . |

| [11] | 李思远;包睿莹;杨伟;冯建明杨鸣波. 聚醚醚酮共混改性研究进展[J]. 中国塑料, 2014, 28(05): 1-10 . |

| [12] | 钱善华 张翔 熊福祥 倪自丰 李庆忠. 压力速度对PE-UHMW摩擦学性能影响的试验研究 [J]. , 2013, 27(11): 54-58. |

| [13] | 鲜艳 王宏刚 任俊芳. PE-HD-g-MAH对PA66/PE-UHMW共混物力学与摩擦学行为的影响[J]. 中国塑料, 2013, 27(06): 75-80 . |

| [14] | 史丽萍, 丁兰英, 张静, 路琴. UPR/GF/纳米Si02复合材料的摩擦学性能和力学性能研究[J]. 中国塑料, 2013, 27(01): 57-61. |

| [15] | 路琴 史丽萍. 基于聚甲醛及其复合材料的摩擦学研究进展[J]. 中国塑料, 2011, 25(09): 16-20 . |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2