京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2

《中国塑料》编辑部 ©2008-2024 版权所有

地址:北京市海淀区阜成路11号 邮编:100048

编辑部:010-68985541 联系信箱:cp@plaschina.com.cn

广告部/发行部:010-68985253 本系统由北京玛格泰克科技发展有限公司设计开发

中国塑料 ›› 2025, Vol. 39 ›› Issue (2): 32-39.DOI: 10.19491/j.issn.1001-9278.2025.02.007

收稿日期:2024-05-15

出版日期:2025-02-26

发布日期:2025-02-27

通讯作者:

王颖(1979—),女,研究员,从事医用卫生材料和医用纤维材料研究,wangy0116.bjhy@sinopec.com作者简介:张正(1993—),男,博士,从事医卫防护材料的研究,zhangzh.bjhy@sinopec.com

基金资助:

ZHANG Zheng( ), LI Fangquan, ZHU Guixiang, GUO Min, WANG Ying(

), LI Fangquan, ZHU Guixiang, GUO Min, WANG Ying( )

)

Received:2024-05-15

Online:2025-02-26

Published:2025-02-27

Contact:

WANG Ying

E-mail:zhangzh.bjhy@sinopec.com;wangy0116.bjhy@sinopec.com

摘要:

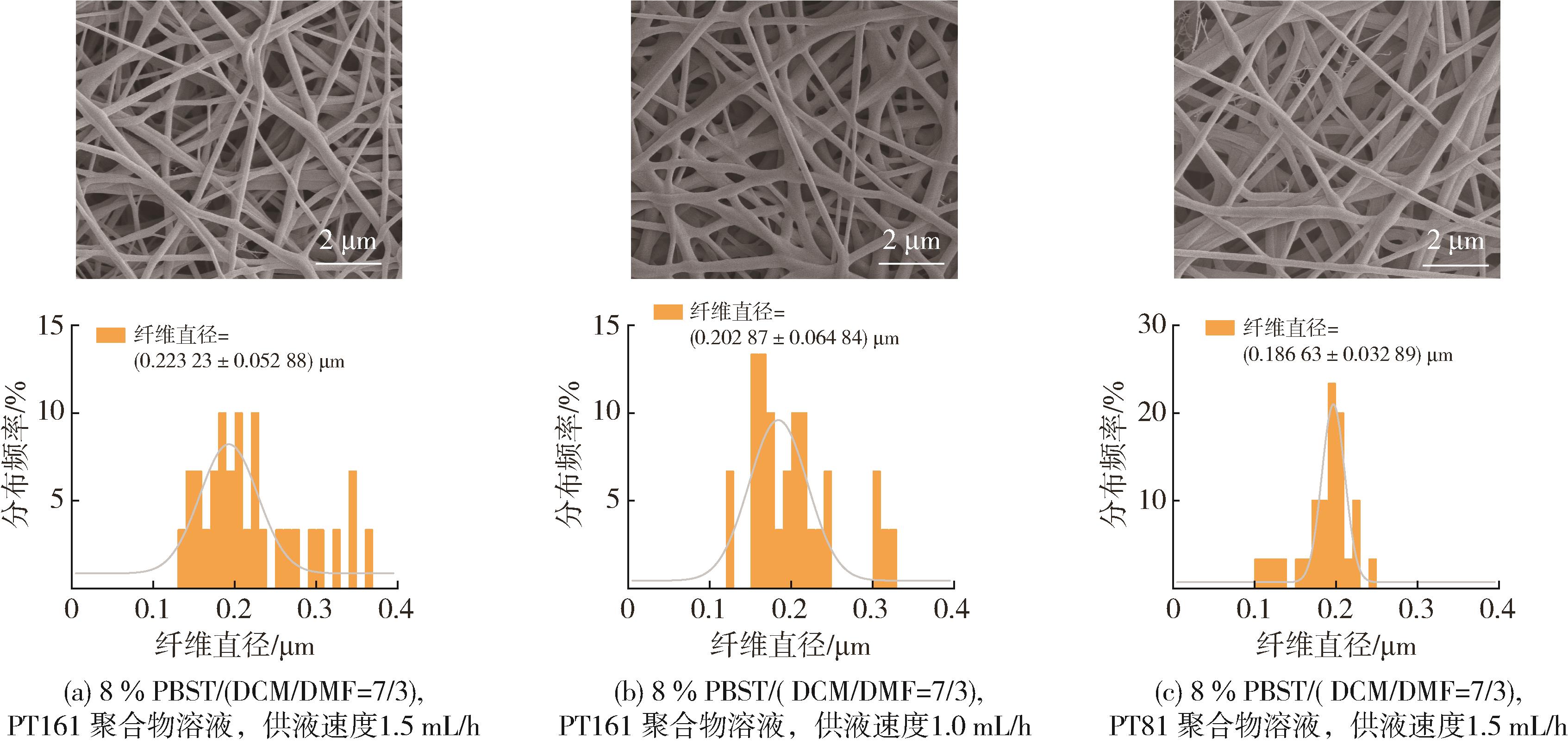

利用溶液静电纺丝法分别研究了聚对苯二甲酸⁃共⁃丁二酸丁二醇酯(PBST)聚合物在单一溶剂体系二氯甲烷(DCM)和双组分溶剂体系二氯甲烷/N,N⁃二甲基甲酰胺(DMF)中的可纺性,探讨了聚合物溶液浓度、供液速度、溶剂比例等纺丝参数对PBST纳米纤维直径的影响。通过加入四正丁基氯化铵(TBAC)有机盐,实现了PBST纳米纤维的进一步细化,并研究了不同比例TBAC在不同溶剂体系中的助剂作用。结果表明,TBAC的加入可以大幅增加聚合物纺丝溶液的导电性,提升PBST的可纺性,并显著降低PBST纳米纤维直径。同时,对所制备的溶液静电纺PBST纳米纤维材料的空气过滤性能也进行了初步探究。在PBST质量浓度为5 %,溶剂体系为DCM/DMF(质量比7/3),PBST和TBAC质量比为4/1时,PBST纤维最细,平均直径可达到65 nm;在PBST质量浓度为8 %,溶剂体系为DCM/DMF(质量比7/3), PBST和TBAC质量比为16/1时,PBST纳米纤维材料滤效达到99.98 %,滤阻236.9 Pa。

中图分类号:

张正, 李方全, 祝桂香, 郭敏, 王颖. 生物可降解静电纺PBST超细纳米纤维的制备及工艺研究[J]. 中国塑料, 2025, 39(2): 32-39.

ZHANG Zheng, LI Fangquan, ZHU Guixiang, GUO Min, WANG Ying. Study on preparation technology of ultrafine biodegradable electrospun PBST nanofibers[J]. China Plastics, 2025, 39(2): 32-39.

| 样品 | 5 % PBST/DCM | 8 % PBST/DCM | 10 % PBST/DCM |

|---|---|---|---|

| 黏度 | 11.0 | 32.4 | 66.7 |

| 样品 | 5 % PBST/DCM | 8 % PBST/DCM | 10 % PBST/DCM |

|---|---|---|---|

| 黏度 | 11.0 | 32.4 | 66.7 |

| 1 | Fahimirad S, Fahimirad Z, Sillanpää M. Efficient removal of water bacteria and viruses using electrospun nanofibers[J]. Science of the Total Environment, 2021, 751:141673. |

| 2 | Li K, Zhou W, Zeng S. Optical micro/nanofiber⁃based localized surface plasmon resonance biosensors: fiber diameter dependence[J]. Sensors, 2018, 18 (10): 3295. |

| 3 | Ding B, Wang M, Yu J, et al. Gas sensors based on electrospun nanofibers[J]. Sensors, 2009, 9 (3): 1 609⁃1 624. |

| 4 | Ding B, Wang M, Wang X, et al. Electrospun nanomaterials for ultrasensitive sensors[J]. Materials Today, 2010, 13 (11): 16⁃27. |

| 5 | Marnn P, Claude N J, Oo T T, et al. Challenges of mask pollutants to our environment during covid-19 pandemic period[J]. American Journal of Environment and Sustainable Development, 2021, 6 (4): 118⁃127. |

| 6 | Shah A A, Kato S, Shintani N, et al. Microbial degradation of aliphatic and aliphatic⁃aromatic co⁃polyesters[J]. Applied Microbiology and Biotechnology, 2014, 98: 3 437⁃3 447. |

| 7 | Škrlová K, Rybková Z, Stachurová T, et al. Long⁃term antimicrobial effect of polylactide⁃based composites suitable for biomedical use[J]. Polymer Testing, 2022, 116: 107760. |

| 8 | Rajgond V, Mohite A, More N, et al. Biodegradable polyester⁃polybutylene succinate (PBS): a review[J]. Polymer Bulletin, 2023: 1⁃50. |

| 9 | Naeimirad M, Krins B, Gruter G J M. A review on melt⁃spun biodegradable fibers[J]. Sustainability, 2023, 15 (19): 14474. |

| 10 | Ahmed F E, Lalia B S, Hashaikeh R. A Review on electrospinning for membrane fabrication: challenges and applications[J]. Desalination, 2015, 356: 15⁃30. |

| 11 | Tebyetekerwa M, Xu Z, Yang S, et al. Electrospun nanofibers⁃based face masks[J]. Advanced Fiber Materials, 2020, 2(3): 161⁃166. |

| 12 | Li Y, Abedalwafa M A, Tang L, et al. Electrospun nanofibers for sensors [M]. Electrospinning: Nanofabrication and Applications, Elsevier, 2019: 571⁃601. |

| 13 | Vhatkar S S, Kumari A, Kumar P, et al. Electrospun nanofibers for energy and environment protection[M]. Electrospun Nanofibers: Fabrication, Functionalisation and Applications, Springer, 2021: 25⁃52. |

| 14 | Parham S, Kharazi A Z, Bakhsheshi⁃Rad H R, et al. Electrospun nano⁃fibers for biomedical and tissue engineering applications: a comprehensive review[J]. Materials, 2020, 13 (9): 2153. |

| 15 | Wei Z, Liu Y, Hu H, et al. Biodegradable Poly(butylene succinate⁃co⁃terephthalate) nanofibrous membranes functionalized with cyclodextrin polymer for effective methylene blue adsorption[J]. RSC Advances, 2016, 6 (110): 108 240⁃108 246. |

| 16 | Wei Z, Pan Z, Li F, et al. Poly(butylene succinate⁃co⁃terephthalate) nanofibrous membrane composited with cyclodextrin polymer for superhydrophilic property[J]. RSC Advances, 2018, 8(3): 1 378⁃1 384. |

| 17 | Zhang F, Sun X F, Liu Y. Orthogonal design study on the morphology of electrospun poly(butylene succinate⁃co⁃butylene terephthalate)(PBST) nanofibers[J]. Advanced Materials Research, 2013, 749: 23⁃26. |

| 18 | Yuan D, Chen Z, Xiang X, et al. The Establishment and biological assessment of a whole tissue⁃engineered intervertebral disc with PBST fibers and a chitosan hydrogel in vitro and in vivo[J]. Journal of Biomedical Materials Research Part B: Applied Biomaterials, 2019, 107(7): 2 305⁃2 316. |

| 19 | Wannatong L, Sirivat A, Supaphol P. Effects of solvents on electrospun polymeric fibers: preliminary study on polystyrene[J]. Polymer International, 2004, 53 (11): 1 851⁃1 859. |

| 20 | Veleirinho B, Rei M F, Silva J A. Solvent and concentration effects on the properties of electrospun poly(ethylene terephthalate) nanofiber mats[J]. Journal of Polymer Science Part B: Polymer Physics, 2008, 46(5): 460⁃471. |

| 21 | Gu X, Song X, Shao C, et al. Electrospinning of poly (butylene⁃carbonate): effect of solvents on the properties of the nanofibers film[J]. International Journal of Electrochemical Science, 2014, 9(12): 8 045⁃8 056. |

| 22 | Chuangchote S, Sagawa T, Yoshikawa S. Electrospinning of poly(vinyl pyrrolidone): effects of solvents on electrospinnability for the fabrication of poly(p⁃phenylene vinylene) and TiO2 nanofibers[J]. Journal of Applied Polymer Science, 2009, 114 (5): 2 777⁃2 791. |

| 23 | Hadjizadeh A, Savoji H, Ajji A. A facile approach for the mass production of submicro/micro poly (lactic acid) fibrous mats and their cytotoxicity test towards neural stem cells[J]. BioMed Research International, 2016: 921316. |

| 24 | Tiwari S K, Venkatraman S S. Importance of Viscosity parameters in electrospinning: of monolithic and core–shell fibers[J]. Materials Science and Engineering: C, 2012, 32 (5): 1 037⁃1 042. |

| 25 | Yan J, Kang W, Cheng B. Guiding parameters for electrospinning process[M]. Advanced Nanofibrous Materials Manufacture Technology Based on Electrospinning, CRC Press, 2019: 82⁃111. |

| 26 | Wang H, Wan T, Wang H, et al. Novel colorimetric membranes based on polylactic acid⁃grafted⁃citrated methacrylated urethane (PLA⁃CMU) to monitor cod freshness[J]. International Journal of Biological Macromolecules, 2022, 194: 452⁃460. |

| 27 | Bhattacharjee A, Roy M N. Ion association and solvation behavior of tetraalkylammonium iodides in binary mixtures of dichloromethane+ N, N⁃dimethylformamide probed by a conductometric study[J]. Physical Chemistry Chemical Physics, 2010, 12 (43): 14 534⁃14 542. |

| [1] | 叶淋泉, 钱焘焘, 李融冰, 曾乐. 气相色谱同时测定饮用水瓶中IPA、EG、DEG含量的方法研究[J]. 中国塑料, 2025, 39(1): 80-84. |

| [2] | 周天宇, 李玖重, 张婧帆. 废弃聚异氰脲酸酯泡沫塑料的降解回收及再生利用[J]. 中国塑料, 2025, 39(1): 92-96. |

| [3] | 王晨, 李向阳, 周丽. 芳基二酰胺成核剂对均聚聚丙烯应用性能及结晶行为的影响[J]. 中国塑料, 2024, 38(12): 123-129. |

| [4] | 孟承翰, 罗皓文, 刘昊, 费继龙, 杨健飞, 杨振, 贾良元. 柠檬酸改性苎麻纤维增强聚丁二酸丁二醇酯的性能研究[J]. 中国塑料, 2024, 38(12): 54-59. |

| [5] | 李明昆, 林荣涛. PC/ABS高温下耐疲劳性能的影响因素研究[J]. 中国塑料, 2024, 38(12): 77-80. |

| [6] | 魏策, 陈天宇, 张秀涛, 张翼遥, 张思博, 张骁雨, 黄晶, 东为富. 动态共价交联网络在热塑性塑料中的应用:研究进展与未来展望[J]. 中国塑料, 2024, 38(12): 8-18. |

| [7] | 李航, 杜玲枝, 吴晓林, 冯巧, 李桂丽. 酚醛⁃不饱和聚酯树脂石墨双极板复合材料研究[J]. 中国塑料, 2024, 38(10): 5-9. |

| [8] | 吴俊峰, 杨慎宇. 聚羟基脂肪酸酯/氧化石墨烯复合材料的制备及性能表征[J]. 中国塑料, 2024, 38(10): 43-47. |

| [9] | 林炳荣. 厌氧发酵液为底物合成聚羟基脂肪酸酯(PHA)的研究进展[J]. 中国塑料, 2024, 38(10): 36-42. |

| [10] | 吕东轩, 徐鹏武, 杨伟军, 钮德宇, 孙钰杰, 马丕明. 强韧化聚(3⁃羟基丁酸⁃co⁃3⁃羟基戊酸酯)/聚碳酸酯共混物的制备及耐久性研究[J]. 中国塑料, 2024, 38(10): 10-15. |

| [11] | 李锐超, 朱光明, 张雪蓓, 郭欣怡. 氰酸酯低温固化体系的研究进展[J]. 中国塑料, 2024, 38(9): 123-128. |

| [12] | 马建心, 王国梁, 杜中杰, 王武聪, 金华, 邹威, 王洪, 张晨. 羟基官能化ACR的制备及其在PBT改性中的应用研究[J]. 中国塑料, 2024, 38(9): 14-19. |

| [13] | 胡凌骁, 姜慧慧. 基于可视化实验的PET膜贴合后除泡过程与压力的关系[J]. 中国塑料, 2024, 38(9): 82-87. |

| [14] | 殷茂峰, 王晓珂, 孙国华, 张信, 李鹏鹏, 马劲松, 肖军, 侯连龙. 红外光谱快速检测生物降解聚酯的研究[J]. 中国塑料, 2024, 38(9): 94-100. |

| [15] | 何和智, 黄宗海, 赖文, 熊华威. PLA/PBAT/CB防静电包装材料的制备及其性能研究[J]. 中国塑料, 2024, 38(7): 1-8. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2