京ICP备13020181号-2

© 《China Plastics》

© 《China Plastics》

China Plastics ›› 2022, Vol. 36 ›› Issue (3): 26-32.DOI: 10.19491/j.issn.1001-9278.2022.03.005

• Materials and Properties • Previous Articles Next Articles

GUO Yiming( ), DONG Xiaochen, LIANG Shitong, WANG Sen, LIU Jichun(

), DONG Xiaochen, LIANG Shitong, WANG Sen, LIU Jichun( )

)

Received:2021-11-09

Online:2022-03-26

Published:2022-03-25

CLC Number:

GUO Yiming, DONG Xiaochen, LIANG Shitong, WANG Sen, LIU Jichun. Effects of graphite type and size on flame retardancy of high⁃impact polystyrene and it’s action mechanism[J]. China Plastics, 2022, 36(3): 26-32.

Add to citation manager EndNote|Ris|BibTeX

URL: https://www.plaschina.com.cn/EN/10.19491/j.issn.1001-9278.2022.03.005

| 样品名称 | 点燃时间/s | PHRR/ kW·m-2 | AHRR/ kW·m-2 | THR/ MJ·m-2 | 平均有效燃烧热/ MJ·kg-1 | TSR/ m2·m-2 | FPI/ 10⁃3s·m2·kW⁃1 | 残炭率/% |

|---|---|---|---|---|---|---|---|---|

| PS⁃HI | 63 | 738 | 280 | 119 | 34 | 5 112 | 85 | 1.9 |

| PS⁃HI/EG50 | 45 | 131 | 95 | 77 | 35 | 578 | 344 | 45.0 |

| PS⁃HI/EG150 | 50 | 230 | 105 | 76 | 35 | 1 222 | 217 | 41.1 |

| PS⁃HI/NG50 | 50 | 436 | 118 | 94 | 32 | 3 786 | 115 | 30.6 |

| PS⁃HI/NG150 | 57 | 378 | 123 | 97 | 32 | 4 103 | 151 | 30.8 |

| 样品名称 | 点燃时间/s | PHRR/ kW·m-2 | AHRR/ kW·m-2 | THR/ MJ·m-2 | 平均有效燃烧热/ MJ·kg-1 | TSR/ m2·m-2 | FPI/ 10⁃3s·m2·kW⁃1 | 残炭率/% |

|---|---|---|---|---|---|---|---|---|

| PS⁃HI | 63 | 738 | 280 | 119 | 34 | 5 112 | 85 | 1.9 |

| PS⁃HI/EG50 | 45 | 131 | 95 | 77 | 35 | 578 | 344 | 45.0 |

| PS⁃HI/EG150 | 50 | 230 | 105 | 76 | 35 | 1 222 | 217 | 41.1 |

| PS⁃HI/NG50 | 50 | 436 | 118 | 94 | 32 | 3 786 | 115 | 30.6 |

| PS⁃HI/NG150 | 57 | 378 | 123 | 97 | 32 | 4 103 | 151 | 30.8 |

| 样品名称 | LOI/% | UL 94等级 |

|---|---|---|

| PS⁃HI | 18.1 | NR |

| PS⁃HI/EG50 | 24.0 | NR |

| PS⁃HI/NG50 | 20.2 | NR |

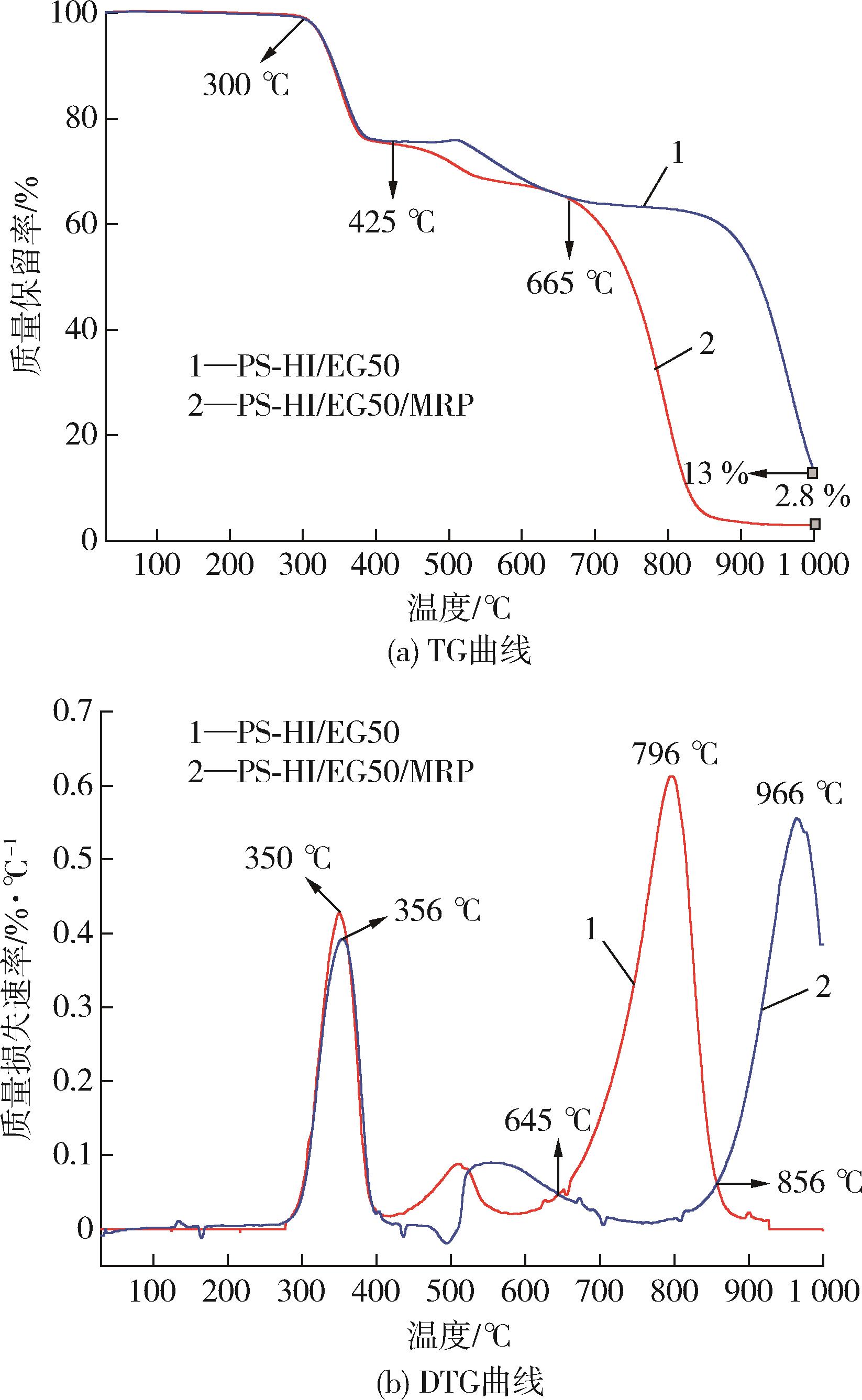

| PS⁃HI/EG50/MRP | 25.0 | V⁃0 |

| PS⁃HI/NG50/MRP | 22.4 | V⁃2 |

| 样品名称 | LOI/% | UL 94等级 |

|---|---|---|

| PS⁃HI | 18.1 | NR |

| PS⁃HI/EG50 | 24.0 | NR |

| PS⁃HI/NG50 | 20.2 | NR |

| PS⁃HI/EG50/MRP | 25.0 | V⁃0 |

| PS⁃HI/NG50/MRP | 22.4 | V⁃2 |

| 1 | CULLIS C F, HIRSCHLER M M, TAO Q M. The effect of red phosphorus on the flammability and smoke⁃producing tendency of poly(vinyl chloride) and polystyrene [J]. European Polymer Journal, 1986, 22(6): 161⁃167. |

| 2 | ROBERT H N, PARTTYWISIAN N. Poly(alky/arylphosphazenes) and their precursors [J]. Chemical Reviews, 1988, 88(3): 541⁃562. |

| 3 | LEE K, KIM J. Studies on the thermal stablilzation enhancement of ABS: synersistic effect by triphenyl phosphate and epoxy resin mixtures [J]. Polymer, 2002, 43(8): 2 249⁃2 253. |

| 4 | 刘继纯,常海波,李晴媛,等. Mg(OH)2/聚苯乙烯复合材料的阻燃机制 [J],复合材料学报, 2012, 29(5): 32⁃40. |

| LIU J C, CHANG H B, LI Q Y, et al. Flame retardant mechanism of Mg(OH)2/polystyrene composites [J]. Acta Materiae Compositae Sinica, 2012, 29(5): 32⁃40. | |

| 5 | CUI W G, GUO F, CHEN J F. Preparation and properties of flame retardant high impact polystyrene [J]. Fire Safety Journal, 2007, 42(3): 232⁃239. |

| 6 | LIU H, YI J H. Polystyrene/magnesium hydroxide nanocomposite particles prepared by surface⁃initiated in⁃situ polymerization [J]. Applied Surface Science, 2009, 255(11): 5 714⁃5 720. |

| 7 | MANZI⁃NSHUTI C, CHEN D, SU S P, et al. Structure⁃property relationships of new polystyrene nanocomposites prepared from initiator⁃containing layered double hydroxides of zinc aluminum and magnesium aluminum [J]. Polymer Degradation and Stability, 2009, 94(8): 1 290⁃1 297. |

| 8 | LIU J C, LI H, CHANG H B, et al. Effect of water erosion on flame retardancy of high impact polystyrene/magnesium hydroxide composite and its mode of action [J]. Fire and Materials, 2020, 44(2): 180⁃188. |

| 9 | LU H D, WILKIE C A. Study on intumescent flame retarded polystyrene composites with improved flame retardancy [J]. Polymer Degradation and Stability, 2010, 95(12): 2 388⁃2 395. |

| 10 | 焦清介, 吴中伟, 臧充光, 等. 膨胀型无卤阻燃HIPS热分解动力学及阻燃机理研究 [J]. 化学学报, 2009, 67(2): 151⁃156. |

| JIAO Q J, WU Z W, ZANG C G, et al. Thermal degradation kinetics of intumescent halogen⁃free flame⁃retarding HIPS and its retarding mechanism [J]. Acta Chimica Sinica, 2009, 67(2): 151⁃156. | |

| 11 | SU S P, JIANG D D, WILKIE C A. Novel polymerically⁃modified clays permit the preparation of intercalated and exfoliated nanocomposites of styrene and its copolymers by melt blending [J]. Polymer Degradation and Stability, 2004, 83(2): 333⁃346. |

| 12 | ZHENG X X, JIANG D D, WANG D Y, et al. Flammability of styrenic polymer clay nanocomposites based on a methyl methacrylate oligomerically⁃modified clay [J]. Polymer Degradation and Stability, 2006, 91(2): 289⁃297. |

| 13 | ISITMAN N A, KAYNAK C. Tailored flame retardancy via nanofiller dispersion state: synergistic action between a conventional flame⁃retardant and nanoclay in high⁃impact polystyrene [J]. Polymer Degradation and Stability, 2010, 95(9): 1 759⁃1 768. |

| 14 | ATTIA N F, AFIFI H A, HASSAN M A. Synergistic study of carbon nanotubes, rice husk ash and flame retardant materials on the flammability of polystyrene nanocomposites [J]. Materials Today: Proceedings, 2015, 2(7): 3 998⁃4 005. |

| 15 | 边策, 曹金波, 毕立, 等. 不同无卤阻燃剂对PPO/HIPS合金性能影响研究 [J]. 上海塑料, 2021, 49(2): 27⁃31. |

| BIAN C, CAO J B, BI L, et al. Effect of different halogen⁃free flame retardants on properties of PPO/HIPS alloy [J]. Shanghai Plastics, 2021, 49(2): 27⁃31. | |

| 16 | 刘继纯, 罗洁, 郑喜俊, 等. 微胶囊红磷和聚苯醚对高抗冲聚苯乙烯的协同阻燃作用 [J]. 复合材料学报, 2013, 30(4) : 44⁃52. |

| LIU J C, LUO J, ZHENG X J. Synergistic effect of MRP and PPO on the flame retardancy of HIPS [J]. Acta Materiae Compositae Sinica, 2013, 30(4) : 44⁃52. | |

| 17 | YAO H Y, MCKINNEY M A, DICK C. Crossing⁃lin⁃king of polystyrene by friedel⁃crafts chemisty: reaction of p⁃hydroxymethylbenzyl chloride with polystyrene [J]. Polymer Degradation and Stability, 2001, 72(3): 399⁃405. |

| 18 | SUZUKI M, WILKIE C A. The thermal degradation of acrylonitrile⁃butadiene⁃styrene terpolymer grafted with methacrylic acid [J]. Polymer Degradation and Stability, 1995, 47(2): 223⁃228. |

| 19 | PRICE D, BULLETTA K J, CUNLIFFEA L K.et al. Cone calorimetry studies of polymer systems flame retarded by chemically bonded phosphorus[J]. Polymer Degradation and Stability, 2005, 88(1): 74⁃79. |

| 20 | 王星, 胡立嵩, 夏林, 等. 石墨资源概况与提纯方法研究 [J]. 化工时刊, 2015, 29(2): 19⁃22. |

| WANG X, HU L S, XIA L, et al. Graphite resources and graphite purification methods research [J]. Chemical Industry Times, 2015, 29(2): 19⁃22. | |

| 21 | SCHARTEL B, HULL T R. Development of fire⁃retarded materials—interpretation of cone calorimeter data [J]. Fire and Materials, 2007, 31(5): 327⁃354. |

| 22 | AI L H, YANG L, HU J F, et al. Synergistic flame retardant effect of organic phosphorus⁃nitrogen and inorganic boron flame retardant on polyethylene [J]. Polymer Engineering and Science, 2020, 60(2): 414⁃422. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||