京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2

《中国塑料》编辑部 ©2008-2024 版权所有

地址:北京市海淀区阜成路11号 邮编:100048

编辑部:010-68985541 联系信箱:cp@plaschina.com.cn

广告部/发行部:010-68985253 本系统由北京玛格泰克科技发展有限公司设计开发

中国塑料 ›› 2022, Vol. 36 ›› Issue (9): 148-159.DOI: 10.19491/j.issn.1001-9278.2022.09.020

李岩1,2,3( ), 唐晓旭1,2,3, 张伟杰1,2,3, 黄瑞鹏1,2,3, 张杉1,2,3

), 唐晓旭1,2,3, 张伟杰1,2,3, 黄瑞鹏1,2,3, 张杉1,2,3

收稿日期:2022-05-19

出版日期:2022-09-26

发布日期:2022-09-26

作者简介:李岩(1992—),女,中级工程师,从事建筑材料研究,2544713316@qq.com

基金资助:

LI Yan1,2,3( ), TANG Xiaoxu1,2,3, ZHANG Weijie1,2,3, HUANG Ruipeng1,2,3, ZHANG Shan1,2,3

), TANG Xiaoxu1,2,3, ZHANG Weijie1,2,3, HUANG Ruipeng1,2,3, ZHANG Shan1,2,3

Received:2022-05-19

Online:2022-09-26

Published:2022-09-26

摘要:

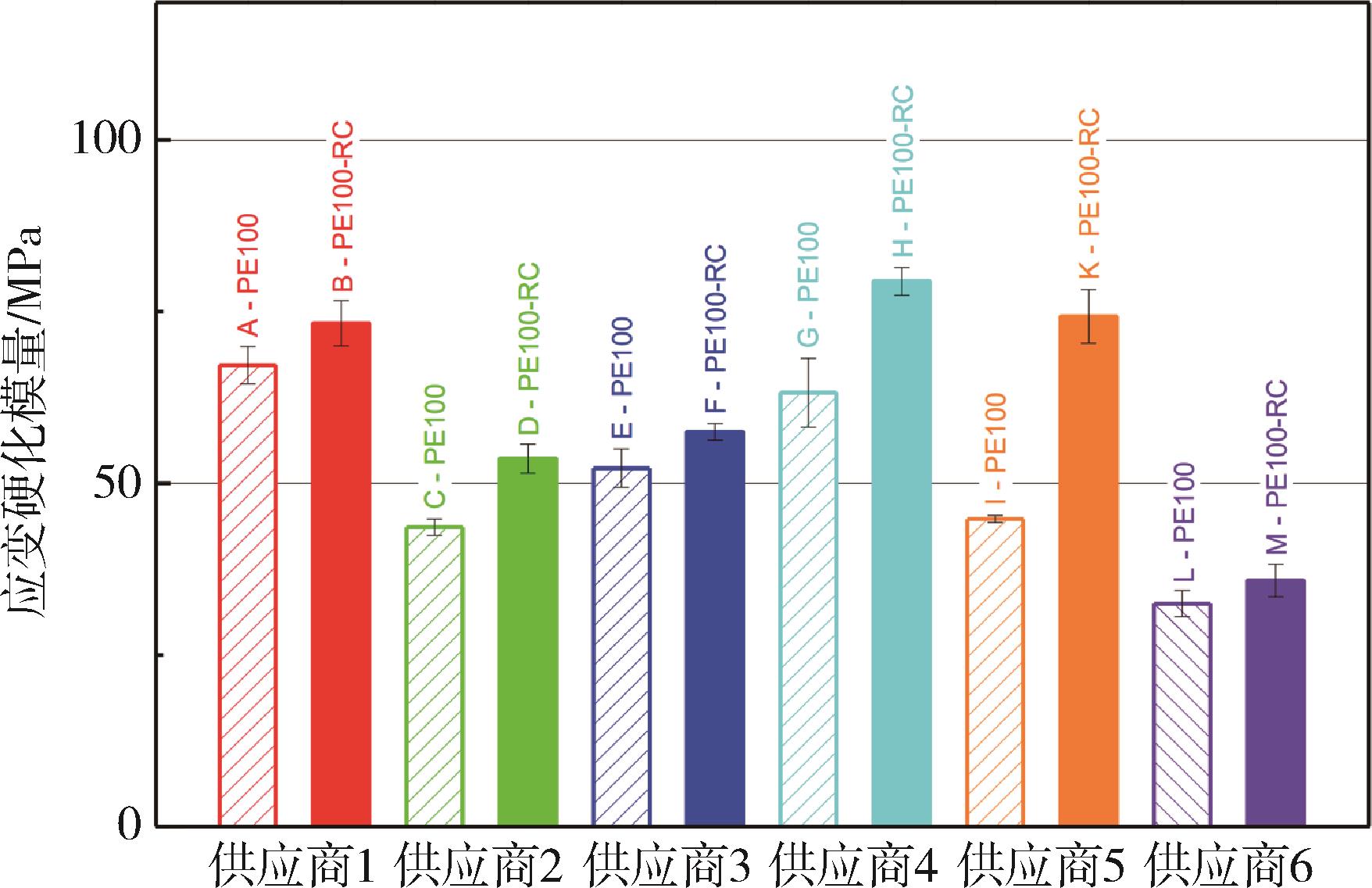

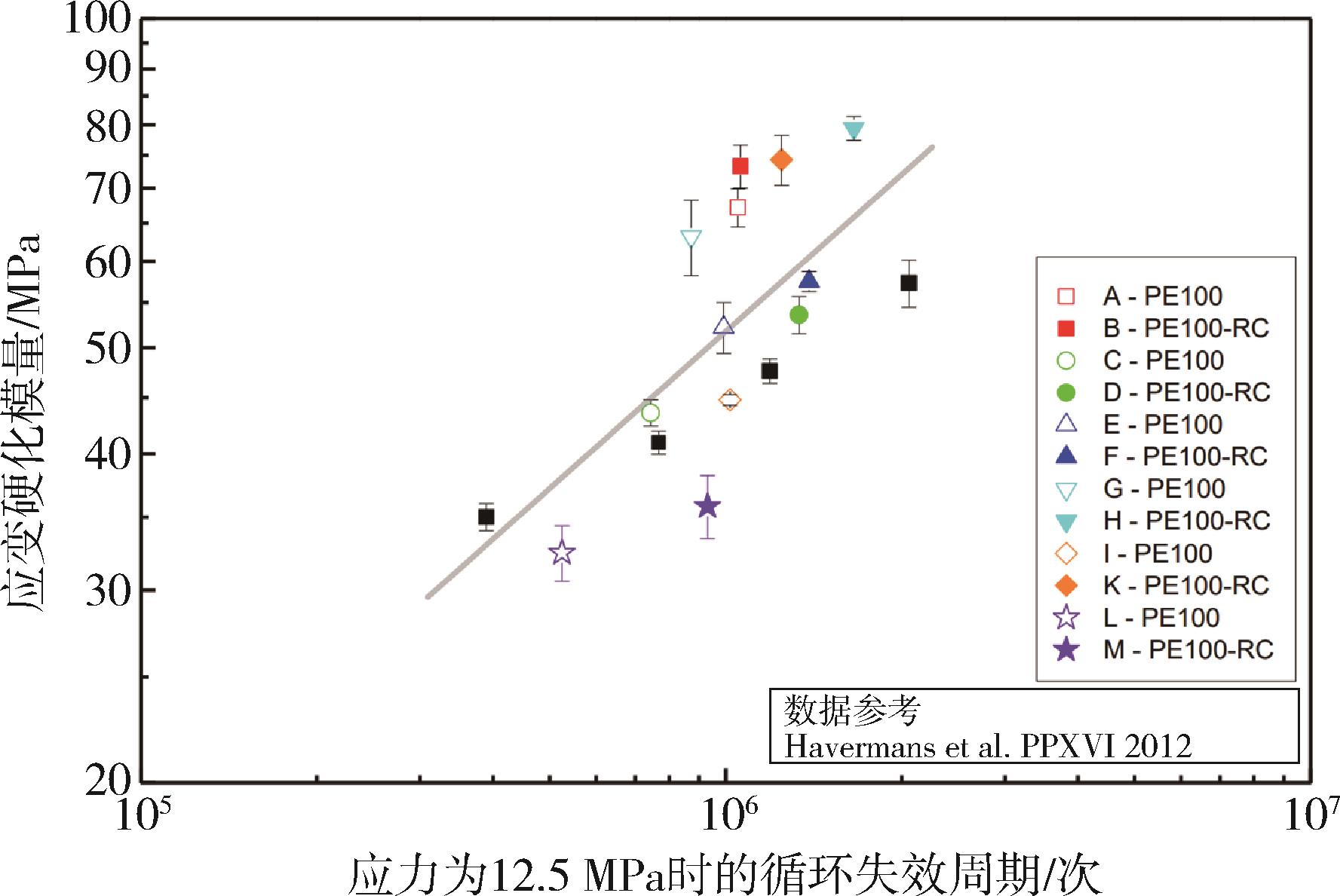

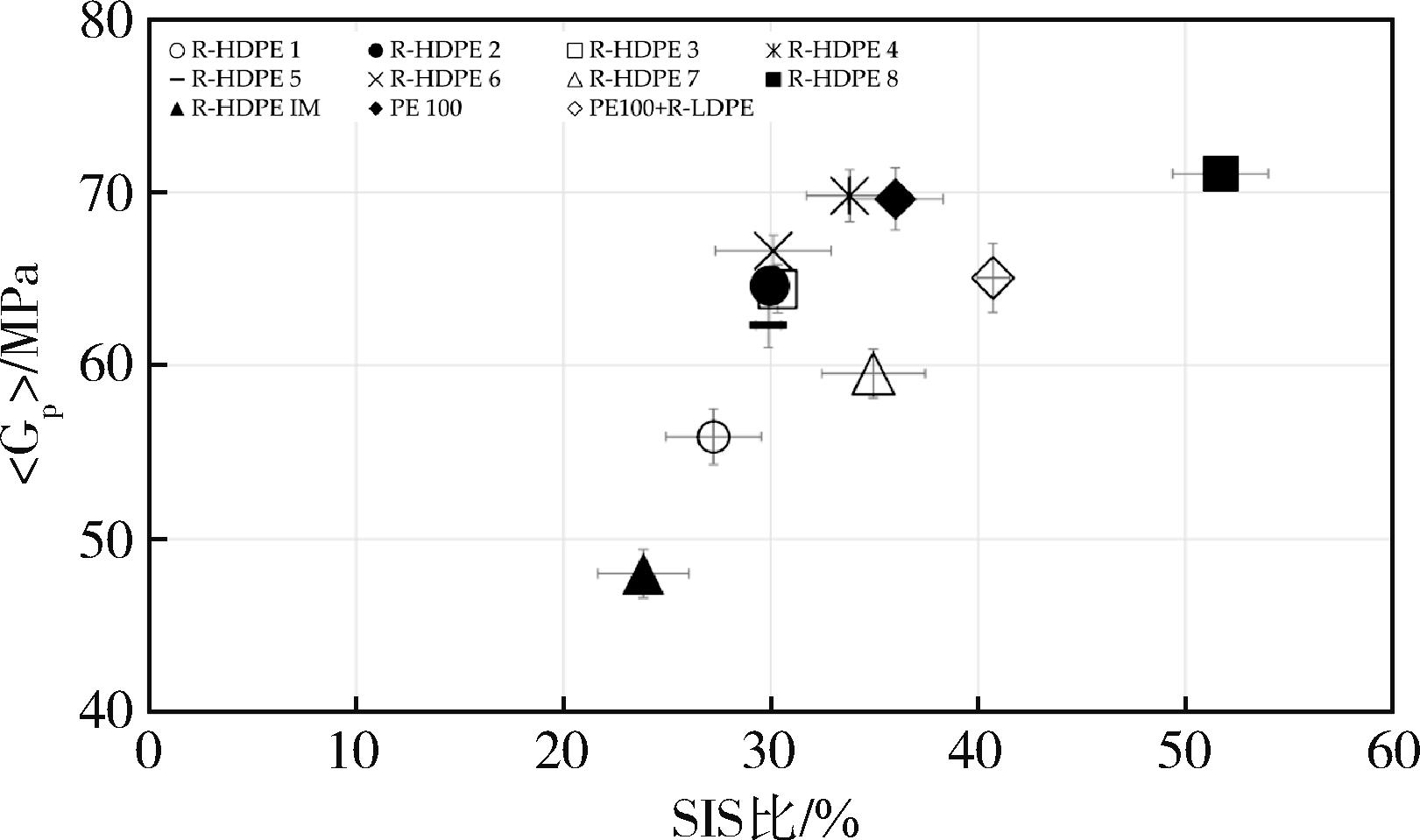

概述了聚乙烯(PE)管材3种典型失效破坏模式(韧性破坏、脆性破坏、热氧老化破坏),简述了慢速裂纹增长的分子机理和断裂力学机理,详细介绍了应变硬化模量(SH)方法的测试原理和试验过程,介绍了目前SH法测试与材料微观结构相关性的研究进展,综述了国内外关于SH法评价管材耐慢速裂纹增长性能的可靠性研究以及应用SH法评价材料耐环境应力开裂性能的研究进展,并对应用SH法在控制产品质量方面提出展望。

中图分类号:

李岩, 唐晓旭, 张伟杰, 黄瑞鹏, 张杉. 基于应变硬化模量方法评价聚乙烯管材耐慢速裂纹增长性能研究进展[J]. 中国塑料, 2022, 36(9): 148-159.

LI Yan, TANG Xiaoxu, ZHANG Weijie, HUANG Ruipeng, ZHANG Shan. Research progress in evaluation of slow crack growth resistance of polyethylene pipes based on strain hardening modulus[J]. China Plastics, 2022, 36(9): 148-159.

| 项目 | 尺寸/mm |

|---|---|

| 夹具之间的初始距离(L) | 30.0±0.5 |

| 标距长度(l0) | 12.5±0.1 |

| 窄平行部分长度(l1) | 16.0±1.0 |

| 夹区的平行部位间距(l2) | 46.0±1.0 |

| 总长度最小值(l3) | 70 |

| 半径(R1) | 10.0±0.5 |

| 半径(R2) | 8.0±0.5 |

| 窄平行部分宽度(b1) | 4.0±0.1 |

| 末端宽度(b2) | 20.0±1.0 |

| 厚度(h) |

| 项目 | 尺寸/mm |

|---|---|

| 夹具之间的初始距离(L) | 30.0±0.5 |

| 标距长度(l0) | 12.5±0.1 |

| 窄平行部分长度(l1) | 16.0±1.0 |

| 夹区的平行部位间距(l2) | 46.0±1.0 |

| 总长度最小值(l3) | 70 |

| 半径(R1) | 10.0±0.5 |

| 半径(R2) | 8.0±0.5 |

| 窄平行部分宽度(b1) | 4.0±0.1 |

| 末端宽度(b2) | 20.0±1.0 |

| 厚度(h) |

| 试样 | 共聚单体类型 | 共聚单体含量/1 000 C | 晶片厚度/nm | Mw/kg·mol-1 | Mw/Mn | 应变硬化模量/MPa |

|---|---|---|---|---|---|---|

| PE1 | 1⁃己烯 | 3.4 | 144.64 | 564.5 | 27.4 | 71.6 |

| PE2 | 1⁃己烯 | 2.3 | 177.99 | 468.2 | 20.4 | 63.0 |

| PE3 | 1⁃丁烯 | 2.5 | 180.52 | 502.6 | 24.2 | 55.4 |

| PE4 | 1⁃丁烯 | 1.5 | 187.30 | 465.3 | 23.0 | 52.6 |

| PE5 | 1⁃丁烯 | 1.2 | 252.21 | 456.8 | 21.2 | 45.8 |

| 试样 | 共聚单体类型 | 共聚单体含量/1 000 C | 晶片厚度/nm | Mw/kg·mol-1 | Mw/Mn | 应变硬化模量/MPa |

|---|---|---|---|---|---|---|

| PE1 | 1⁃己烯 | 3.4 | 144.64 | 564.5 | 27.4 | 71.6 |

| PE2 | 1⁃己烯 | 2.3 | 177.99 | 468.2 | 20.4 | 63.0 |

| PE3 | 1⁃丁烯 | 2.5 | 180.52 | 502.6 | 24.2 | 55.4 |

| PE4 | 1⁃丁烯 | 1.5 | 187.30 | 465.3 | 23.0 | 52.6 |

| PE5 | 1⁃丁烯 | 1.2 | 252.21 | 456.8 | 21.2 | 45.8 |

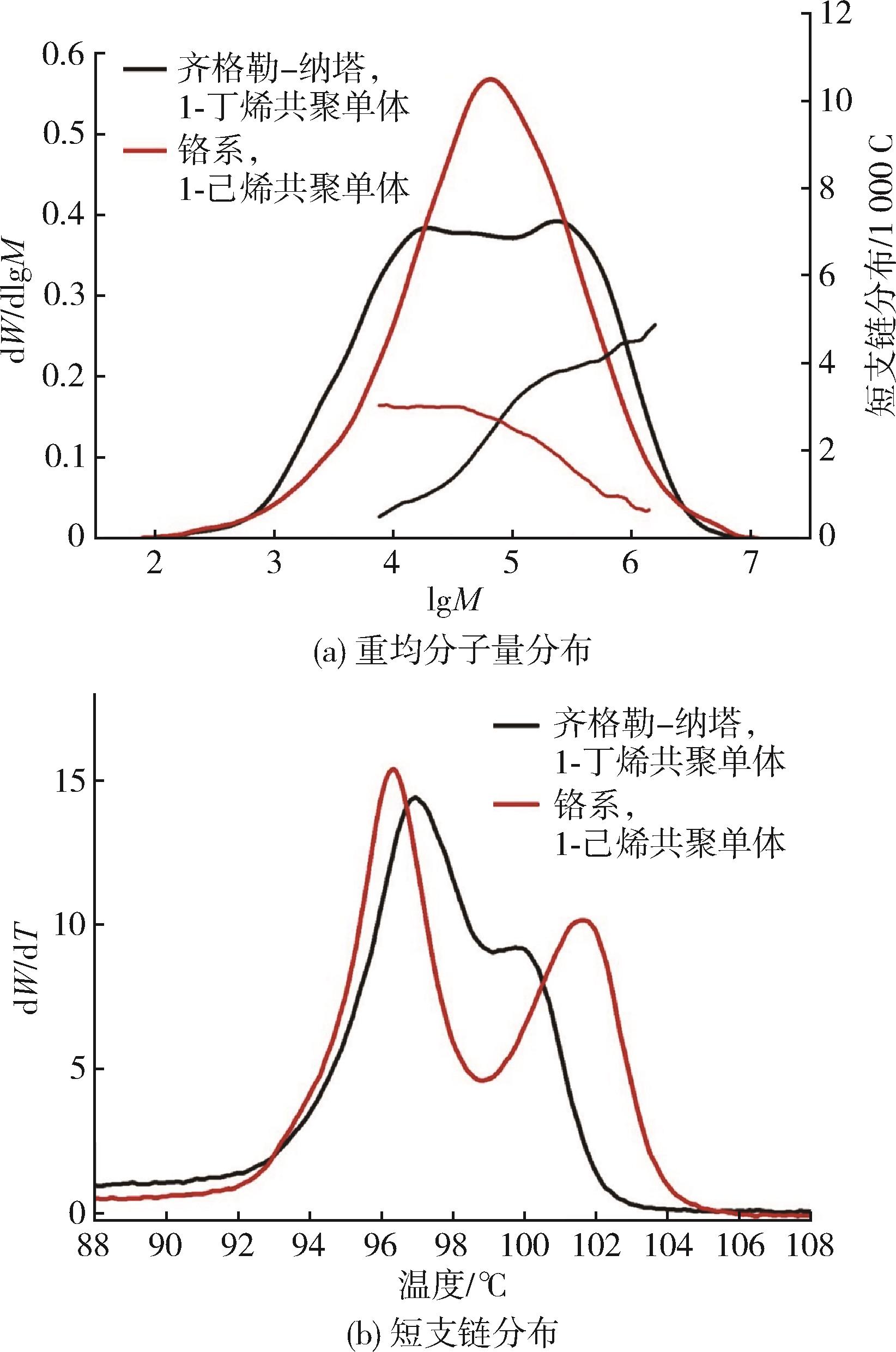

| 试样 | 催化剂 | 共聚单体类型 | 密度/kg·m-3 | Mw /kg·mol-1 | Mw/Mn | 短支链分布/1000C | 应变硬化模量/MPa |

|---|---|---|---|---|---|---|---|

| PEAD1 | 齐格勒⁃纳塔 | 1⁃丁烯 | 955.3 | 260 | 30 | 2.7 | 52.0 |

| PEAD2 | 齐格勒⁃纳塔 | 1⁃丁烯 | 957.0 | 290 | 26 | 3.4 | 53.5 |

| PEAD3 | 铬系 | 1⁃己烯 | 957.4 | 430 | 68 | 2.1 | 57.6 |

| PEAD4 | 铬系 | 1⁃己烯 | 955.0 | 462 | 79 | 1.9 | 64.0 |

| 试样 | 催化剂 | 共聚单体类型 | 密度/kg·m-3 | Mw /kg·mol-1 | Mw/Mn | 短支链分布/1000C | 应变硬化模量/MPa |

|---|---|---|---|---|---|---|---|

| PEAD1 | 齐格勒⁃纳塔 | 1⁃丁烯 | 955.3 | 260 | 30 | 2.7 | 52.0 |

| PEAD2 | 齐格勒⁃纳塔 | 1⁃丁烯 | 957.0 | 290 | 26 | 3.4 | 53.5 |

| PEAD3 | 铬系 | 1⁃己烯 | 957.4 | 430 | 68 | 2.1 | 57.6 |

| PEAD4 | 铬系 | 1⁃己烯 | 955.0 | 462 | 79 | 1.9 | 64.0 |

| 试样 | 共聚 单体类型 | NPT法 | SH法 | ||

|---|---|---|---|---|---|

| 破坏时间/h | 标准偏差 | 应变硬化 模量/MPa | 标准偏差 | ||

| PE1 | 1⁃己烯 | 2 275 | 12.58 | 51.4 | 1.28 |

| PE2 | 1⁃己烯 | 2 300 | 16.5 | 54.8 | 1.15 |

| PE3 | 1⁃丁烯 | 2 250 | 10.35 | 48.6 | 0.84 |

| 试样 | 共聚 单体类型 | NPT法 | SH法 | ||

|---|---|---|---|---|---|

| 破坏时间/h | 标准偏差 | 应变硬化 模量/MPa | 标准偏差 | ||

| PE1 | 1⁃己烯 | 2 275 | 12.58 | 51.4 | 1.28 |

| PE2 | 1⁃己烯 | 2 300 | 16.5 | 54.8 | 1.15 |

| PE3 | 1⁃丁烯 | 2 250 | 10.35 | 48.6 | 0.84 |

| 1 | ZHANG Y, P⁃Y BEN JAR. Phenomenological modelling of tensile fracture in PE pipe by considering damage evolution [J]. Materials & Design, 2015, 77:72⁃82. |

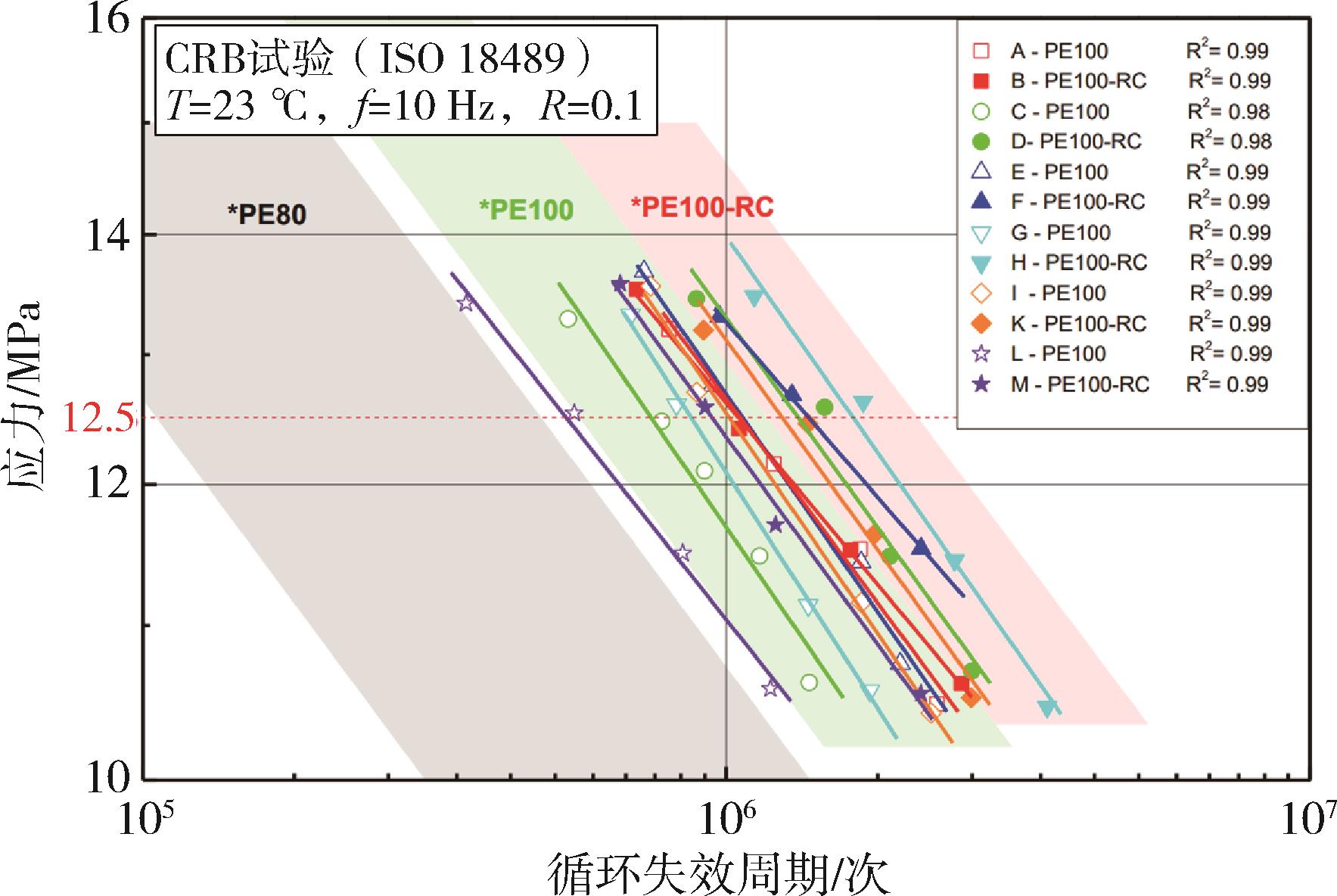

| 2 | FRANK A, PINTER G. Evaluation of the applicability of the cracked round bar test as standardized PE⁃pipe ranking tool [J]. Polymer Testing, 2014, 33:161⁃171. |

| 3 | Kratochvilla Thomas R, Frank Andreas, Pinter Gerald. Determination of slow crack growth behaviour of polyethylene pressure pipes with cracked round bar test [J]. Polymer Testing, 2014, 40:299⁃303. |

| 4 | 王志刚, 杨波, 李茂东,等. 聚乙烯管材耐慢速裂纹增长性能的加速评价方法研究进展[J]. 中国塑料, 2017, 31(7):121⁃125. |

| WANG Z G, YANG B, LI M D, et al. Research progresses in accelerated evaluation methods for slow⁃crack⁃growth resistant performance of polyethylene pipes [J]. China Plastics, 2017, 31(7):121⁃125. | |

| 5 | 杨波,何嘉平,翟伟,等. 基于循环载荷法评价聚乙烯管材性能的可靠性研究[J].中国塑料, 2020, 34(3):54⁃61. |

| YANG B, HE J P, ZHAI W, et al. Evaluation of performance reliability for polyethylene pipe by cyclic loading method [J]. China Plastics, 2020, 34(3):54⁃61. | |

| 6 | KUHLMAN C J, TWEEDY L K, KANNINEN M F. Forecasting the long⁃term service performance of polyethylene gas distribution pipes [J]. Proceedings of Plastics Pipes VIII, 1992, 13: 233⁃237. |

| 7 | BEECH S H, FERGUSON C R, CLUTTON E Q. Mechanisms of slow crack growth in PE pipe grades [J].BOOK⁃INSTITUTE OF MATERIALS, 2001, 759:401⁃410. |

| 8 | BEECH S H, MALLINSON J N. Slow crack growth performance of today's plastics pipeline materials[J].Plastics Rubber and Composites Processing and Applications,1998,27(9):418⁃423. |

| 9 | NEZBEDOVÁE, HUTAŘP, ZOUHARM, et al. The applicability of the pennsylvania notch test for a new generation of PE pipe grades[J]. Polymer Testing, 2013, 32(1): 106⁃114. |

| 10 | FLEISSNER M. Langsames rißwachstum und zeitstand⁃festigkeit von rohren aus polyethylene[J]. Kunststoffe, 1987, 77(1): 45⁃50. |

| 11 | FLEISSNER M. Experience with a full notch creep test in determining the stress crack performance of polyethylenes [J]. Polymer Engineering & Science, 1998, 38(2): 330⁃340. |

| 12 | 黄学斌,伏喜斌,徐火力. 聚乙烯管道热熔对接焊接头冷拉伸性能研究[J]. 机械制造文摘⁃焊接分册, 2015, 2: 1⁃4. |

| HUANG X B, FU X B, XU H L. Study on cold tensile properties of butt welded joints of polyethylene pipe[J].Mechanical Manufacturing Abstracts Welding,2015, 2:1⁃4. | |

| 13 | 王晓芹. 聚乙烯管材热熔对接焊拉伸性能的研究[J]. 甘肃科技,2017,33(11):53⁃54. |

| WANG X Q. Study on Tensile properties of butt welding of polyethylene pipe [J]. Gansu Science and Technology, 2017, 33(11): 53⁃54. | |

| 14 | 铁文安,杨冬莹,孙芳莉. 聚乙烯管材热熔对接接头性能的研究[J]. 工程塑料应用, 2007, 35(10): 37⁃39. |

| TIE W A, YANG D Y, SUN F L. Study on the proper⁃ties of butt fusion joint of polyethylene pipe[J]. Applica⁃tion of Engineering Plastics, 2007, 35(10): 37⁃39. | |

| 15 | KURELEC L, TEEUWEN M, SCHOFFELEERS H, et al. Strain hardening modulus as a measure of environmental stress crack resistance of high density polyethylene[J]. Polymer, 2005, 46(17): 6 369⁃6 379. |

| 16 | MCCARTHY M, DEBLIECK R, MINDERMANN P, et al. New accelerated method to determine slow crack grow behavior of polyethylene pipe materials[C]//Proceedings of Plastics Pipes XIV, Budapest, Hungary, 2008. |

| 17 | 孙逊. 聚烯烃管道[M]. 北京:化学工业出版社, 2002:274⁃275. |

| 18 | 徐成. 聚乙烯管韧性失效寿命预测方法研究[D].杭州:浙江大学, 2012. |

| 19 | 赵启辉, 柯锦玲, 刘斯佳. PE100⁃RC材料的发展及在燃气管道的应用[J]. 煤气与热力, 2012, 32(7):28⁃32. |

| ZHAO Q H, KE J L, LIU S J. Development of PE100⁃RC material and its application in gas pipeline[J]. GAS & HEAT, 2012, 32(7):28⁃32. | |

| 20 | BrownNorman, BhattacharyaS K. The initiation of slow crack growth in linear polyethylene under single edge notch tension and plane strain [J]. Journal of Materials Science, 1985, 20(12):4 553⁃4 560. |

| 21 | HUANG Y L, BROWN N. The effect of molecular weight on slow crack growth in linear polyethylene homopolymers[J]. Journal of Materials Science, 1988, 23(10):3 648⁃3 655. |

| 22 | ROSE L J, CHANNELL A D, FRYE C J, et al. Slow crack growth in polyethylene: A novel predictive model based on the creep of craze fibrils[J]. Journal of Applied Polymer Science, 1994, 54(13):2 119⁃2 124. |

| 23 | FAWAZ J, DEVECI S, MITTAL V. Molecular and morphological studies to understand slow crack growth (SCG) of polyethylene [J]. Colloid and Polymer Science, 2016, 294(8):1 269⁃1 280. |

| 24 | CAZENAVE J, SEGUELA R, SIXOU B, et al. Short⁃term mechanical and structural approaches for the evaluation of polyethylene stress crack resistance[J]. Polymer, 2009, 47(11):3 904⁃3 914. |

| 25 | 高宁,谢泽祥,申开智, 等.聚乙烯管材耐慢速裂纹增长性能研究进展[J].现代塑料加工应用,2020,32(2):55⁃58. |

| GAO N, XIE Z X, SHEN K Z, et al. Research progress on the slow crack growth resistance of PE pipes[J]. Moden Plastics Processing and Applicaiton,2020,32(2):55⁃58. | |

| 26 | BROWN N, ONOFRIO JD, LU X. The transition between ductile and slow⁃crack⁃growth failure in polyethylene [J]. Polymer, 1987, 28(8):1 326⁃1 330. |

| 27 | LU X C, IshikawaNarumi, BrownNorman. The critical molecular weight for resisting slow crack growth in a polyethylene[J]. Journal of Polymer Science Part B: Polymer Physics, 1996, 34(10):1 809⁃1 813. |

| 28 | 梁泉水, 陈开源. 聚乙烯管材发生慢速裂纹增长的影响因素及对策[J]. 广东化工, 2009, 36(11):78⁃80. |

| LIANG Q S, CHEN K Y. Influencing factors on slow crack growth resistance of polyethylene pipe and countermeasures[J]. Guangdong Chemical Industry, 2009, 36(11):78⁃80. | |

| 29 | HUANG Y L, BROWN N. The effect of molecular weight on slow crack growth in linear polyethylene homopolymers [J]. Journal of Materials Science, 1988, 23(10):3 648⁃3 655. |

| 30 | 谢侃, 唐岩, 李延亮, 等. 聚乙烯管材料抵抗慢速裂纹扩展性能研究[J]. 中国塑料, 2005, 19(3):20⁃24. |

| XIE K, TANG Y, LI Y L, et al. Study on resistance to slow⁃crack⁃growth of polyethylene pipe[J]. China Plastics, 2005, 19(3):20⁃24. | |

| 31 | GARCÍARAFAEL A, CARREROA, MARTÍNC, et al. Effects of the structural components on slow crack growth process in polyethylene blends. Composition intervals prediction for pipe applications [J]. Journal of Applied Polymer Science, 2011, 121(6):3 269⁃3 276. |

| 32 | GARCÍARAFAEL A, CARREROA, AROCAM, et al. Domínguez. Slow crack growth resistance in resin blends of chromium and metallocene catalyzed ethylene⁃hexene copolymers for pipe applications[J]. Polymer Engineering & Science, 2010, 48(5):925⁃933. |

| 33 | Colin Li Pi Shan, SoaresJoao B P, Alexander Penlidis. PE⁃HD/LLDPE reactor blends with bimodal microstructures—part I: mechanical properties [J]. Polymer, 2002, 43(26):7 345⁃7 365. |

| 34 | Colin Li Pi Shan, SoaresJoao B P, Alexander Penlidis. PE⁃HD/LLDPE reactor blends with bimodal microstructures⁃Part II: rheological properties [J]. Polymer, 2003, 44(1):177⁃185. |

| 35 | Des Lauriers Paul J, Mc Daniel Max P, Rohlfing David C, et al. A comparative study of multimodal vs. bimodal polyethylene pipe resins for PE⁃100 applications[J]. Polymer Engineering and Science, 2010, 45(9):1 203⁃1 213. |

| 36 | Laura Hubert, David L, Seguela R, et al. Physical and mechanical properties of polyethylene for pipes in relation to molecular architecture. I. Microstructure and crystallisation kinetics [J]. Polymer, 2001, 42(20):8 425⁃8 434. |

| 37 | Hubert L, David L, Séguéla R, et al. Physical and mechanical properties of polyethylene for pipes in relation to molecular architecture. II. Short⁃term creep of isotropic and drawn materials [J]. Journal of Applied Polymer Science, 2002, 84(12): 2 308⁃2 317. |

| 38 | FAN Y D, XUE Y H, NIE W, et al. Characterization of the microstructure of bimodal PE⁃HD resin[J]. Polymer Journal, 2009, 41(8):622⁃628. |

| 39 | HE X L, ZHA X J, ZHU X, et al. Effect of short chain branches distribution on fracture behavior of polyethylene pipe resins[J]. Polymer Testing, 2018, 68:219⁃228. |

| 40 | HU Y L, SHAO Y Q, LIU Z, et al. Effect of short⁃chain branching on the tie chains and dynamics of bimodal polyethylene: Molecular dynamics simulation[J]. European Polymer Journal, 2018, 103:312⁃321. |

| 41 | Krishnaswamy Rajendra K, YANG Q, Fernandez⁃BallesterLucia, et al. Kornfield. Effect of the distribution of short⁃chain branches on crystallization kinetics and mecha⁃nical properties of high⁃density polyethylene[J]. Macromolecules, 2008, 41(5):1 693⁃1 704. |

| 42 | LU X C, Andrew Mcghie, Norman Brown. The dependence of slow crack growth in a linear polyethylene on test temperature and morphology [J]. Journal of Polymer Science Part B:Polymer Physics, 1993, 31(7):767⁃772. |

| 43 | FAWAZ J, DEVECI S, MITTAL V. Molecular and morphological studies to understand slow crack growth (SCG) of polyethylene [J]. Colloid and Polymer Science, 2016, 294(8):1 269⁃1 280. |

| 44 | SUN N, Mirko Wenzel, Alina Adams. Morphology of high⁃density polyethylene pipes stored under hydrostatic pressure at elevated temperature [J]. Polymer, 2014, 55(16):3 792⁃3 800. |

| 45 | 查晓娟. 高等级聚乙烯管材料的结构与性能研究[D]. 上海:华东理工大学,2018. |

| 46 | Nezbedová E, Hutar P, Zouhar M, et al. The applicability of the pennsylvania notch test for a new generation of PE pipe grades [J]. Polymer Testing, 2013, 32(1):106⁃114. |

| 47 | HUANG Y L, Norman Brown. Dependence of slow crack growth in polyethylene on butyl branch density: Morphology and theory [J]. Journal of Polymer Science Part B:Polymer Physics, 2010, 29(1):129⁃137. |

| 48 | Šindelář P, Nezbedová E, Šimková P, et al. Effect of structural parameters on rapid crack propagation and slow crack growth in high density polyethylene pipeline materials[J]. Plastics Rubber and Composites, 2005, 34(7):329⁃333. |

| 49 | Elyashevich G K. Structure and long⁃term mechanical pro⁃perties of oriented polyethylene [J]. Physics of the Solid State, 2005, 47(6):1 020⁃1 027. |

| 50 | 严小伟,历伟,任晓红,等. PE100管材料的聚集态结构和性能的固体NMR分析[J]. 材料研究学报, 2008, 22(2):157⁃163. |

| YAN X W, LI W, REN X H, et al. Investigations of the structure and property relationship of PE100 pipe materials by solid state NMR techniques[J]. Chinese Journal of Materials Research, 2008, 22(2):157⁃163. | |

| 51 | Men Y F, Rieger J, Enderle H⁃F, et al. The mobility of the amorphous phase in polyethylene as a determining factor for slow crack growth [J]. The European Physical Journal E, 2004, 15(4):421⁃425. |

| 52 | 何曼君, 张红东, 陈维孝, 等. 高分子物理⁃第3版[M].上海:复旦大学出版社, 2007,参考页面范围. |

| 53 | 王志刚, 杨波, 王靖然, 等. 聚乙烯管材热熔对接接头抵抗慢速裂纹扩展性能评价[J]. 中国塑料, 2020, 34(9):52⁃55. |

| WANG Z G, YANG B, WANG J R, et al. Evaluation of slow crack growth resistance for polyethylene pipe butt⁃fusion welded joint[J]. China Plastics, 2020, 34(9):52⁃55. | |

| 54 | 国家市场监督管理总局,国家标准化管理委员会. 管道系统用聚乙烯材料与慢速裂纹增长相关的应变硬化模量的测定 [S].北京:中国标准出版社,2021. |

| 55 | 翟伟, 杨波, 李茂东,等. 聚乙烯管材耐慢速裂纹增长性能的快速评价的研究现状[J]. 高分子材料科学与工程, 2018, 34(11):175⁃182. |

| ZHAI W, YANG B, LI M D,et al. Tests for slow crack growth failure in polyethylene pipes[J]. Polymer Materials Science and Engineering, 2018, 34(11):175⁃182. | |

| 56 | 朱天戈, 杨化浩, 武鹏, 等. 应变硬化模量评价聚乙烯管材专用料SCG性能方法研究[J]. 塑料工业, 2018, 46(5):93⁃96. |

| ZHU T G, YANG H H, WU P, et al. Study on determination of SCG properties of PE pipe resins using strain hardening modulus[J]. China Plastics Industry, 2018, 46(5):93⁃96. | |

| 57 | Deblieck Rudy A C, Van Beek D J M, Klaas Remerie, et al. Failure mechanisms in polyolefines: The role of cra⁃zing, shear yielding and the entanglement network[J]. Polymer, 2011, 52(14):2 979⁃2 990. |

| 58 | Nuria Robledo, Carlos Domínguez, García⁃MunOz Rafael A. Alternative accelerated and short⁃term methods for evaluating slow crack growth in polyethylene resins with high crack resistance[J]. Polymer Testing, 2017, 62:366⁃372. |

| 59 | Kurelec L, Teeuwen M, Schoffeleers H, et al. Strain hardening modulus as a measure of environmental stress crack resistance of high density polyethylene[J]. Polymer, 2005, 46:6 369⁃6 379. |

| 60 | Maxwell A S, Pilkington G. Prediction of environmental stress cracking resistance in linear low density polyethylenes[J]. Polymer Engineering & Science, 2010, 48: 360⁃364. |

| 61 | 陈国华, 黄晓之, 李茂东,等. 基于应变硬化与微观结构相关性的PE管材耐慢速裂纹扩展性能研究[J]. 塑料工业, 2018, 46(5):97⁃101. |

| CHEN G H, HUANG X Z, LI M D, et al. Research on slow crack growth resistance of PE pipes based on correlation between strain hardening and microstructure[J]. China Plastics Industry, 2018, 46(5):97⁃101. | |

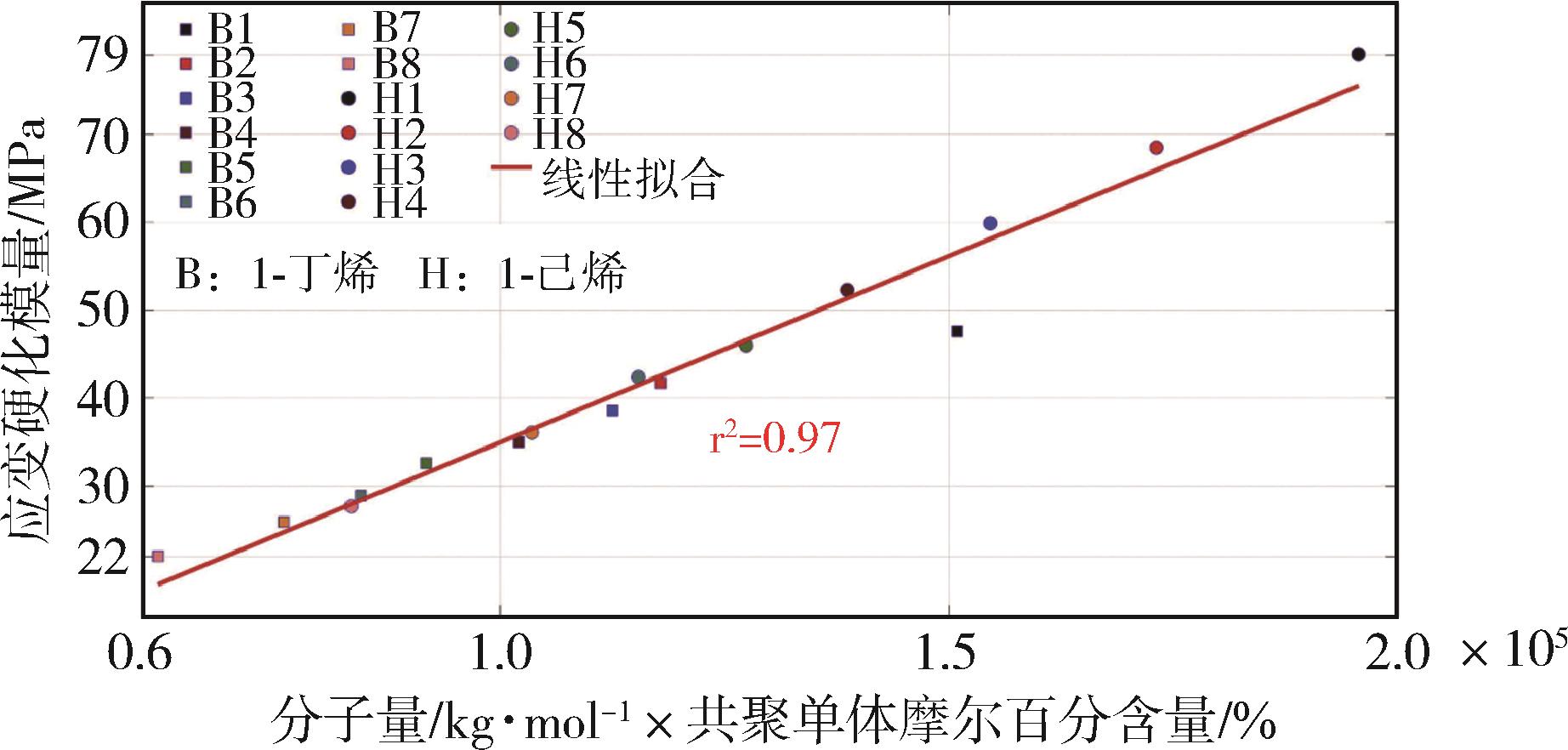

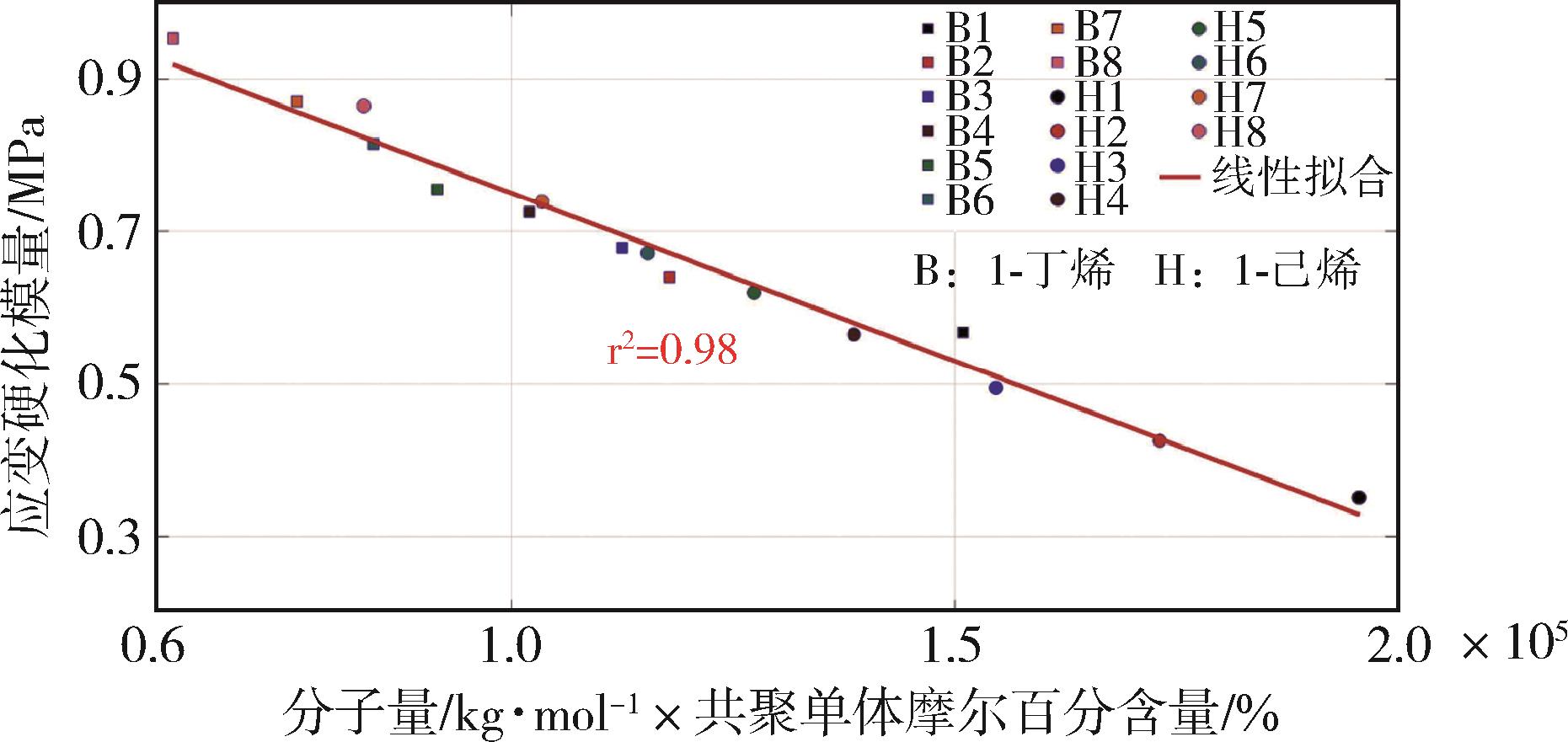

| 62 | Carlos Domínguez, Nuria Robledo, Beatriz Paredes, et al. Strain hardening test on the limits of slow crack growth evaluation in high resistance polyethylene resins: effect of comonomer type[J]. Polymer Testing, 2020, 81:1⁃7. |

| 63 | Suleyman Deveci, Senthil Kumar Kaliappan, FawazJoel, et al. Sensitivity of post yield axial deformation properties of high⁃density ethylene/α⁃olefin copolymers in relation to molecular structure and slow crack growth resistance[J]. Polymer Testing, 2018, 72:285⁃297. |

| 64 | HUANG Y L, Norman Brown. Dependence of slow crack growth in polyethylene on butyl branch density: morphology and theory, Journal of Polymer Science Part B:Polymer Physics, 1991,29: 129⁃137. |

| 65 | Deslauriers Paul J, Rohlfing David C. Estimating slow crack growth performance of polyethylene resins from primary structures such as molecular weight and short chain branching[J], Polyolefin Characterization⁃ICPC 2008, 2009, 282:136⁃149. |

| 66 | 李茂东, 陈国华, 杨波, 等. 聚乙烯管材应变硬化模量与裂纹扩展速率相关性研究[J]. 中国塑料, 2018, 32(9):96⁃101. |

| LI M D, CHEN G H, YANG B, et al. Research on correlation of strain hardening modulus and crack growth rate of polyethylene pipes[J]. China Plastics, 2018, 32(9):96⁃101. | |

| 67 | Isabelle Berger, Andreas Frank, Florian Arbeiter, et al. Characterization of slow crack growth resistance of polyethylene pipe grades with cyclic cracked round bar (CRB) test in correlation to strain hardening (SH) test[J]. Technical Conference of the Society of Plastics Engineers, 2017, 5: 1⁃5. |

| 68 | D J M (Linda) Havermans van Beek, Rudy Deblieck. Strain hardening: an elegant and fast method to predict the slow crack growth behavior of PE⁃HD pipe materials[J]. Society of Plastics Engineers, 2011,1: 1⁃5. |

| 69 | 王志刚, 杨波,李茂东, 等. 基于应变硬化模量的PE材料耐SCG性能加速评价方法[J]. 塑料工业, 2018, 46(12):110⁃113. |

| WANG Z G, YANG B, LI M d, et al. Accelerate evaluation method for testing the SCG resisitance of PE materials based on strain hardening modulus [J]. China Plastics Industry, 2018, 46(12):110⁃113. | |

| 70 | Anna Gobetti, Giorgio Ramorino. Application of short⁃term methods to estimate the environmental stress crac⁃king resistance of recycled PE⁃HD[J]. Journal of Polymer Research, 2020, 27(11):353. |

| [1] | 杨波, 杨圳, 曾辰, 王志刚, 翟伟, 曹福想. 基于循环载荷试验的聚乙烯管材寿命预测研究[J]. 中国塑料, 2022, 36(9): 63-69. |

| [2] | 何安淇, 黄剑, 张莹, 孙华丽, 项爱民, 徐海云. 喷水灭火氯化聚氯乙烯管道的压力设计基础及国内外标准比较[J]. 中国塑料, 2022, 36(9): 131-139. |

| [3] | 张兵. 无规共聚聚丙烯管材氧化诱导时间测试探究[J]. 中国塑料, 2022, 36(8): 107-109. |

| [4] | 余大荣, 辛勇. 超高分子量聚乙烯改性研究进展[J]. 中国塑料, 2022, 36(8): 135-145. |

| [5] | 李果, 朱惠豪, 马玉录, 王玉, 吉华建, 谢林生. 导热型微孔透气薄膜的制备及性能研究[J]. 中国塑料, 2022, 36(7): 14-20. |

| [6] | 周舒毅, 朱敏, 刘忆颖, 曹舒惠, 蔡启轩, 聂慧, 张玉霞, 周洪福. 高分子止血材料研究进展[J]. 中国塑料, 2022, 36(7): 74-84. |

| [7] | 吴雄杰, 朱东波, 孙江波, 高龙美, 储雨, 程劲松, 谢爱迪. 聚乙烯/纳米硫酸钙粉体复合软包装应用性能研究[J]. 中国塑料, 2022, 36(6): 10-15. |

| [8] | 雷育杰, 陈明焕, 王洁瑶, 陈旺治, 李磊. 回收聚乙烯的交联发泡及其产品性能研究[J]. 中国塑料, 2022, 36(6): 124-129. |

| [9] | 刘伟, 吴显, 陈小澄, 成晓琼, 张纯. 羧基化填料对聚乙烯醇/纳米纤维素水凝胶力学、导电和传感性能的影响[J]. 中国塑料, 2022, 36(6): 16-23. |

| [10] | 张文才, 郝晓刚, 李萍, 林浩, 裴强, 丰功吉, 付兆华, 于小芳. 聚乙烯接枝马来酸酐含量对废旧聚乙烯改性沥青性能的影响[J]. 中国塑料, 2022, 36(6): 24-31. |

| [11] | 祝景云, 衣惠君, 鄢薇, 李大伟. 合成膜专用聚乙烯树脂原料的研发[J]. 中国塑料, 2022, 36(6): 77-80. |

| [12] | 夏云霞, 李磊, 罗章生, 朱倩沁, 何力军. 基于闪蒸法制备再生聚乙烯无纺布及其性能研究[J]. 中国塑料, 2022, 36(5): 14-18. |

| [13] | 王轲, 龙春光. PE⁃UHMW/海泡石纤维复合材料的力学性能与摩擦学性能研究[J]. 中国塑料, 2022, 36(5): 19-23. |

| [14] | 李福杰, 齐斌, 徐华亭, 王立梅. 交联壳聚糖/聚乙烯醇/蜗牛黏液复合膜的制备及性能研究[J]. 中国塑料, 2022, 36(5): 53-61. |

| [15] | 温原, 毛现朋, 徐科杰. 试样厚度对聚乙烯拉伸性能的影响[J]. 中国塑料, 2022, 36(4): 43-46. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2