京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2

《中国塑料》编辑部 ©2008-2024 版权所有

地址:北京市海淀区阜成路11号 邮编:100048

编辑部:010-68985541 联系信箱:cp@plaschina.com.cn

广告部/发行部:010-68985253 本系统由北京玛格泰克科技发展有限公司设计开发

中国塑料 ›› 2025, Vol. 39 ›› Issue (9): 75-80.DOI: 10.19491/j.issn.1001-9278.2025.09.012

徐锋1,2( ), 李英杰1,2, 杨居一3, 李旋3, 储成林3(

), 李英杰1,2, 杨居一3, 李旋3, 储成林3( )

)

收稿日期:2024-10-11

出版日期:2025-09-26

发布日期:2025-09-22

通讯作者:

储成林(1972-),教授,主要研究方向为材料研发及检测技术,clchu@seu.edu.cn作者简介:徐锋(1977-),高级工程师,主要研究方向为特种设备检验检测,490910632@qq.com

基金资助:

XU Feng1,2( ), LI Yingjie1,2, YANG Juyi3, LI Xuan3, CHU Chenglin3(

), LI Yingjie1,2, YANG Juyi3, LI Xuan3, CHU Chenglin3( )

)

Received:2024-10-11

Online:2025-09-26

Published:2025-09-22

Contact:

CHU Chenglin

E-mail:490910632@qq.com;clchu@seu.edu.cn

摘要:

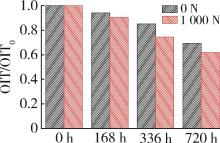

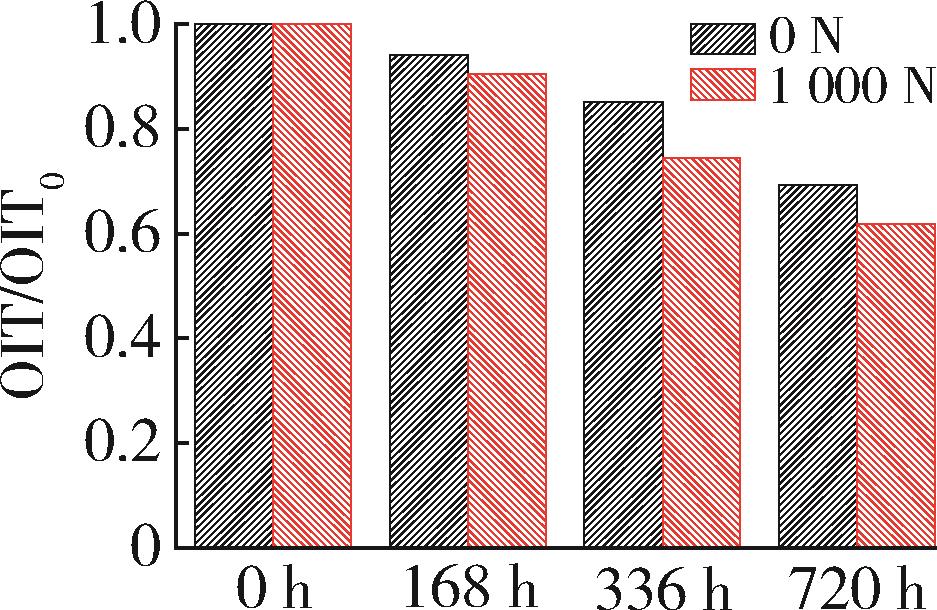

设计并搭建了模拟外部载荷工况的热氧老化实验装置用于研究聚乙烯燃气管道在外载作用下的老化行为。通过拉伸实验、扫描电子显微镜(SEM)、傅里叶红外光谱(FTIR)和差示扫描量热法(DSC)分析了高温外载作用下聚乙烯管材力学性能、微观组织以及热学性能变化。结果表明,随着高温老化时间的增加,聚乙烯管材的断裂伸长率和氧化诱导期下降,羰基指数和结晶度增加;外部载荷作用会加速聚乙烯的老化,在1 000 N外部载荷作用下,基于断裂伸长率、羰基指数和氧化诱导期所对应的老化速率分别是无外载作用时的1.82、1.17和1.3倍。

中图分类号:

徐锋, 李英杰, 杨居一, 李旋, 储成林. 高温外载作用下聚乙烯燃气管道老化行为研究[J]. 中国塑料, 2025, 39(9): 75-80.

XU Feng, LI Yingjie, YANG Juyi, LI Xuan, CHU Chenglin. Aging behaviors of polyethylene gas pipeline under high temperature and external load[J]. China Plastics, 2025, 39(9): 75-80.

老化 时间/h | 屈服强度/MPa | 断裂伸长率/% | ||

|---|---|---|---|---|

| 0 N | 1 000 N | 0 N | 1 000 N | |

| 0 | 23.1±1.5 | 23.1±1.5 | 512±20 | 512±20 |

| 168 | 23.5±1.8 | 21.8±1.5 | 480±18 | 448±16 |

| 336 | 23.2±2.1 | 22.9±2.3 | 437±19 | 367±21 |

| 720 | 22.8±1.1 | 22.8±2.4 | 370±15 | 283±18 |

老化 时间/h | 屈服强度/MPa | 断裂伸长率/% | ||

|---|---|---|---|---|

| 0 N | 1 000 N | 0 N | 1 000 N | |

| 0 | 23.1±1.5 | 23.1±1.5 | 512±20 | 512±20 |

| 168 | 23.5±1.8 | 21.8±1.5 | 480±18 | 448±16 |

| 336 | 23.2±2.1 | 22.9±2.3 | 437±19 | 367±21 |

| 720 | 22.8±1.1 | 22.8±2.4 | 370±15 | 283±18 |

| 老化时间/h | 结晶度/% | |

|---|---|---|

| 0 N | 1 000 N | |

| 0 | 51.8 | 51.8 |

| 168 | 53.2 | 53.1 |

| 336 | 53.6 | 54.2 |

| 720 | 56.9 | 57.3 |

| 老化时间/h | 结晶度/% | |

|---|---|---|

| 0 N | 1 000 N | |

| 0 | 51.8 | 51.8 |

| 168 | 53.2 | 53.1 |

| 336 | 53.6 | 54.2 |

| 720 | 56.9 | 57.3 |

| 性能指标 | 老化速率/h-1 | |

|---|---|---|

| 0 N | 1 000 N | |

| 断裂伸长率 | 4.57×10-4 | 8.32×10-4 |

| 羰基指数 | 2×10-3 | 2.34×10-3 |

| 氧化诱导期 | 5.2×10-4 | 6.8×10-4 |

| 性能指标 | 老化速率/h-1 | |

|---|---|---|

| 0 N | 1 000 N | |

| 断裂伸长率 | 4.57×10-4 | 8.32×10-4 |

| 羰基指数 | 2×10-3 | 2.34×10-3 |

| 氧化诱导期 | 5.2×10-4 | 6.8×10-4 |

| [1] | Hoàng Eric M, Allen Norman S, Liauw Christopher M, et al. The thermo⁃oxidative degradation of metallocene polyethyene. Part 1: Long⁃term thermal oxidation in the solid state [J]. Polymer Degradation and Stability, 2006, 91(6): 1356‐1362. |

| [2] | Archodoulaki V M, Lüftl S, Seidler S. Oxidation induction time studies on the thermal degradation behavior of polyoxymethylene [J]. Polymer Testing, 2006, 25(1): 83‐90. |

| [3] | 杨圳. 聚乙烯管材循环载荷法寿命预测研究[D]. 广州: 广东工业大学, 2021. |

| [4] | 武立文, 乔亮, 范峻铭, 等. 聚乙烯管道寿命预测研究进展[J]. 中国塑料, 2023, 37(11): 149⁃162. |

| WU L W, QIAO L, FAN J M, et al. Research progress in life prediction of polyethylene pipeline [J]. China Plastics, 2023, 37(11): 149⁃162. | |

| [5] | 郭骏骏, 晏华, 胡志德, 等. 基于主成分分析的高密度聚乙烯环境适应行为研究[J]. 材料工程, 2015, 43(1): 96⁃103. |

| GUO J J, YAN H, HU Z D, et al. Adaptive behaviour to environment of PE⁃HD by principal component analysis [J]. Journal of Materials Engineering, 2015, 43(1): 96⁃103. | |

| [6] | 林金峰, 王胜辉. 聚乙烯材料的老化和耐候性研究进展[J]. 化工装备技术, 2018, 39(5): 14⁃17. |

| LIN J F, WANG S H. Research progress on aging and weather resistant properties of polyethylene materials [J]. Chemical Equipment Technology, 2018, 39(5): 14⁃17. | |

| [7] | 代星辰,黄奕昶,关凯书.基于压痕测试技术的聚乙烯老化力学性能评价[J]. 机械工程材料, 2023, 47(1):106⁃110. |

| DAI X C, HUANG Y C, GUAN K S. Evaluation of aging mechanical properties of polyethylene based on indentation testing technology [J]. Materials for Mechanical Engineering, 2023, 47(1): 106⁃110. | |

| [8] | 兰惠清, 沙 迪, 孟 涛, 等. 承压燃气聚乙烯管道热氧老化规律研究[J]. 天然气工业, 2016, 36(4): 78⁃83. |

| LAN H Q, SHA D, MENG T, et al. Thermal oxidative aging laws of PE gas pressure pipes [J]. Natural Gas Industry, 2016, 36(4): 78⁃83. | |

| [9] | 杨 毅. 压力荷载影响下聚乙烯管热氧老化行为及机理研究[D]. 广州: 华南理工大学, 2019. |

| [10] | 李长俊, 马树锋, 季楚凌, 等. 地面堆载对埋地管道的安全影响分析[J]. 中国安全生产科学技术, 2015, 11(11): 23⁃28. |

| LI C J, MA S F, JI C L, et al. Study on influence to safety of buried pipelines caused by ground loads [J]. Journal of Safety Science and Technology, 2015, 11(11): 23⁃28. | |

| [11] | Abdelkader Djebli, Mostefa Bendouba, Abdelkrim Aid, et al. Fatigue life prediction and damage modelling of high⁃density polyethylene under constant and two⁃block loading [J]. Procedia Engineering, 2015, 101: 2⁃9. |

| [12] | 陈国华, 方 顺, 杨 毅, 等. 循环载荷作用下聚乙烯管材老化性能及寿命预测[J]. 塑料工业, 2022, 50(08): 95⁃100. |

| CHEN G H, FANG S, YANG Y, et al. Aging property and life prediction of polyethylene pipe under cyclic loading [J]. China Plastic Industry, 2022, 50(08): 95⁃100. | |

| [13] | Mitra Khiabani Moghadam, Morshedian Jalil, Ehsani Morteza, et al. Lifetime prediction of HV silicone rubber insulators based on mechanical tests after thermal aging [J]. IEEE Transactions on Dielectrics & Electrical Insulation, 2013, 20(3): 711⁃716. |

| [14] | 代军, 晏华, 郭骏骏, 等. 结晶度对聚乙烯热氧老化特性的影响[J]. 材料研究学报, 2017, 31(1): 41⁃48. |

| DAI J, YAN H, GUO J J, et al. Effects of crystallinity on degradation properties of polyethylene by thermo⁃oxidation aging [J]. Chinese Journal of Material Research, 2017, 31 (1): 41⁃48. | |

| [15] | 代军, 晏华, 王雪梅, 等. 结晶度对高密度聚乙烯光氧老化特性的影响[J]. 化工进展, 2017, 36(03): 1 003⁃1 011. |

| DAI J, YAN H, WANG X M, et al. Influence of crystallinity on degradation properties of high density polyethylene by photo⁃oxidation aging [J]. Chemical Industry and Engineering Progress, 2017, 36(03): 1 003⁃1 011. | |

| [16] | 张学敏, 侯林, 冯金茂, 等. 在役埋地聚乙烯给水管道自然老化行为研究[J]. 中国塑料, 2022, 36(2): 49⁃55. |

| ZHANG X M, HOU L, FENG J M, et al. Study on natural aging behavior of buried polyethylene water supply pipeline in service [J]. China Plastics, 2022, 36(2): 49⁃55. | |

| [17] | Zha Sixi, Lan Huiqing, Lin Nan, et al. Degradation and characterization methods for polyethylene gas pipes after natural and accelerated aging [J]. Polymer Degradation and Stability, 2023, 208: 110247. |

| [18] | 王志刚, 杨 波, 曾 辰, 等. 高温内压环境下聚乙烯燃气管道老化性能评价研究[J]. 中国塑料, 2022, 36(10): 84⁃89. |

| WANG Z G, YANG B, ZENG C, et al. Aging evaluation of polyethylene gas pipes under high temperature and inner pressure environment [J]. China Plastics, 2022, 36(10): 84⁃89. | |

| [19] | 王洋, 兰惠清, 左建东, 等. 聚乙烯老化试验研究现状[C]//第二届全国压力管道等承压设备安全运行及检测评价技术学术会议. 中国腐蚀与防护学会承压设备专业委员会,中国特种设备检验协会, 2016. |

| [20] | Popov A A, Zaikov G E, Semeriov N N. Kinetics of chemical reactions of stressed polymers [J]. International Journal of Polymeric Materials and Polymeric Biomaterials, 1992, 17(3/4): 143⁃149. |

| [21] | Ya Rapoport N, Gennadii E Zaikov. Kinetics and mechanism of the oxidation of polymers in a stressed state [J]. Russian Chemical Reviews, 1983, 52(9): 897⁃916. |

| [1] | 范兆荣, 谷亚新, 刘阳, 王晓丹, 刘运学. 固废漆渣在聚乙烯防水板材中的应用研究[J]. 中国塑料, 2025, 39(6): 84-88. |

| [2] | 徐璐, 刘剑, 王振超, 张士军, 郄继春, 尤启江, 蔡智会. 燃气用高密度聚乙烯电熔管件熔接研究[J]. 中国塑料, 2025, 39(2): 60-66. |

| [3] | 梁济峰, 瞿金平. 体积脉动注塑rPE⁃HD/rPET混杂体系结构性能演变[J]. 中国塑料, 2024, 38(8): 1-7. |

| [4] | 段凯歌, 陈小蝶, 倪佳, 梅振威, 周朝锡, 叶小平, 朱辉, 于东明. 紫外交联高密度聚乙烯材料的制备及性能研究[J]. 中国塑料, 2024, 38(5): 24-27. |

| [5] | 蒲强, 何霞, 王国荣, 胡刚. 点载荷作用下聚乙烯燃气管道的损伤分析[J]. 中国塑料, 2024, 38(3): 67-72. |

| [6] | 刘孟恩, 汤千熠, 张明耀, 刘伯军. 水性抗氧剂组成以及含量对ASA树脂性能的影响[J]. 中国塑料, 2024, 38(3): 73-78. |

| [7] | 祝景云, 衣惠君, 鄢薇, 李大伟. 合成膜专用聚乙烯树脂原料的研发[J]. 中国塑料, 2022, 36(6): 77-80. |

| [8] | 李永青, 杨小龙, 陈文静, 闫晓堃, 马秀清. 改性剂及高密度聚乙烯插层和剥离蒙脱石的分子动力学模拟[J]. 中国塑料, 2022, 36(2): 67-74. |

| [9] | 祝景云, 谷凤来, 鄢薇, 衣惠君. 耐温PE⁃HD管材专用料的结构与性能[J]. 中国塑料, 2022, 36(12): 24-30. |

| [10] | 张兆阳, 唐敢, 柯雪, 王鑫, 江学良, 刘仿军, 游峰. 硫酸钙晶须改性聚乙烯/聚酰胺6复合材料的热性能与力学性能研究[J]. 中国塑料, 2022, 36(11): 35-40. |

| [11] | 王雅珍, 刘新雨, 董少波, 兰天宇, 祖立武. 相容剂对PE⁃HD/玉米秸秆生物炭复合材料性能的影响[J]. 中国塑料, 2022, 36(1): 128-134. |

| [12] | 常频, 张毅, 孙峰, 乔亮, 范峻铭. 基于冲压试验的聚乙烯力学性能预测[J]. 中国塑料, 2022, 36(1): 25-31. |

| [13] | 王琳. 低黄变复配抗氧体系对PE⁃HD发黄问题改善评价[J]. 中国塑料, 2022, 36(1): 73-77. |

| [14] | 雷振凯, 张熙, 龚洁, 卡米尔·帕拉提null. 单翼迷宫式滴灌带抗热氧老化性能的影响研究[J]. 中国塑料, 2021, 35(9): 40-45. |

| [15] | 刘耀, 丁剑峰, 夏浙安, 李欣欣. 聚酰胺6/短切碳纤维/铜盐复合材料抗热氧老化机理的研究[J]. 中国塑料, 2021, 35(7): 12-17. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2