京ICP备13020181号-2

© 《China Plastics》

© 《China Plastics》

China Plastics ›› 2024, Vol. 38 ›› Issue (8): 53-61.DOI: 10.19491/j.issn.1001-9278.2024.08.009

• Materials and Properties • Previous Articles Next Articles

ZHU Guangze1( ), XIA Zhidong1(

), XIA Zhidong1( ), ZHOU Wei1(

), ZHOU Wei1( ), WANG Xiaolu1, WU Yufeng1,2, GUO Fu1,3

), WANG Xiaolu1, WU Yufeng1,2, GUO Fu1,3

Received:2023-12-04

Online:2024-08-26

Published:2024-08-19

CLC Number:

ZHU Guangze, XIA Zhidong, ZHOU Wei, WANG Xiaolu, WU Yufeng, GUO Fu. Investigation on co⁃pyrolysis of polyester enamel wire and its pyrolysis product[J]. China Plastics, 2024, 38(8): 53-61.

Add to citation manager EndNote|Ris|BibTeX

URL: https://www.plaschina.com.cn/EN/10.19491/j.issn.1001-9278.2024.08.009

| 反应机理 | 符号 | G(α) | |

|---|---|---|---|

| 化学反应机理 | 一步反应 | F1 | -ln(1-α) |

| 一步半反应 | F1.5 | 2[(1-α)-1/2-1] | |

| 两步反应 | F2 | (1-α)-1-1 | |

| 三步反应 | F3 | [(1-α)-2-1]/2 | |

| 扩散机理 | 一维扩散 | D1 | α2 |

| 二维扩散 | D2 | (1-α)ln(1-α)+α | |

| 三维扩散 | D3 | [1-(1-α)1/3]2 | |

| 四维扩散 | D4 | 1-(2/3)α-(1-α)2/3 | |

| 幂率 | 1/2幂定律反应 | P2 | α1/2 |

| 1/3幂定律反应 | P3 | α1/3 | |

| 指数定律反应 | P4 | α1/4 | |

| 相界面反应机理 | 一维反应 | R1 | α |

| 二维反应 | R2 | 1-(1-α)1/2 | |

| 三维反应 | R3 | 1-(1-α)1/3 | |

| 随机成核与生长反应机理 | 成核生长(n=1.5) | A1.5 | [-ln(1-α)]2/3 |

| 成核生长(n=2) | A2 | [-ln(1-α)]1/2 | |

| 成核生长(n=3) | A3 | [-ln(1-α)]1/3 | |

| 成核生长(n=4) | A4 | [-ln(1-α)]1/4 | |

| 反应机理 | 符号 | G(α) | |

|---|---|---|---|

| 化学反应机理 | 一步反应 | F1 | -ln(1-α) |

| 一步半反应 | F1.5 | 2[(1-α)-1/2-1] | |

| 两步反应 | F2 | (1-α)-1-1 | |

| 三步反应 | F3 | [(1-α)-2-1]/2 | |

| 扩散机理 | 一维扩散 | D1 | α2 |

| 二维扩散 | D2 | (1-α)ln(1-α)+α | |

| 三维扩散 | D3 | [1-(1-α)1/3]2 | |

| 四维扩散 | D4 | 1-(2/3)α-(1-α)2/3 | |

| 幂率 | 1/2幂定律反应 | P2 | α1/2 |

| 1/3幂定律反应 | P3 | α1/3 | |

| 指数定律反应 | P4 | α1/4 | |

| 相界面反应机理 | 一维反应 | R1 | α |

| 二维反应 | R2 | 1-(1-α)1/2 | |

| 三维反应 | R3 | 1-(1-α)1/3 | |

| 随机成核与生长反应机理 | 成核生长(n=1.5) | A1.5 | [-ln(1-α)]2/3 |

| 成核生长(n=2) | A2 | [-ln(1-α)]1/2 | |

| 成核生长(n=3) | A3 | [-ln(1-α)]1/3 | |

| 成核生长(n=4) | A4 | [-ln(1-α)]1/4 | |

| 模型 | 聚酯漆膜 | 聚酯漆膜+焦炭 | ||||

|---|---|---|---|---|---|---|

| A/min-1 | E/kJ·mol-1 | R2 | A/min-1 | E/kJ·mol-1 | R2 | |

| F1 | 9.9×1011 | 164.583 9 | 0.997 98 | 5.9×1011 | 160.318 9 | 0.996 97 |

| F1.5 | 4.5×1014 | 196.925 4 | 0.998 56 | 2.4×1014 | 191.903 7 | 0.996 94 |

| F2 | 4.8×1017 | 234.180 4 | 0.985 93 | 2.4×1017 | 228.285 8 | 0.987 82 |

| F3 | 4.8×1024 | 320.671 0 | 0.950 61 | 1.9×1024 | 312.714 5 | 0.952 75 |

| D1 | 3.2×1017 | 241.621 5 | 0.959 28 | 1.4×1017 | 235.186 4 | 0.957 60 |

| D2 | 2.6×1019 | 268.600 4 | 0.975 54 | 1.1×1019 | 261.591 7 | 0.974 98 |

| D3 | 3.7×1021 | 303.111 8 | 0.990 03 | 1.4×1021 | 295.329 9 | 0.990 34 |

| D4 | 4.8×1019 | 279.932 4 | 0.981 38 | 1.9×1019 | 272.674 3 | 0.981 14 |

| P2 | 802.6 | 51.920 9 | 0.944 38 | 651.6 | 50.3745 3 | 0.941 79 |

| P3 | 13.5 | 30.844 9 | 0.929 85 | 11.7 | 29.8472 6 | 0.926 25 |

| P4 | 1.5 | 20.302 8 | 0.909 35 | 1.3 | 19.5794 7 | 0.904 20 |

| R1 | 7.8×107 | 115.157 2 | 0.955 01 | 5.2×107 | 111.981 3 | 0.953 09 |

| R2 | 2.8×109 | 137.413 8 | 0.982 77 | 1.8×109 | 133.755 6 | 0.982 63 |

| R3 | 9.5×109 | 145.894 1 | 0.989 13 | 5.9×109 | 142.053 0 | 0.989 44 |

| A1 | 2.5×107 | 105.945 3 | 0.996 71 | 1.7×107 | 103.135 2 | 0.997 77 |

| A2 | 1.1×105 | 76.630 1 | 0.996 41 | 8.5×104 | 74.5433 2 | 0.997 54 |

| A3 | 429.0 | 47.315 0 | 0.995 71 | 357.5 | 45.9597 9 | 0.996 98 |

| A4 | 23.4 | 32.657 4 | 0.994 80 | 20.3 | 31.6597 1 | 0.996 24 |

| 模型 | 聚酯漆膜 | 聚酯漆膜+焦炭 | ||||

|---|---|---|---|---|---|---|

| A/min-1 | E/kJ·mol-1 | R2 | A/min-1 | E/kJ·mol-1 | R2 | |

| F1 | 9.9×1011 | 164.583 9 | 0.997 98 | 5.9×1011 | 160.318 9 | 0.996 97 |

| F1.5 | 4.5×1014 | 196.925 4 | 0.998 56 | 2.4×1014 | 191.903 7 | 0.996 94 |

| F2 | 4.8×1017 | 234.180 4 | 0.985 93 | 2.4×1017 | 228.285 8 | 0.987 82 |

| F3 | 4.8×1024 | 320.671 0 | 0.950 61 | 1.9×1024 | 312.714 5 | 0.952 75 |

| D1 | 3.2×1017 | 241.621 5 | 0.959 28 | 1.4×1017 | 235.186 4 | 0.957 60 |

| D2 | 2.6×1019 | 268.600 4 | 0.975 54 | 1.1×1019 | 261.591 7 | 0.974 98 |

| D3 | 3.7×1021 | 303.111 8 | 0.990 03 | 1.4×1021 | 295.329 9 | 0.990 34 |

| D4 | 4.8×1019 | 279.932 4 | 0.981 38 | 1.9×1019 | 272.674 3 | 0.981 14 |

| P2 | 802.6 | 51.920 9 | 0.944 38 | 651.6 | 50.3745 3 | 0.941 79 |

| P3 | 13.5 | 30.844 9 | 0.929 85 | 11.7 | 29.8472 6 | 0.926 25 |

| P4 | 1.5 | 20.302 8 | 0.909 35 | 1.3 | 19.5794 7 | 0.904 20 |

| R1 | 7.8×107 | 115.157 2 | 0.955 01 | 5.2×107 | 111.981 3 | 0.953 09 |

| R2 | 2.8×109 | 137.413 8 | 0.982 77 | 1.8×109 | 133.755 6 | 0.982 63 |

| R3 | 9.5×109 | 145.894 1 | 0.989 13 | 5.9×109 | 142.053 0 | 0.989 44 |

| A1 | 2.5×107 | 105.945 3 | 0.996 71 | 1.7×107 | 103.135 2 | 0.997 77 |

| A2 | 1.1×105 | 76.630 1 | 0.996 41 | 8.5×104 | 74.5433 2 | 0.997 54 |

| A3 | 429.0 | 47.315 0 | 0.995 71 | 357.5 | 45.9597 9 | 0.996 98 |

| A4 | 23.4 | 32.657 4 | 0.994 80 | 20.3 | 31.6597 1 | 0.996 24 |

| 1 | 文博杰,代涛,韩中奎,等.中国铜资源在用存量与二次供应潜力[J].地球学报,2023,44(02):325⁃332. |

| WEN B J, DAI T, HAN Z K, et al. Copper in⁃use stock and recycling potential in China[J]. Acta Geoscientica Sinica,2023,44(02):325⁃332. | |

| 2 | 中华人民共和国自然资源部.中国矿产资源报告2022[M].北京:地质出版社,2022. |

| 3 | 国家统计局.中国统计年鉴2022[M].北京:中国统计出版社,2022. |

| 4 | 中国有色金属工业协会铜业分会[EB/OL].. |

| 5 | 张楠. 新能源产业发展背景下我国铜资源供需现状与趋势[J]. 中国矿业, 2023, 32 (06): 2⁃9. |

| ZHANG N. Analysis of supply and demand status and trend of copper resources in China under development background of new energy industry[J]. China Mining Magazine, 2023, 32(6): 2⁃9. | |

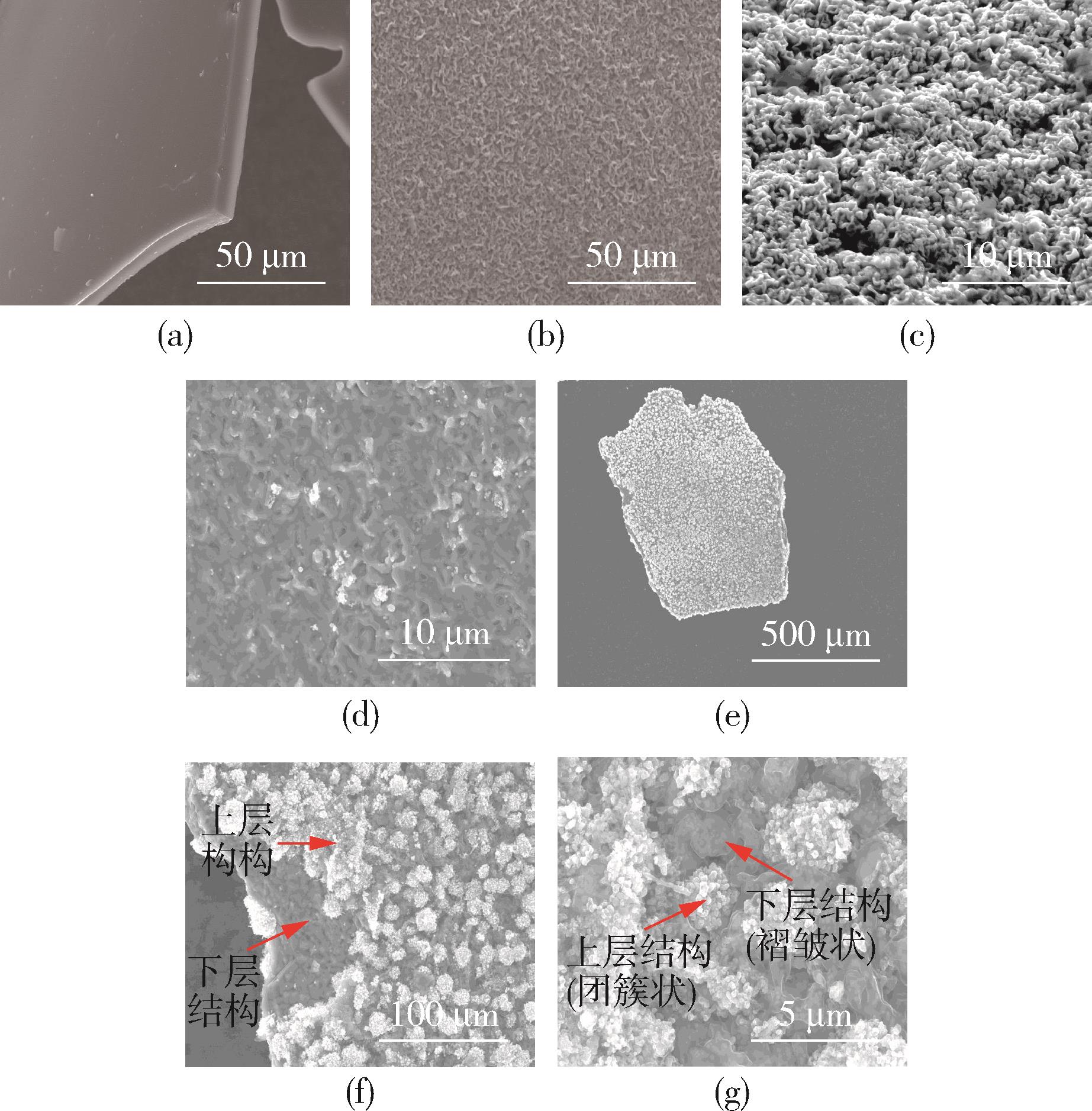

| 6 | Zhou Wei, Zhu Guangze, Cheng Hao,et al. Investigation of EPET,EPEI,and EPU pyrolysis coke acteristics: Thermal decomposition behaviours,pyrolysis products and mechanism[J].Journal of Analytical and Applied Pyrolysis,2023,175:106203. |

| 7 | 陈甲斌.中国铜资源保供需要关注的三个问题[J]. 中国国土资源经济,2022,35(10):4⁃10,74. |

| CHEN J B.Three problems need to be concerned regarding China′s copper resource supply guarantee[J]. Natural Resource Economics of China, 2022,35(10):4⁃10,74. | |

| 8 | 韩见, 夏鹏, 邢佳韵,等. 后疫情时代中国铜资源供应形势分析[J]. 地球学报, 2021, 42(02):223⁃228. |

| HAN J, XIA P, XING J Y, et al. An analysis of China's copper resources supply situation in the post⁃COVID-19 era[J]. Acta Geoscientica Sinica, 2021, 42(02): 223⁃228. | |

| 9 | 文进军,陈景达,龚明睿. 漆包线行业VOCs深度治理问题思考与对策[J]. 节能与环保,2023,(06): 49⁃51. |

| WHEN J J, CHEN J D, GONG M R. Problems and countermeasures on deep treatment of VOCs in enameled wire Industry[J]. Energy Conservation and Environmental Protection, 2023,(06): 49⁃51. | |

| 10 | 胡辰玮,李彬,吴玉锋,等.废有机⁃无机复合材料热解回收技术现状与展望[J].材料导报,2021,35(21):21 091⁃21 098,21 112. |

| HU C W, LI B, WU Y F, et al. Status and progress of recycling waste organic⁃inorganic composites by pyrolysis[J]. Materials Reports, 2021,35(21):21 091⁃21 098,21 112. | |

| 11 | Sanmartín Patricia, Cappitelli Francesca, Mitchell Ralph. Current methods of graffiti removal: A review [J].Construction and Building Materials, 2014, 71:363⁃374. |

| 12 | Li Bingyi, Wang Xiaolu, Xia Zhidong,et al. Co⁃pyrolysis of waste polyester enameled wires and polyvinyl chloride:Evolved products and pyrolysis mechanism analysis[J]. Journal of Analytical and Applied Pyrolysis,2023,169:105816. |

| 13 | 范春龙,钱立新,丁龙,等.废铜漆包线热解烟气中二噁英的排放特性与减排机理[J].中国环境科学,2023,43(11):5 855⁃5 862. |

| FAN C L, QIAN L X, DING L, et al. Emission characteristics and abatement mechanism of dioxins in the pyrolysis flue gas of scrap copper enameled wire[J]. China Environmental Science, 2023,43(11):5 855⁃5 862. | |

| 14 | 李欢欢. 典型热解焦炭对热解气中焦油模化物的催化裂解研究[D].杭州:浙江大学,2018. |

| 15 | 陆鹏.废弃物衍生炭基催化剂催化脱除气化焦油的研究[D]. 杭州:浙江大学,2020. |

| 16 | Zhang Lei, Shu Hao, Yang Jia. Gas⁃modified pyrolysis coke for in situ catalytic cracking of coal tar[J]. ACS omega, 2020, 5:14 911⁃14 923. |

| 17 | Li Jie, Liu Zhengyi, Tian Yuanyu, et al. Catalytic conversion of gaseous tars using land, coastal and marine biomass⁃derived char catalysts in a bench⁃scale downstream combined fixed bed system[J]. Bioresource Technology, 2020, 304:122735. |

| 18 | 徐靖,王雪,张代林,等. 煤与废轮胎共热解行为及热解焦炭微晶结构研究[J]. 煤炭转化,2022,45 (05): 53⁃62. |

| XU J, WANG X, ZHANG D L, et al. Study on co⁃pyrolysis behavior of coal and waste tires and microcrystalline structure of pyrolytic char[J]. Coal Conversion,2022,45(5):53⁃62. | |

| 19 | 张浩. 有机固体废弃物热解行为研究[D]. 北京:北京化工大学,2023. |

| 20 | 马大朝,高伟康,孙翔,等.稻壳与聚氯乙烯共热解的特性及动力学[J].环境工程,2020,38(01):135⁃140. |

| MA D C, GAO W K, SUN X, et al. Characteristics and kinetics of co⁃pyrolysis of rice husk and PVC[J]. Environmental Engineering, 2020, 38(1): 135⁃140. | |

| 21 | Gao N, Li A, Quan C, et al. TG⁃FTIR and Py⁃GC/MS analysis on pyrolysis and combustion of pine sawdust[J]. Journal of Analytical and Applied Pyrolysis, 2013,100: 26–32. |

| 22 | Ding Z, Liu J, Chen H, et al. Co⁃pyrolysis performances, synergistic mechanisms, and products of textile dyeing sludge and medical plastic wastes[J].Science of the Total Environment, 2021:799. |

| 23 | 朱光泽, 周炜, 夏志东, 等. 有机废弃物热解分析技术现状与展望[J]. 中国塑料, 2023, 37(11): 101⁃116. |

| ZHU G Z, ZHOU W, XIA Z D, et al. Current situation and prospect of pyrolysis analysis technology of organic wastes[J]. China Plastics, 2023, 37(11): 101⁃116. | |

| 24 | 孙林. 废纸盒催化热解制备富氢燃气及多孔石墨碳的实验研究[D].武汉:华中科技大学,2023. |

| 25 | 李宗儒. 玉米芯综合利用制备芳烃化学品及碳基吸波材料[D].淮安:安徽理工大学,2023. |

| 26 | Wang S, Jiang D, Cao B, et al. Study on the interaction effect of seaweed bio⁃coke and rice husk volatiles during co⁃pyrolysis[J]. Journal of Analytical and Applied Pyrolysis,2018,132:111–122. |

| 27 | Xu Shannan, Benjamin Bernard Uzoejinwa, Shuang Wang, et al. Study on co⁃pyrolysis synergistic mechanism of seaweed and rice husk by investigation of the characteristics of char/coke[J]. Renewable Energy, 2019, 132:527–542. |

| 28 | Liu Wei, Wang Na, Han Junwei, et al. Thermal degradation behaviors and evolved products analysis of polyester paint and waste enameled wires during pyrolysis[J]. Waste Management, 2020, 107:82⁃90. |

| 29 | 杨琦玲,王儒威.烟煤热解过程分子官能团的演化特征及动力学模型[J].环境工程,2023,41(07):138⁃144. |

| YANG Q L, WANG R W. Evolution characteristic and kinetic model for functional groups in bituminous coal during pyrolysis [J]. Environmental Engineering, 2023, 41(7): 138⁃144. | |

| 30 | 曹子昂,王雷,李皓,等. TG⁃FTIR技术对纤维素和聚氯乙烯共热解的反应特性和产物的分析[J].塑料科技,2023,51(01):18⁃24. |

| CAO Z A, WANG L, LI H, et al. TG⁃FTIR analysis of reaction characteristics and products of co⁃pyrolysis of cellulose and PVC[J]. Plastics Science and Technology, 2023,51(01):18⁃24. |

| [1] | ZHU Guangze, ZHOU Wei, XIA Zhidong, WANG Xiaolu, LI Bingyi, GUO Fu, WU Yufeng. Current situation and prospect of pyrolysis analysis technology of organic wastes [J]. China Plastics, 2023, 37(11): 101-116. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||