京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2

《中国塑料》编辑部 ©2008-2024 版权所有

地址:北京市海淀区阜成路11号 邮编:100048

编辑部:010-68985541 联系信箱:cp@plaschina.com.cn

广告部/发行部:010-68985253 本系统由北京玛格泰克科技发展有限公司设计开发

中国塑料 ›› 2025, Vol. 39 ›› Issue (10): 60-68.DOI: 10.19491/j.issn.1001-9278.2025.10.011

苏羽航1,5( ), 卢修强1,5, 毛健全2, 尹望林3, 刘向4, 柯俊沐1,5, 林渊智1,5(

), 卢修强1,5, 毛健全2, 尹望林3, 刘向4, 柯俊沐1,5, 林渊智1,5( )

)

收稿日期:2025-03-17

出版日期:2025-10-26

发布日期:2025-10-21

通讯作者:

林渊智(1967—),教授级高级工程师,主要从事包装材料高性能化研究,963947786@qq.com作者简介:苏羽航(1984—),副教授,主要从事包装材料开发研究,443900336@qq.com

基金资助:

SU Yuhang1,5( ), LU Xiuqiang1,5, MAO Jianquan2, YIN Wanglin3, LIU Xiang4, KE Junmu1,5, LIN Yuanzhi1,5(

), LU Xiuqiang1,5, MAO Jianquan2, YIN Wanglin3, LIU Xiang4, KE Junmu1,5, LIN Yuanzhi1,5( )

)

Received:2025-03-17

Online:2025-10-26

Published:2025-10-21

Contact:

LIN Yuanzhi

E-mail:443900336@qq.com;963947786@qq.com

摘要:

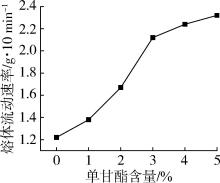

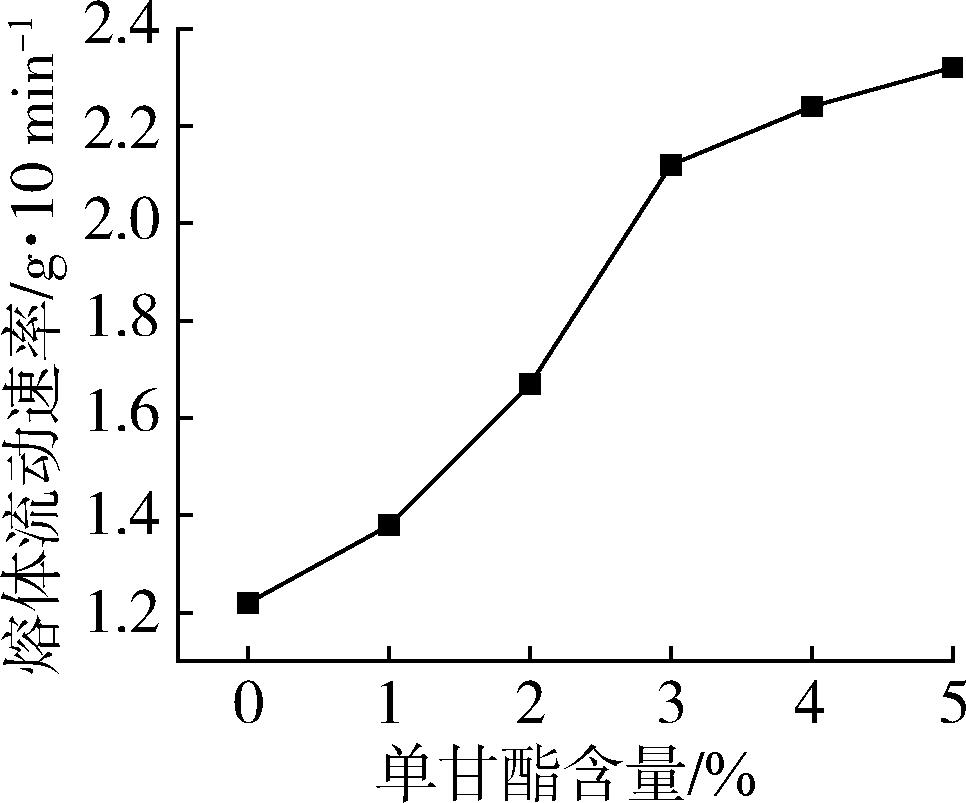

将丙烯酸乙酯接枝至甲壳素上,通过三层流延共挤制备聚丙烯/改性甲壳素厌氧生物降解薄膜。通过核磁共振、傅里叶变换红外、拉曼光谱、热失重分析、差示扫描量热、扫描电子显微镜、薄膜物理性能测试、堆肥厌氧降解实验等,对甲壳素接枝丙烯酸乙酯进行表征,对聚丙烯/改性甲壳素厌氧生物降解助剂的加工性能,薄膜的物理性能、降解性能进行测试。结果表明,丙烯酸乙酯成功接枝至甲壳素上,甲壳素的热分解温度提高至340 ℃。在3 %单甘酯的协调作用下,改性甲壳素含量为10 %的厌氧生物降解助剂的流动性、改性甲壳素在助剂中的分散性得到改善。在厌氧生物降解薄膜中,改性甲壳素含量≤1.5 %时,可以起到异相成核作用,聚丙烯结晶度提高,熔点提高,结晶速率加快。薄膜的纵向拉伸强度,在改性甲壳素含量为2 %时,达到12.8 MPa的最大值,而薄膜的断裂伸长率则不断下降,韧性降低,此时薄膜的透光率为87.6 %,雾度为4.6 %,薄膜的雾率低于双向拉伸聚丙烯(BOPP)国家标准的要求。将改性甲壳素含量为1.5 %的聚丙烯薄膜进行堆肥厌氧降解实验,聚丙烯薄膜的降解率随堆肥时间的增加而不断增加,到56天时,平均降解率达到9.19 %。

中图分类号:

苏羽航, 卢修强, 毛健全, 尹望林, 刘向, 柯俊沐, 林渊智. 聚丙烯/改性甲壳素厌氧型生物降解薄膜的制备[J]. 中国塑料, 2025, 39(10): 60-68.

SU Yuhang, LU Xiuqiang, MAO Jianquan, YIN Wanglin, LIU Xiang, KE Junmu, LIN Yuanzhi. Preparation and characterizations of polypropylene/ethyl acrylate⁃modified chitinanaerobic biodegradable films[J]. China Plastics, 2025, 39(10): 60-68.

| 聚丙烯含量/g | 改性甲壳素含量/g | 单硬酯酸甘油酯含量/g |

|---|---|---|

| 200 | 0 | 0 |

| 196 | 4 | 0 |

| 192 | 8 | 0 |

| 188 | 12 | 0 |

| 184 | 16 | 0 |

| 180 | 20 | 0 |

| 178 | 20 | 2 |

| 176 | 20 | 4 |

| 174 | 20 | 6 |

| 172 | 20 | 8 |

| 170 | 20 | 10 |

| 聚丙烯含量/g | 改性甲壳素含量/g | 单硬酯酸甘油酯含量/g |

|---|---|---|

| 200 | 0 | 0 |

| 196 | 4 | 0 |

| 192 | 8 | 0 |

| 188 | 12 | 0 |

| 184 | 16 | 0 |

| 180 | 20 | 0 |

| 178 | 20 | 2 |

| 176 | 20 | 4 |

| 174 | 20 | 6 |

| 172 | 20 | 8 |

| 170 | 20 | 10 |

| 项目 | 料筒1区 | 料筒2区 | 料筒3区 | 料筒4区 | 夹头区 | 换网区 | 过渡1区 | 转接体区 |

|---|---|---|---|---|---|---|---|---|

| 模头温区 | 210 | 210 | 210 | 210 | 210 | 210 | 210 | 210 |

| A机 | 210 | 215 | 220 | — | 220 | 220 | 220 | — |

| B机 | 210 | 215 | 220 | — | 220 | 220 | 220 | — |

| C机 | 210 | 215 | 220 | 220 | 220 | 220 | 220 | 220 |

| 项目 | 分配器上 | 分配器下 | 模头1区 | 模头2区 | 模头3区 | 左侧板 | 右侧板 | 模唇 |

| 项目 | 料筒1区 | 料筒2区 | 料筒3区 | 料筒4区 | 夹头区 | 换网区 | 过渡1区 | 转接体区 |

|---|---|---|---|---|---|---|---|---|

| 模头温区 | 210 | 210 | 210 | 210 | 210 | 210 | 210 | 210 |

| A机 | 210 | 215 | 220 | — | 220 | 220 | 220 | — |

| B机 | 210 | 215 | 220 | — | 220 | 220 | 220 | — |

| C机 | 210 | 215 | 220 | 220 | 220 | 220 | 220 | 220 |

| 项目 | 分配器上 | 分配器下 | 模头1区 | 模头2区 | 模头3区 | 左侧板 | 右侧板 | 模唇 |

| 测试项目 | 接种物 (堆肥) | 阳性控制 (微晶纤维素) | 聚丙烯降解膜 |

|---|---|---|---|

| pH值 | 8.04 | — | — |

| 水分含量/% | 66.3 | 4.5 | 0.5 |

| 总干固体含量/% | 33.7 | 95.5 | 99.5 |

| 挥发性固体含量/% | 42.9 | 100 | 100 |

| 总有机碳含量/% | 15.84 | 44.49 | 81.69 |

| 挥发性脂肪酸(g/kg湿重物) | 0.68 | — | — |

| 氨氮(g/kg湿重物) | 0.02 | — | — |

| 测试项目 | 接种物 (堆肥) | 阳性控制 (微晶纤维素) | 聚丙烯降解膜 |

|---|---|---|---|

| pH值 | 8.04 | — | — |

| 水分含量/% | 66.3 | 4.5 | 0.5 |

| 总干固体含量/% | 33.7 | 95.5 | 99.5 |

| 挥发性固体含量/% | 42.9 | 100 | 100 |

| 总有机碳含量/% | 15.84 | 44.49 | 81.69 |

| 挥发性脂肪酸(g/kg湿重物) | 0.68 | — | — |

| 氨氮(g/kg湿重物) | 0.02 | — | — |

| 测试项目 | 接种物 | 阳性控制(微晶纤维素) | 聚丙烯降解膜 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 反应瓶1 | 反应瓶2 | 反应瓶3 | 反应瓶4 | 反应瓶5 | 反应瓶6 | 反应瓶7 | 反应瓶8 | 反应瓶9 | |

| 接种物实际加入量(湿度)/g | 1 000.03 | 1 000.02 | 1 000.04 | 1 000.04 | 999.79 | 999.98 | 1 000.03 | 999.97 | 1 000.03 |

| 接种物总干固体含量/g | 336.77 | 336.77 | 336.78 | 336.78 | 336.75 | 336.76 | 336.77 | 336.75 | 336.77 |

| 接种物挥发性固体含量/g | 191.63 | 191.64 | 191.64 | 191.64 | 191.63 | 191.64 | 191.63 | 191.64 | 191.63 |

| 待测样品实际加入量/g | — | — | — | 15.75 | 15.75 | 15.72 | 15.23 | 15.22 | 15.28 |

| 试验材料加入的初始碳含量/g | — | — | — | 6.7 | 6.7 | 6.7 | 12.4 | 12.4 | 12.4 |

| 测试项目 | 接种物 | 阳性控制(微晶纤维素) | 聚丙烯降解膜 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 反应瓶1 | 反应瓶2 | 反应瓶3 | 反应瓶4 | 反应瓶5 | 反应瓶6 | 反应瓶7 | 反应瓶8 | 反应瓶9 | |

| 接种物实际加入量(湿度)/g | 1 000.03 | 1 000.02 | 1 000.04 | 1 000.04 | 999.79 | 999.98 | 1 000.03 | 999.97 | 1 000.03 |

| 接种物总干固体含量/g | 336.77 | 336.77 | 336.78 | 336.78 | 336.75 | 336.76 | 336.77 | 336.75 | 336.77 |

| 接种物挥发性固体含量/g | 191.63 | 191.64 | 191.64 | 191.64 | 191.63 | 191.64 | 191.63 | 191.64 | 191.63 |

| 待测样品实际加入量/g | — | — | — | 15.75 | 15.75 | 15.72 | 15.23 | 15.22 | 15.28 |

| 试验材料加入的初始碳含量/g | — | — | — | 6.7 | 6.7 | 6.7 | 12.4 | 12.4 | 12.4 |

| 改性甲壳素含量/% | 聚丙烯 含量/% | 熔融温度/ ℃ | 结晶温度/ ℃ | 熔融焓/ J·g-1 | 结晶度/ % |

|---|---|---|---|---|---|

| 0 | 100 | 175.6 | 96.4 | 102.8 | 49.2 |

| 0.5 | 99.335 | 175.8 | 97.5 | 105.1 | 50.6 |

| 1 | 98.67 | 176.7 | 98.1 | 108.3 | 52.5 |

| 1.5 | 98.005 | 177.3 | 98.6 | 109.9 | 53.6 |

| 2 | 97.34 | 175.2 | 95.2 | 102.0 | 50.1 |

| 2.5 | 96.675 | 174.8 | 94.8 | 99.1 | 49.0 |

| 改性甲壳素含量/% | 聚丙烯 含量/% | 熔融温度/ ℃ | 结晶温度/ ℃ | 熔融焓/ J·g-1 | 结晶度/ % |

|---|---|---|---|---|---|

| 0 | 100 | 175.6 | 96.4 | 102.8 | 49.2 |

| 0.5 | 99.335 | 175.8 | 97.5 | 105.1 | 50.6 |

| 1 | 98.67 | 176.7 | 98.1 | 108.3 | 52.5 |

| 1.5 | 98.005 | 177.3 | 98.6 | 109.9 | 53.6 |

| 2 | 97.34 | 175.2 | 95.2 | 102.0 | 50.1 |

| 2.5 | 96.675 | 174.8 | 94.8 | 99.1 | 49.0 |

| 天数/天 | 各反应容器实际产生释放的气态碳体积/mL | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 空白对照 | 阳性参比物 | 聚丙烯降解膜 | ||||||||||

| 反应瓶1 | 反应瓶2 | 反应瓶3 | 平均值 | 反应瓶4 | 反应瓶5 | 反应瓶6 | 平均值 | 反应瓶7 | 反应瓶8 | 反应瓶9 | 平均值 | |

| 3 | 631 | 591 | 562 | 595 | 5 360 | 5 044 | 5 203 | 5 202 | 640 | 700 | 720 | 687 |

| 6 | 731 | 735 | 702 | 723 | 2 797 | 2 798 | 2 979 | 2 858 | 1 145 | 1 174 | 1 198 | 1 172 |

| 10 | 693 | 788 | 792 | 758 | 3 640 | 3 831 | 3 625 | 3 699 | 1 189 | 1 228 | 1 160 | 1 192 |

| 15 | 664 | 652 | 511 | 609 | 1 830 | 2 071 | 1 867 | 1 923 | 771 | 852 | 902 | 842 |

| 19 | 310 | 380 | 467 | 386 | 678 | 660 | 580 | 639 | 673 | 499 | 518 | 563 |

| 24 | 450 | 330 | 428 | 403 | 559 | 535 | 509 | 534 | 522 | 495 | 461 | 493 |

| 29 | 258 | 228 | 345 | 277 | 368 | 410 | 351 | 376 | 395 | 367 | 331 | 364 |

| 35 | 251 | 245 | 330 | 275 | 398 | 335 | 251 | 328 | 420 | 385 | 341 | 382 |

| 45 | 360 | 320 | 390 | 357 | 498 | 468 | 409 | 458 | 468 | 490 | 532 | 497 |

| 56 | 152 | 180 | 250 | 194 | 410 | 280 | 279 | 323 | 490 | 493 | 523 | 502 |

| 天数/天 | 各反应容器实际产生释放的气态碳体积/mL | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 空白对照 | 阳性参比物 | 聚丙烯降解膜 | ||||||||||

| 反应瓶1 | 反应瓶2 | 反应瓶3 | 平均值 | 反应瓶4 | 反应瓶5 | 反应瓶6 | 平均值 | 反应瓶7 | 反应瓶8 | 反应瓶9 | 平均值 | |

| 3 | 631 | 591 | 562 | 595 | 5 360 | 5 044 | 5 203 | 5 202 | 640 | 700 | 720 | 687 |

| 6 | 731 | 735 | 702 | 723 | 2 797 | 2 798 | 2 979 | 2 858 | 1 145 | 1 174 | 1 198 | 1 172 |

| 10 | 693 | 788 | 792 | 758 | 3 640 | 3 831 | 3 625 | 3 699 | 1 189 | 1 228 | 1 160 | 1 192 |

| 15 | 664 | 652 | 511 | 609 | 1 830 | 2 071 | 1 867 | 1 923 | 771 | 852 | 902 | 842 |

| 19 | 310 | 380 | 467 | 386 | 678 | 660 | 580 | 639 | 673 | 499 | 518 | 563 |

| 24 | 450 | 330 | 428 | 403 | 559 | 535 | 509 | 534 | 522 | 495 | 461 | 493 |

| 29 | 258 | 228 | 345 | 277 | 368 | 410 | 351 | 376 | 395 | 367 | 331 | 364 |

| 35 | 251 | 245 | 330 | 275 | 398 | 335 | 251 | 328 | 420 | 385 | 341 | 382 |

| 45 | 360 | 320 | 390 | 357 | 498 | 468 | 409 | 458 | 468 | 490 | 532 | 497 |

| 56 | 152 | 180 | 250 | 194 | 410 | 280 | 279 | 323 | 490 | 493 | 523 | 502 |

| 天数/天 | 累计气态碳产生量/g | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 空白对照 | 阳性参比物 | 聚丙烯降解膜 | ||||||||||

| 反应瓶1 | 反应瓶2 | 反应瓶3 | 平均值 | 反应瓶4 | 反应瓶5 | 反应瓶6 | 平均值 | 反应瓶7 | 反应瓶8 | 反应瓶9 | 平均值 | |

| 3 | 3 | 0.34 | 0.32 | 0.30 | 0.32 | 2.87 | 2.70 | 2.79 | 2.79 | 0.34 | 0.38 | 0.39 |

| 6 | 6 | 0.73 | 0.71 | 0.68 | 0.71 | 4.37 | 4.20 | 4.39 | 4.32 | 0.95 | 1.01 | 1.03 |

| 10 | 10 | 1.10 | 1.13 | 1.10 | 1.11 | 6.32 | 6.25 | 6.33 | 6.30 | 1.59 | 1.67 | 1.65 |

| 15 | 15 | 1.46 | 1.48 | 1.37 | 1.44 | 7.30 | 7.36 | 7.33 | 7.33 | 2.00 | 2.13 | 2.13 |

| 19 | 19 | 1.63 | 1.68 | 1.62 | 1.64 | 7.66 | 7.71 | 7.64 | 7.67 | 2.36 | 2.40 | 2.41 |

| 24 | 24 | 1.87 | 1.86 | 1.85 | 1.86 | 7.96 | 8.00 | 7.91 | 7.96 | 2.64 | 2.67 | 2.66 |

| 29 | 29 | 2.01 | 1.98 | 2.03 | 2.00 | 8.16 | 8.22 | 8.10 | 8.16 | 2.85 | 2.87 | 2.84 |

| 35 | 35 | 2.14 | 2.11 | 2.21 | 2.15 | 8.37 | 8.40 | 8.23 | 8.33 | 3.08 | 3.08 | 3.02 |

| 45 | 45 | 2.33 | 2.28 | 2.42 | 2.34 | 8.64 | 8.65 | 8.45 | 8.58 | 3.33 | 3.34 | 3.31 |

| 56 | 56 | 2.41 | 2.38 | 2.55 | 2.45 | 8.86 | 8.80 | 8.60 | 8.75 | 3.59 | 3.60 | 3.59 |

| 天数/天 | 累计气态碳产生量/g | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 空白对照 | 阳性参比物 | 聚丙烯降解膜 | ||||||||||

| 反应瓶1 | 反应瓶2 | 反应瓶3 | 平均值 | 反应瓶4 | 反应瓶5 | 反应瓶6 | 平均值 | 反应瓶7 | 反应瓶8 | 反应瓶9 | 平均值 | |

| 3 | 3 | 0.34 | 0.32 | 0.30 | 0.32 | 2.87 | 2.70 | 2.79 | 2.79 | 0.34 | 0.38 | 0.39 |

| 6 | 6 | 0.73 | 0.71 | 0.68 | 0.71 | 4.37 | 4.20 | 4.39 | 4.32 | 0.95 | 1.01 | 1.03 |

| 10 | 10 | 1.10 | 1.13 | 1.10 | 1.11 | 6.32 | 6.25 | 6.33 | 6.30 | 1.59 | 1.67 | 1.65 |

| 15 | 15 | 1.46 | 1.48 | 1.37 | 1.44 | 7.30 | 7.36 | 7.33 | 7.33 | 2.00 | 2.13 | 2.13 |

| 19 | 19 | 1.63 | 1.68 | 1.62 | 1.64 | 7.66 | 7.71 | 7.64 | 7.67 | 2.36 | 2.40 | 2.41 |

| 24 | 24 | 1.87 | 1.86 | 1.85 | 1.86 | 7.96 | 8.00 | 7.91 | 7.96 | 2.64 | 2.67 | 2.66 |

| 29 | 29 | 2.01 | 1.98 | 2.03 | 2.00 | 8.16 | 8.22 | 8.10 | 8.16 | 2.85 | 2.87 | 2.84 |

| 35 | 35 | 2.14 | 2.11 | 2.21 | 2.15 | 8.37 | 8.40 | 8.23 | 8.33 | 3.08 | 3.08 | 3.02 |

| 45 | 45 | 2.33 | 2.28 | 2.42 | 2.34 | 8.64 | 8.65 | 8.45 | 8.58 | 3.33 | 3.34 | 3.31 |

| 56 | 56 | 2.41 | 2.38 | 2.55 | 2.45 | 8.86 | 8.80 | 8.60 | 8.75 | 3.59 | 3.60 | 3.59 |

| 天数/天 | 生物分解百分率/% | |||||||

|---|---|---|---|---|---|---|---|---|

| 阳性参比物 | 聚丙烯降解膜 | |||||||

| 反应瓶4 | 反应瓶5 | 反应瓶6 | 平均值 | 反应瓶7 | 反应瓶8 | 反应瓶9 | 平均值 | |

| 3 | 37.76 | 35.52 | 37.16 | 36.87 | 0.00 | 0.48 | 0.73 | 0.40 |

| 6 | 54.33 | 52.09 | 55.37 | 53.88 | 1.77 | 2.42 | 2.82 | 2.34 |

| 10 | 77.91 | 76.42 | 78.06 | 77.46 | 3.95 | 4.35 | 4.44 | 4.27 |

| 15 | 87.16 | 87.76 | 88.96 | 87.91 | 4.35 | 5.24 | 6.13 | 5.24 |

| 19 | 90.00 | 90.00 | 89.85 | 90.00 | 5.89 | 5.81 | 6.37 | 6.05 |

| 24 | 90.90 | 91.64 | 90.45 | 91.04 | 6.21 | 6.53 | 6.53 | 6.45 |

| 29 | 91.79 | 93.13 | 90.60 | 91.94 | 6.77 | 7.18 | 6.53 | 6.85 |

| 35 | 92.99 | 93.88 | 89.85 | 92.24 | 7.58 | 7.82 | 6.53 | 7.34 |

| 45 | 94.18 | 95.07 | 90.00 | 93.13 | 8.06 | 8.55 | 7.18 | 7.98 |

| 56 | 96.27 | 95.82 | 90.30 | 94.03 | 9.52 | 9.84 | 8.39 | 9.19 |

| 天数/天 | 生物分解百分率/% | |||||||

|---|---|---|---|---|---|---|---|---|

| 阳性参比物 | 聚丙烯降解膜 | |||||||

| 反应瓶4 | 反应瓶5 | 反应瓶6 | 平均值 | 反应瓶7 | 反应瓶8 | 反应瓶9 | 平均值 | |

| 3 | 37.76 | 35.52 | 37.16 | 36.87 | 0.00 | 0.48 | 0.73 | 0.40 |

| 6 | 54.33 | 52.09 | 55.37 | 53.88 | 1.77 | 2.42 | 2.82 | 2.34 |

| 10 | 77.91 | 76.42 | 78.06 | 77.46 | 3.95 | 4.35 | 4.44 | 4.27 |

| 15 | 87.16 | 87.76 | 88.96 | 87.91 | 4.35 | 5.24 | 6.13 | 5.24 |

| 19 | 90.00 | 90.00 | 89.85 | 90.00 | 5.89 | 5.81 | 6.37 | 6.05 |

| 24 | 90.90 | 91.64 | 90.45 | 91.04 | 6.21 | 6.53 | 6.53 | 6.45 |

| 29 | 91.79 | 93.13 | 90.60 | 91.94 | 6.77 | 7.18 | 6.53 | 6.85 |

| 35 | 92.99 | 93.88 | 89.85 | 92.24 | 7.58 | 7.82 | 6.53 | 7.34 |

| 45 | 94.18 | 95.07 | 90.00 | 93.13 | 8.06 | 8.55 | 7.18 | 7.98 |

| 56 | 96.27 | 95.82 | 90.30 | 94.03 | 9.52 | 9.84 | 8.39 | 9.19 |

| [1] | 卢洪超,徐 萌,权 慧,等. 双向拉伸过程中聚丙烯薄膜结构与性能的演变[J]. 塑料工业,2023,51(9): 82⁃87. |

| LU H C, XU M, QUAN H, et al. Evolution of polypropylene film structure and properties during biaxial stretching[J]. China Plastics Industry, 2023, 51(9): 82⁃87. | |

| [2] | 胡延庆,胡 凡,周剑池,等. 废弃塑料回收与转化的研究进展[J]. 中国塑料,2024,38(4): 79⁃87. |

| HU Y C, HU F, ZHOU J C, et al. Research progress in upcycling of waste plastics[J]. China Plastics, 2024, 38(4): 79⁃87. | |

| [3] | 许 振,高 通,刘雪琪,等. 废弃塑料的升级回收利用:策略、现状与前景[J/OL]. 科学通报:2 862⁃2 877. |

| XU Z, GAO T, LIU X Q, et al. Upcycling of waste plastics: strategies, status⁃quo, and prospects. [J/OL]. Chinese Science Bulletin:2 862⁃2 877. | |

| [4] | 韦丽明. 全球落实2030可持续发展议程举措及塑料薄膜/片及未来包装产业可持续发展的趋势研究[J]. 塑料包装,2022,32(3): 1⁃10. |

| WEI L M. Research on measures for the implementation of 2030 agenda for sustainable development in global countries and sustainable development trend of plastic film and packaging industry[J]. Plastic Packaging, 2022, 32(3): 1⁃10. | |

| [5] | 文麒霖,贾雪华,孙炎君,等. 生物可降解塑料包装薄膜的制备及应用进展[J]. 中国塑料,2024,38(9): 112⁃ 122. |

| WEN Q L, JIA X H, SUN Y J, et al. Research progress in preparation and applications of biodegradable plastic packaging films[J]. China Plastics, 2024, 38(9): 112⁃122. | |

| [6] | 王正祥. 我国聚乳酸产业发展现状与对策研究[J]. 中国工程科学,2021,23(6): 155⁃166. |

| WANG Z X. China’s polylactic acid industry: current status and development strategies[J]. Strategic Study of CAE, 2021,23(6): 155⁃166. | |

| [7] | PAKALAPATI H, CHANG C K, SHOW P L, et al. Development of polyhydroxyalkanoates production from waste feedstocks and applications[J]. Journal of Bioscience and Bioengineering, 2018, 126(3): 282⁃292. |

| [8] | 李冬娜,马晓军. 聚羟基烷酸酯降解包装材料的生物合成及进展[J]. 包装工程,2020,41(5): 128⁃136. |

| LI D N, MA X J. Biosynthesis and progress of polyhydroxyalkanoates degradable packaging materials[J]. Packaging Engineering, 2020, 41(5): 128⁃136. | |

| [9] | ROOHI, ZAHEER MR, KUDDUS M. PHB (poly⁃β⁃hydroxybutyrate) and its enzymatic degradation[J]. Polymers for Advanced Technologies, 2018, 29(1): 30⁃40. |

| [10] | AKHLAQ S, SINGH D, MITTAL N, et al. Polyhydroxybutyrate biosynthesis from different waste materials,degradation,and analytic methods: a short review[J]. Polymer Bulletin, 2022, 5(5): 1⁃33. |

| [11] | 杨 帆,吴 宏,马双翼. PBAT及其改性复合材料的研究进展与应用[J]. 广东化工,2024,51(21): 17⁃19. |

| YANG F, WU H, MA S Y. Recent research progress and application of PBAT and its modified composites[J]. Guangdong Chemical Industry, 2024, 51(21):17⁃19. | |

| [12] | AN H W, WANG Y, JIA S L, et al. Biodegradable poly (butylene adipate⁃co⁃terephthalate)/poly (glycolic acid) films: Effect of poly (glycolic acid) crystal on mechanical and barrier properties[J]. Chinese Journal of Polymer Science, 2023, 41(7): 1 123⁃1 132. |

| [13] | 朱 建,陈 慧,卢 凯,等. 淀粉基生物可降解材料的研究新进展[J]. 高分子学报,2020,51(9):983⁃995. |

| ZHU J, CHEN H, LU K, et al. Recent progress on starch⁃based biodegradable materials[J]. Acta Polymerica Sinica, 2020, 51(9): 983⁃995. | |

| [14] | 王子璇,谢 晶,薛 斌,等. 壳聚糖食品包装膜研究进展[J]. 食品工业科技,2019,40(6): 303⁃307,311. |

| WANG Z X, XIE J, XUE B, et al. Research progress of chitosan food packaging film[J]. Science and Technology of Food Industry, 2019, 40(6): 303⁃307,311. | |

| [15] | 王 笑,刘 哈,王月莹. 可再生高强度纤维素基包装材料制备及其智能化应用[J]. 中国造纸,2024,43(7): 149⁃158. |

| WANG X, LIU H, WANG Y Y. Preparation and intelligent application of renewable high strength cellulose⁃based packaging material[J]. China Pulp & Paper, 2024, 43(7): 149⁃158. | |

| [16] | 蒋凤华,谢林青,孙承君,等. 常见塑料薄膜制品在UV作用下的性能变化特征[J]. 科学通报,2021,66(13): 1 571⁃1 579. |

| JIANG F H, XIE L Q, SUN C J, et al. The characteristic change of plastic film from common used packing bags under UV photodegradation[J]. Chinese Science Bulletin, 2021, 66(13): 1 571⁃1 579. | |

| [17] | 徐春梅,井丽敏,张 斌,等. 热塑性淀粉基薄膜研究进展[J]. 功能材料,2024,55(2): 115⁃123. |

| XU C M, JIN L M, ZHANG B, et al. Advances in thermoplastic starch⁃based films[J]. Functional materials, 2024, 55(2): 115⁃123. | |

| [18] | 石 洁,王雪嵘,徐朝阳. 食品包装用壳聚糖薄膜的研究进展[J]. 包装工程,2022,43(3): 42⁃50. |

| SHI J, WANG X R, XU C Y. Research progress of chitosan films for food packaging[J]. Packaging Engineering, 2022, 43(3): 42⁃50. | |

| [19] | 周 忆,杨皓月,邢荣娥,等. 利用微生物法两步发酵从虾壳中提取甲壳素的绿色制备工艺研究[J]. 海洋科学. 2024,48(9): 94⁃102. |

| ZHOU Y, YANG H Y, XIN R E, et al. Green preparation of chitin from shrimp shells by two⁃step fermentation using microbiological method[J]. Marine Sciences, 2024, 48(9): 94⁃102. | |

| [20] | 付 宁,杨俊玲,倪 磊. 壳聚糖制备条件的研究和结构表征[J]. 天津工业大学学报,2009,28(2): 63⁃66. |

| FU N, YANG J L, NI L. Research of preparation conditions and structure characterization of chitosan[J]. Journal of Tianjin Polytechnic University, 2009, 28(2): 63⁃66. | |

| [21] | HSU S T, LIN W C, HSIAO W F, et al. Preparation of methacrylic acid‐grafted chitin using cerium (IV) ion and its application in adsorbing paraquat[J]. Journal of Applied Polymer Science, 2012, 127(1): 760⁃764. |

| [22] | Committee D20.D5511⁃18 standard test method for determining anaerobic biodegradation of plastic materials under high⁃solids anaerobic⁃digestion conditions [S]. West Conshohocken, United States: ASTM International, 2018. |

| [23] | FENG M, LU X M, HOU D F, et al. Solubility, chain characterization, and derivatives of chitin[M]. Handbook of Chitin and Chitosan. Netherlands: Elsevier Inc, 2020:101⁃129. |

| [24] | 殷晶莉,杨占红. 单甘酯的合成及在塑料工业中的应用[J]. 塑料助剂,2012,6: 11⁃15. |

| YIN J L, YANG Z H. Synthesis of glycerin monostearate and its application in plastic industry[J]. Plastic Additives, 2012, 6: 11⁃15. | |

| [25] | 刘荣炽,张广强,方大观,等. 普通用途双向拉伸聚丙烯(BOPP)薄膜 [S].北京:中国国家标准化管理委员会,2008. |

| [1] | 姜自印, 龚昌景, 姚臻, 曹堃. 反应挤出法制备含氟改性聚丙烯[J]. 中国塑料, 2019, 33(9): 1-7. |

| [2] | 杨斯乔, 李海朝. 温度对甲壳素/明胶复合膜的影响[J]. 中国塑料, 2019, 33(10): 28-34. |

| [3] | 刘运学, 唐元亮, 李兰葛大利牛晚扬. 废弃聚苯乙烯颗粒接枝改性制备防水涂料的研究[J]. 中国塑料, 2015, 29(04): 102-106 . |

| [4] | 唐二军. PMMA接枝纳米ZnO复合粒子改性PVC塑料性能研究[J]. 中国塑料, 2008, 22(11): 78-81 . |

| [5] | 孙晓巍, 台立民. 淀粉/PS-g-MAH共混体系相容性及降解性能的研究[J]. 中国塑料, 2008, 22(10): 38-41. |

| [6] | 尹汉成, 宋健, 石振民, 杨福金, 张敏. BOPP薄膜生产线蒸汽梯级利用的研究[J]. 中国塑料, 2007, 21(7): 83-87. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2