京ICP备13020181号-2

© 《China Plastics》

© 《China Plastics》

China Plastics ›› 2025, Vol. 39 ›› Issue (8): 26-33.DOI: 10.19491/j.issn.1001-9278.2025.08.005

• Materials and Properties • Previous Articles Next Articles

ZHANG Yusen1, TIE Rui1, LI Ziming1, LIAO Baosheng1, GUO Runqi1, JIN Yujuan1( ), ZHANG Zhe1, JIANG Suchen1,2

), ZHANG Zhe1, JIANG Suchen1,2

Received:2024-09-05

Online:2025-08-26

Published:2025-07-30

CLC Number:

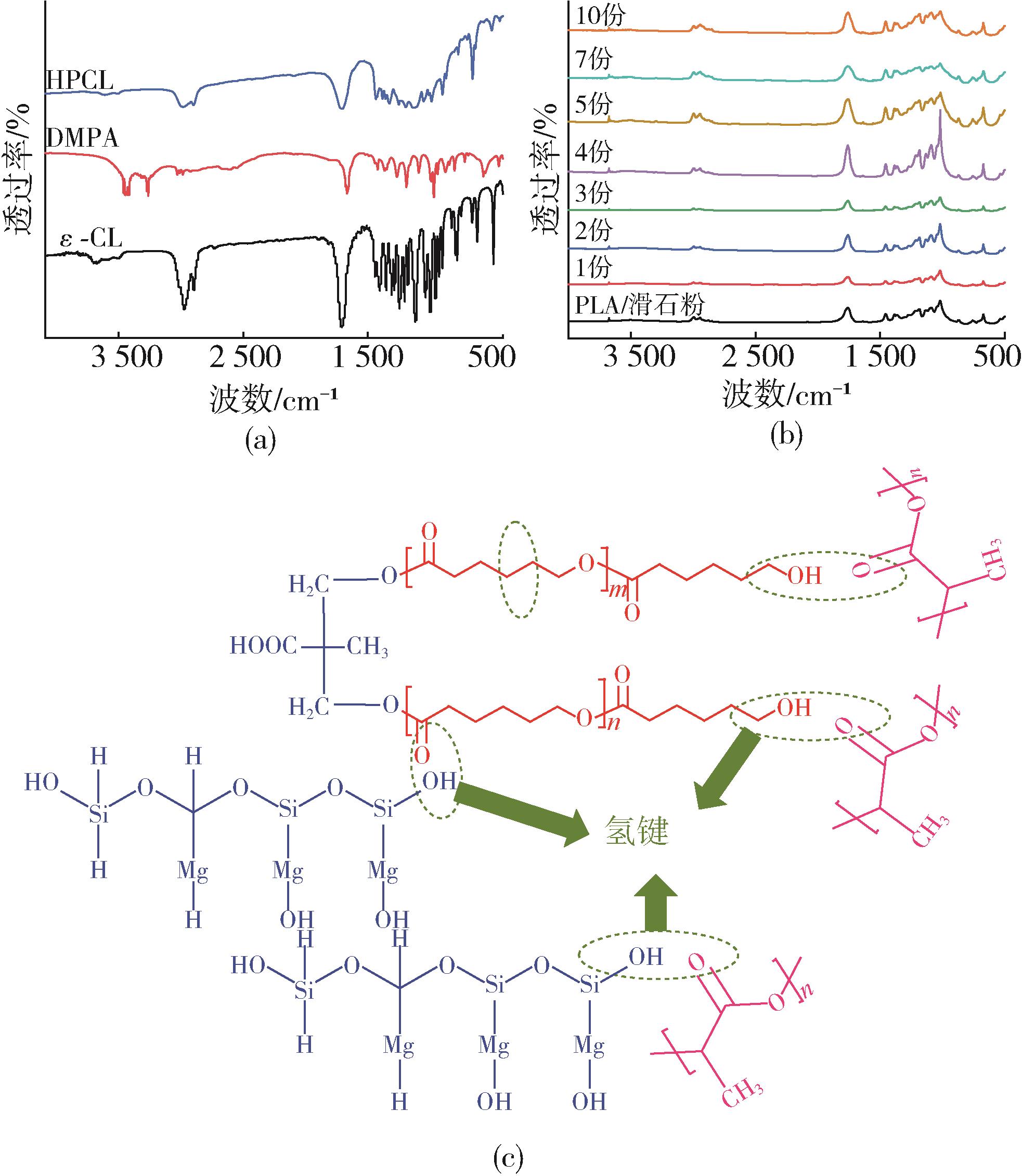

ZHANG Yusen, TIE Rui, LI Ziming, LIAO Baosheng, GUO Runqi, JIN Yujuan, ZHANG Zhe, JIANG Suchen. Study of toughening modification of poly(lactic acid)/talc blends with hyperbranched polycaprolactone[J]. China Plastics, 2025, 39(8): 26-33.

Add to citation manager EndNote|Ris|BibTeX

URL: https://www.plaschina.com.cn/EN/10.19491/j.issn.1001-9278.2025.08.005

| 样品 | Tc/℃ | △Hc/ J·g-1 | Tm1/ ℃ | Tm2/ ℃ | △Hm/ J·g-1 | Xc/% |

|---|---|---|---|---|---|---|

| PLA | 99.96 | — | — | 172.36 | 10.38 | 15.83 |

| PLA/滑石粉 | 105.23 | 21.79 | 156.22 | 164.44 | 16.02 | 24.42 |

| 1份HPCL | 104.82 | 22.50 | 156.29 | 164.70 | 15.71 | 23.95 |

| 2份HPCL | 104.41 | 21.47 | 155.94 | 164.52 | 16.21 | 24.71 |

| 3份HPCL | 104.48 | 21.85 | 155.91 | 164.46 | 16.41 | 25.02 |

| 4份HPCL | 104.68 | 21.53 | 155.94 | 164.42 | 16.49 | 25.14 |

| 5份HPCL | 104.10 | 21.35 | 155.89 | 164.50 | 15.72 | 23.97 |

| 7份HPCL | 103.91 | 20.32 | 156.03 | 164.55 | 15.40 | 23.48 |

| 10份HPCL | 102.57 | 19.21 | 156.25 | 165.01 | 14.54 | 22.17 |

| 样品 | Tc/℃ | △Hc/ J·g-1 | Tm1/ ℃ | Tm2/ ℃ | △Hm/ J·g-1 | Xc/% |

|---|---|---|---|---|---|---|

| PLA | 99.96 | — | — | 172.36 | 10.38 | 15.83 |

| PLA/滑石粉 | 105.23 | 21.79 | 156.22 | 164.44 | 16.02 | 24.42 |

| 1份HPCL | 104.82 | 22.50 | 156.29 | 164.70 | 15.71 | 23.95 |

| 2份HPCL | 104.41 | 21.47 | 155.94 | 164.52 | 16.21 | 24.71 |

| 3份HPCL | 104.48 | 21.85 | 155.91 | 164.46 | 16.41 | 25.02 |

| 4份HPCL | 104.68 | 21.53 | 155.94 | 164.42 | 16.49 | 25.14 |

| 5份HPCL | 104.10 | 21.35 | 155.89 | 164.50 | 15.72 | 23.97 |

| 7份HPCL | 103.91 | 20.32 | 156.03 | 164.55 | 15.40 | 23.48 |

| 10份HPCL | 102.57 | 19.21 | 156.25 | 165.01 | 14.54 | 22.17 |

| 样品 | Td5 %/℃ | Td10 %/℃ | Tdmax/℃ |

|---|---|---|---|

| PLA | 358.87 | 366.37 | 391.73 |

| PLA/滑石粉 | 297.07 | 320.56 | 360.24 |

| 1份HPCL | 307.99 | 324.83 | 360.84 |

| 2份HPCL | 302.99 | 319.31 | 359.44 |

| 3份HPCL | 290.97 | 310.66 | 360.07 |

| 4份HPCL | 291.97 | 308.95 | 356.67 |

| 5份HPCL | 292.64 | 309.62 | 353.53 |

| 7份HPCL | 298.25 | 310.94 | 351.98 |

| 10份HPCL | 297.13 | 309.32 | 332.59 |

| 样品 | Td5 %/℃ | Td10 %/℃ | Tdmax/℃ |

|---|---|---|---|

| PLA | 358.87 | 366.37 | 391.73 |

| PLA/滑石粉 | 297.07 | 320.56 | 360.24 |

| 1份HPCL | 307.99 | 324.83 | 360.84 |

| 2份HPCL | 302.99 | 319.31 | 359.44 |

| 3份HPCL | 290.97 | 310.66 | 360.07 |

| 4份HPCL | 291.97 | 308.95 | 356.67 |

| 5份HPCL | 292.64 | 309.62 | 353.53 |

| 7份HPCL | 298.25 | 310.94 | 351.98 |

| 10份HPCL | 297.13 | 309.32 | 332.59 |

| [1] | Nofar M, Sacligil D, Carreau P J, et al.Poly (lactic acid) blends: Processing, properties and applications[J]. International Journal of Biological Macromolecules,2019, 125:307⁃360. |

| [2] | Rezvani Ghomi E, Fatemeh K, Saedi Ardahaei A, et al.The life cycle assessment for polylactic acid (PLA) to make it a low⁃carbon material[J]. Polymers,2021, 13(11): 1854. |

| [3] | Saini P, Arora M, Kumar M. Poly(lactic acid) blends in biomedical applications[J]. Advanced Drug Delivery Reviews, 2016, 107:47⁃59. |

| [4] | 丁燕, 江驰, 潘剑婷,等.无机填料增强增韧聚乳酸基生物可降解材料的研究进展[J]. 云南化工,2024, 51(06): 18⁃21. |

| DING Y, JIANG C, PAN J T,et al. Development of inorganic filler⁃enhanced and toughening of PLA⁃based biodegradable materials[J]. Yunnan chemical industry, 2024, 51 (06): 18⁃21. | |

| [5] | 汶少华.聚乳酸生物可降解材料填料复合改性研究进展[J]. 广州化工,2017, 45(03): 6⁃8. |

| WEN S H.Research on composite modification of PLA biodegradable materials[J]. Guangzhou chemical industry, 2017, 45 (03): 6⁃8. | |

| [6] | De Santis F, Pantani R. Melt compounding of poly (lactic acid) and talc: Assessment of material behavior during processing and resulting crystallization[J]. Journal of Polymer Research,2015, 22(12):126. |

| [7] | Petchwattana N, Covavisaruch S, Petthai S.Influence of talc particle size and content on crystallization behavior, mechanical properties and morphology of poly(lactic acid)[J]. Polymer Bulletin,2014, 71(8): 1 947⁃1 959. |

| [8] | 许鹏飞, 潘宏伟, 张会良,等. 聚乳酸共混增韧和耐热性能的研究[J]. 塑料科技, 2020, 48(05): 54⁃59. |

| XU P F, PAN H W, ZHANG H L,et al.Study on acid toughness and heat resistance[J]. Plastic Technology, 2020, 48 (05): 54⁃59. | |

| [9] | Khuenkeao T, Petchwattana N, Covavisaruch S.Thermal and mechanical properties of bioplastic poly(lactic acid) compounded with silicone rubber and talc[C]//31st International Conference of the Polymer⁃Processing⁃Society (PPS),South Korea,2016. |

| [10] | Huda M S, Drzal L T, Misra M,et al.A study on biocomposites from recycled newspaper fiber and poly(lactic acid)[J]. Industrial & Engineering Chemistry Research,2005, 44(15): 5 593⁃5 601. |

| [11] | Han X L, Jin Y J, Huang J, et al.Highly toughening modification of hyperbranched polyester with environment⁃friendly caprolactone as end group on poly(3⁃hydroxybutyrate⁃co-3⁃hydroxyvalerate)[J]. Journal of Polymers and the Environment, 2022, 30(8): 3 209⁃3 217. |

| [12] | Li S P, Yao Y.Synergistic improvement of epoxy composites with multi⁃walled carbon nanotubes and hyperbranched polymers[J]. Composites Part B⁃Engineering, 2019, 165:293⁃300. |

| [13] | Yang J P, Chen Z K, Yang G, et al.Simultaneous improvements in the cryogenic tensile strength, ductility and impact strength of epoxy resins by a hyperbranched polymer[J]. Polymer,2008, 49(13/14): 3 168⁃3 175. |

| [14] | Yoon C S, Ji D S. The effects of blend composition and blending time on the ester interchange reaction and tensile properties of PLA/LPCL/HPCL blends[J]. Fibers and Polymers,2003, 4(2): 59⁃65. |

| [15] | Choi J, Kwak S Y.Hyperbranched poly(ε⁃caprolactone) as a nonmigrating alternative plasticizer for phthalates in flexible PVC[J]. Environmental Science & Technology,2007, 41(10): 3 763⁃3 768. |

| [16] | Li Y, Yu E, Yang X,et al.Multiarm hyperbranched polyester⁃b⁃Poly(ε⁃caprolactone):Plasticization effect and migration resistance for PVC[J]. Journal of Vinyl & Additive Technology,2020, 26(1): 35⁃42. |

| [17] | Park H, Choe Y.Enhancing toughness and impact strength of epoxy resins by using hyperbranched polymers[J]. International Journal of Polymer Science,2021:689. |

| [18] | Tie R, Huang Y S, Jin Y J, et al.Toughening modification of polylactic acid by long⁃chain hyperbranched polymers containing polycaprolactone end groups[J]. Journal of Polymers and the Environment,2022, 30(12): 5 327⁃5 338. |

| [19] | 李艳, 符金玉, 冯刚,等.超支化聚己内酯对环氧树脂的增韧作用[J]. 高分子材料科学与工程,2018, 34(01): 41⁃44. |

| LI Y, FU J Y, FENG G,et al.Toughening effect of hyperbranched polycaprolactone on epoxy resin[J]. Polymer Materials Science and Engineering, 2018, 34 (01): 41⁃44. | |

| [20] | 胡晨曦, 王宇韬, 吕明福,等.滑石粉改性PBAT/PLA复合材料的制备及性能研究[J]. 塑料科技,2022, 50(07): 44⁃48. |

| HU C X, WANG Y T, LV M F,et al.Preparation and Properties of Talcum Modified PBAT/PLA Composites[J]. Plastics Science and Technology,2022, 50(07): 44⁃48. | |

| [21] | 李艳.超支化聚己内酯的合成及其增韧作用研究[D].河北大学,2017. |

| [22] | 孙闯闯, 丁建萍, 魏志和,等.耐水解PLA/PBS/滑石粉复合材料的制备及性能[J]. 现代塑料加工应用,2024, 36(02): 33⁃36. |

| SUN C C, DING J P, WEI Z H,et al.Preparation and properties of PLA / PBS / talc composites[J]. Modern Plastic Processing Applications, 2024, 36 (02): 33⁃36. | |

| [23] | Qian S, Zhang H, Yao W,et al.Effects of bamboo cellulose nanowhisker content on the morphology, crystallization, mechanical, and thermal properties of PLA matrix biocomposites[J]. Composites Part B⁃Engineering, 2018, 133:203⁃209. |

| [24] | Chattopadhyay D K, Webster D C.Thermal stability and flame retardancy of polyurethanes[J]. Progress in Polymer Science,2009, 34(10): 1 068⁃1 133. |

| [25] | Huang J W, Fang Y Q, Zhou S D, et al.Enhanced compatibility and toughness of poly(3⁃hydroxybutyrate⁃co-3⁃hydroxyvalerate)/polycaprolactone blends by ring⁃opening polymerization and hydrogen bonding of epoxy⁃terminated hyperbranched polyester[J]. Journal of Applied Polymer Science,2024:981. |

| [26] | Liu Q, Shyr T W, Tung C H, et al.Particular thermal properties of poly(3⁃hydroxybutyrate⁃co-3⁃hydroxyvalerate) oligomers[J]. Journal of Polymer Research, 2012, 19(1):981. |

| [27] | 吴悠, 王博华, 孙健健,等.端环氧基型超支化聚合物对PPC/PBS共混物的改性研究[J]. 中国塑料, 2021, 35(04): 5⁃11. |

| WU Y, WANG B H, SUN J J, et al.Modification of PPC/PBS blend by terminal epoxy⁃type hyperbranched polymer[J]. Chinese Plastic, 2021, 35 (04): 5⁃11. | |

| [28] | Guo M, Jin Y, Han X, et al.Simultaneously strengthening and toughening biodegradable polylactic acid/thermoplastic starch blends by compatibilizing with epoxy⁃terminated hyperbranched polyester[J]. Journal of Polymers and the Environment,2024, 32(7): 3 025⁃3 038. |

| [1] | NING Dingyi, ZHAO Tianjiao, DONG Yapeng, WANG Meizhen, HAO Xinyu, WANG Bo. Research progress in blending modification for regulating crystallization and mechanical properties of poly(lactic acid) [J]. China Plastics, 2025, 39(6): 126-132. |

| [2] | ZHEN Qi, QIN Zixuan, ZHANG Heng, CUI Jingqiang, WANG Guofeng, CHENG Wensheng, LI Han. Study on annealing process of polylactic acid melt blown microfibrous for medical packaging [J]. China Plastics, 2025, 39(6): 24-30. |

| [3] | FENG Shuo, ZHOU Shuyi, JIAO Yang, HU Miao, ZHANG Ruoxuan, JIN Yujuan. Effect of epoxy⁃terminated hyperbranched polyester on properties of poly(lactic acid)/talc blends [J]. China Plastics, 2025, 39(5): 36-42. |

| [4] | CHEN Yezhong, GONG Dejun, FU Xuejun, OUYANG Chunping, ZHANG Yi, YIN Yansheng. Effects of lubricant type on mechanical and emanation properties of PBAT/PLA/calcium carbonate composites [J]. China Plastics, 2025, 39(5): 77-82. |

| [5] | ZHANG Weizhen, ZHANG Qi, LI Yuan, LU Yonglai, ZHANG Shijun. Preparation and properties of PA6/CF composites toughened with epoxidized silicone rubber/methyl silicone rubber compounding system [J]. China Plastics, 2025, 39(3): 7-11. |

| [6] | LI Wanlong, YANG Weimin, WANG Shuo, LI Changjin, ZHANG Yang, TAN Jing, YAN Hua, LI Haoyi. Study on enhancement modification of melt⁃differential electrospun poly(lactic acid) fiber with CH⁃S04 [J]. China Plastics, 2025, 39(2): 1-5. |

| [7] | LIU Sheng, WANG Qian, LIU Shun, LIU Haitang. Effect of novel lignin⁃based nucleating agents on performance of regenerated PET [J]. China Plastics, 2025, 39(2): 72-76. |

| [8] | GAO Ting, PENG Qiang, MA Xiuqing. Research progress in modification of polycarbonate [J]. China Plastics, 2025, 39(1): 37-43. |

| [9] | CUI Bao, YANG Jianjun, WU Qingyun, WU Mingyuan, ZHANG Jianan, LIU Jiuyi. Research Progress in blending modification of polylactic acid composites and their applications [J]. China Plastics, 2024, 38(9): 129-136. |

| [10] | LIU Gang, YAO Cheng, JIA Lei, CHEN Xipeng, CAI Hansheng. Study on hot⁃stretching⁃induced structure evolution of isotactic polypropylene used in capacitance films [J]. China Plastics, 2024, 38(9): 36-40. |

| [11] | DING Xinyi, DUN Dongxing, QIN Junxi, CHEN Yulei, HAN Yufei, ZHANG Yuxia, ZHOU Hongfu. Study on microstructure and properties of ST⁃NAB3 nucleating agent⁃modified chain⁃extended polylactic acid [J]. China Plastics, 2024, 38(9): 41-46. |

| [12] | LIANG Jifeng, QU Jinping. Structure and property evolutions of rPE⁃HD/rPET blending system via volume⁃pulsatile injection molding [J]. China Plastics, 2024, 38(8): 1-7. |

| [13] | DONG Guang, HOU Yangzhe, YUAN Hongyue, LIU Xianhu, PAN Yamin. Progress in porous poly(lactic acid) material and their structure and performance optimization [J]. China Plastics, 2024, 38(8): 132-140. |

| [14] | HU Yongxiang, XIE Jiling, LI Weiming, ZHANG Lu, TANG Xianggang, LYU Yitong, SHEN Hongwang, JU Guannan. Effect of maleic anhydride graft⁃modified ground tire rubber on properties of poly(lactic acid) [J]. China Plastics, 2024, 38(7): 20-24. |

| [15] | WANG Jie, XIN Dehua, LI Hui, JIANG Hongshi, ZHOU Hongfu, ZHAO Jianguo. Effect of hybrid reinforcement of nanoclay and silica on properties of poly(lactic acid) [J]. China Plastics, 2024, 38(7): 43-48. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||