京ICP备13020181号-2

© 《China Plastics》

© 《China Plastics》

China Plastics ›› 2024, Vol. 38 ›› Issue (9): 66-72.DOI: 10.19491/j.issn.1001-9278.2024.09.012

• Processing and Application • Previous Articles Next Articles

FU Lingjie, XUE Peng, ZHOU Guofa( )

)

Received:2023-12-21

Online:2024-09-26

Published:2024-09-27

CLC Number:

FU Lingjie, XUE Peng, ZHOU Guofa. Effect of melt viscoelastic characteristics on manufacturing precision of in⁃mold micro assembly molding[J]. China Plastics, 2024, 38(9): 66-72.

Add to citation manager EndNote|Ris|BibTeX

URL: https://www.plaschina.com.cn/EN/10.19491/j.issn.1001-9278.2024.09.012

| 材料回归参数变量名 | 变量值( | 变量值( |

|---|---|---|

| σ0 | 4 551.2 | 32.773 |

| A01 | -11.23 | 0.052 24 |

| B01 | -1 233.4 | 2 698.654 |

| B02 | 2 573.73 | -3 656.2 |

| B03 | -1 516.64 | 1 588.435 |

| A1 | 0.191 1 | 43.806 |

| A2 | 1.3×10-3 | -0.208 8 |

| A3 | 1.628×10-6 | 2.595×10-4 |

| B1 | 4.796 4 | -637.165 |

| B2 | -9.27 | 146.866 |

| 材料回归参数变量名 | 变量值( | 变量值( |

|---|---|---|

| σ0 | 4 551.2 | 32.773 |

| A01 | -11.23 | 0.052 24 |

| B01 | -1 233.4 | 2 698.654 |

| B02 | 2 573.73 | -3 656.2 |

| B03 | -1 516.64 | 1 588.435 |

| A1 | 0.191 1 | 43.806 |

| A2 | 1.3×10-3 | -0.208 8 |

| A3 | 1.628×10-6 | 2.595×10-4 |

| B1 | 4.796 4 | -637.165 |

| B2 | -9.27 | 146.866 |

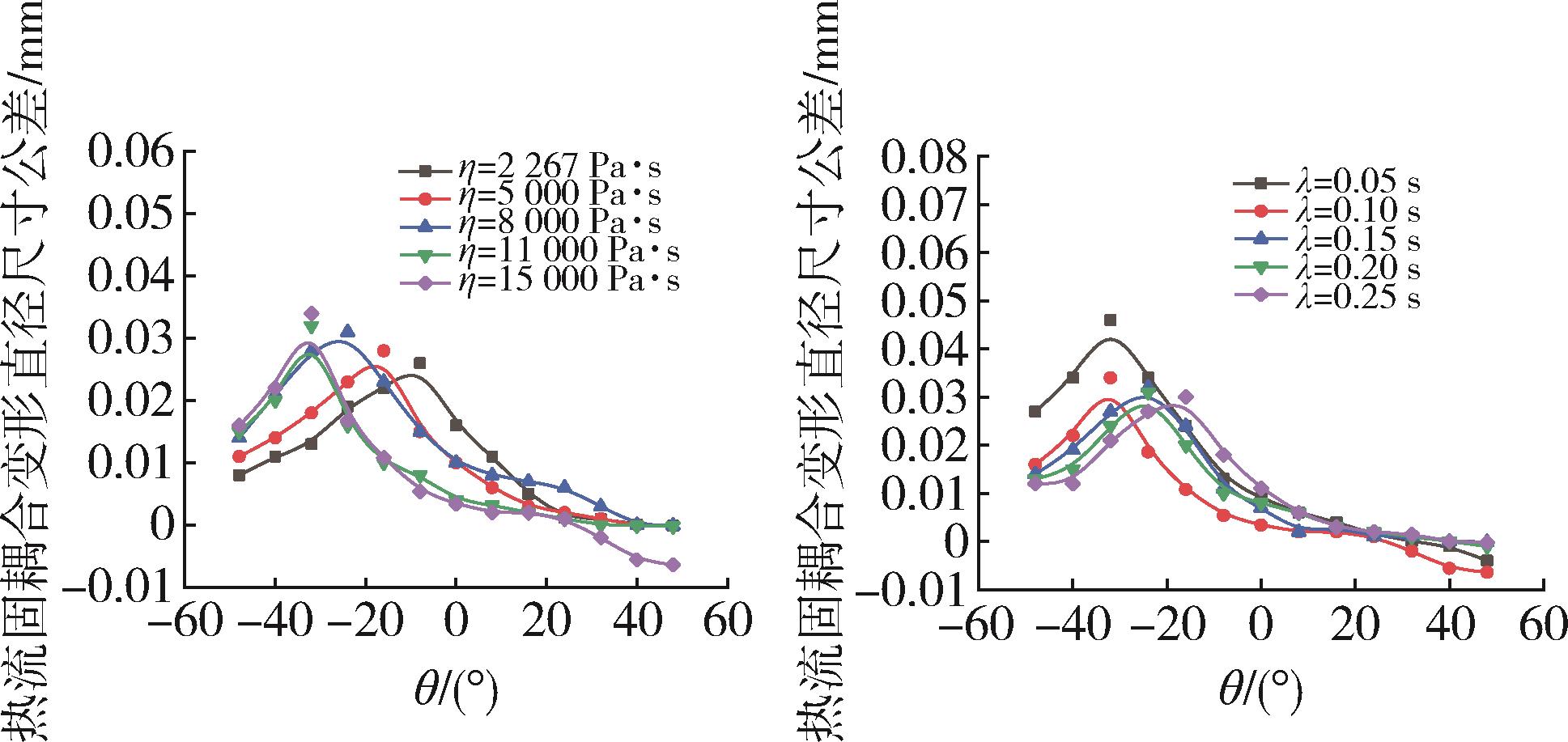

| 参考黏度/Pa·s | 考虑体积收缩直径 制造尺寸公差/μm | 松弛时间/ s | 考虑体积收缩直径制造尺寸公差/μm |

|---|---|---|---|

| 2 267 | 11 | 0.05 | 31 |

| 5 000 | 13 | 0.10 | 19 |

| 8 000 | 16 | 0.15 | 17 |

| 11 000 | 17 | 0.20 | 16 |

| 15 000 | 19 | 0.25 | 15 |

| 参考黏度/Pa·s | 考虑体积收缩直径 制造尺寸公差/μm | 松弛时间/ s | 考虑体积收缩直径制造尺寸公差/μm |

|---|---|---|---|

| 2 267 | 11 | 0.05 | 31 |

| 5 000 | 13 | 0.10 | 19 |

| 8 000 | 16 | 0.15 | 17 |

| 11 000 | 17 | 0.20 | 16 |

| 15 000 | 19 | 0.25 | 15 |

| 1 | Shao C, Ye X, Qian J, et al. Robotic precision assembly system for microstructures[J]. Proceedings of the Institution of Mechanical Engineers, Part I: Journal of Systems and Control Engineering,2020,234(8):948⁃958. |

| 2 | Liu S, Xu D, Zhang D, et al. High precision automatic assembly based on microscopic vision and force information[J]. IEEET Automat Sci Eng, 2016, 13(1): 382⁃393. |

| 3 | Zhang Z, Yu Y, Gao J, et al. An air⁃filled microgripper in micro⁃assembly system with coaxial alignment function[J]. Assembly Autom, 2014,34(4): 333–341. |

| 4 | Ananthanarayanan A, Gupta S K, Bruck H A. Characterization of a reverse molding sequence at the mesoscale for in‐mold assembly of revolute joints[J]. Polymer Engineering & Science, 2010, 50(9): 1 843⁃1 852. |

| 5 | Meister Steve, Drummer Dietmar. Micro assembly injection moulding with variothermal mould tempering[J]. Microsystem Technologies, 2017, 23(4):1 017⁃1 025. |

| 6 | 薛 鹏,张 宇,周国发.微细万向球形机械运动副模内微装配成型控形模拟研究[J].中国塑料, 2023,37(01):66⁃73. |

| XUE P, ZHANG Y, ZHOU G F. Simulation study on shape control of micro⁃fine universal direction spherical mechanical kinematic pair for in⁃mold micro assembly molding[J]. China Plastics, 2023,37(01):66⁃73. | |

| 7 | 周国发, 阳培民, 罗 智, 等. 基于黏弹性热流固耦合作用的模内微装配成型过程数值模拟[J]. 化工学报, 2017, 68(3): 1 129⁃1 137. |

| ZHOU G F, YANG P M, LUO Z, et al. Numerical simulation on in mold micro assembly molding process based on viscoelastic thermal fluid structure coupling[J]. CIESC Journal,2017,68(3):1 129⁃1 137. | |

| 8 | 周国发,郑传义,计 操.自润滑液膜辅助模内微装配成型精密控形技术与机理研究[J].中国塑料,2019,33(05):61⁃66. |

| ZHOU G F, ZHENG C Y, JI C. Research on precision shape control technology and mechanism of self⁃lubricating liquid film⁃assisted in⁃mold micro assembly molding[J]. China Plastics,2019,33(05):61⁃66. | |

| 9 | Matthew E Dirckx. Demolding of Hot Embossed Polymer Microstructures[D]. USA:Massachusetts Institute of Technology,2010. |

| 10 | Nicoli Margret Ames. A thermo⁃mechanical finite deformation theory of plasticity for amorphous polymers: application to micro⁃hot⁃embossing of poly(methyl methacrylate)[D].USA: Massachusetts Institute of Technology, 2007. |

| 11 | 郭 勇. 聚合物热黏弹塑性微热压成型机理研究[D]. 南昌: 南昌大学,2019. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||