京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2

《中国塑料》编辑部 ©2008-2024 版权所有

地址:北京市海淀区阜成路11号 邮编:100048

编辑部:010-68985541 联系信箱:cp@plaschina.com.cn

广告部/发行部:010-68985253 本系统由北京玛格泰克科技发展有限公司设计开发

中国塑料 ›› 2022, Vol. 36 ›› Issue (10): 138-148.DOI: 10.19491/j.issn.1001-9278.2022.10.020

张家乐1,2, 薄采颖1, 贝钰1,2, 沙野2, 贾普友1( ), 周永红1

), 周永红1

收稿日期:2022-05-09

出版日期:2022-10-26

发布日期:2022-10-27

通讯作者:

贾普友(1986—),副研究员,研究领域为生物基助剂和生物基高分子材料,jiapuyou@icifp.cn基金资助:

ZHANG Jiale1,2, BO Caiying1, BEI Yu1,2, SHA Ye2, JIA Puyou1( ), ZHOU Yonghong1

), ZHOU Yonghong1

Received:2022-05-09

Online:2022-10-26

Published:2022-10-27

Contact:

JIA Puyou

E-mail:jiapuyou@icifp.cn

摘要:

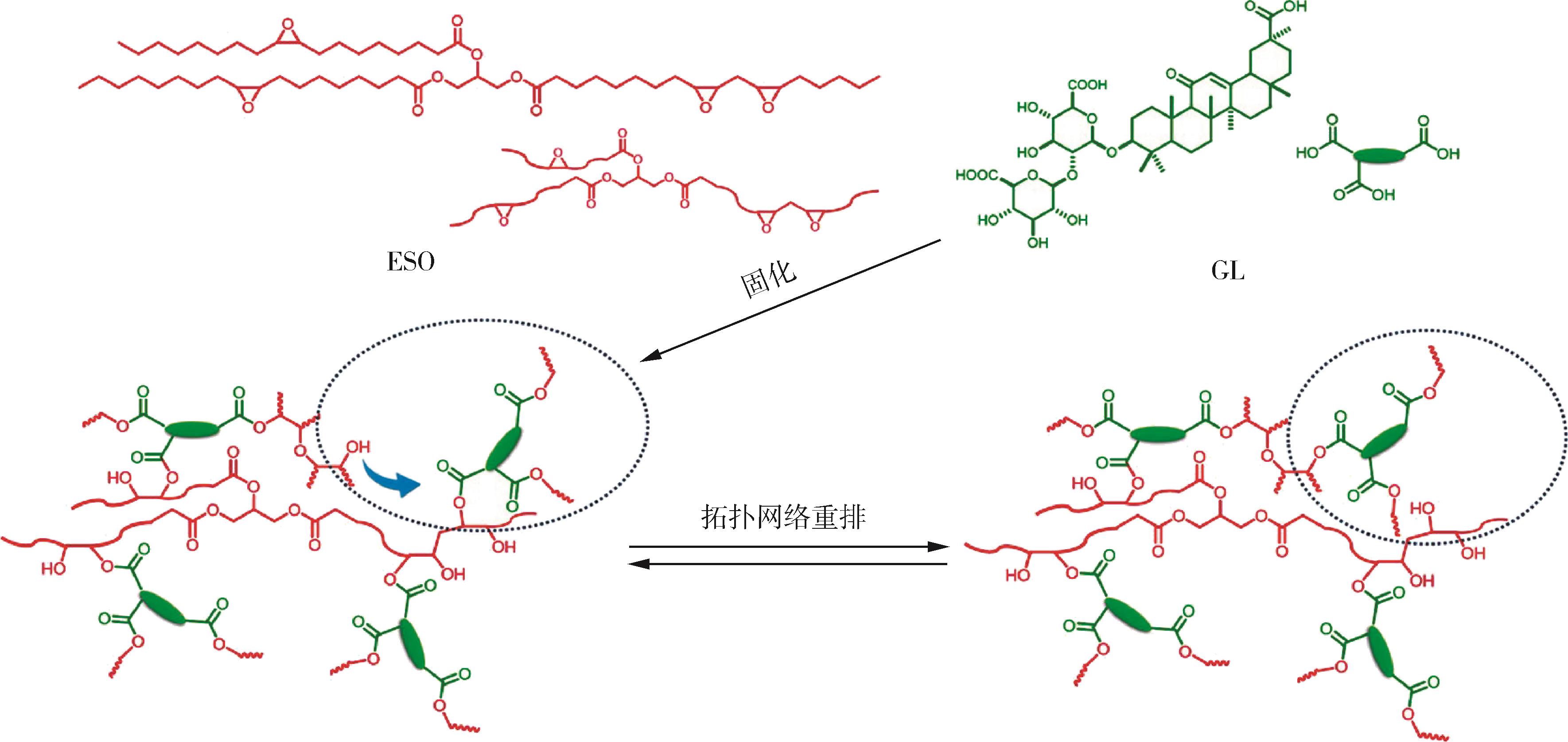

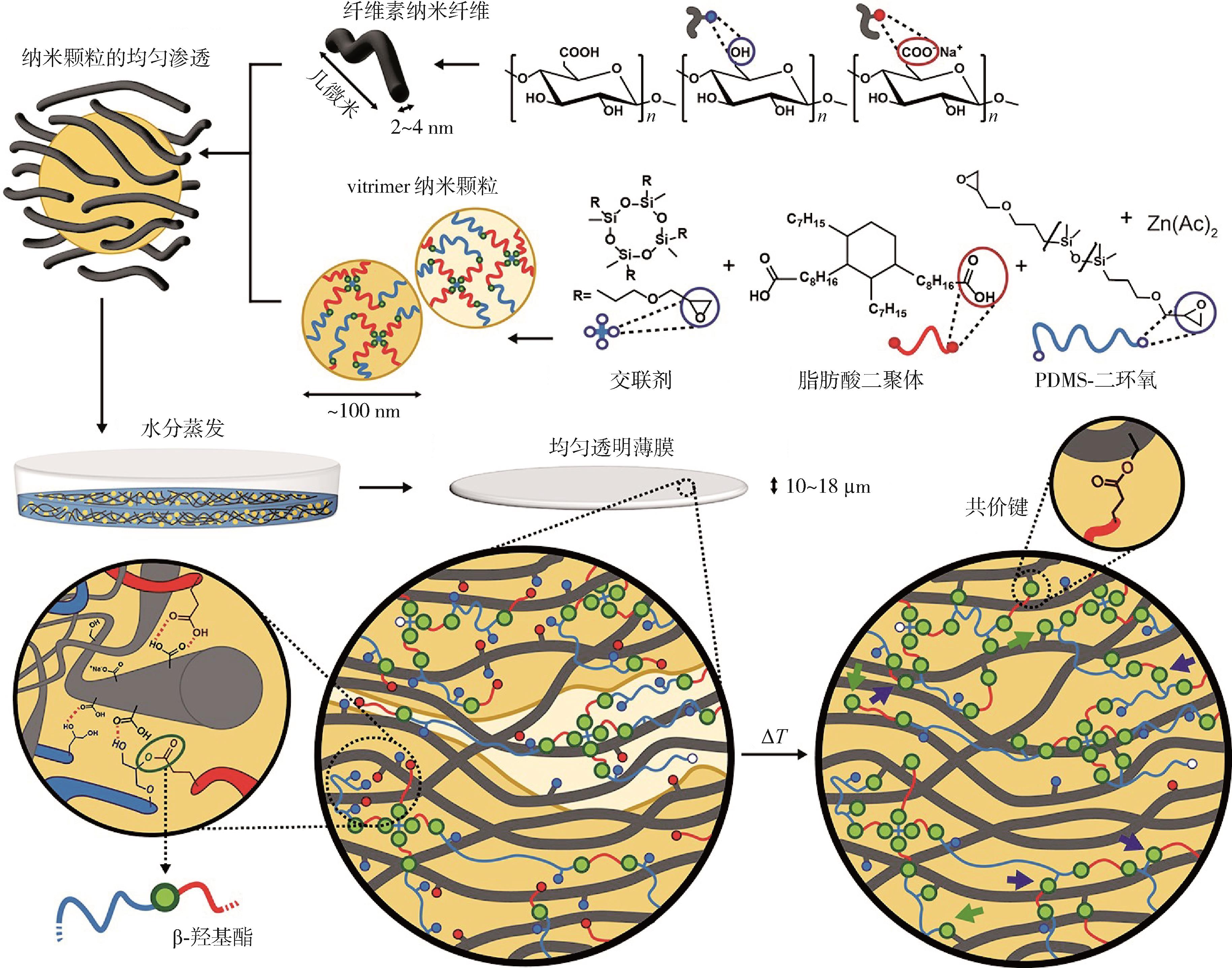

介绍了类玻璃高分子(vitrimer)材料的发展史、拓扑冻结转变温度,对基于酯交换、烷基转移和转氨基化的vitrimer动态机理和基于木质素、植物油、纤维素和香草醛的生物基vitrimer的研究进行了概述,并对生物基vitrimer材料进行了展望。

中图分类号:

张家乐, 薄采颖, 贝钰, 沙野, 贾普友, 周永红. 生物基vitrimer材料研究进展[J]. 中国塑料, 2022, 36(10): 138-148.

ZHANG Jiale, BO Caiying, BEI Yu, SHA Ye, JIA Puyou, ZHOU Yonghong. Research progress in bio⁃based vitrimer materials[J]. China Plastics, 2022, 36(10): 138-148.

| 1 | De Gennes P G, Gennes P G. Scaling concepts in polymer physics[M]. Cornell University Press, 1979:203⁃213. |

| 2 | Doi M, Edwards S F. The theory of polymer dynamics[M]. Oxford University Press, 1988:135⁃150. |

| 3 | Ferry J D. Viscoelastic properties of polymers[M]. John Wiley & Sons, 1980:361⁃396. |

| 4 | Biron M. Thermoplastics and thermoplastic composites: technical information for plastics users[M]. Elsevier, 2007:259⁃274. |

| 5 | Li H, Englund K. Recycling of carbon fiber⁃reinforced thermoplastic composite wastes from the aerospace industry[J]. Journal of Composite Materials, 2017, 51(9): 1 265⁃1 273. |

| 6 | Zheng N, Xu Y, Zhao Q, et al. Dynamic covalent polymer networks: a molecular platform for designing functions beyond chemical recycling and self⁃healing[J]. Chemical Reviews, 2021, 121(3): 1 716⁃1 745. |

| 7 | Kloxin C J, Scott T F, Adzima B J, et al. Covalent adaptable networks (CANs): a unique paradigm in cross⁃linked polymers[J]. Macromolecules, 2010, 43(6): 2 643⁃2 653. |

| 8 | Montarnal D, Capelot M, Tournilhac F, et al. Silica⁃like malleable materials from permanent organic networks[J]. Science, 2011, 334(6058): 965⁃968. |

| 9 | Denissen W, Winne J M, Du Prez F E. Vitrimers: permanent organic networks with glass⁃like fluidity[J]. Chemical Science, 2016, 7(1): 30⁃38. |

| 10 | Angell C A. Formation of glasses from liquids and biopolymers[J]. Science, 1995, 267(5206): 1924⁃1 935. |

| 11 | Zhang X. Reconfigurable,Easy Repairable and low⁃temperature resistant dynamic 3D polymer structures[J]. Acta Polymerica Sinica,2016(6):685⁃687. |

| 12 | Huang X, Liu H C, Fan Z, et al. Hyperbranched polymer toughened and reinforced self⁃healing epoxy vitrimer[J]. Acta Polymerica Sinica,2019,50(5):535⁃542. |

| 13 | Kloxin C J, Bowman C N. Covalent adaptable networks: smart, reconfigurable and responsive network systems[J]. Chemical Society Reviews, 2013, 42(17): 7 161⁃7 173. |

| 14 | Scheutz G M, Lessard J J, Sims M B, et al. Adaptable crosslinks in polymeric materials: resolving the intersection of thermoplastics and thermosets[J]. Journal of the American Chemical Society, 2019, 141(41): 16 181⁃16 196. |

| 15 | Denissen W, Winne J M, Du Prez F E. Vitrimers: permanent organic networks with glass⁃like fluidity[J]. Chemical Science, 2016, 7(1): 30⁃38. |

| 16 | Williams M L, Landel R F, Ferry J D. The temperature dependence of relaxation mechanisms in amorphous polymers and other glass⁃forming liquids[J]. Journal of the American Chemical society, 1955, 77(14): 3 701⁃3 707. |

| 17 | Ngai K L, Plazek D J. Relation of internal rotational isomerism barriers to the flow activation energy of entangled polymer melts in the high⁃temperature Arrhenius region[J]. Journal of Polymer Science: Polymer Physics Edition, 1985, 23(10): 2 159⁃2 180. |

| 18 | Kheirandish S, Stadlbauer M. Molecular stress function theory and analysis of branching structure in industrial polyolefins[J]. Journal of Thermal Analysis and Calorimetry, 2009, 98(3): 629⁃637. |

| 19 | Liu C Y H J, Keunings R B C. New linearized relation for the universal viscosity⁃temperature behavior of polymer melts[J]. Macromolecules, 2006, 39(25): 8 867⁃8 869. |

| 20 | Morris B A. The science and technology of flexible packaging: multilayer films from resin and process to end use[M]. William Andrew, 2016:382⁃403. |

| 21 | Brutman J P, Delgado P A, Hillmyer M A. Polylactide vitrimers[J]. ACS Macro letters, 2014, 3(7): 607⁃610. |

| 22 | Capelot M, Unterlass M M, Tournilhac F, et al. Catalytic control of the vitrimer glass transition[J]. ACS Macro Letters, 2012, 1(7): 789⁃792. |

| 23 | Zee N, Nicolaÿ R. Vitrimers: permanently crosslinked polymers with dynamic network topology[J]. Progress in Polymer Science, 2020:101233. |

| 24 | Denissen W, Droesbeke M, Nicolaÿ R, et al. Chemical control of the viscoelastic properties of vinylogous urethane vitrimers[J]. Nature Communications, 2017, 8(1): 1⁃7. |

| 25 | Self J L, Dolinski N D, Zayas M S, et al. Brønsted⁃acid⁃catalyzed exchange in polyester dynamic covalent networks[J]. ACS Macro Letters, 2018, 7(7): 817⁃821. |

| 26 | Fortman D J, Brutman J P, Cramer C J, et al. Mechanically activated, catalyst⁃free polyhydroxyurethane vitrimers[J]. Journal of the American Chemical Society, 2015, 137(44): 14 019⁃14 022. |

| 27 | Obadia M M, Jourdain A, Cassagnau P, et al. Tuning the viscosity profile of ionic vitrimers incorporating 1, 2, 3‐triazolium cross‐links[J]. Advanced Functional Materials, 2017, 27(45): 1703258. |

| 28 | Liu L W. Rreparation and properties of cellulose based vitrimer with dynamic ester bonds[D]. Dalian: Dalian University of Technology. |

| 29 | Chabert E, Vial J, Cauchois J P, et al. Multiple welding of long fiber epoxy vitrimer composites[J]. Soft Matter. 2016, 12(21): 4 838⁃4 845. |

| 30 | He C, Shi S, Wang D, et al. Poly (oxime–ester) vitrimers with catalyst⁃free bond exchange[J]. Journal of the American Chemical Society, 2019, 141(35): 13 753⁃13 757. |

| 31 | Zhang Z P, Rong M Z, Zhang M Q. Polymer engineering based on reversible covalent chemistry: A promising innovative pathway towards new materials and new functionalities[J]. Progress in Polymer Science, 2018, 80(5): 39⁃93. |

| 32 | Yang Y, Xu Y, Ji Y, et al. Functional epoxy vitrimers and composites[J]. Progress in Materials Science, 2021, 120(7): 100710. |

| 33 | Altuna F I, Hoppe C E, Williams R J J. Epoxy vitrimers with a covalently bonded tertiary amine as catalyst of the transesterification reaction[J]. European Polymer Journal, 2019, 113(4): 297⁃304. |

| 34 | Hiroaki U, Takayuki O, Ichiro S, et al. Naphthalene derivatives: EP, EP0763523 A1[P]. 1996. |

| 35 | Denissen W, Winne J M, Du Prez F E. Vitrimers: permanent organic networks with glass⁃like fluidity[J]. Chemical Science, 2016, 7(1): 30⁃38. |

| 36 | Spiesschaert Y, Guerre M, Imbernon L, et al. Filler reinforced polydimethylsiloxane⁃based vitrimers[J]. Polymer, 2019, 172(20): 239⁃246. |

| 37 | Hendriks B, Waelkens J, Winne J M, et al. Poly (thioether) vitrimers via transalkylation of trialkylsulfonium salts[J]. ACS Macro Letters, 2017, 6(9): 930⁃934. |

| 38 | Obadia M M, Mudraboyina B P, Serghei A, et al. Reprocessing and recycling of highly cross⁃linked ion⁃conducting networks through transalkylation exchanges of C–N bonds[J]. Journal of the American Chemical Society, 2015, 137(18): 6 078⁃6 083. |

| 39 | Laurichesse S, Avérous L. Chemical modification of lignins: towards biobased polymers[J]. Progress in Polymer Science, 2014, 39(7):1 266⁃1 290. |

| 40 | Duval A, Lawoko M. A review on lignin⁃based polymeric, micro⁃ and nano⁃structured materials[J]. Reactive & Functional Polymers, 2014, 85(12):78⁃96. |

| 41 | Upton B M, Kasko A M. Strategies for the conversion of lignin to high⁃value polymeric materials: review and perspective[J]. Chemical Reviews, 2016, 116(4): 2 275⁃2 306. |

| 42 | Duval A, Lange H, Lawoko M, et al. Reversible crosslinking of lignin via the furan–maleimide Diels–Alder Reaction[J]. Green Chemistry, 2015, 17(11): 4 991⁃5 000. |

| 43 | Hao C, Liu T, Zhang S, et al. A high⁃lignin⁃content, removable, and glycol⁃assisted repairable coating based on dynamic covalent bonds[J]. Chem Sus Chem, 2019, 12(5): 1 049⁃1 058. |

| 44 | Tang R, Xue B, Tan J, et al. Regulating lignin⁃based epoxy Vitrimer performance by fine⁃tuning the lignin structure[J]. 2022, 4 (2):1 117⁃1 125. |

| 45 | Xue B, Tang R, Xue D, et al. Sustainable alternative for bisphenol a epoxy resin high⁃performance and recyclable lignin⁃based epoxy vitrimers[J]. Industrial Crops and Products, 2021, 168:113583. |

| 46 | Liu W, Fang C, Chen F, et al. Strong, reusable, and self⁃healing lignin⁃containing polyurea adhesives[J]. Chem Sus Chem, 2020, 13(17): 4 691⁃4 701. |

| 47 | Shuai Z, Liu T, Cheng H, et al. Preparation of a lignin⁃based vitrimer material and its potential use for recoverable adhesives[J]. Green Chemistry, 2018, 20:10.1039. |

| 48 | Chao L A, Yc A, Yong Z A, et al. Strong and recyclable soybean oil⁃based epoxy adhesives based on dynamic borate⁃science direct[J]. European Polymer Journal, 2021, 162: 110923. |

| 49 | Zhao X L, Liu Y Y, Weng Y X, et al. Sustainable epoxy vitrimers from epoxidized soybean oil and vanillin[J]. ACS Sustainable Chemistry And Engineering, 2020, 8(39):15 020⁃15 029. |

| 50 | Yzxa B, Pan F D, Sld A, et al. Catalyst⁃free self⁃healing fully bio⁃based vitrimers derived from tung oil: Strong mechanical properties, shape memory, and recyclability⁃science direct[J]. Industrial Crops and Products, 2021,171: 113978. |

| 51 | Di Mauro C, Malburet S, Graillot A, et al. Recyclable, repairable, and reshapable (3R) Thermoset materials with shape memory properties from bio⁃based epoxidized vegetable oils[J]. ACS Applied Bio Materials, 2020, 3(11): 8 094⁃8 104. |

| 52 | Zhao W, Feng Z, Liang Z, et al. Vitrimer⁃cellulose paper composites: a new class of strong, smart, green, and sustainable materials[J]. ACS applied materials & interfaces, 2019, 11(39): 36 090⁃36 099. |

| 53 | Lossada F, Guo J, Jiao D, et al. Vitrimer chemistry meets cellulose nanofibrils: bioinspired nanopapers with high water resistance and strong adhesion[J]. Biomacromolecules, 2018, 20(2): 1 045⁃1 055. |

| 54 | Xu C, Zheng Z, Wu W, et al. Design of healable epoxy composite based on β⁃hydroxyl esters crosslinked networks by using carboxylated cellulose nanocrystals as crosslinker[J]. Composites Science and Technology, 2019, 181(8):107677.1⁃107677.9. |

| 55 | Lucherelli M A, Duval A, Avérous L. Biobased vitrimers: towards sustainable and adaptable performing polymer materials[J]. Progress in Polymer Science, 2022,127(4):101515. |

| 56 | Lossada F, Guo J, Jiao D, et al. Vitrimer chemistry meets cellulose nanofibrils: bioinspired nanopapers with high water resistance and strong adhesion[J]. Biomacromolecules, 2018, 20(2): 1 045⁃1 055. |

| 57 | Liu L W, Ju B Z. Preperation and property of vitrimer based on cellulose and transesterification[J/OL].New Chemical Materials:1⁃7[2022⁃0507]. . |

| 58 | Geng H, Wang Y, Yu Q, et al. Vanillin⁃based polyschiff Vitrimers: reprocessability and chemical recyclability[J]. ACS Sustainable Chemistry & Engineering, 2018, 6(11):15 463⁃15 470. |

| 59 | Memon H, Liu H, Rashid M A, et al. Vanillin⁃based epoxy Vitrimer with high performance and closed⁃loop recyclability[J]. Macromolecules, 2020, 53(2):621⁃630. |

| [1] | 徐云飞, 赵在胜, 邢雅静, 蒋晶. 聚乳酸/聚氨酯复合多孔材料制备及吸油性能研究[J]. 中国塑料, 2021, 35(11): 24-31. |

| [2] | 文泽伟, 刘福亚, 崔晓杰, 张葛, 孟伟华, 谢吉星, 徐建中. 机械力改性芦苇纤维及其对聚乳酸复合材料的阻燃性能研究[J]. 中国塑料, 2021, 35(11): 38-43. |

| [3] | 刘伟, 吴显, 张纯. 赤泥对聚乳酸热性能、力学性能和发泡行为的影响研究[J]. 中国塑料, 2021, 35(11): 49-54. |

| [4] | 唐于婧, 王亚桥, 倪敬越, 王从龙, 王向东. 立构复合晶对聚乳酸发泡行为的影响[J]. 中国塑料, 2021, 35(8): 117-124. |

| [5] | 刁晓倩, 翁云宣, 付烨, 周迎鑫. 生物降解塑料应用及性能评价方法综述[J]. 中国塑料, 2021, 35(8): 152-161. |

| [6] | 陈新启, 白云, 刘珊珊, 高峡, 刘伟丽, 张梅, 吴毓炜, 黄艳, 赵宏亮. 核磁法定量分析生物降解塑料中聚乳酸等组分[J]. 中国塑料, 2021, 35(8): 181-188. |

| [7] | 张博, 王小峰, 郭萌, 白志媛, 任翠红, 韩文娟, 宇山浩, 李倩. 聚乳酸表面羧基化改性及细胞相容性研究[J]. 中国塑料, 2021, 35(5): 17-23. |

| [8] | 吴悠, 王博华, 孙健健, 靳玉娟. 端环氧基型超支化聚合物对PPC/PBS共混物的改性研究[J]. 中国塑料, 2021, 35(4): 5-11. |

| [9] | 周红涛, 钱坤, 董硕. 平面三向织物增强橡胶复合材料撕裂性能研究[J]. 中国塑料, 2021, 35(1): 54-59. |

| [10] | 马巧云, 翁云宣, 张彩丽. 氯化铁催化醇解反应回收聚乳酸[J]. 中国塑料, 2020, 34(11): 73-80. |

| [11] | 王星然, 王明昊, 顿东星, 李善哲, 张雪冬, 周洪福. 聚合物/碳系填料发泡复合材料电磁屏蔽性能的研究进展[J]. 中国塑料, 2020, 34(10): 110-118. |

| [12] | 魏诗艺, 唐韵韬, 柴晨泽, 张玉霞, 周洪福. 聚乳酸开孔材料研究进展[J]. 中国塑料, 2020, 34(10): 100-109. |

| [13] | 祖钰, 任亚男, 胡晶. 聚乳酸/聚(3⁃羟基丁酸⁃co⁃3⁃羟基戊酸酯)共混材料3D打印线材改性研究[J]. 中国塑料, 2020, 34(7): 36-43. |

| [14] | 宋鑫宇, 翁云宣, 张彩丽, 黄志刚. 聚乳酸/竹粉复合材料的改性及性能研究[J]. 中国塑料, 2020, 34(7): 21-29. |

| [15] | 宋彦志, 祝志峰, 李世安. 辛烯基琥珀酸酯⁃羧甲基淀粉膜力学性能的研究[J]. 中国塑料, 2020, 34(4): 25-29. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2