京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2

《中国塑料》编辑部 ©2008-2024 版权所有

地址:北京市海淀区阜成路11号 邮编:100048

编辑部:010-68985541 联系信箱:cp@plaschina.com.cn

广告部/发行部:010-68985253 本系统由北京玛格泰克科技发展有限公司设计开发

中国塑料 ›› 2022, Vol. 36 ›› Issue (12): 92-99.DOI: 10.19491/j.issn.1001-9278.2022.12.014

收稿日期:2022-08-31

出版日期:2022-12-26

发布日期:2022-12-20

作者简介:金清平(1975—),男,博士,教授,从事FRP性能及其工程结构研究,jinqingping@wust.edu.cn

基金资助:

JIN Qingping( ), ZHOU Dian, HU Yanlei

), ZHOU Dian, HU Yanlei

Received:2022-08-31

Online:2022-12-26

Published:2022-12-20

摘要:

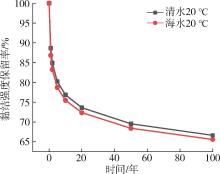

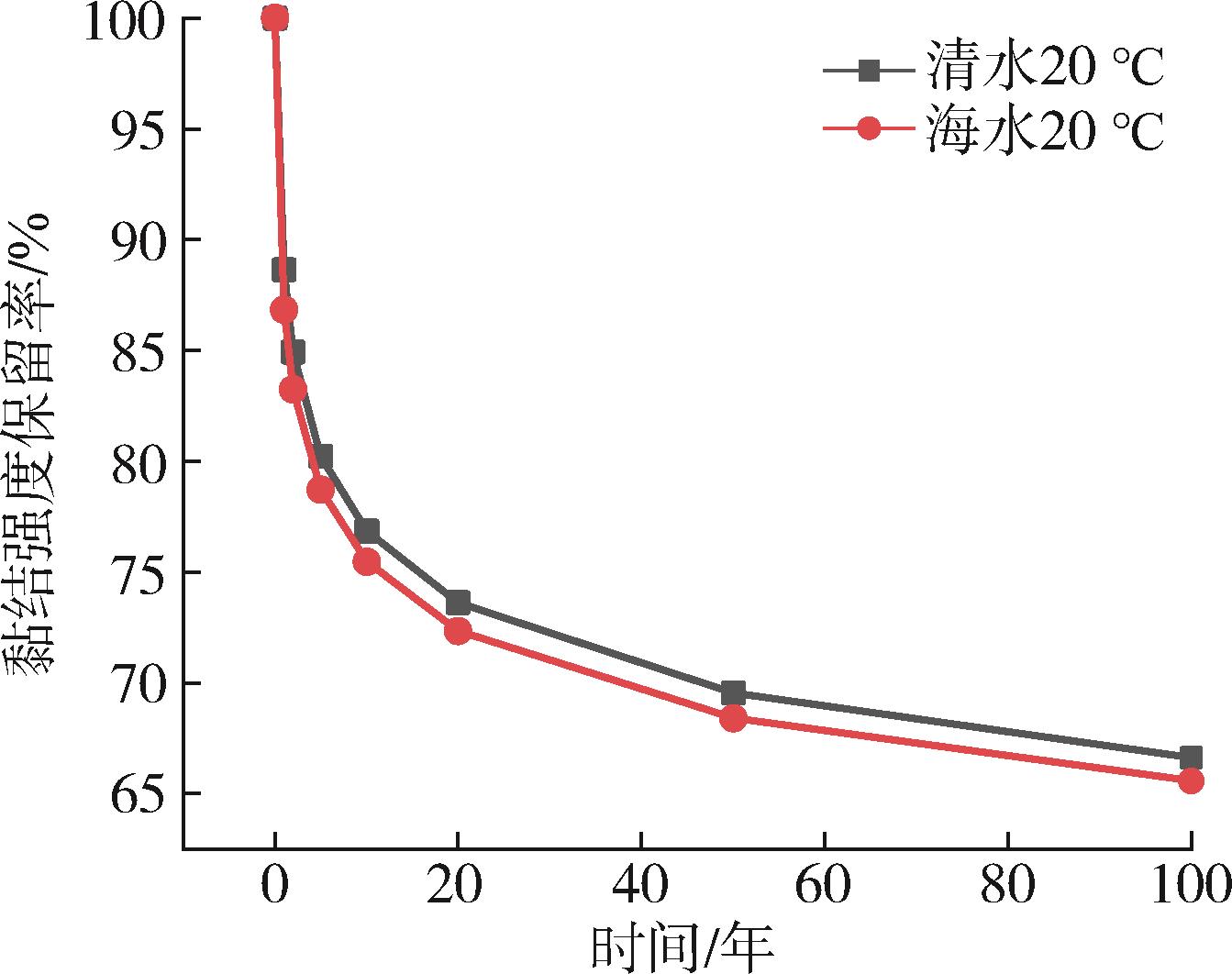

为研究海水环境下GFRP筋与海水海砂混凝土的黏结行为,设计并测试了54个GFRP筋⁃海水海砂混凝土中心拉拔试件,采用温度加速实验,研究清水和海水环境腐蚀后试件黏结强度的变化,并分析了试件的黏结滑移曲线上升段。结果表明,海水温度的升高加速了GFRP筋⁃海水海砂混凝土试件黏结强度的退化,在相同浸泡条件下,60 ℃的黏结强度相较于10 ℃降低了15 %左右;海水环境对试件黏结强度的影响略大于清水环境。分别使用BPE模型、CMR模型和Malvar模型对试件黏结滑移曲线上升段进行分析,结果表明,海水环境下GFRP筋⁃海水海砂混凝土黏结滑移曲线上升段宜采用Malvar模型。最后根据TSF寿命预测法得出,在20 ℃海水环境下,GFRP筋⁃海水海砂混凝土试件使用100年后的黏结强度保留率为65.58 %。

中图分类号:

金清平, 周典, 胡岩磊. 海水环境下GFRP筋⁃海水海砂混凝土黏结行为演化规律[J]. 中国塑料, 2022, 36(12): 92-99.

JIN Qingping, ZHOU Dian, HU Yanlei. Evolution of bonding behavior of GFRP reinforcement⁃seawater⁃sea sand concrete under seawater conditions[J]. China Plastics, 2022, 36(12): 92-99.

| 腐蚀环境 | 腐蚀温度/℃ | 腐蚀周期/d | Fmax/kN | smax/mm | τmax/MPa |

|---|---|---|---|---|---|

| 清水 | 10 | 3.65 | 130.05 | 30.65 | 20.70 |

| 18.00 | 128.65 | 31.65 | 20.49 | ||

| 36.5 | 126.60 | 29.73 | 20.16 | ||

| 40 | 3.65 | 128.95 | 29.35 | 20.53 | |

| 18.00 | 121.75 | 31.18 | 19.39 | ||

| 36.5 | 115.55 | 31.56 | 18.40 | ||

| 60 | 3.65 | 126.40 | 33.13 | 20.13 | |

| 18.00 | 119.65 | 30.44 | 19.05 | ||

| 36.5 | 108.15 | 29.53 | 17.22 | ||

| 海水 | 10 | 3.65 | 129.75 | 28.76 | 20.66 |

| 18.00 | 127.95 | 31.47 | 20.37 | ||

| 36.5 | 126.75 | 29.45 | 20.18 | ||

| 40 | 3.65 | 125.45 | 27.16 | 19.98 | |

| 18.00 | 123.35 | 26.72 | 19.64 | ||

| 36.5 | 112.65 | 28.84 | 17.94 | ||

| 60 | 3.65 | 123.80 | 26.90 | 19.71 | |

| 18.00 | 116.75 | 28.17 | 18.59 | ||

| 36.5 | 106.35 | 28.67 | 16.93 |

| 腐蚀环境 | 腐蚀温度/℃ | 腐蚀周期/d | Fmax/kN | smax/mm | τmax/MPa |

|---|---|---|---|---|---|

| 清水 | 10 | 3.65 | 130.05 | 30.65 | 20.70 |

| 18.00 | 128.65 | 31.65 | 20.49 | ||

| 36.5 | 126.60 | 29.73 | 20.16 | ||

| 40 | 3.65 | 128.95 | 29.35 | 20.53 | |

| 18.00 | 121.75 | 31.18 | 19.39 | ||

| 36.5 | 115.55 | 31.56 | 18.40 | ||

| 60 | 3.65 | 126.40 | 33.13 | 20.13 | |

| 18.00 | 119.65 | 30.44 | 19.05 | ||

| 36.5 | 108.15 | 29.53 | 17.22 | ||

| 海水 | 10 | 3.65 | 129.75 | 28.76 | 20.66 |

| 18.00 | 127.95 | 31.47 | 20.37 | ||

| 36.5 | 126.75 | 29.45 | 20.18 | ||

| 40 | 3.65 | 125.45 | 27.16 | 19.98 | |

| 18.00 | 123.35 | 26.72 | 19.64 | ||

| 36.5 | 112.65 | 28.84 | 17.94 | ||

| 60 | 3.65 | 123.80 | 26.90 | 19.71 | |

| 18.00 | 116.75 | 28.17 | 18.59 | ||

| 36.5 | 106.35 | 28.67 | 16.93 |

| 相关系数(R2) | 总数 | 均值 | 标准差 | 方差 | 变异系数 |

|---|---|---|---|---|---|

| BPE | 18 | 0.983 9 | 0.011 9 | 1.417 8×10-4 | 0.012 1 |

| CMR | 18 | 0.978 2 | 0.009 6 | 9.139 2×10-5 | 0.009 8 |

| Malvar | 18 | 0.994 6 | 0.003 1 | 9.813 6×10-6 | 0.003 2 |

| 相关系数(R2) | 总数 | 均值 | 标准差 | 方差 | 变异系数 |

|---|---|---|---|---|---|

| BPE | 18 | 0.983 9 | 0.011 9 | 1.417 8×10-4 | 0.012 1 |

| CMR | 18 | 0.978 2 | 0.009 6 | 9.139 2×10-5 | 0.009 8 |

| Malvar | 18 | 0.994 6 | 0.003 1 | 9.813 6×10-6 | 0.003 2 |

| 环境温度/℃ | 清水环境 | 海水环境 | ||

|---|---|---|---|---|

| 40 | 60 | 40 | 60 | |

| 达到80 %强度保留率所需时间/d | 371 | 88 | 404 | 64 |

| TSF(参考温度40 ℃) | 1 | 4.216 | 1 | 6.312 5 |

| 环境温度/℃ | 清水环境 | 海水环境 | ||

|---|---|---|---|---|

| 40 | 60 | 40 | 60 | |

| 达到80 %强度保留率所需时间/d | 371 | 88 | 404 | 64 |

| TSF(参考温度40 ℃) | 1 | 4.216 | 1 | 6.312 5 |

| 1 | ZHAO Yifan, HU Xiang, SHI Caijun, et al. A review on seawater sea⁃sand concrete: Mixture proportion, hydration, microstructure and properties[J]. Construction and Building Materials, 2021,295:123602. |

| 2 | GUO Menghuan, HU Biao, XING Feng, et al. Characterization of the mechanical properties of eco⁃friendly concrete made with untreated sea sand and seawater based on statistical analysis[J]. Construction and Building Materials, 2020,234:117339. |

| 3 | Pranavan S, Srinivasan G. Investigation on behaviour of M⁃sand and sea sand based concrete[J]. Materials Today : Proceedings, 2021,45:7 079⁃7 085. |

| 4 | ZHOU Jikai, HE Xu, ZHANG Lunchao. CT characteristic analysis of sea⁃sand concrete exposed in simulated marine environment[J]. Construction and Building Materials, 2021,268: 121170. |

| 5 | Falah M W. Effect of seawater for mixing and curing on structural concrete[J]. The IES Journal Part A: Civil & Structural Engineering, 2010,3(4): 235⁃243. |

| 6 | Etxeberria M, Fernandez J M, Limeira J. Secondary aggregates and seawater employment for sustainable concrete dyke blocks production: case study[J]. Construction and Building Materials, 2016,113:586⁃595. |

| 7 | Vafaei D, Hassanli R, Ma X, et al. Sorptivity and mechanical properties of fiber⁃reinforced concrete made with seawater and dredged sea⁃sand[J]. Construction and Building Materials, 2021,270:121436. |

| 8 | 中国桥梁工程学术研究综述:2021[J]. 中国公路学报, 2021,34(02):1⁃97. |

| Review on China's Bridge Engineering Research: 2021[J]. China Journal of Highway and Transport, 2021, 34(02): 1⁃97. | |

| 9 | Altalmas A, El Refai A, Abed F. Bond degradation of basalt fiber⁃reinforced polymer (BFRP) bars exposed to accelerated aging conditions[J]. Construction and Building Materials, 2015,81:162⁃171. |

| 10 | YAN Fei, LIN Zhibin. Bond durability assessment and long⁃term degradation prediction for GFRP bars to fiber⁃reinforced concrete under saline solutions[J]. Composite Structures, 2017,161:393⁃406. |

| 11 | 高 婧, 范凌云. CFRP筋与海水海砂混凝土黏结性能试验与机制分析[J]. 复合材料学报, 2022,39(03):1 194⁃1 204. |

| GAO J, FAN L Y. Experiment on bond performance between CFRP bar and seawater sea sand concrete and its working mechanism[J]. Acta Materiae Compositae Sinica, 2022,39(03):1 194⁃1 204. | |

| 12 | ZHOU Jikai, CHEN Xudong, CHEN Shixue. Durability and service life prediction of GFRP bars embedded in concrete under acid environment[J]. Nuclear Engineering and Design, 2011,241(10):4 095⁃4 102. |

| 13 | DONG Zhiqiang, GANG Wu, BO Xu, et al. Bond performance of alkaline solution pre⁃exposed FRP bars with concrete[J]. Magazine of Concrete Research, 2018,70(17):1⁃31. |

| 14 | DONG Zhiqiang, WU Gang, ZHAO Xiaoling, et al. Long⁃term bond durability of fiber⁃reinforced polymer bars embedded in seawater sea⁃sand concrete under ocean environments[J]. Journal of Composites for Construction, 2018,22(5), 04018042. |

| 15 | DONG Zhiqiang, WU Gang, XU Bo, et al. Bond durability of BFRP bars embedded in concrete under seawater conditions and the long⁃term bond strength prediction[J]. Materials and design, 2016,92:552⁃562. |

| 16 | CHANG Yufei, WANG Yanlei, WANG Mifeng, et al. Bond durability and degradation mechanism of GFRP bars in seawater sea⁃sand concrete under the coupling effect of seawater immersion and sustained load[J]. Construction and Building Materials, 2021,307:124878. |

| 17 | ASTM. Standard practice for the preparation of substitute ocean water: [S].ASTM International,2021. |

| 18 | Guide for the design and construction of structural concrete reinforced with FRP bars: ACI 440.1R-15 [S]. Farmington Hills: American Concrete Institute, 2015. |

| 19 | Davalos J F, Chen Y, Ray I. Effect of FRP bar degradation on interface bond with high strength concrete[J]. Cement & Concrete Composites, 2008,30(8):722⁃730. |

| 20 | HU Xiaolong, XIAO Jiangzhuang, ZHANG Kaijian, et al. The state⁃of⁃the⁃art study on durability of FRP reinforced concrete with seawater and sea sand[J]. Journal of Building Engineering, 2022,51, 104294. |

| 21 | LIU Tianqiao, LIU Xing, FENG Peng. A comprehensive review on mechanical properties of pultruded FRP composites subjected to long⁃term environmental effects[J]. Composites Part B: Engineering, 2020,191:107958. |

| 22 | Mikols W J, Seferis J C, Apicella A, et al. Evaluation of structural changes in epoxy systems by moisture sorption⁃desorption and dynamic mechanical studies[J]. Polymer composites, 1982,3(3):118⁃124. |

| 23 | Won J, Lee S, Kim Y, et al. The effect of exposure to alkaline solution and water on the strength–porosity relationship of GFRP rebar[J]. Composites Part B: Engineering, 2008,39(5):764⁃772. |

| 24 | PI Zhengyu, XIAO Huigang, DU Junjie, et al. Interfacial microstructure and bond strength of nano⁃SiO2⁃coated steel fibers in cement matrix[J]. Cement and Concrete Composites, 2019,103:1⁃10. |

| 25 | Eligehausen, R, Popov E, Bertero V. Local bond stress⁃slip relationships of deformed bars under generalized excitations: experimental results and analytical mode[J]. Earthquake Engineering Research Center, 1983:69⁃80. |

| 26 | Cosenza E, Manfredi G, Realfonzo R. Analytical modelling of bond between FRP reinforcing bars and concrete. Non⁃metallic (FRP) reinforcement for concrete structures[D]. Naples:University of Naples,1995. |

| 27 | Malvar L J. Bond stress⁃slip characteristics of FRP rebars[R]. Port Hueneme, California: Naval Facilities Engineering Service Center, 1994. |

| 28 | Cosenza E, Manfredi G, Realfonzo R. Behavior and modeling of bond of FRP rebars to concrete[J]. Journal of Composites for Construction, 1997,1(2):40⁃51. |

| 29 | Dejke V, Tepfers R. Durability and service life prediction of GFRP for concrete reinforcement[J]. FRPRCS-5: Fiber⁃reinforced Plastics for Reinforced Concrete Structures, 2001, 1:505⁃514. |

| 30 | Bulletin Fib 40.FRP Reinforcement in RC structures[Z].International Federation for Structural Concrete (fib), 2007:160. |

| [1] | 杨波, 杨圳, 曾辰, 王志刚, 翟伟, 曹福想. 基于循环载荷试验的聚乙烯管材寿命预测研究[J]. 中国塑料, 2022, 36(9): 63-69. |

| [2] | 张庭, 金清平, 宋仕娥, 曹南南, 邓思远. 不同腐蚀环境下FRP筋耐久性与寿命预测研究进展[J]. 中国塑料, 2022, 36(3): 75-81. |

| [3] | 金清平, 易建明, 高永红, 曹南南, 邓思远. 自然环境温度下碱对玻璃纤维增强塑料筋力学性能的影响研究[J]. 中国塑料, 2022, 36(2): 89-95. |

| [4] | 吴昆, 樊亚勤, 沈倩, 苗壮, 周城. 核电用聚四氟乙烯密封件老化状态研究及使用寿命预测[J]. 中国塑料, 2022, 36(10): 98-103. |

| [5] | 焦旗, 李瑞龙, 陈凑喜, 张守玉, 宋程鹏, 陈同海, 姜如愿, 郑鹏程. 基于三元复合抗氧剂体系煤基PP的使用寿命预测研究[J]. 中国塑料, 2022, 36(1): 15-24. |

| [6] | 赵兴民, 赵建平, 燕集中. 高密度聚乙烯管材光氧老化性能及寿命预测[J]. 中国塑料, 2021, 35(6): 33-39. |

| [7] | 谷亚新 赵梓怡. 基于BP神经网络算法的聚乙烯管材寿命预测[J]. 中国塑料, 2018, 32(07): 105-108. |

| [8] | 侯向陶, 许忠斌, 顾云柱. 塑料管道失效分析及寿命预测的研究进展[J]. 中国塑料, 2014, 28(07): 11-16 . |

| [9] | 王冰 李玲. 聚合物基复合材料吸湿性能研究进展[J]. 中国塑料, 2013, 27(02): 14-18 . |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2