京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2

《中国塑料》编辑部 ©2008-2024 版权所有

地址:北京市海淀区阜成路11号 邮编:100048

编辑部:010-68985541 联系信箱:cp@plaschina.com.cn

广告部/发行部:010-68985253 本系统由北京玛格泰克科技发展有限公司设计开发

中国塑料 ›› 2024, Vol. 38 ›› Issue (4): 79-87.DOI: 10.19491/j.issn.1001-9278.2024.04.013

收稿日期:2023-09-11

出版日期:2024-04-26

发布日期:2024-04-22

通讯作者:

豆义波(1987-),男,副教授,从事废弃塑料资源化回收, douyb@buct.edu.cn基金资助:

HU Yanqing1, HU Fan1, ZHOU Jianchi1, DOU Yibo1,2( )

)

Received:2023-09-11

Online:2024-04-26

Published:2024-04-22

Contact:

DOU Yibo

E-mail:douyb@buct.edu.cn

摘要:

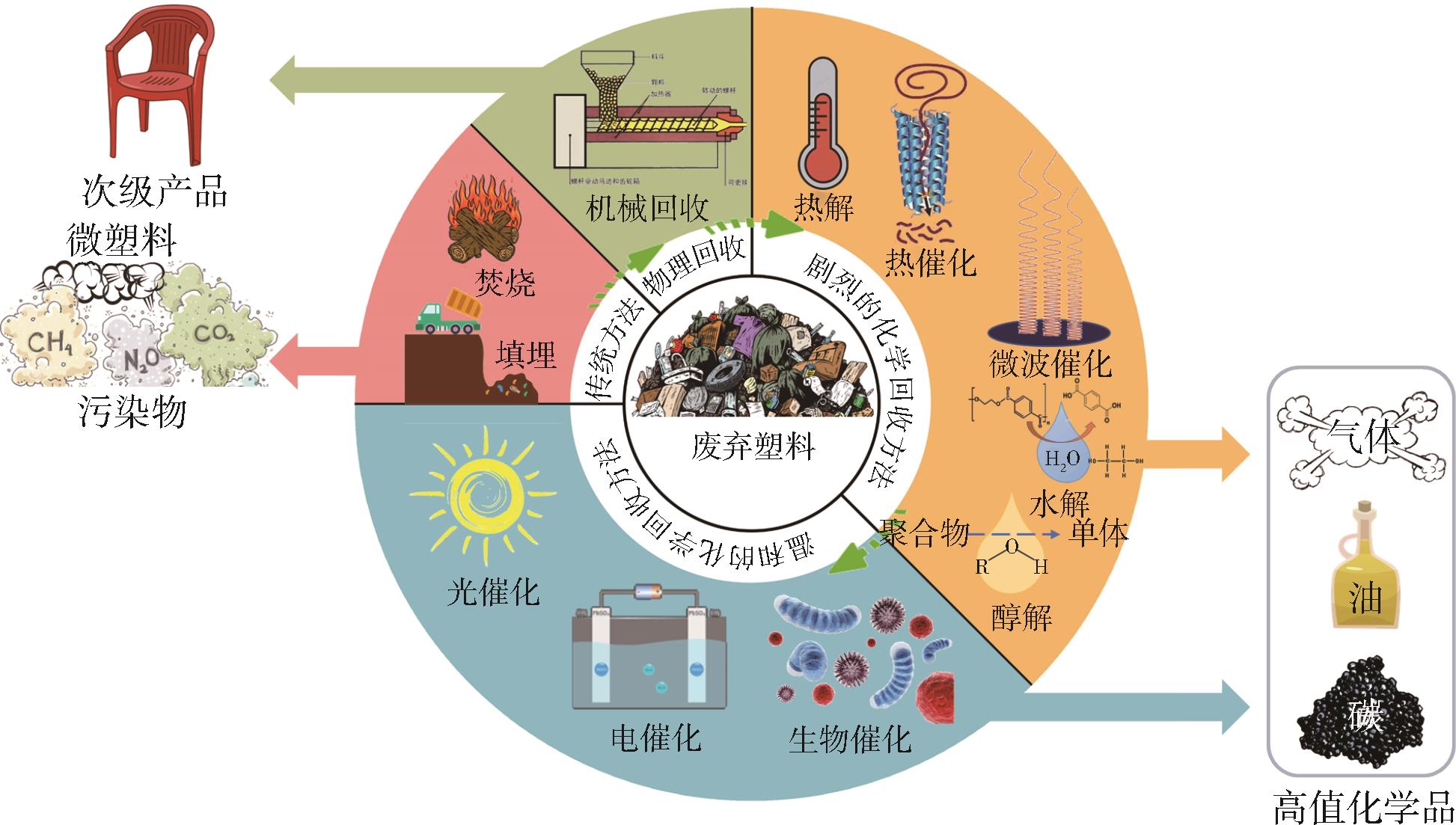

综述了塑料在传统物理机械回收和当前研究热点化学升级转化的成果,重点对化学催化方法包括热催化、微波催化、生物催化、电催化、光催化等具有潜在应用前景的方法进行了阐述。系统介绍了化学升级转化塑料,特别是催化转化中核心催化剂的设计构筑、催化产物种类、产率和选择性的调控以及构效关系的机理揭示。此外,通过对比各类方法探讨了优缺点、总结了相关方法面临的问题。最后,基于目前废旧塑料回收存在的挑战和后期发展方向提出了建议,以期为废弃塑料回收为高附加值化学品提供理论指导。

中图分类号:

胡延庆, 胡凡, 周剑池, 豆义波. 废弃塑料回收与转化的研究进展[J]. 中国塑料, 2024, 38(4): 79-87.

HU Yanqing, HU Fan, ZHOU Jianchi, DOU Yibo. Research progress in upcycling of waste plastics[J]. China Plastics, 2024, 38(4): 79-87.

| 方法 | 反应条件 | 产物 | 效率和产率 | 产物选择性 | |

|---|---|---|---|---|---|

| 传统方法 | 填埋 | 常温常压 | — | — | — |

| 焚烧 | CO2、大量污染物 | — | — | ||

| 物理回收 | 机械回收 | 加热、熔融等 | 次级产品 | — | — |

| 剧烈的化学回收 | 热解 | 高温高压 | 短链烯烃、氢气、单体、油、焦炭等 | 效率较高、产率较高 | 较低 |

| 催化热解 | 效率高、产率高 | 较高 | |||

| 微波催化 | 效率极高、产率极高 | 高 | |||

| 水解醇解 | 效率较高、产率较高 | 较高 | |||

| 温和的化学回收 | 生物催化 | 常温常压 | 氢气、单体、小分子有机酸等 | 效率高、产率高 | 高 |

| 电催化 | 效率较低、产率较低 | 高 | |||

| 光催化 | 效率较低、产率较低 | 高 | |||

| 方法 | 反应条件 | 产物 | 效率和产率 | 产物选择性 | |

|---|---|---|---|---|---|

| 传统方法 | 填埋 | 常温常压 | — | — | — |

| 焚烧 | CO2、大量污染物 | — | — | ||

| 物理回收 | 机械回收 | 加热、熔融等 | 次级产品 | — | — |

| 剧烈的化学回收 | 热解 | 高温高压 | 短链烯烃、氢气、单体、油、焦炭等 | 效率较高、产率较高 | 较低 |

| 催化热解 | 效率高、产率高 | 较高 | |||

| 微波催化 | 效率极高、产率极高 | 高 | |||

| 水解醇解 | 效率较高、产率较高 | 较高 | |||

| 温和的化学回收 | 生物催化 | 常温常压 | 氢气、单体、小分子有机酸等 | 效率高、产率高 | 高 |

| 电催化 | 效率较低、产率较低 | 高 | |||

| 光催化 | 效率较低、产率较低 | 高 | |||

| 1 | 陈 欢, 万 坤, 牛 波, 等. 废弃塑料化学回收及升级再造研究进展 [J]. 化工进展, 2022, 41(3): 1 453⁃1 469. |

| CHEN H, WAN K, NIU B, et al. Recent progresses in chemical recycling and upcycling of waste plastics [J]. Chemical Industry and Engineering Progress, 2022, 41(3): 1 453⁃1 469. | |

| 2 | 徐丽洁,刘豪杰,薛 瑞,等. 多学科交叉助力废塑料生物法循环回收利用 [J]. 化工进展, 2022, 41(9): 5 029⁃5 036. |

| XU L J, LIU H J, XUE R, et al. Interdisciplinary assistance for biological recycling of waste plastics [J]. Chemical Industry and Engineering Progress, 2022, 41(9): 5 029⁃5 036. | |

| 3 | 刘文璐, 张晓红,乔金樑. 废塑料化学回收技术研究进展 [J]. 塑料工业, 2022, 50(9): 1⁃7. |

| LIU W L, ZHANG X H, QIAO J L. Research progress on chemical recycling technologies of waste plastics [J]. China Plastics Industry, 2022, 50(9): 1⁃7. | |

| 4 | 范炜亮,王克俭. 塑料包装废弃物的回收利用 [J]. 塑料包装, 2021, 31(1): 53⁃57. |

| FAN W L, WANG K J. Recovery and utilization of plastic packaging waste [J]. Plastics Packaging, 2021, 31(1): 53⁃57. | |

| 5 | 张雅珊, 陈宗耀,马伟芳. 微塑料的迁移转化及其生态风险研究进展 [J]. 化工进展, 2022, 41(11): 6 080⁃6 098. |

| ZHANG Y S, CHEN Z W, MA W F.Research progress on the migration and transformation of microplastics and environmental risks [J]. Chemical Industry and Engineering Progress, 2022, 41(11): 6 080⁃6 098. | |

| 6 | 吴 娜. 生活垃圾填埋过程中溴代阻燃剂的污染释放特征研究 [D]. 青岛: 青岛理工大学. 2019. |

| 7 | 张国义,杨秀成. 浅析塑料对环境和公众健康的影响 [J]. 皮革制作与环保科技, 2022, 3(15): 149⁃150,157. |

| ZHANG G Y, YANG X C. Influence of plastics on environment and public health [J]. Leather Manufacture and Environmental Technology, 2022, 3(15): 149⁃150,157. | |

| 8 | Velis C A, Cook E. Mismanagement of plastic waste through open burning with emphasis on the global south: a systematic review of risks to occupational and public health [J]. Environmental Science & Technology, 2021, 55(11): 7 186⁃7 207. |

| 9 | 朱桂丹, 陕 洁, 尹 绚, 等. 塑料废弃物的管理及资源化利用 [J]. 广东化工, 2021, 48(16): 170⁃172. |

| ZHU G D, SHAN J, YIN X, et al. Plastics waste management and its resource utilization [J]. Guangdong Chemical Industry, 2021, 48(16): 170⁃172. | |

| 10 | Chu M, Tu W, Yang S, et al. Sustainable chemical upcycling of waste polyolefins by heterogeneous catalysis [J]. SusMat, 2022, 2(2): 161⁃185. |

| 11 | 汪作仑. PET废料的回收利用方法 [J]. 节能与环保, 2006(8): 38⁃40. |

| WANG Z L, PET waste recycling methods [J]. Energy Conservation and Environmental Protection, 2006(8): 38⁃40. | |

| 12 | Majumdar A, Shukla S, Singh A A, et al. Circular fashion: properties of fabrics made from mechanically recycled poly⁃ethylene terephthalate (PET) bottles [J]. Resources, Conservation and Recycling, 2020, 161: 104915. |

| 13 | Poulakis J G, Papaspyrides C D. Dissolution/reprecipitation: a model process for PET bottle recycling [J]. Journal of Applied Polymer Science, 2001, 81(1): 91⁃95. |

| 14 | 阮浩达. 废弃热固性聚氨酯回收再生制备及试验研究 [D]. 合肥: 安徽建筑大学. 2022. |

| 15 | 朱道平. 塑料包装废弃物回收处理途径及新进展 [J]. 中国包装, 2009, 29(4): 28⁃31. |

| ZHU D P. Plastic packaging waste recycling and treatment ways and new developments [J]. China Packaging, 29(4): 28⁃31. | |

| 16 | 田 朋. 超亚临界甲醇及其共溶剂体系中PET(催化)解聚研究 [D]. 杭州: 浙江工业大学, 2008. |

| 17 | DAI X X, New progress of pet bottles recycling technology [J]. Synthetic Fiber in China, 2007(8): 35⁃37. |

| 18 | Jie X, Li W, Slocombe D, et al. Microwave⁃initiated catalytic deconstruction of plastic waste into hydrogen and high⁃value carbons [J]. Nature Catalysis, 2020, 3(11): 902⁃912. |

| 19 | Klaimy S, Lamonier J F, Casetta M, et al. Recycling of plastic waste using flash pyrolysis⁃effect of mixture composition [J]. Polymer Degradation and Stability, 2021, 187: 109540. |

| 20 | Chang S H. Plastic waste as pyrolysis feedstock for plastic oil production: a review [J]. Science of the Total Environment, 2023, 877: 162719. |

| 21 | Li D, Lei S, Wang P, et al. Study on the pyrolysis behaviors of mixed waste plastics [J]. Renewable Energy, 2021, 173: 662⁃674. |

| 22 | Chaudhary A, Lakhani J, Dalsaniya P, et al. Slow pyrolysis of low⁃density poly⁃ethylene (LDPE): a batch experiment and thermodynamic analysis [J]. Energy, 2023, 263(B): 125810. |

| 23 | Soni V K, Singh G, Vijayan B K, et al. Thermochemical recycling of waste plastics by pyrolysis: a review [J]. Energy & Fuels, 2021, 35(16): 12 763⁃12 808. |

| 24 | Al⁃Salem S M, Dutta A. Wax recovery from the pyrolysis of virgin and waste plastics [J]. Industrial & Engineering Chemistry Research, 2021, 60(22): 8 301⁃8 309. |

| 25 | Herklotz A, Schwarz T, Haberland J. Stoffliche verwertung polyolefinischer kunststoffabfälle durch thermolyse [J]. Chemie Ingenieur Technik, 2014, 86(9): 1 359⁃1 359. |

| 26 | Kunwar B, Cheng H N, Chandrashekaran S R, et al. Plastics to fuel: a review [J]. Renewable and Sustainable Energy Reviews, 2016, 54(4): 421⁃428. |

| 27 | Miandad R, Barakat M A, Aburiazaiza A S, et al. Catalytic pyrolysis of plastic waste: a review [J]. Process Safety and Environmental Protection, 2016, 102: 822⁃838. |

| 28 | Dong Q, Lele A D, Zhao X, et al. Depolymerization of plastics by means of electrified spatiotemporal heating [J]. Nature, 2023, 616(7957): 488⁃494. |

| 29 | 孙艺蕾,马 跃,李术元,等. 聚烯烃塑料的热解和催化热解研究进展 [J]. 化工进展, 2021, 40(5): 2 784⁃2 801. |

| SUN Y L, MA Y, LI S Y, et al. Research progress in the pyrolysis and catalytic pyrolysis of waste polyolefin plastics [J]. Chemical Industry and Engineering Progress, 2021, 40(5): 2 784⁃2 801. | |

| 30 | Zheng K, Wu Y, Hu Z, et al. Progress and perspective for conversion of plastic wastes into valuable chemicals [J]. Chemical Society Reviews, 2023, 52(1): 8⁃29. |

| 31 | 肖皓宇,杨海平,张 雄,等. 塑料催化热解制备高附加值产品的研究进展 [J]. 化工学报, 2022, 73(8): 3 461⁃3 471. |

| XIAO H Y, YANG H P, ZHANG X, et al. Recent progress of catalytic pyrolysis of plastics to produce high value⁃added products [J]. CIESC Journal, 2022, 73(8): 3 461⁃3 471. | |

| 32 | Peng Y, Wang Y, Ke L, et al. A review on catalytic pyrolysis of plastic wastes to high⁃value products [J]. Energy Conversion and Management, 2022, 254: 115243. |

| 33 | Wang Z, Wang H. Mechanistic diversity of transfer hydrogenolysis over noble metal nanocatalysts: Pt⁃ and Ru⁃Catalyzed Azo⁃Hydrogenolysis by various hydrogen donors [J]. The Journal of Physical Chemistry C, 2022, 126(40): 17 102⁃17 113. |

| 34 | 魏 晗,刘明杰,周 航,等. 废弃聚烯烃塑料催化裂解为燃料的研究进展 [J]. 工业催化, 2022, 30(8): 1⁃10. |

| WEI H, LIU M J, ZHOU H, et al. Progress on catalytic cracking of waste polyolefin plastics to product fuels [J]. Industrial Catalysis, 2022, 30(8): 1⁃10. | |

| 35 | Mason A H, Motta A, Das A, et al. Rapid atom⁃efficient polyolefin plastics hydrogenolysis mediated by a well⁃defined single⁃site electrophilic/cationic organo⁃zirconium catalyst [J]. Nature Communications, 2022, 13(1): 7 187. |

| 36 | Wu X, Tennakoon A, Yappert R, et al. Size⁃controlled nanoparticles embedded in a mesoporous architecture leading to efficient and selective hydrogenolysis of polyolefins [J]. Journal of the American Chemical Society, 2022, 144(12): 5 323⁃5 334. |

| 37 | Zhang F, Zeng M, Yappert R D, et al. Polyethylene upcycling to long⁃chain alkylaromatics by tandem hydrogenolysis/aromatization [J]. Science, 2020, 370(6515): 437⁃441. |

| 38 | Li R, Zhang Z, Liang X, et al. Polystyrene waste thermochemical hydrogenation to ethylbenzene by a N⁃bridged Co, Ni dual⁃Atom catalyst [J]. Journal of the American Chemical Society, 2023, 145(29): 16 218⁃16 227. |

| 39 | Qiu Z, Lin S, Chen Z, et al. A reusable, impurity⁃tolerant and noble metal⁃free catalyst for hydrocracking of waste polyolefins [J]. Science Advances, 2023, 9(25): 5 332. |

| 40 | 刘 楠, 胡一铭, 杨 颖, 等. 废旧聚丙烯/活性炭微波共裂解制取可燃裂解气与轻质裂解油 [J]. 化工进展, 2022, 41(z1): 150⁃159. |

| LIU N, HU Y M, YANG Y, et al. Microwave assisted co⁃pyrolysis of waste polypropylene /activated carbon to produce combustible pyrolysis gas and light pyrolysis oil [J]. Chemical Industry and Engineering Progress, 2022, 41(z1): 150⁃159. | |

| 41 | 涂 鑫,周艳萍,黄卡玛. 微波辅助催化裂解废弃塑料制氢的研究 [J]. 真空电子技术, 2023(1): 69⁃74,94. |

| TU X, ZHOU Y P, HUANG K M, Study on hydrogen production from plastic wastes by microwave assisted catalytic cracking [J], Vacuum Electronic, 2023 (1): 69⁃74,94. | |

| 42 | Yuan Z, Yang J, Manos G, et al. Microwave catalytic depolymerization of polyethylene terephthalate plastic to the monomers [J]. CCS Chemistry, 2023(12):2 818⁃2 831. |

| 43 | Yao L, Yi B, Zhao X, et al. Microwave⁃assisted decomposition of waste plastic over Fe/FeAl2O4 to produce hydrogen and carbon nanotubes [J]. Journal of Analytical and Applied Pyrolysis, 2022, 165: 105577. |

| 44 | 申传超. 典型过渡金属有机配合物在催化醇解PET中的应用基础研究 [D]. 北京: 北京化工大学. 2022. |

| 45 | 李志斌,唐 辉,罗大伟,等. 废弃PET化学回收及制备不饱和聚酯树脂的研究进展 [J]. 化工进展, 2022, 41(6): 3 279⁃3 292. |

| LI Z B, TANG H, LUO D W, et al. Progress in chemical recycling of waste PET and preparation of unsaturated polyester resins [J]. Chemical Industry and Engineering Progress, 2022, 41(6): 3 279⁃3 292. | |

| 46 | George N, Kurian T. Recent developments in the chemical recycling of postconsumer poly(ethylene terephthalate) waste [J]. Industrial & Engineering Chemistry Research, 2014, 53(37): 14 185⁃14 198. |

| 47 | Wang Y, Wang H, Chen H, et al. Towards recycling purpose: converting PET plastic waste back to terephthalic acid using pH⁃responsive phase transfer catalyst[J]. Chinese Journal of Chemical Engineering, 2022, 51: 53⁃60. |

| 48 | Campanelli J R, Cooper D G, Kamal M R. Catalyzed hydrolysis of polyethylene terephthalate melts [J]. Journal of Applied Polymer Science, 1994, 53(8): 985⁃991. |

| 49 | Ügdüler S, Van Geem K M, Denolf R, et al. Towards closed⁃loop recycling of multilayer and coloured PET plastic waste by alkaline hydrolysis [J]. Green Chemistry, 2020, 22(16): 5 376⁃5 394. |

| 50 | Zhang Y, Jiang H, Du Y, et al. Surface alcoholysis induced by alkali⁃activation ethanol: a novel scheme for binary flotation of polyethylene terephthalate from other plastics [J]. Journal of Cleaner Production, 2021, 314: 128096. |

| 51 | 张 良. 废聚氨酯硬泡醇解回收多元醇初步研究 [D]. 重庆: 重庆大学. 2012. |

| 52 | 徐 惠,熊 峰,彭振军,等. 响应面法优化废旧PET催化醇解工艺 [J]. 精细化工, 2018, 35(12): 1 999⁃2 005. |

| XU H, XIONG F, PENG Z J, et al. Optimization of catalytic alcoholysis process of waste PET(polyethylene terephthalate) by response surface methodology [J]. Fine Chemicals, 2018, 35(12): 1 999⁃2 005. | |

| 53 | 李晓静,王 磊,潘振勇,等. 废旧聚氨酯泡沫的醇解以及醇解产物的应用 [J]. 现代制造技术与装备, 2019 (9): 176⁃177. |

| LI X J, WANG L, PAN Z Y, et al. Alcoholysis of waste polyurethane foams and application of alcohollytic products [J]. Modern Manufacturing Technology and Equipment, 2019 (9): 176⁃177. | |

| 54 | Jiao X, Zheng K, Hu Z, et al. Conversion of waste plastics into value⁃added carbonaceous fuels under mild conditions [J]. Advanced Materials, 2021, 33(50): 2005192. |

| 55 | Xiao Han J L, Tian Sen, Fei Tao, et al. Microbial cell factories for bio⁃based biodegradable plastics production [J]. iScience, 2022, 25(11): 105462. |

| 56 | Zeenat, Elahi A, Bukhari D A, et al. Plastics degradation by microbes: a sustainable approach [J]. Journal of King Saud University⁃Science, 2021, 33(6): 101538. |

| 57 | 李树木. 塑料降解回收缓解白色污染的研究进展 [J]. 山东化工, 2021, 50(15): 76⁃77. |

| LIU S M, Research progress of plastic degradation and recycling to alleviate white pollution[J]. Shandong Chemical Industry, 2021, 50(15): 76⁃77. | |

| 58 | Srikanth M, Sandeep T S R S, Sucharitha K, et al. Biodegradation of plastic polymers by fungi: a brief review[J]. Bioresources and Bioprocessing, 2022, 9(1): 1⁃10. |

| 59 | Ana L D F L, Maíra C P, Eduardo R S, et al. Diverse groups of Fungi are associated with plastics in the surface waters of the western south atlantic and the antarctic peninsula [J]. Molecular Ecology, 2020, 29(10): 1 903⁃1 918. |

| 60 | Sánchez C. Fungal potential for the degradation of petroleum⁃based polymers: an overview of macro⁃ and microplastics biodegradation [J]. Biotechnology Advances, 2020, 40(19): 107501. |

| 61 | Taghavi N, Singhal N, Zhuang W Q, et al. Degradation of plastic waste using stimulated and naturally occurring microbial strains [J]. Chemosphere, 2021, 263: 127975. |

| 62 | Sullivan K P, Werner A Z, Ramirez K J, et al. Mixed plastics waste valorization through tandem chemical oxidation and biological funneling [J]. Science, 2022, 378(6616): 207⁃211. |

| 63 | Yifan Yan H Z, Xu Si⁃Min, Yang Jiangrong, et al. Electrocatalytic upcycling of biomass and plastic wastes to biodegradable polymer monomers and hydrogen fuel at high current densities [J]. Journal of the American Chemical Society, 2023, 145(11): 6 144⁃6 155. |

| 64 | Wang J, Li X, Wang M, et al. Electrocatalytic valorization of poly(ethylene terephthalate) plastic and CO2 for simultaneous production of formic acid [J]. ACS Catalysis, 2022, 12(11): 6 722⁃6 728. |

| 65 | Sherbo R S, Delima R S, Chiykowski V A, et al. Complete electron economy by pairing electrolysis with hydrogenation [J]. Nature Catalysis, 2018, 1(7): 501⁃507. |

| 66 | Ren T, Duan Z, Wang H, et al. Electrochemical co⁃production of ammonia and biodegradable polymer monomer glycolic acid via the co⁃electrolysis of nitrate wastewater and waste plastic [J]. ACS Catalysis, 2023, 13(15): 10 394⁃10 404. |

| 67 | Liu F, Gao X, Shi R, et al. A general electrochemical strategy for upcycling polyester plastics into added⁃value chemicals by a CuCo2O4 catalyst [J]. Green Chemistry, 2022, 24(17): 6 571⁃6 577. |

| 68 | Miao F, Liu Y, Gao M, et al. Degradation of polyvinyl chloride microplastics via an electro⁃Fenton⁃like system with a TiO2/graphite cathode [J]. Journal of Hazardous materials, 2020, 399: 123023. |

| 69 | Zhang T, Li X, Wang J, et al. Photovoltaic⁃driven electrocatalytic upcycling poly(ethylene terephthalate) plastic waste coupled with hydrogen generation [J]. Journal of Hazardous materials, 2023, 450: 131054. |

| 70 | Shi R, Liu K S, Liu F, et al. Electrocatalytic reforming of waste plastics into high value⁃added chemicals and hydrogen fuel [J]. Chemical Communications, 2021, 57(94): 12 595⁃12 598. |

| 71 | Uekert T, Kuehnel M F, Wakerley D W, et al. Plastic waste as a feedstock for solar⁃driven H2 generation [J]. Energy & Environmental Science, 2018, 11(10): 2 853⁃2 857. |

| 72 | Chu S, Zhang B, Zhao X, et al. Photocatalytic conversion of plastic waste: from photodegradation to photosynthesis [J]. Advanced Energy Materials, 2022, 12(22): 1⁃23. |

| 73 | Uekert T, Kasap H, Reisner E. Photoreforming of nonrecyclable plastic waste over a carbon nitride/nickel phosphide catalyst [J]. Journal of the american chemical society, 2019, 141(38): 15 201⁃15 210. |

| 74 | Xingchen Jiao K Z, Hu Zexun, Shan Zhu, et al. Conversion of waste plastics into value⁃added carbonaceous fuels under mild conditions [J]. Advanced Materials, 2021, 33(50): e2005192. |

| 75 | Wan Y, Wang H, Liu J, et al. Enhanced degradation of polyethylene terephthalate plastics by CdS/CeO2 heterojunction photocatalyst activated peroxymonosulfate [J]. Journal of Hazardous materials, 2023, 452: 131375. |

| 76 | Qin J, Dou Y, Zhou J, et al. Photocatalytic valorization of plastic waste over Zinc oxide encapsulated in a metal⁃organic framework [J]. Advanced Functional Materials, 2023, 33(28): 2214839. |

| 77 | Qin J, Dou Y, Wu F, et al. In⁃situ formation of Ag2O in metal⁃organic framework for light⁃driven upcycling of microplastics coupled with hydrogen production[J]. Applied Catalysis B: Environmental, 2022, 319: 121940. |

| 78 | Liu Y, Wang X, Li Q, et al. Photothermal catalytic polyester upcycling over cobalt single⁃site catalyst [J]. Advanced Functional Materials, 2023, 33(2): 2210283. |

| [1] | 周迎鑫, 翁云宣, 张彩丽, 刁晓倩, 宋鑫宇. 聚对苯二甲酸乙二醇酯回收技术和标准现状[J]. 中国塑料, 2021, 35(8): 162-171. |

| [2] | 孙小东, 曹鼎, 胡倩倩, 姚文清, 李景虹, 冯拥军. 废弃塑料的化学回收资源化利用研究进展[J]. 中国塑料, 2021, 35(8): 44-54. |

| [3] | 周宏伟, 李立峰, 林武, 安瑛, 杨卫民. 固体废弃塑料挤注压一体化设备的研发[J]. 中国塑料, 2016, 30(03): 105-108 . |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2