京ICP备13020181号-2

© 《China Plastics》

© 《China Plastics》

China Plastics ›› 2022, Vol. 36 ›› Issue (12): 16-23.DOI: 10.19491/j.issn.1001-9278.2022.12.003

• Materials and Properties • Previous Articles Next Articles

HUANG Jiawei1,2, HAN Xiaolong1,2, WU You1,2, JIN Yujuan1,2( ), GUO Maolin1,2

), GUO Maolin1,2

Received:2022-10-04

Online:2022-12-26

Published:2022-12-20

CLC Number:

HUANG Jiawei, HAN Xiaolong, WU You, JIN Yujuan, GUO Maolin. Toughening modification of PHBV with EVA elastomer[J]. China Plastics, 2022, 36(12): 16-23.

EVA 含量/% | Tc/℃ | ΔHc/ J·g-1 | Tm/℃ | ΔHm/ J·g-1 | Xc/% | T0/℃ |

|---|---|---|---|---|---|---|

| 纯PHBV | 106.4 | 71.3 | 172.3 | 80.1 | 54.9 | 281.0 |

| 5 | 107.1 | 75.6 | 168.1 | 94.4 | 61.4 | 277.5 |

| 10 | 107.9 | 87.1 | 168.1 | 109.4 | 67.4 | 286.9 |

| 15 | 106.4 | 80.5 | 167.7 | 106.7 | 62.1 | 277.6 |

| 20 | 107.8 | 85.9 | 168.2 | 108.0 | 59.2 | 290.8 |

| 25 | 106.7 | 75.9 | 168.0 | 97.4 | 50.0 | 281.3 |

| 30 | 105.2 | 64.0 | 167.7 | 80.8 | 38.7 | 287.8 |

EVA 含量/% | Tc/℃ | ΔHc/ J·g-1 | Tm/℃ | ΔHm/ J·g-1 | Xc/% | T0/℃ |

|---|---|---|---|---|---|---|

| 纯PHBV | 106.4 | 71.3 | 172.3 | 80.1 | 54.9 | 281.0 |

| 5 | 107.1 | 75.6 | 168.1 | 94.4 | 61.4 | 277.5 |

| 10 | 107.9 | 87.1 | 168.1 | 109.4 | 67.4 | 286.9 |

| 15 | 106.4 | 80.5 | 167.7 | 106.7 | 62.1 | 277.6 |

| 20 | 107.8 | 85.9 | 168.2 | 108.0 | 59.2 | 290.8 |

| 25 | 106.7 | 75.9 | 168.0 | 97.4 | 50.0 | 281.3 |

| 30 | 105.2 | 64.0 | 167.7 | 80.8 | 38.7 | 287.8 |

| 1 | Geyer R, Jambeck J RLaw K L. Production, use, and fate of all plastics ever made [J]. Science Advances, 2017, 3(7): e1700782. |

| 2 | Dauvergne P. Why is the global governance of plastic failing the oceans [J]. Global Environmental Change⁃Human and Policy Dimensions, 2018, 51: 22⁃31. |

| 3 | Jambeck J R, Geyer R, Wilcox C, et al. Plastic waste inputs from land into the ocean [J]. Science, 2015, 347(6223): 768⁃771. |

| 4 | Larsson M, Markbo O, Jannasch P. Melt processability and thermomechanical properties of blends based on polyhydroxyalkanoates and poly(butylene adipate⁃co⁃terephthalate) [J]. RSC Adv, 2016, 6(50): 44354–44363. |

| 5 | Pal AK, Wu F, Misra M, et al. Polyhydroxyalkanoate (PHA) based sustainable nanocomposites with improved mechanical and barrier properties for packaging applications [J]. Detroit, USA: Society of Plastics Engineers (SPE) Annual Technical Conference (ANTEC), 2019, March. |

| 6 | Sharma S, Singh A A, Majumdar A, et al. Harnessing the ductility of polylactic acid/halloysite nanocomposites by synergistic effects of impact modifier and plasticiser [J]. Compos B Eng, 2020, 188: 107845. |

| 7 | Bugnicourt E, Cinelli P, Lazzeri A, et al. Polyhydroxyalkanoate (PHA): review of synthesis, characteristics, processing and potential applications in packaging [J]. Express Polym Lett, 2014, 8(11): 791⁃808. |

| 8 | Javadi A, Srithep Y, Lee J, et al. Processing and characterization of solid and microcellular PHBV/PBAT blend and its RWF/ nanoclay composites [J]. Compos Appl Sci Manuf, 2010, 41(8): 982⁃990. |

| 9 | SilvaA P B, MontagnaL S, PassadorF R, et al. Biodegradable nanocomposites based on PLA/PHBV blend reinforced with carbon nanotubes with potential for electrical and electromagnetic applications[J]. Express Polym Lett,2021, 15:987⁃1 003. |

| 10 | Li J, Lai MF, Liu J J. Control and development of crystallinity and morphology in poly(β⁃hydroxybutyrate⁃co⁃β⁃hydroxyvalerate)/poly(propylene carbonate) blends [J]. Appl Polym Sci, 2005, 98(3): 1 427⁃1 436. |

| 11 | Javadi A, Kramschuster A J, Pilla S, et al. Processing and characterization of microcellular PHBV/PBAT blends [J]. Polym Eng Sci, 2010, 50(7): 1 440⁃1 448. |

| 12 | Karimpour⁃Motlagh N, Moghadam A S, Khonakdar H A, et al. A Theoretical and experimental analysis of the effect of nanoclay on gas perm⁃selectivity of biodegradable PLA/EVA Blends in the presence and absence of compatibilizer[J]. Macromolecular Materials and Engineering, 2020, 305(12): 2000433. |

| 13 | Lin J, Li J, Wang J J, et al. Effects of thermoplastic elastomer on the morphology and mechanical properties of glass fiber⁃reinforced polycarbonate/acrylonitrile⁃butadiene⁃styrene[J]. Polymer Engineering and Science, 2019, 59: 144⁃151. |

| 14 | Ma P, Hristova⁃Bogaerds D G, Goossens J G P, et al. Toughening of poly(lactic acid) by ethylene⁃co⁃vinyl acetate copolymer with different vinyl acetate contents[J]. European Polymer Journal, 2012, 48(1): 146⁃154. |

| 15 | Park H Y, Hwang S W, Ryu H C, et al. Effect of maleated EVA on compatibility and toughness of PETG/EVA blend[J]. Journal of Applied Polymer Science, 2013,127(4): 2 600⁃2 606. |

| 16 | Tanase E E, Popa M E, alet, Rapa M. PHB/cellulose fibers based materials: physical, mechanical and barrier properties. agriculture and agricultural science procedia [C]. Amsterdam: Elsevier Science Bv, 2015, 608⁃615. |

| 17 | Zytner P, Wu F, Misra M, et al. Toughening of biodegradable poly(3⁃hydroxybutyrate⁃co-3⁃hydroxyvalerate)/poly(epsilon⁃caprolactone) blends by in situ reactive compatibilization [J]. ACS Omega, 2020, 5(25): 14 900⁃14 910. |

| 18 | Yu H Y, Qin Z Y, Liu Y N, et al. Simultaneous improvement of mechanical properties and thermal stability of bacterial polyester by cellulose nanocrystals [J]. Carbohydr Polym, 2012, 89: 971⁃978. |

| 19 | Yu H Y, Qin Z Y, Liu L, et al. Comparison of the reinforcing effects for cellulose nanocrystals obtained by sulfuric and hydrochloric acid hydrolysis on the mechanical and thermal properties of bacterial polyester [J]. Composites Science and Technology, 2013, 87: 22⁃28. |

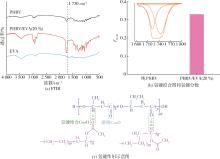

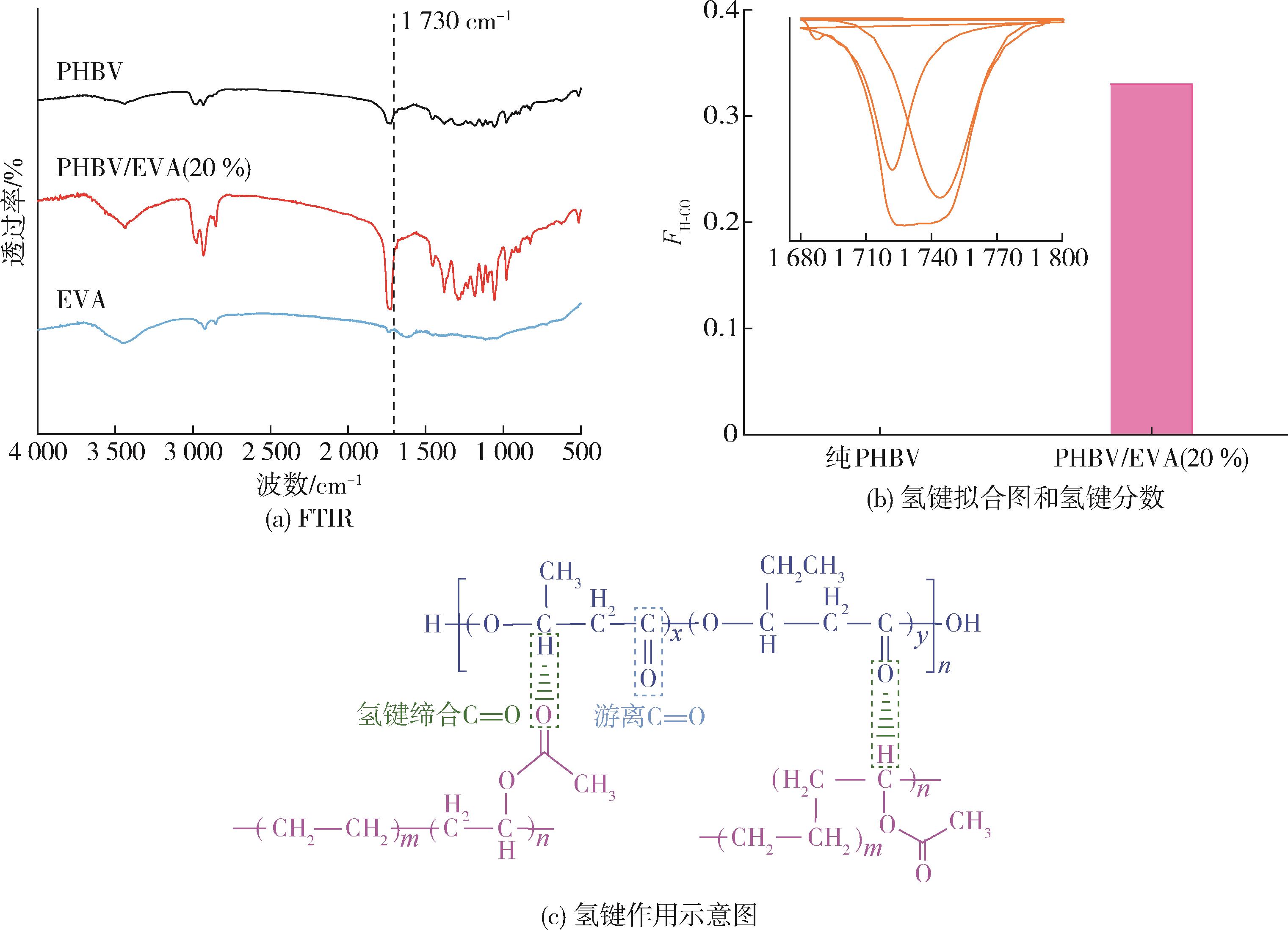

| 20 | Fei B, Chen C, Wu H, et al. Quantitative FTIR study of PHBV/bisphenol A blends [J]. European Polymer Journal, 2003, 39(10): 1 939⁃1 946. |

| 21 | YuH Y, QinZ Y, YanC F, et al. Green nanocomposites based on functionalized cellulose nanocrystals: a study on the relationship between interfacial interaction and property enhancement[J]. ACS Sustain Chem Eng, 2014, (2): 875⁃886. |

| 22 | Chen G X, Yoon J S. Thermal stability of poly(L⁃lactide)/poly(butylene succinate)/clay nanocomposites [J]. Polymer Degradation and Stability, 2005, 88(2): 206⁃212. |

| 23 | Zhang X Z, Zhang Y. Reinforcement effect of poly (butylene succinate) (PBS)⁃grafted cellulose nanocrystal on toughened PBS/polylactic acid blends [J]. Carbohydrate Polymers, 2016, 140: 374⁃382. |

| [1] | ZHANG Lin, XIA Zhangchuan, HE Yadong, XIN Chunling, WANG Ruixue, REN Feng. Influence of gas flow of plasma jet carrier on modification effect for glass fiber [J]. China Plastics, 2022, 36(9): 7-15. |

| [2] | HUANG Jiawei, HAN Xiaolong, WU You, JIN Yujuan, WANG Zhao. Toughening modification of poly (3⁃hydroxybutyrate⁃co⁃3⁃hydroxyvalerate) by bio⁃based engineering polyester elastomer [J]. China Plastics, 2022, 36(9): 24-31. |

| [3] | MA Chao, MA Lanrong, WEI Liao, YIN Huibo, LIN Xiang. A review of modification processing and water⁃soluble degradation ability of polyglycolic acid material [J]. China Plastics, 2022, 36(9): 74-84. |

| [4] | MA Guocheng, HE Zhen, CHEN Shaojun. Research progress in degradability of cellulose acetate [J]. China Plastics, 2022, 36(9): 111-121. |

| [5] | YANG Chaoyong, GUO Jinqiang, WANG Fuyu, ZHNAG Yuxia. Research progress in preparation and modification methods of high-performance plastic films [J]. China Plastics, 2022, 36(9): 167-179. |

| [6] | YU Darong, XIN Yong. Research progress in modification of ultrahigh molecular weight polyethylene [J]. China Plastics, 2022, 36(8): 135-145. |

| [7] | YU Jiuyang, WANG Zhonghao, CHEN Qi, XIA Yazhong. Study on properties of advanced resin matrix composites for valve body manufacturing [J]. China Plastics, 2022, 36(8): 16-22. |

| [8] | CHEN Baiquan, ZHENG Youming, TIAN Jibo, XHANG Lei, WANG Jinsong, LIN Xiajie, DUAN Yapeng. Preparation and properties of polyamide flame⁃retardant composite reinforced with high content of glass fiber [J]. China Plastics, 2022, 36(8): 42-48. |

| [9] | FENG Kai, LI Yongqing, MA Xiuqing, HAN Ying. Research progress and application in toughening modification of polyoxymethylene [J]. China Plastics, 2022, 36(7): 157-164. |

| [10] | CHEN Ke, LIU Mingfei, ZHAO Biao, PAN Kai. Research progress in flame retardancy and ablation resistance of silicone⁃modified polymeric materials [J]. China Plastics, 2022, 36(6): 149-154. |

| [11] | DENG Tianxiang, XU Lina, LI Shouhai, ZHANG Yan, YAO Na, JIA Puyou, DING Haiyang, LI Mei. Research progress in grafting and crosslinking modification of PVC [J]. China Plastics, 2022, 36(5): 140-148. |

| [12] | WANG Rongchen, ZHANG Heng, SUN Huanwei, DUAN Shuxia, QIN Zixuan, LI Han, ZHU Feichao, ZHANG Yifeng. Research progress in preparation and hydrophilic modification of polylactic acid nonwovens for medical and health applications [J]. China Plastics, 2022, 36(5): 158-166. |

| [13] | ZHAO Xinxin, JIN Xiaodong, SHI Yan, SUN Shibing, LYU Feng, TIAN Yingliang, ZHAO Zhiyong. Surface modification of extruded polystyrene based on ultraviolet⁃ozone irradiation [J]. China Plastics, 2022, 36(5): 8-13. |

| [14] | CHEN Wenjing, YANG Xiaolong, HAN Shuntao, HAN Ying, MA Xiuqing. Research progress in modification methods of polyacrylonitrile materials [J]. China Plastics, 2022, 36(4): 158-165. |

| [15] | DONG Luqian, XU Fang, WENG Yunxuan. Research progress in modification and applications of poly(glycolic acid) [J]. China Plastics, 2022, 36(4): 166-174. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||