京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2

《中国塑料》编辑部 ©2008-2024 版权所有

地址:北京市海淀区阜成路11号 邮编:100048

编辑部:010-68985541 联系信箱:cp@plaschina.com.cn

广告部/发行部:010-68985253 本系统由北京玛格泰克科技发展有限公司设计开发

中国塑料 ›› 2023, Vol. 37 ›› Issue (11): 24-34.DOI: 10.19491/j.issn.1001-9278.2023.11.004

收稿日期:2023-04-25

出版日期:2023-11-26

发布日期:2023-11-22

通讯作者:

袁鸿(1963—),男,教授,主要从事弹塑性力学、复合材料断裂力学、复合材料结构检测与补强加固、仪器仪表元件研究,tyuanhong@jnu.edu.cn作者简介:潘宏阳(1998—),男,硕士研究生,从事复合材料结构分析与损伤诊断研究,13383933434@163.com

PAN Hongyang1( ), CHEN Zongyong2, LIAO Tingmao2, YUAN Hong1,3(

), CHEN Zongyong2, LIAO Tingmao2, YUAN Hong1,3( )

)

Received:2023-04-25

Online:2023-11-26

Published:2023-11-22

Contact:

YUAN Hong

E-mail:13383933434@163.com;tyuanhong@jnu.edu.cn

摘要:

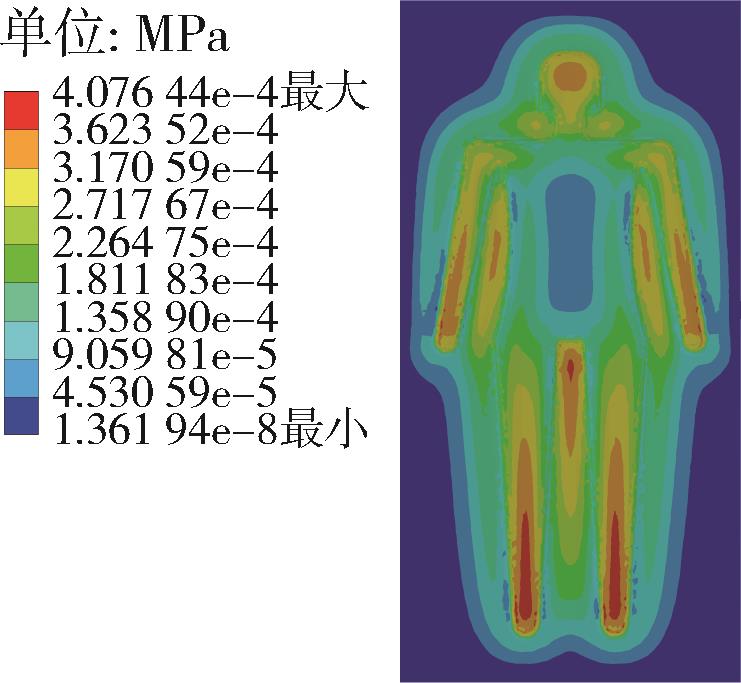

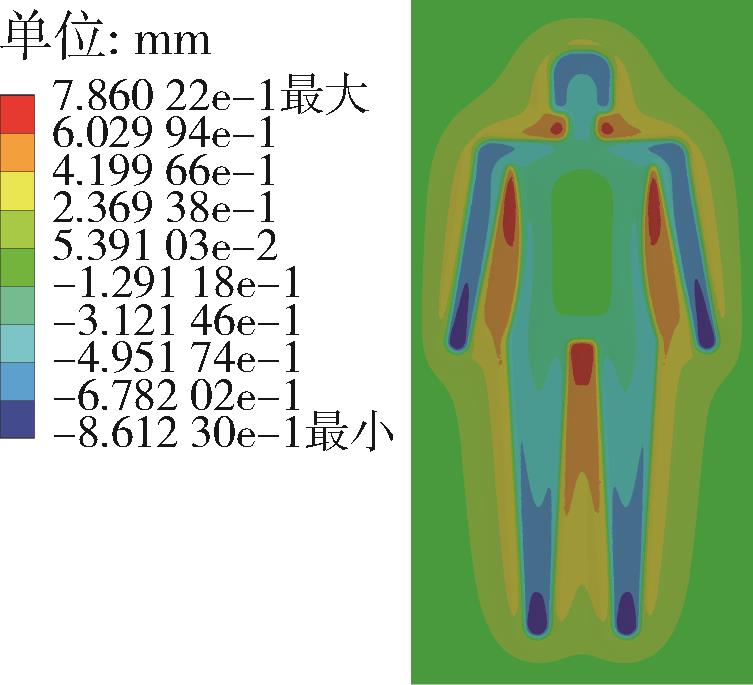

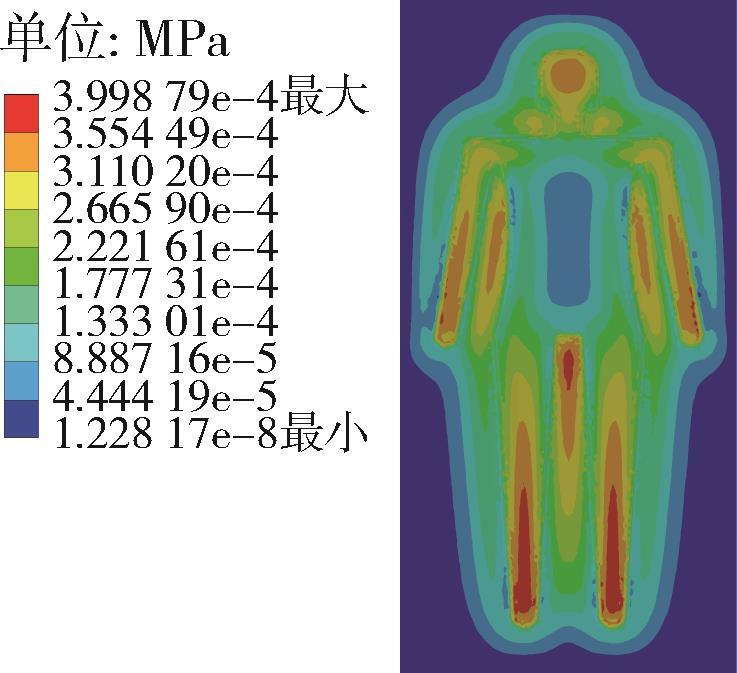

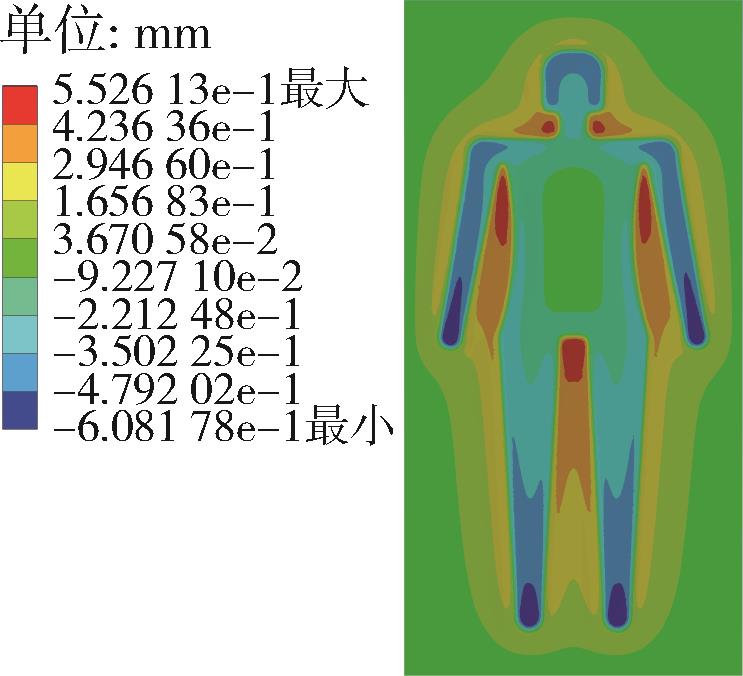

选择聚烯烃弹性体(POE)作为床垫的芯层材料,通过对POE试件进行静力学测试和疲劳耐久性测试,比较分析各试件的加载变形曲线,探讨POE的抗疲劳压缩性能、支撑性能影响因素。同时,选择二阶Ogden模型和三参数Mooney⁃Rivlin模型表征POE的非线性力学行为,简化人⁃床界面接触过程,利用有限元评估出POE床垫的减压性能。结果表明:POE的厚度、硬度损失两者之间无明显的几何关系,并未随着密度的增大显著增大,密度对最小静态缓冲系数影响不大;POE压缩系数大于2.8,硬度压力值达到0.77 N/cm2,满足不同重量的人对床垫材料的支撑要求;二阶Ogden模型和三参数Mooney⁃Rivlin模型具备预测POE材料大变形的能力,但三参数Mooney⁃Rivlin模型在描述小变形范围内存在不足;2种密度的POE床垫较于乳胶/山棕床垫应力传导均匀、层次分明,峰值压力减压百分比最高达94.11 %、94.23 %,足以满足日常生产生活的需要。

中图分类号:

潘宏阳, 陈宗勇, 廖廷茂, 袁鸿. 聚烯烃弹性体的力学性能及对床垫体压分布的影响[J]. 中国塑料, 2023, 37(11): 24-34.

PAN Hongyang, CHEN Zongyong, LIAO Tingmao, YUAN Hong. Mechanical properties of polyolefin elastomer and its effect on pressure distribution of mattress body[J]. China Plastics, 2023, 37(11): 24-34.

| POE试件 | C⁃1 | C⁃2 | C⁃3 | 平均值 | 标准差 |

|---|---|---|---|---|---|

| 低密度 | 73.56 | 73.62 | 73.64 | 73.61 | 0.04 |

| 高密度 | 75.30 | 77.76 | 76.28 | 77.11 | 1.59 |

| POE试件 | C⁃1 | C⁃2 | C⁃3 | 平均值 | 标准差 |

|---|---|---|---|---|---|

| 低密度 | 73.56 | 73.62 | 73.64 | 73.61 | 0.04 |

| 高密度 | 75.30 | 77.76 | 76.28 | 77.11 | 1.59 |

| 试件编号 | 质量/g | 密度/kg·m-3 | d1-d2/mm | H1/N | H2/N | ||

|---|---|---|---|---|---|---|---|

| D1⁃1 | 526.38 | 72.91 | 5.67 | 11.34 | 442.59 | 142.03 | 67.91 |

| D1⁃2 | 524.97 | 72.71 | 7.62 | 15.24 | 299.13 | 129.32 | 56.77 |

| 平均值 | 525.68 | 72.81 | 6.65 | 13.29 | 370.86 | 135.68 | 62.34 |

| 标准差 | 1.00 | 0.14 | 1.38 | 2.76 | 101.44 | 8.99 | 7.88 |

| D2⁃1 | 574.91 | 79.63 | 6.78 | 13.56 | 377.97 | 123.04 | 67.45 |

| D2⁃2 | 584.25 | 80.92 | 5.63 | 11.26 | 396.15 | 159.76 | 59.67 |

| D2⁃3 | 579.39 | 80.25 | 5.61 | 11.22 | 407.08 | 161.19 | 60.40 |

| 平均值 | 579.52 | 80.27 | 6.01 | 12.01 | 393.73 | 148.00 | 62.51 |

| 标准差 | 4.67 | 0.65 | 0.67 | 1.34 | 14.70 | 21.62 | 4.30 |

| 试件编号 | 质量/g | 密度/kg·m-3 | d1-d2/mm | H1/N | H2/N | ||

|---|---|---|---|---|---|---|---|

| D1⁃1 | 526.38 | 72.91 | 5.67 | 11.34 | 442.59 | 142.03 | 67.91 |

| D1⁃2 | 524.97 | 72.71 | 7.62 | 15.24 | 299.13 | 129.32 | 56.77 |

| 平均值 | 525.68 | 72.81 | 6.65 | 13.29 | 370.86 | 135.68 | 62.34 |

| 标准差 | 1.00 | 0.14 | 1.38 | 2.76 | 101.44 | 8.99 | 7.88 |

| D2⁃1 | 574.91 | 79.63 | 6.78 | 13.56 | 377.97 | 123.04 | 67.45 |

| D2⁃2 | 584.25 | 80.92 | 5.63 | 11.26 | 396.15 | 159.76 | 59.67 |

| D2⁃3 | 579.39 | 80.25 | 5.61 | 11.22 | 407.08 | 161.19 | 60.40 |

| 平均值 | 579.52 | 80.27 | 6.01 | 12.01 | 393.73 | 148.00 | 62.51 |

| 标准差 | 4.67 | 0.65 | 0.67 | 1.34 | 14.70 | 21.62 | 4.30 |

| 样品编号 | Mn | Sf | HA40 %/30 s/N | HB40 %/0 s/N | HC25 %/30 s/N | HC40 %/30 s/N | HC65 %/30 s/N |

|---|---|---|---|---|---|---|---|

| D1⁃1 | 13.13 | 3.36 | 292.06 | 313.25 | 257.85 | 381.94 | 825.65 |

| D1⁃2 | 13.05 | 4.19 | 312.96 | 335.05 | 243.09 | 365.98 | 849.16 |

| D1⁃3 | 13.44 | 3.86 | 320.55 | 346.49 | 273.96 | 424.39 | 931.39 |

| D2⁃1 | 13.66 | 3.46 | 454.50 | 492.16 | 402.12 | 595.66 | 1 377.76 |

| D2⁃2 | 13.39 | 3.40 | 502.48 | 542.12 | 447.57 | 662.68 | 1 414.88 |

| D2⁃3 | 11.30 | 3.29 | 411.52 | 443.06 | 361.63 | 559.22 | 1 176.62 |

| 样品编号 | Mn | Sf | HA40 %/30 s/N | HB40 %/0 s/N | HC25 %/30 s/N | HC40 %/30 s/N | HC65 %/30 s/N |

|---|---|---|---|---|---|---|---|

| D1⁃1 | 13.13 | 3.36 | 292.06 | 313.25 | 257.85 | 381.94 | 825.65 |

| D1⁃2 | 13.05 | 4.19 | 312.96 | 335.05 | 243.09 | 365.98 | 849.16 |

| D1⁃3 | 13.44 | 3.86 | 320.55 | 346.49 | 273.96 | 424.39 | 931.39 |

| D2⁃1 | 13.66 | 3.46 | 454.50 | 492.16 | 402.12 | 595.66 | 1 377.76 |

| D2⁃2 | 13.39 | 3.40 | 502.48 | 542.12 | 447.57 | 662.68 | 1 414.88 |

| D2⁃3 | 11.30 | 3.29 | 411.52 | 443.06 | 361.63 | 559.22 | 1 176.62 |

| 超弹性模型 | Mooney⁃Rivlin(三参数) | Ogden(N=2) | Yeoh(N=3) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 拟合参数 | C10 | C01 | C11 | R2 | u1 | α1 | u2 | α2 | R2 | C10 | C20 | C30 | R2 |

| 低密度试件 | 7 051.0 | -3 126.0 | 253.0 | 0.980 8 | 10 200.0 | 7.05 | 9 743.0 | -3.55 | 0.999 2 | 3 067.0 | -1 169.0 | 235.7 | 0.973 3 |

| 高密度试件 | 9 830.0 | -4 264.0 | 344.8 | 0.988 1 | 13 950.0 | 6.36 | 13 140.0 | -3.21 | 0.999 8 | 4 408.0 | -1 609.0 | 324.0 | 0.982 4 |

| 超弹性模型 | Mooney⁃Rivlin(三参数) | Ogden(N=2) | Yeoh(N=3) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 拟合参数 | C10 | C01 | C11 | R2 | u1 | α1 | u2 | α2 | R2 | C10 | C20 | C30 | R2 |

| 低密度试件 | 7 051.0 | -3 126.0 | 253.0 | 0.980 8 | 10 200.0 | 7.05 | 9 743.0 | -3.55 | 0.999 2 | 3 067.0 | -1 169.0 | 235.7 | 0.973 3 |

| 高密度试件 | 9 830.0 | -4 264.0 | 344.8 | 0.988 1 | 13 950.0 | 6.36 | 13 140.0 | -3.21 | 0.999 8 | 4 408.0 | -1 609.0 | 324.0 | 0.982 4 |

| 材料 | Ez/ MPa | υz | Exy/ MPa | υxy | G/ MPa | ρ/ kg·m-3 |

|---|---|---|---|---|---|---|

| 乳胶/山棕 | 0.070 | 0.024 | 10.151 | 0.424 | 0.107 | 162.6 |

| 材料 | Ez/ MPa | υz | Exy/ MPa | υxy | G/ MPa | ρ/ kg·m-3 |

|---|---|---|---|---|---|---|

| 乳胶/山棕 | 0.070 | 0.024 | 10.151 | 0.424 | 0.107 | 162.6 |

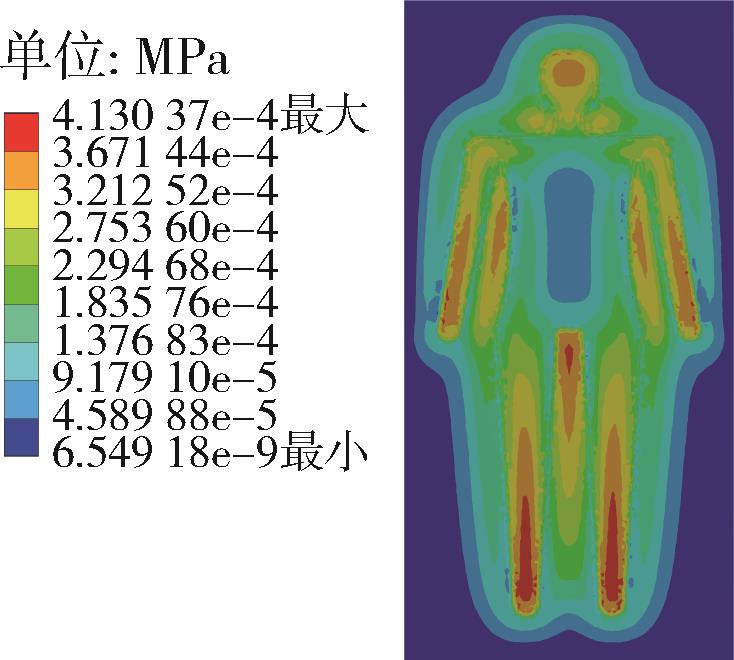

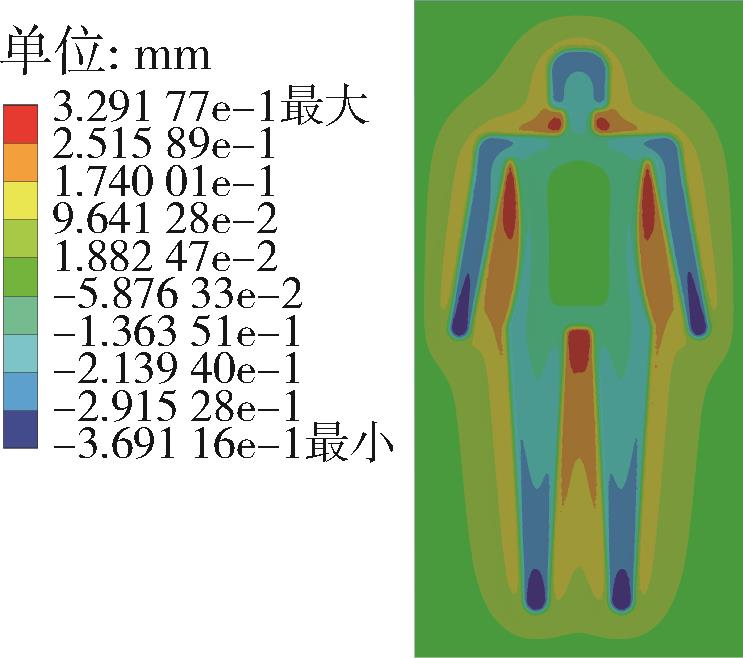

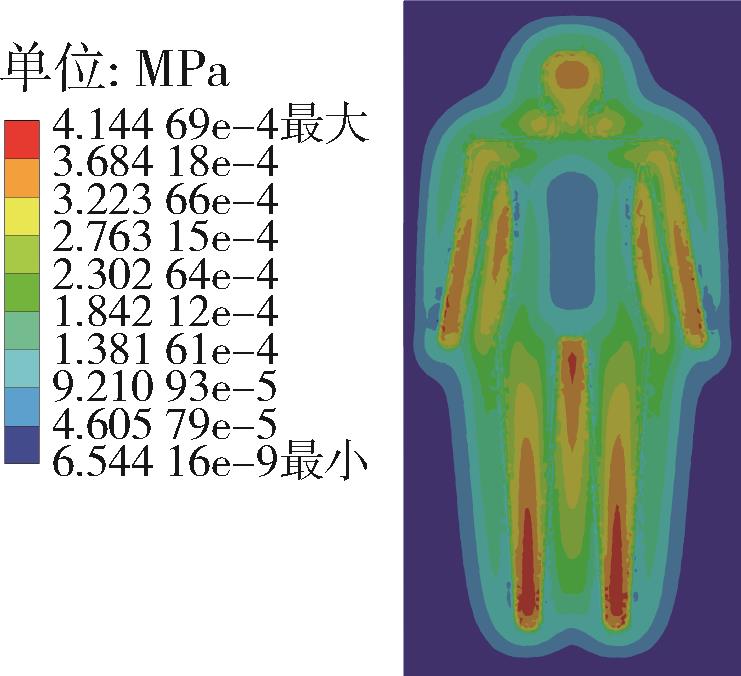

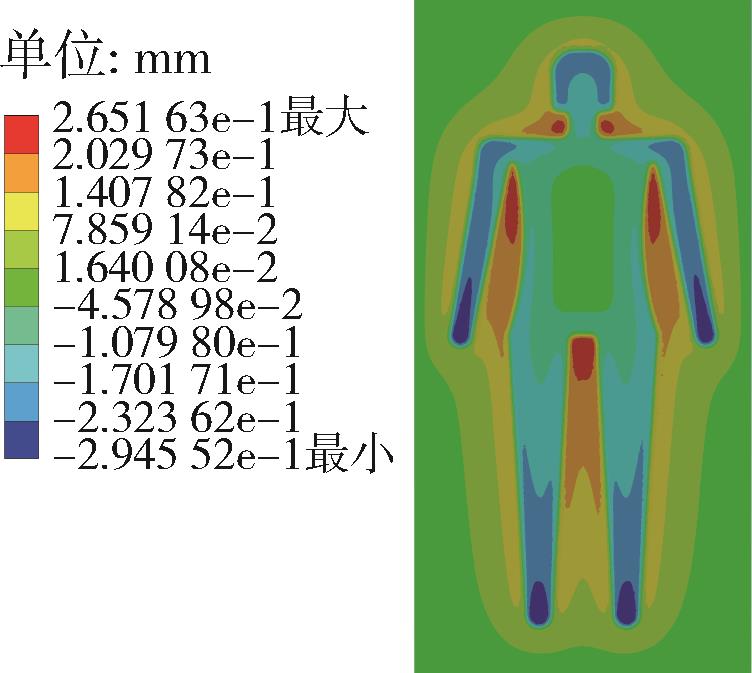

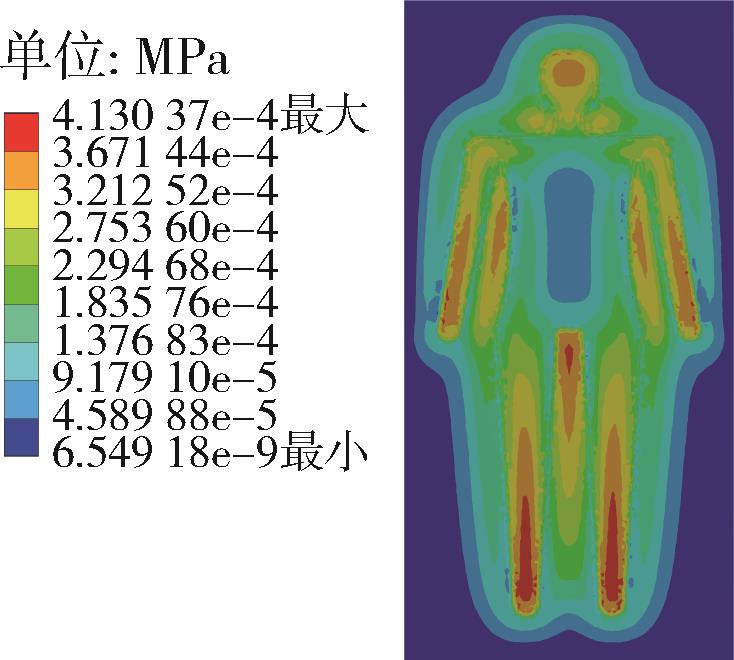

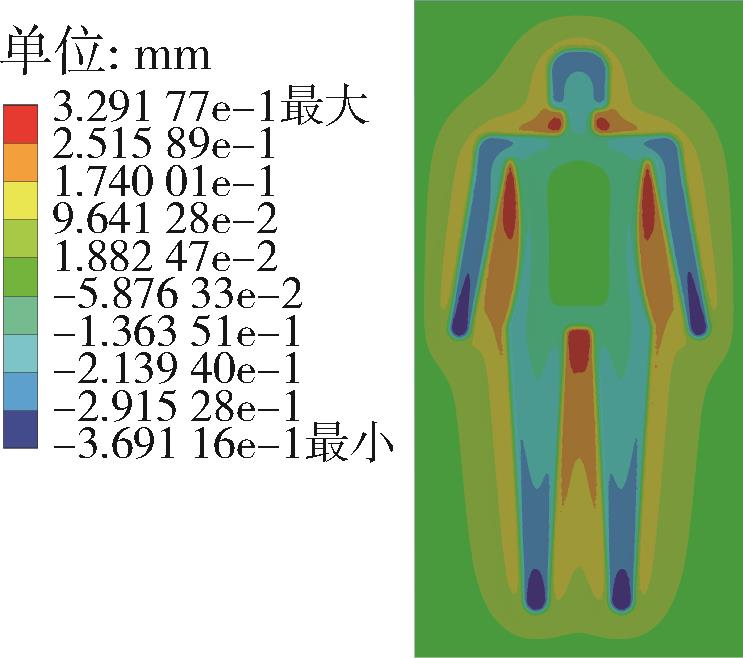

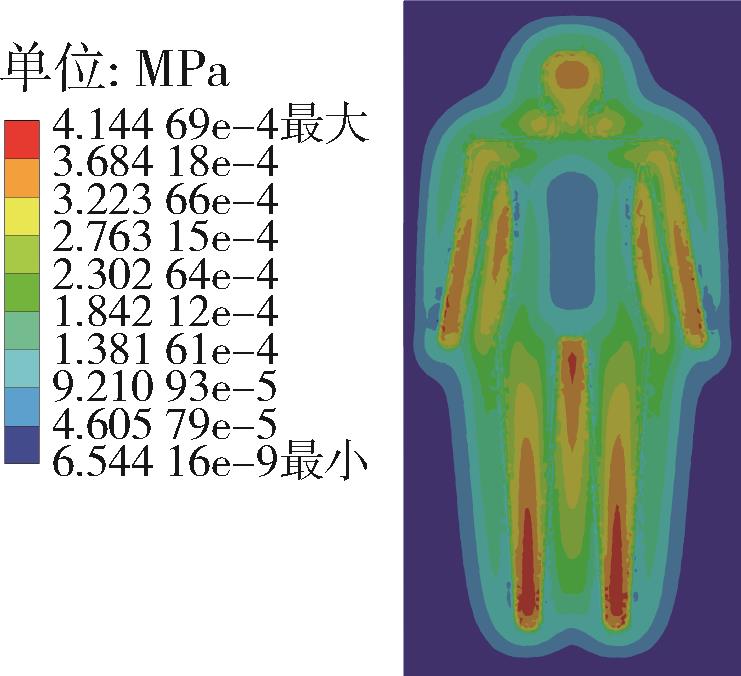

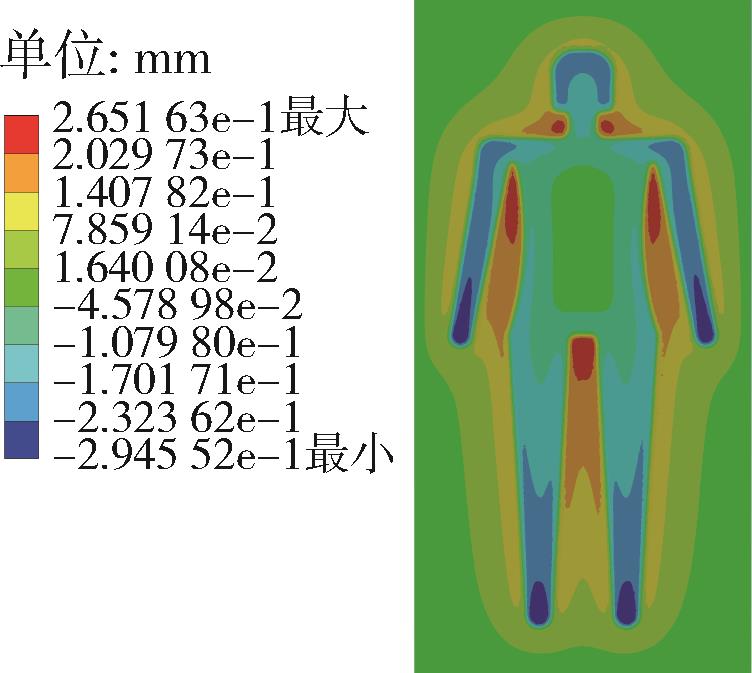

| 超弹性模型 | 低密度试件 | 高密度试件 | ||

|---|---|---|---|---|

| 体压分布 | 定向变形 | 体压分布 | 定向变形 | |

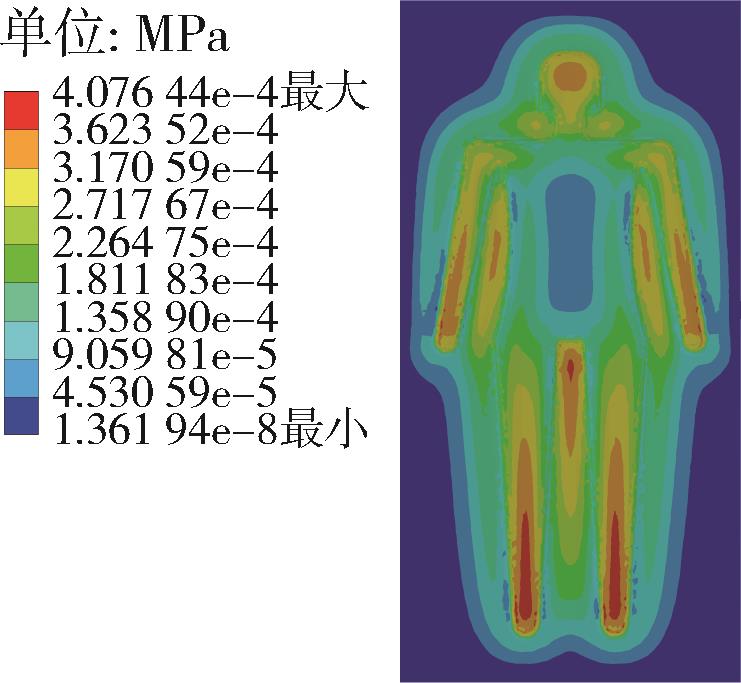

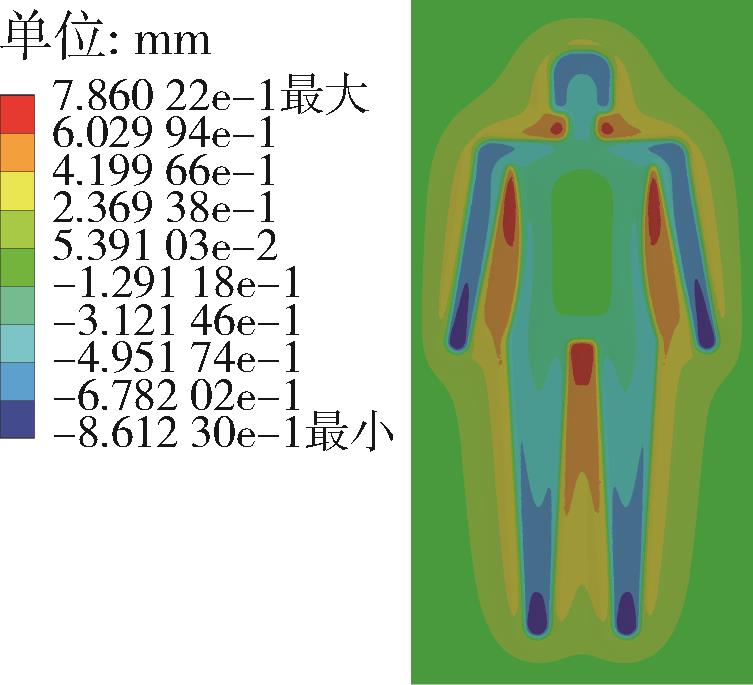

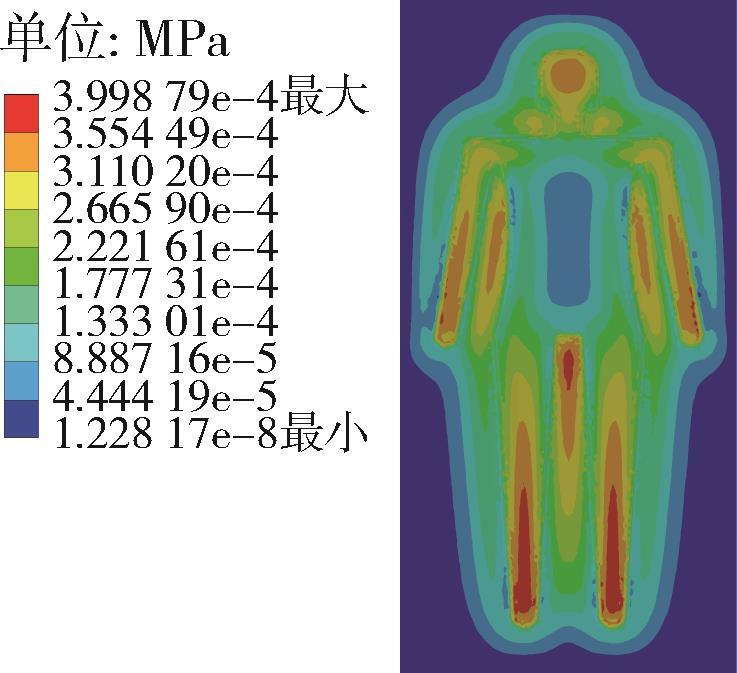

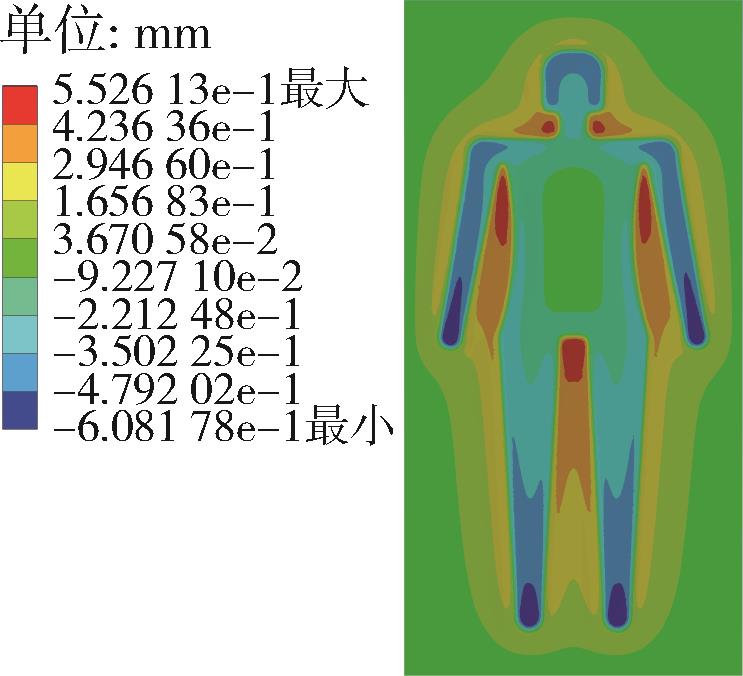

| 三参数Mooney⁃Rivlin模型 |  |  |  |  |

| 二阶Ogden模型 |  |  |  |  |

| 超弹性模型 | 低密度试件 | 高密度试件 | ||

|---|---|---|---|---|

| 体压分布 | 定向变形 | 体压分布 | 定向变形 | |

| 三参数Mooney⁃Rivlin模型 |  |  |  |  |

| 二阶Ogden模型 |  |  |  |  |

| 1 | Tonetti L, Martoni M, Natale V. Effects of different mattresses on sleep quality in healthy subjects: an actigraphic study[J]. Biological Rhythm Research, 2011, 42(2): 89⁃97. |

| 2 | Yu Hyunsoo, Oh⁃Soon Shin, Kim Sayup, et al. Effect of an inflatable air mattress with variable rigidity on sleep quality[J]. Sensors, 2020, 20(18): 5317. |

| 3 | Rebecca Robbins, Mahmoud Affouf, Azizi Seixas, et al. Four⁃year trends in sleep duration and quality: a longitudinal study using data from a commercially available sleep tracker[J]. Journal of Medical Internet Research, 2020, 22: 14735. |

| 4 | Scott Jonathon P R, McNaughton Lars R, Polman Remco C J. Effects of sleep deprivation and exercise on cognitive, motor performance and mood[J]. Physiology & Behavior, 2006, 87(2): 396⁃408. |

| 5 | Chen Zongyong, Li Yuqian, Liu Rong, et al. Effects of interface pressure distribution on human sleep quality[J]. PLOS One, 2014, 9(6): 99969. |

| 6 | Se Jin Park, Min Seung Nam, Murali Subramaniyam, et al. The evaluation of compatibility between human and mattress using EMG[C]//Advances in Human Aspects of Healthcare: Kraków, Poland, AHFE International, 2021:8 347⁃8 352. |

| 7 | Jacobson Bert H, Tia Wallace, Hugh Gemmell. Subjective rating of perceived back pain, stiffness and sleep quality following introduction of medium⁃firm bedding systems[J]. Journal of Chiropractic Medicine, 2006, 5(4): 128⁃134. |

| 8 | Lee Hyunja, Sejin Park. Quantitative effects of mattress types (comfortable vs. uncomfortable) on sleep quality through polysomnography and skin temperature[J]. International Journal of Industrial Ergonomics, 2006, 36(11): 943⁃949. |

| 9 | 赵欢,申黎明. 空气纤维材料床垫对人⁃床界面温度及人体热舒适的影响[J]. 家具, 2019, 40(4): 103⁃108. |

| ZHAO H, SHEN L M. The effect of air fiber materials mattress on human⁃mattress interface temperature and thermal comfort of human body[J]. Furniture, 2019, 40(4): 103⁃108. | |

| 10 | 王静,史永森,李亚玲,等. 聚烯烃弹性体催化剂研究进展[J]. 分子催化, 2020, 34(6): 579⁃591. |

| WANG J, SHI Y S, LI Y L, et al. The development of catalysts for polyolefin⁃based elastomer[J]. Journal of Molecular Catalysis(China), 2020, 34(6): 579⁃591. | |

| 11 | Zhao Xin⁃Tong, Yong⁃Feng Men. Fractionation of polyolefin elastomer by a modified SSA technique[J]. Chinese Journal of Polymer Science, 2022, 40(10): 1 252⁃1 258. |

| 12 | Zhang Heng, Meng Yuan, Cao Yufeng, et al. Form⁃stable phase change materials based on polyolefin elastomer and octadecylamine⁃functionalized graphene for thermal energy storage[J]. Nanotechnology, 2020, 31(24): 245402. |

| 13 | 吴薇,贾珺博,王文燕,等. 聚烯烃弹性体研究进展[J]. 弹性体, 2022, 32(4): 90⁃94. |

| WU W, JIA J B, WANG W Y, et al. Research progress of polyolefin elastomers[J]. China Elastomerics, 2022, 32(4): 90⁃94. | |

| 14 | 赵佳仪,门永锋. 聚烯烃弹性体的拉伸形变机理研究进展[J]. 中国科学:化学, 2018, 48(8): 894⁃901. |

| ZHAO J Y, MEN Y F. Progress in understanding of deformation mechanism of polyolefin elastomers during tensile stretching[J]. Scientia Sinica(Chimica), 2018, 48(8): 894⁃901. | |

| 15 | Choi Myung Chan, Jung Ji⁃Yeon, Chang Young⁃Wook. Shape memory thermoplastic elastomer from maleated polyolefin elastomer and nylon 12 blends[J]. Polymer Bulletin, 2014, 71(3): 625⁃635. |

| 16 | Min⁃Su Heo, Kim Tae⁃Hoon, Chang Young⁃Wook, et al. Near⁃infrared light⁃responsive shape memory polymer fabricated from reactive melt blending of semicrystalline maleated polyolefin elastomer and polyaniline[J]. Polymers, 2021, 13(22): 3984. |

| 17 | Bae Tae Soo,Ko Cheol Woong. Biomechanical effect of changes in bed positions and different types of mattresses in preventing decubitus ulcer[J]. Tissue Engineering and Regenerative Medicine, 2014, 11(1): 93⁃98. |

| 18 | Edlich Richard F, Winters Kathryne L, Woodard Charles R, et al. Pressure ulcer prevention[J]. Journal of Long⁃term Effects of Medical Implants, 2004, 14(4): 285⁃304. |

| 19 | De Vocht James W, Wilder David G, Bandstra Eric R, et al. Biomechanical evaluation of four different mattresses[J]. Applied Ergonomics, 2006, 37(3): 297⁃304. |

| 20 | 张宏玉,申黎明,房娇娇,等. TPEE空气纤维与普通海绵组合对床垫综合刚度的影响[J]. 家具, 2022, 43(2): 8⁃12, 18. |

| ZHANG H Y, SHEN L M, FANG J J, et al. The influence of combination of TPEE air fiber and common sponge on the comprehensive stiffness of mattress[J]. Furniture, 2022, 43(2): 8⁃12, 18. | |

| 21 | Cantournet S, Desmorat R, Besson J. Mullins effect and cyclic stress softening of filled elastomers by internal sliding and friction thermodynamics model[J]. International Journal of Solids and Structures, 2009, 46(11): 2 255⁃2 264. |

| 22 | 胡圣飞,陈祥星,李慧,等. 聚丙烯/木粉发泡材料的准静态压缩特性[J]. 高分子材料科学与工程, 2012, 28(11): 55⁃58. |

| HU S F, CHEN X X, LI H, et al. Quasi static compression characteristic of PP/wood flour foams[J]. Polymer Materials Science & Engineering, 2012, 28(11): 55⁃58. | |

| 23 | Casati F M, Herrington R M, Broos R, et al. Tailoring the performance of molded flexible polyurethane foams for car seats[J]. Journal of Cellular Plastics, 1998, 34(5): 430⁃466. |

| 24 | Shen Wenqi, Vértiz Alicia M. Redefining seat comfort[J]. Sae Transactions, 1997, 106: 1 066⁃1 073. |

| 25 | Wong D W C, Wang Y, Lin J, et al. Sleeping mattress determinants and evaluation: a biomechanical review and critique[J]. PeerJ, 2019:7. |

| 26 | Du Zhaoqun, Wu Yuanxin, Li Ming, et al. Analysis of structure of warp⁃knitted spacer fabric on pressure indices[J]. Fibers and Polymers, 2015, 16(11): 2 491⁃2 496. |

| 27 | 张涵茵,王柳,王玉龙. EPO材料缓冲性能的探究[J]. 包装工程, 2019, 40(21): 99⁃104. |

| ZHANG H Y, WANG L, WANG Y L. Cushioning performance of EPO materials[J]. Packaging Engineering, 2019, 40(21): 99⁃104. | |

| 28 | Qu Mingyue, Xia Fenglin, Fang Fangfang, et al. Influence of spacer filament fineness on indentation characterizations of warp⁃knitted spacer fabrics for mattresses[J]. Journal of Engineered Fibers and Fabrics, 2022, 17: 1⁃10. |

| 29 | 林玲,周雁红,张新昌. “齿形”结构EPS材料的等效厚度及静态缓冲性能研究[J]. 塑料工业, 2019, 47(11): 87⁃91. |

| LIN L, ZHOU Y H, ZHANG X C. Study on the equivalent thickness and static buffering performance of “tooth⁃shape” structure EPS foam[J]. China Plastics Industry, 2019, 47(11): 87⁃91. | |

| 30 | Junho Moon,Sinha Tridib Kumar,Kwak Sung Bok, et al. Study on seating comfort of polyurethane multilayer seat cushions[J]. International Journal of Automotive Technology, 2020, 21(5): 1 089⁃1 095. |

| 31 | Kreter P E. Polyurethane foam physical properties as a function of foam density[J]. Journal of Cellular Plastics, 1985, 21(5): 306⁃310. |

| 32 | Liu Yanping, Hu Hong. An experimental study of compression behavior of warp⁃knitted spacer fabric[J]. Journal of Engineered Fibers and Fabrics, 2014, 9(2): 61⁃69. |

| 33 | Chaves Eduardo W V. Notes on continuum mechanics[M]: Springer Science & Business Media, 2013:423⁃462. |

| 34 | Peng Xiangfeng, Han Lei, Li Luxian. A consistently compressible model for the vulcanized rubber based on the Penn's experimental data[J]. Polymer Engineering and Science, 2021, 61(9): 2 287⁃2 294. |

| 35 | Ehret A E, Stracuzzi A. Variations on Ogden’s model: close and distant relatives[J]. Philosophical Transactions of the Royal Society A: Mathematical, Physical and Engineering Sciences, 2022, 380:2234. |

| 36 | Zhou Wei, Wang Chengwen, Fan Peng, et al. The sealing effect improvement prediction of flat rubber ring in roller bit based on yeoh_revised model[J]. Materials, 2022, 15(16): 5529. |

| 37 | Szabolcs Berezvai, Attila Kossa. Closed⁃form solution of the Ogden⁃Hill’s compressible hyperelastic model for ramp loading[J]. Mechanics of Time⁃dependent Materials, 2017, 21(2): 263⁃286. |

| 38 | 胡小玲,刘秀,李明,等. 炭黑填充橡胶超弹性本构模型的选取策略[J]. 工程力学, 2014, 31(5): 34⁃42, 48. |

| HU X L, LIU X, LI M, et al. Selection strategies of hyperelastic constitutive models for carbon black filled rubber[J]. Engineering Mechanics, 2014, 31(5): 34⁃42, 48. | |

| 39 | 李雪冰,危银涛. 一种改进的Yeoh超弹性材料本构模型[J]. 工程力学, 2016, 33(12): 38⁃43. |

| LI X B, WEI Y T. An improved Yeoh constitutive model for hyperelastic material[J]. Engineering Mechanics, 2016, 33(12): 38⁃43. | |

| 40 | Melly Stephen Kirwa, Liu Liwu, Liu Yanju, et al. Modified Yeoh model with improved equibiaxial loading predictions[J]. Acta Mechanica, 2022, 233(2): 437⁃453. |

| 41 | 王鹭,付宾,杨晓翔. 炭黑填充天然橡胶Mullins效应的仿真与计算分析[J]. 计算力学学报, 2017, 34(3): 372⁃378. |

| WANG L, FU B, YANG X X. Numerical simulation and analysis of carbon⁃reinforced rubber's Mullins effect[J]. Chinese Journal of Computational Mechanics, 2017, 34(3): 372⁃378. | |

| 42 | Fan⁃Zhe Low,Chua Matthew Chin⁃Heng, Pan⁃Yin Lim, et al. Effects of mattress material on body pressure profiles in different sleeping postures[J]. Journal of Chiropractic Medicine, 2017, 16(1): 1⁃9. |

| [1] | 陈晖, 孙玲胜, 钱伟栋, 谭博. 选择性激光烧结聚醚砜树脂/碳纤维/炭黑复合材料的性能研究[J]. 中国塑料, 2023, 37(9): 14-18. |

| [2] | 梅园, 李振, 徐禄波, 麻一明. 再生PCTG增韧改性再生PET的性能研究[J]. 中国塑料, 2023, 37(9): 39-43. |

| [3] | 邓卫娟, 王桥, 胡伟, 杨帆, 惠湛. 缓黏结预应力钢绞线用胶黏剂配方试验研究[J]. 中国塑料, 2023, 37(9): 51-56. |

| [4] | 李红波, 杨睿, 苏正涛. 不同硬质增强填料对PTFE性能的影响[J]. 中国塑料, 2023, 37(8): 13-19. |

| [5] | 杜乐, 胡娅洁, 胡健, 孙滔, 云雪艳, 董同力嘎. UV固化制备聚(L⁃乳酸)/壳聚糖薄膜及其热学、力学及抑菌性能研究[J]. 中国塑料, 2023, 37(8): 38-44. |

| [6] | 陈豪 吴志强 姜启运 沈春晖 高山俊. 聚乳酸/聚己二酸对苯二甲酸丁二醇酯共混发泡材料的制备及性能研究[J]. , 2023, 37(7): 1-8. |

| [7] | 廉萌 童发钦 赵飞 刘军 杨永启 郑凤. 玻璃粉复合聚酰亚胺薄膜的制备及性能研究[J]. , 2023, 37(7): 47-52. |

| [8] | 吴加俊 曾佳 刘缓缓 朱民 倪忠斌 施冬健 陈明清. 釜式发泡制备氢化苯乙烯-异戊二烯-苯乙烯/聚丙烯发泡珠粒及其性能研究[J]. , 2023, 37(6): 43-49. |

| [9] | 郑兴博 李佳汶 李子辉 韩文娟 蒋晶 王小峰 李倩. 氮化硼改性超高分子量聚乙烯的摩擦学性能研究[J]. , 2023, 37(5): 28-33. |

| [10] | 于盛睿 刘钦迪 徐磊 骆杰 吴辉庭 韩文 邹佳勇 周华民. 双面覆膜与纤维含量对MIM/IMD工艺翘曲变形及力学性能的影响[J]. , 2023, 37(5): 55-61. |

| [11] | 顾建国 孙建凯 侯培培 何浩 焦文亮. 双轴取向聚氯乙烯管材解取向研究[J]. , 2023, 37(4): 35-38. |

| [12] | 韩阳阳 杨晓炯 张贵恩 董春雨 张小刚. 导电橡胶力学性能和耐高温性能研究[J]. , 2023, 37(3): 24-29. |

| [13] | 董竞辉, 桑晓明, 陈祯, 尹伟浩, 姜骞, 陈兴刚. 短切碳纤维对聚苯腈/碳纤维复合材料性能的影响[J]. 中国塑料, 2023, 37(2): 31-37. |

| [14] | 陈晖, 钱伟栋, 孙玲胜, 谭博. 纳米二氧化硅含量对PES基激光烧结件表面质量和力学性能的影响[J]. 中国塑料, 2023, 37(11): 10-14. |

| [15] | 马秀清, 劳志超, 李明谦, 韩顺涛, 胡楠. 螺杆构型对PLA/PTW共混物性能影响的研究[J]. 中国塑料, 2023, 37(11): 127-134. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2