京ICP备13020181号-2

© 《China Plastics》

© 《China Plastics》

China Plastics ›› 2025, Vol. 39 ›› Issue (10): 18-24.DOI: 10.19491/j.issn.1001-9278.2025.10.004

• Materials and Properties • Previous Articles Next Articles

HOU Qinzheng1( ), LIU Wenlong1, LI Changjin2, QIN Liu3, DING Yumei1, LI Haoyi1, YANG Weimin1(

), LIU Wenlong1, LI Changjin2, QIN Liu3, DING Yumei1, LI Haoyi1, YANG Weimin1( ), HOU Zhengyuan4

), HOU Zhengyuan4

Received:2024-09-12

Online:2025-10-26

Published:2025-10-21

CLC Number:

HOU Qinzheng, LIU Wenlong, LI Changjin, QIN Liu, DING Yumei, LI Haoyi, YANG Weimin, HOU Zhengyuan. Preparation and properties of supercritical carbon dioxide⁃plasticized melt⁃blown polyethylene fiber film[J]. China Plastics, 2025, 39(10): 18-24.

| 组号 | 实验变量 | 实验变量组设置 | 材料处理方式 |

|---|---|---|---|

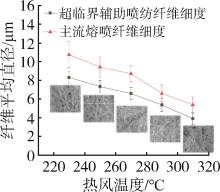

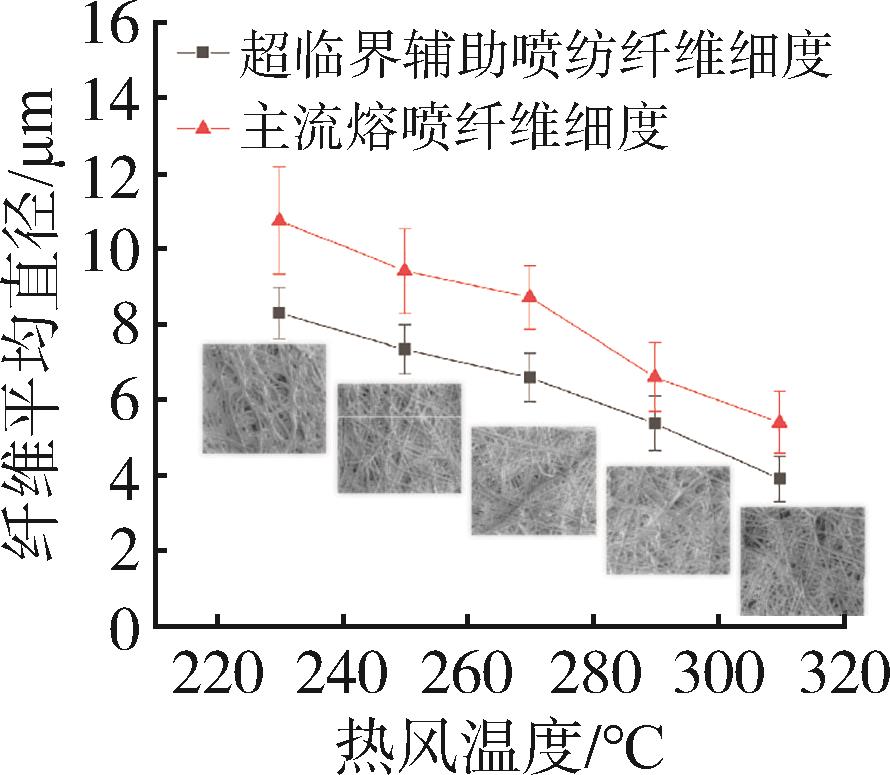

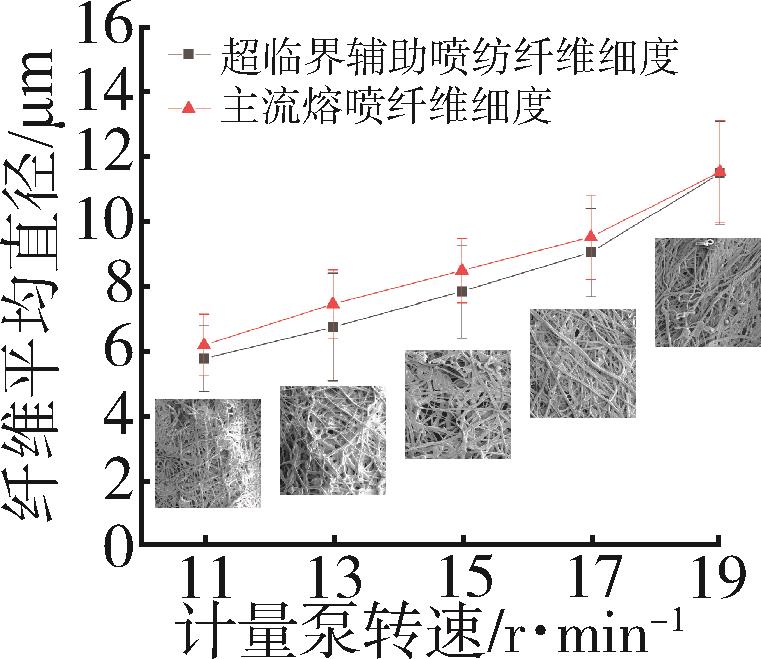

| 1 | 热风温度 | 230、250、270、290、310 ℃ | 未浸润/SC⁃CO2浸润 |

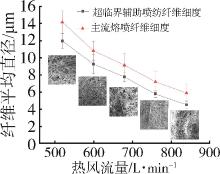

| 2 | 热风流量 | 520、600、680、760、840 L/min | 未浸润/SC⁃CO2浸润 |

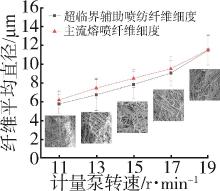

| 3 | 计量泵转速 | 11、13、15、17、19 r/min | 未浸润/SC⁃CO2浸润 |

| 组号 | 实验变量 | 实验变量组设置 | 材料处理方式 |

|---|---|---|---|

| 1 | 热风温度 | 230、250、270、290、310 ℃ | 未浸润/SC⁃CO2浸润 |

| 2 | 热风流量 | 520、600、680、760、840 L/min | 未浸润/SC⁃CO2浸润 |

| 3 | 计量泵转速 | 11、13、15、17、19 r/min | 未浸润/SC⁃CO2浸润 |

| [1] | 邱 芳,卫志美,彭民乐,等.静电纺丝法制备多孔超细聚醚砜纤维及其对双酚A的吸附性能[J].中国塑料, 2015(6):6. |

| QIU F, WEI Z M, PENG M L, et al. Preparation of porous ultrafine polyethersulfone fibers by electrospinning and their adsorption performance for bisphenol A[J]. China Plastics, 2015(6): 6. | |

| [2] | 孙子佳,雒翠梅,王启航,等.ODATA@LCNC的制备及对多功能PLA复合膜的影响[J].中国塑料,2023, 37(12):14⁃22. |

| SUN Z J, LUO C M, WANG Q H, et al. Preparation of ODATA@LCNC and its effects on multifunctional PLA composite Films[J]. China Plastics, 2023, 37(12): 14⁃22. | |

| [3] | 王 迎,杨 云,魏春艳,等.沉积静电纺聚丙烯腈纳米纤维膜窗纱的制备及其性能[J].纺织学报,2018,39(4):14⁃18. |

| WANG Y, YANG Y, WEI C Y, et al. Preparation and properties of sedimentation electrospun polyacrylonitrile nanofiber membrane window screen[J]. Journal of Textile Research, 2018, 39(4): 14⁃18. | |

| [4] | 周舒毅,朱 敏,刘忆颖,等.高分子止血材料研究进展[J].中国塑料,2022,36(7):74. |

| ZHOU S Y, ZHU M, LIU Y Y, et al. Research progress of polymer hemostatic materials[J]. China Plastics, 2022, 36(7): 74. | |

| [5] | Hufenus R, Yan Y, Dauner M, et al. Melt⁃spun fibers for textile applications[J]. Materials, 2020, 13(19): 4 298. |

| [6] | Han M C, He H W, Kong W K, et al. High⁃performance electret and antibacterial polypropylene meltblown nonwoven materials doped with boehmite and ZnO nanoparticles for air filtration[J]. Fibers and Polymers, 2022, 23(7): 1 947⁃1 955. |

| [7] | Bhat G. Melt blown polymeric nanofibers for medical applications⁃an overview[J]. Nanoscience & Technology: Open Access, 2015, 2(1):1⁃9. |

| [8] | 王晓梅,陈才深.聚乳酸/聚丙烯共混纺粘纤维的制备及其性能[J].纺织学报,2017,38(1):13⁃16. |

| WANG X M, CHEN C S. Preparation and properties of poly(lactic acid)/polypropylene blended spunbond fiber[J]. Journal of Textile Research, 2017, 38(1): 13⁃16. | |

| [9] | Zhang L, Hou Q, Li H, et al. Investigation on the sound absorption performance of polypropylene/polyethylene glycol ultrafine fibers by melt differential electrospinning process[J]. Applied Acoustics, 2022, 200: 109056. |

| [10] | Wu W, Sota H, Hirogaki T, et al. Investigation of air filter properties of nanofiber non⁃woven fabric manufactured by a modified melt⁃blowing method along with flash spinning method[J]. Precision Engineering, 2021, 68: 187⁃196. |

| [11] | 王月勤,周世蛟,胡玉涛,等.铸片工艺对锂电池隔膜成孔性能的影响[J].信息记录材料,2020,21(8):1⁃4. |

| WANG Y Q, ZHOU S J, HU Y T, et al. The influence of casting process on the pore⁃forming performance of lithium battery separators[J]. Information Recording Materials, 2020, 21(8): 1⁃4. | |

| [12] | Yu B, Han J, Sun H, et al. The preparation and property of poly (lactic acid)/tourmaline blends and melt‐blown nonwoven[J]. Polymer Composites, 2015, 36(2): 264⁃271. |

| [13] | 戴 行,高瑞雪,李奕国,等.高玻璃化转变温度抗冲击透明聚酯的研究进展[J].化工进展, 2023, 42(5):2 555⁃2 565. |

| DAI X, GAO R X, LI Y G, et al. Research progress on impact⁃resistant transparent polyester with high glass transition temperature[J]. Chemical Industry & Engineering Progress, 2023, 42(5): 2 555⁃2 565. | |

| [14] | 王富玉,高振勇,马祥艳,等.全生物降解聚乳酸/聚碳酸亚丙酯共混物研究进展[J].中国塑料, 2015(2):7. |

| WANG F Y, GAO Z Y, MA X Y, et al. Research progress on fully biodegradable poly(lactic acid)/poly(ethyl carbonate) blends[J]. China Plastics, 2015(2): 7. | |

| [15] | 朱斐超, 张宇静, 张 强, 等. 聚乳酸基生物可降解熔喷非织造材料的研究进展与展望[J]. 纺织学报, 2022, 43(1): 49⁃57. |

| ZHU F C, ZHANG Y J, ZHANG Q, et al. Research progress and prospects of biodegradable poly(lactic acid)⁃based nonwoven materials for meltblown applications[J]. Journal of Textile Research, 2022, 43(1): 49⁃57. | |

| [16] | 王镕琛,张 恒,孙焕惟,等.医疗卫生用聚乳酸非织造材料的制备及其亲水改性研究进展[J].中国塑料, 2022, 36(5):158⁃166. |

| WANG R C, ZHANG H, SUN H Y, et al. Research progress on preparation and hydrophilic modification of poly(lactic acid) nonwoven materials for medical and healthcare applications[J]. China Plastics, 2022, 36(5): 158⁃166. | |

| [17] | 张莉彦,侯钦正,徐锦龙,等.熔体微分静电纺热塑性聚氨酯防水透湿透气超细纤维膜的制备及其性能研究[J].毛纺科技, 2022, 50(12):1⁃10. |

| ZHANG L Y, HOU Q Z, XU J L, et al. Preparation and performance study of thermoplastic polyurethane waterproof, breathable and moisture⁃permeable ultrafine fiber membrane by melt differential electrospinning[J]. Textile Science and Technology, 2022, 50(12): 1⁃10. | |

| [18] | Wu Y, Xia C, Cai L, et al. Water⁃resistant hemp fiber⁃reinforced composites: In⁃situ surface protection by polyethylene film[J]. Industrial Crops and Products, 2018, 112: 210⁃216. |

| [19] | 赵 博.PP/PE医用淋膜非织造布的制备及性能研究[J].合成纤维工业, 2022, 45(6):29⁃32. |

| ZHAO B. Preparation and performance study of PP/PE medical laminated nonwoven fabric[J]. Synthetic Fibre Industry, 2022, 45(6): 29⁃32. | |

| [20] | 盖景刚, 李惠林, 胡国华. 超高分子量聚乙烯二元共混物降粘机理研究[J]. 2009 年全国高分子学术论文报告会论文摘要集 (上册), 2009. |

| GAI J G, LI H L, HU G H. Research on the viscosity reduction mechanism of ultra⁃high molecular weight polyethylene binary blend[J]. Abstracts of Papers from the 2009 National Polymer Academic Conference (Volume 1), 2009. | |

| [21] | Nayak R, Kyratzis I L, Truong Y B, et al. Melt⁃electrospinning of polypropylene with conductive additives[J]. Journal of Materials Science, 2012, 47: 6 387⁃6 396. |

| [22] | Li Y, He H, Ma Y, et al. Rheological and mechanical properties of ultrahigh molecular weight polyethylene/high density polyethy⁃lene/polyethylene glycol blends[J]. Advanced Industrial and Engineering Polymer Research, 2019, 2(1): 51⁃60. |

| [23] | 徐兴家,甄卫军,赵 玲.超临界CO2发泡制备聚氯乙烯微孔材料研究进展[J].中国塑料, 2019, 33(7):117⁃129. |

| XU X J, ZHEN W J, ZHAO L. Research progress on preparation of polyvinyl chloride micro⁃porous materials by supercritical CO2 foaming[J]. China Plastics, 2019, 33(7): 117⁃129. | |

| [24] | 万 辰. 超临界CO2环境下聚乙烯的流变特性及其影响发泡行为的作用机制[D]. 上海, 2017. |

| [25] | Areerat S, Nagata T, Ohshima M. Measurement and prediction of PE⁃LD/CO2 solution viscosity[J]. Polymer Engineering & Science, 2002, 42(11): 2 234⁃2 245. |

| [26] | Ibarra⁃Garza C M, Treviño⁃Quintanilla C D, Bonilla⁃Ríos J. Estimation of the effects of CO2 and temperature on the swelling of PS⁃CO2 mixtures at supercritical conditions on rheological testing[J]. Polymers, 2022, 14(17): 3 490. |

| [27] | 崔文豪,顾瑞星,米皓阳.超临界二氧化碳流场作用下线型聚乙烯剪切塑化行为的分子动力学模拟研究[J].高分子学报, 2024, 55(10): 1 414⁃1 429. |

| CUI W H, GU R X, MI H Y. Molecular dynamics simulation study on shear plasticization behavior of linear polyethylene under supercritical carbon dioxide flow field[J]. Acta Polymerologica Sinica, 2024, 55(10): 1 414⁃1 429. | |

| [28] | 陈明钟, 杨卫民, 李好义, 等. 基于超临界 CO2 制备熔体微分静电纺聚丙烯纤维[J]. 中国塑料, 2016, 30(6): 70⁃73. |

| CHEN M Z, YANG W M, LI H Y, et al. Preparation of melt differential electrospun polypropylene fibers based on supercritical CO2 [J]. China Plastics, 2016, 30(6): 70⁃73. | |

| [29] | 张淑苹, 康卫民, 程博闻, 等. 熔喷非织造过滤材料驻极技术研究进展[J]. 毛纺科技, 2022, 50(5): 117⁃125. |

| ZHANG S P, KANG W M, CHENG B W, et al. Research progress on electrification technology for meltblown nonwoven filter materials[J]. Textile Science and Technology, 2022, 50(5): 117⁃125. |

| [1] | WANG Shuo, YUAN Wenbo, CHENG Yichong, ZANG Yuntao, LENG Dongliang, LI Haiyan, ZHAO Ling, HU Dongdong. Mechanical performance of branched polypropylene foams fabricated via supercritical CO₂ molding [J]. China Plastics, 2025, 39(9): 1-6. |

| [2] | LIN Minghua, WANG Hua, GUO Jianbing, ZHENG Bin, WANG Yao. Polylactic⁃lignin composites synergistically toughened with epoxy soybean oil and tung oleic anhydride [J]. China Plastics, 2025, 39(9): 38-43. |

| [3] | ZHENG Shilun, ZHOU Qiwei, LIU Bin, LIANG Xuzhi, YUAN Mingyuan. Structure and properties of hyperbranched⁃polyester⁃modified carbon nanotubes/waterborne unsaturated polyester composites [J]. China Plastics, 2025, 39(9): 63-67. |

| [4] | MIN Jiaxuan, JIANG Xueliang, YOU Feng, LU Gang. Mechanical and thermal properties of PPC/PHBV blends [J]. China Plastics, 2025, 39(8): 6-11. |

| [5] | HU Lizhou, SUN Yinghui, JIA Yingjie, WANG Qingzhou. Interlaminar interface damage and mechanical properties of glass fiber⁃reinforced plastic mortar pipe [J]. China Plastics, 2025, 39(8): 69-74. |

| [6] | WANG Zheng, XIAO Dong, HUANG Rui, SUN Xiaoqian. Effect of adding different contents of waste plastic particles on mechanical properties of concrete [J]. China Plastics, 2025, 39(7): 130-134. |

| [7] | WANG Wenhao, QIU Siyuan, LI Yajiao, SUN Jingyao, WU Daming, WANG Shuyuan, XU Hong, GAI Yunqing. Analysis of mechanical properties of RTP pipe based on progressive failure model [J]. China Plastics, 2025, 39(7): 44-48. |

| [8] | NING Dingyi, ZHAO Tianjiao, DONG Yapeng, WANG Meizhen, HAO Xinyu, WANG Bo. Research progress in blending modification for regulating crystallization and mechanical properties of poly(lactic acid) [J]. China Plastics, 2025, 39(6): 126-132. |

| [9] | ZHU Kuilin, LYU Chong, GUO Lei, CHEN Yilin, HUANG Yifeng, ZHAO Peiqi, JIANG Xueliang, YOU Feng. Study on dielectric and mechanical properties of cerium oxide⁃modified polypropylene composites [J]. China Plastics, 2025, 39(6): 19-23. |

| [10] | ZHEN Qi, QIN Zixuan, ZHANG Heng, CUI Jingqiang, WANG Guofeng, CHENG Wensheng, LI Han. Study on annealing process of polylactic acid melt blown microfibrous for medical packaging [J]. China Plastics, 2025, 39(6): 24-30. |

| [11] | ZHOU Qi, LI Quan, LI Yajing, LIU Xinan, GU Xinchun, HUANG Shouying. Rheological and mechanical properties of PPC and PLA blends [J]. China Plastics, 2025, 39(6): 31-35. |

| [12] | JIN Yucheng, WANG Jingfan, ZHAO Shicheng. Effect of addition of PE⁃LD on anti⁃sag performance of bimodal polyethylene [J]. China Plastics, 2025, 39(6): 6-9. |

| [13] | MA Hailong, DAI Mingxin. Research progress in applications of recycled plastic aggregates in cement concrete [J]. China Plastics, 2025, 39(6): 89-99. |

| [14] | LIU Wenlong, ZHOU Xiang, LOU Shuang, MA Xiuqing, LI Haoyi, LI Changjin, YANG Weimin. Research progress in refinement mechanism and influencing factors of melt⁃blown fibers [J]. China Plastics, 2025, 39(5): 118-122. |

| [15] | LI Changjin, LIU Wenlong, YANG Weimin, GUO Zifang, LI Haoyi. Preparation and performance of electrostatic melt⁃blown low⁃density polyethylene microfibers [J]. China Plastics, 2025, 39(5): 25-29. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||