京ICP备13020181号-2

© 《China Plastics》

© 《China Plastics》

China Plastics ›› 2025, Vol. 39 ›› Issue (12): 127-134.DOI: 10.19491/j.issn.1001-9278.2025.12.020

• Review • Previous Articles

HOU Qinzheng1( ), LI Haoyi1, LUO Shen1, LI Changjin2, SI Daoxing1, YANG Weimin1(

), LI Haoyi1, LUO Shen1, LI Changjin2, SI Daoxing1, YANG Weimin1( ), DING Yumei1, CHI Bin3

), DING Yumei1, CHI Bin3

Received:2024-12-19

Online:2025-12-26

Published:2025-12-22

CLC Number:

HOU Qinzheng, LI Haoyi, LUO Shen, LI Changjin, SI Daoxing, YANG Weimin, DING Yumei, CHI Bin. Research progress in supercritical fluid⁃assisted polymer processing technology[J]. China Plastics, 2025, 39(12): 127-134.

| 成型工艺及装置示意图 | 主要介绍 | 参考文献 |

|---|---|---|

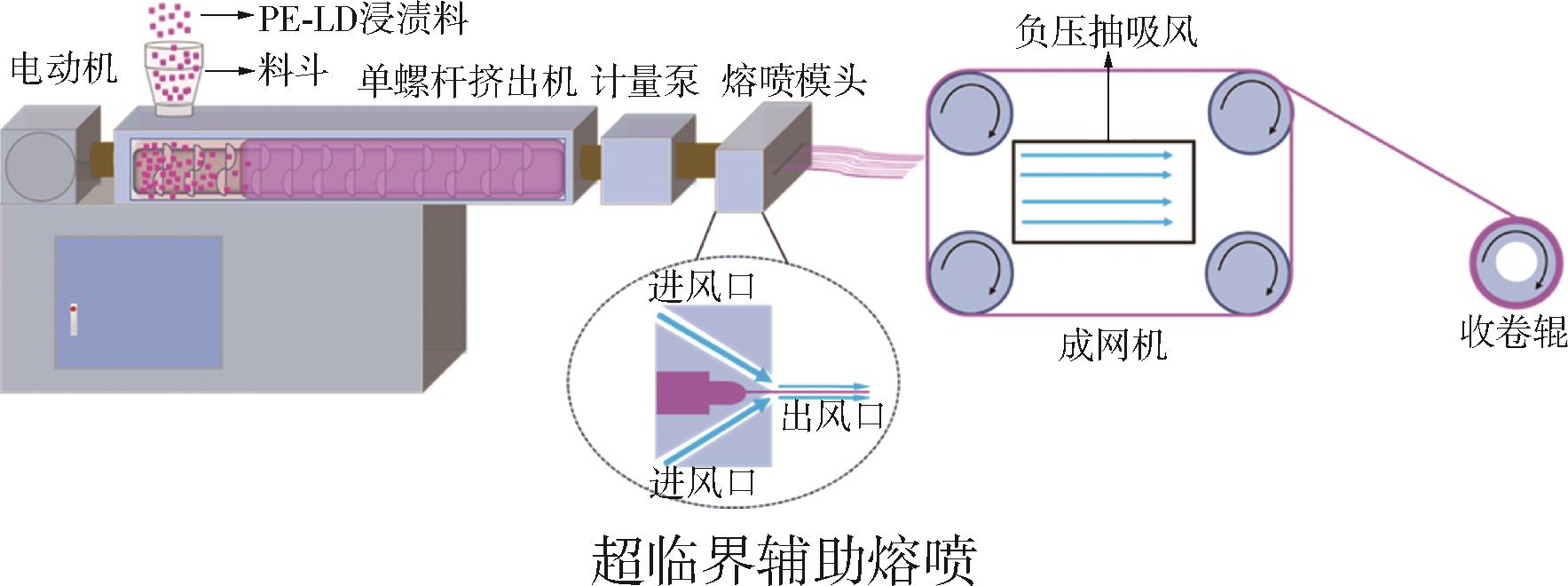

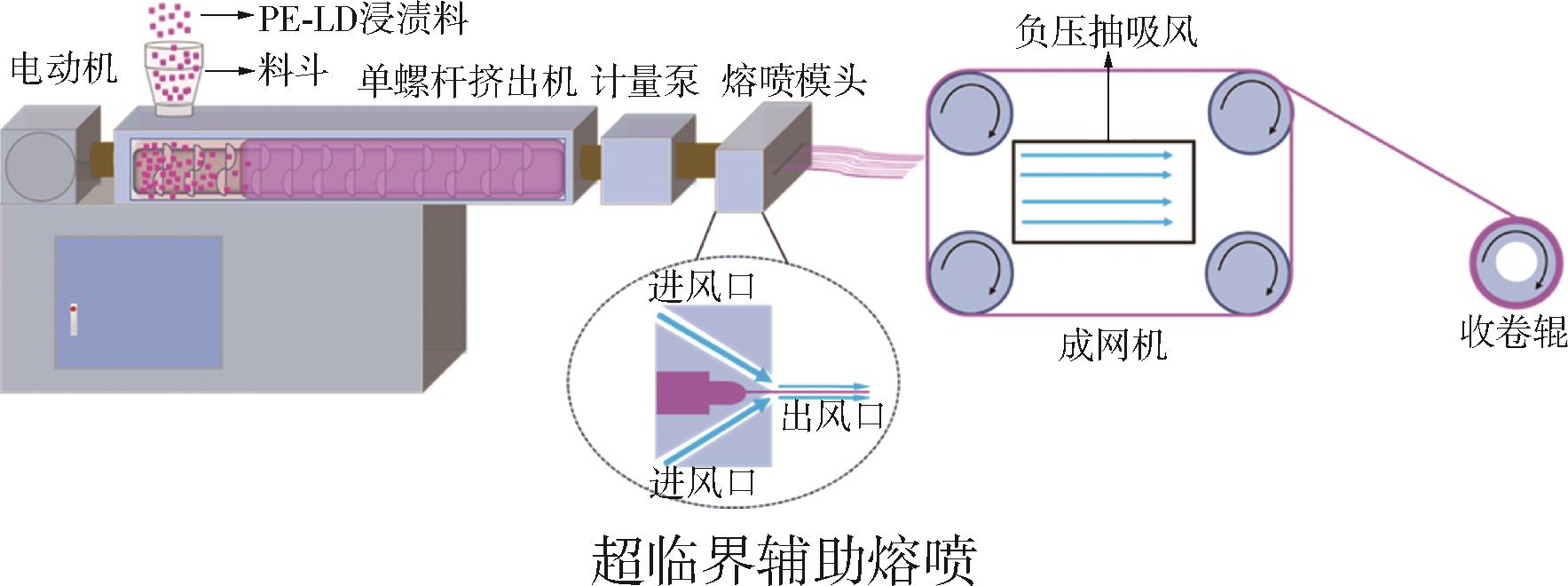

| 主要包括超临界注入釜、挤出机和熔喷模头3部分,物料在超临界注入釜内完成材料的超临界流体注入,输送到挤出机进行塑化均相化并通过熔喷模头喷丝固化成纤。 优点:工艺操作简便,生产连续,纤维铺网较易。 缺点:制备纤维的力学性能较差。 适用性:适用于PP、PE、PLA等各类黏度适中的可熔性塑料纺丝加工。 | — |

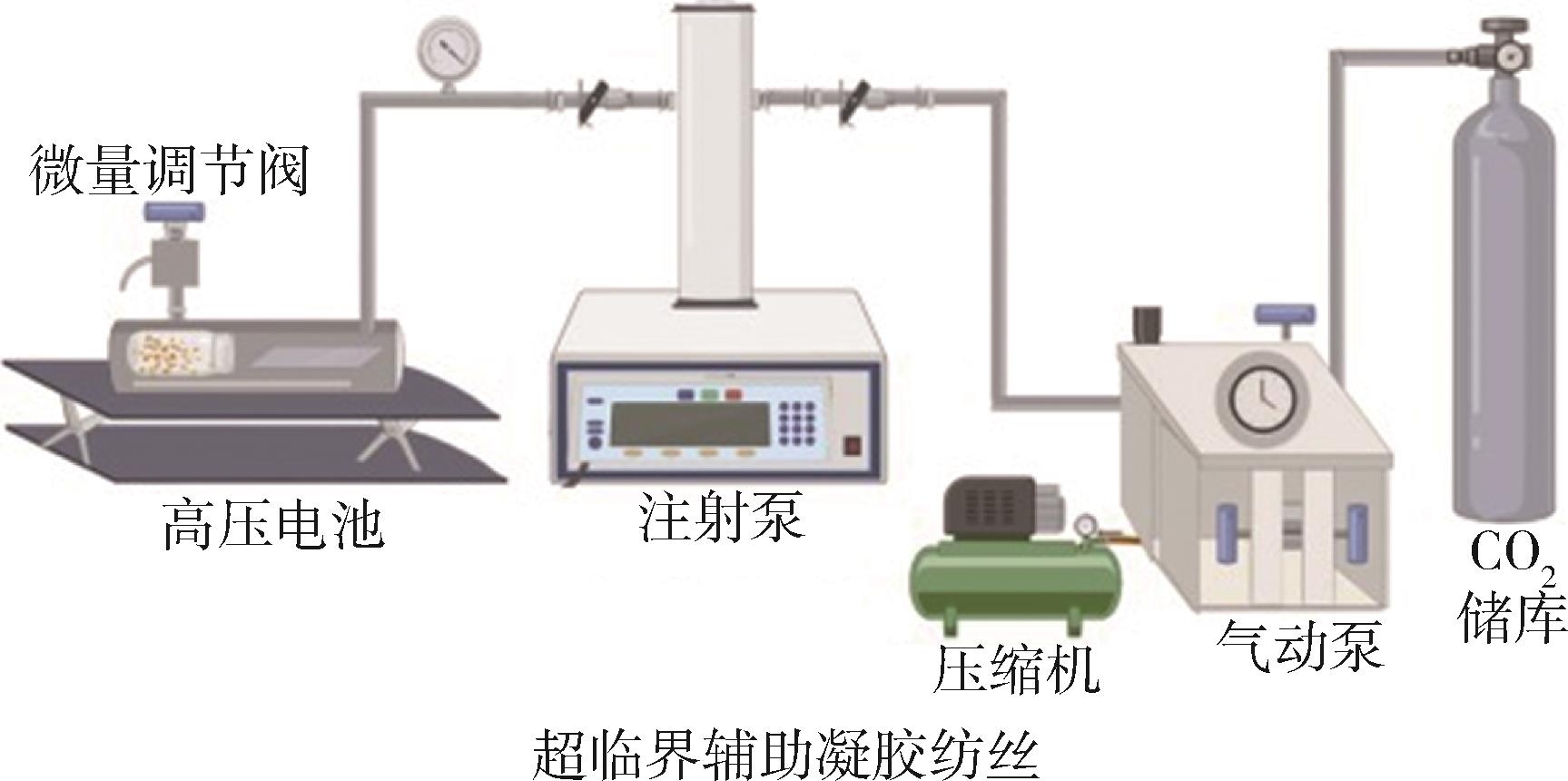

| 通过在挤出机熔融塑化段充入超临界气体形成均相体系,在机头模腔通过压力条件变化实现泡孔的成核、生长及定型。 优点:周期短,效率高,可连续化生产。 缺点:生产工艺较为复杂,设备成本高。 适用性:适用于PP、PE、PLA等各类黏度适中的可熔性塑料纺丝加工。 | [ |

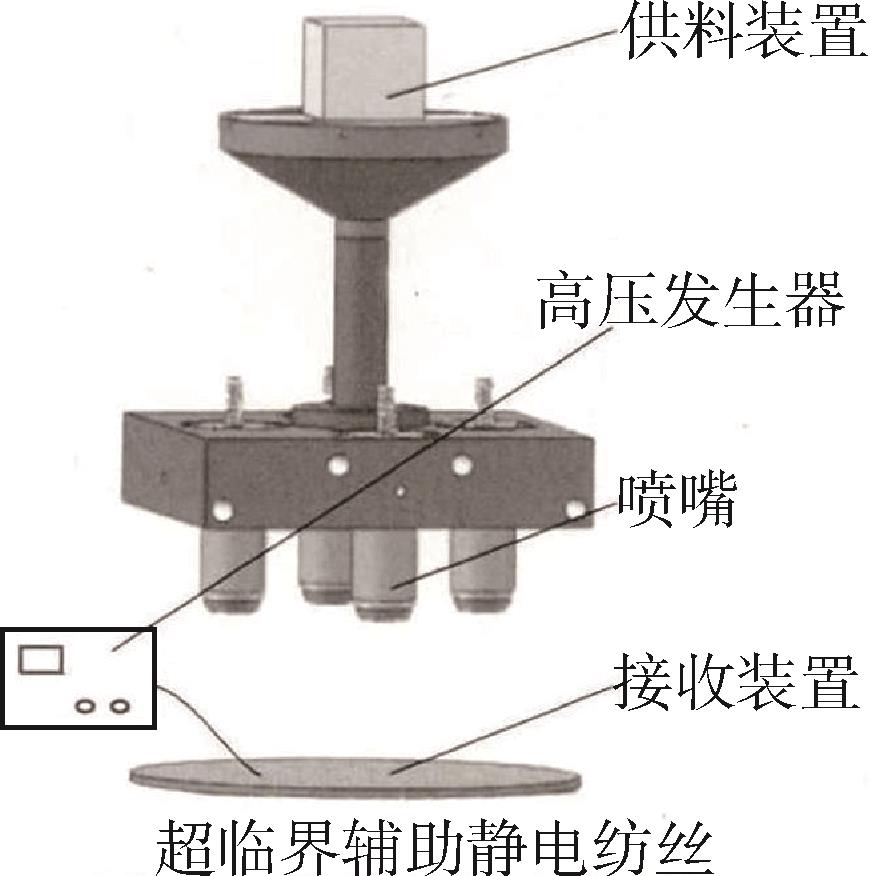

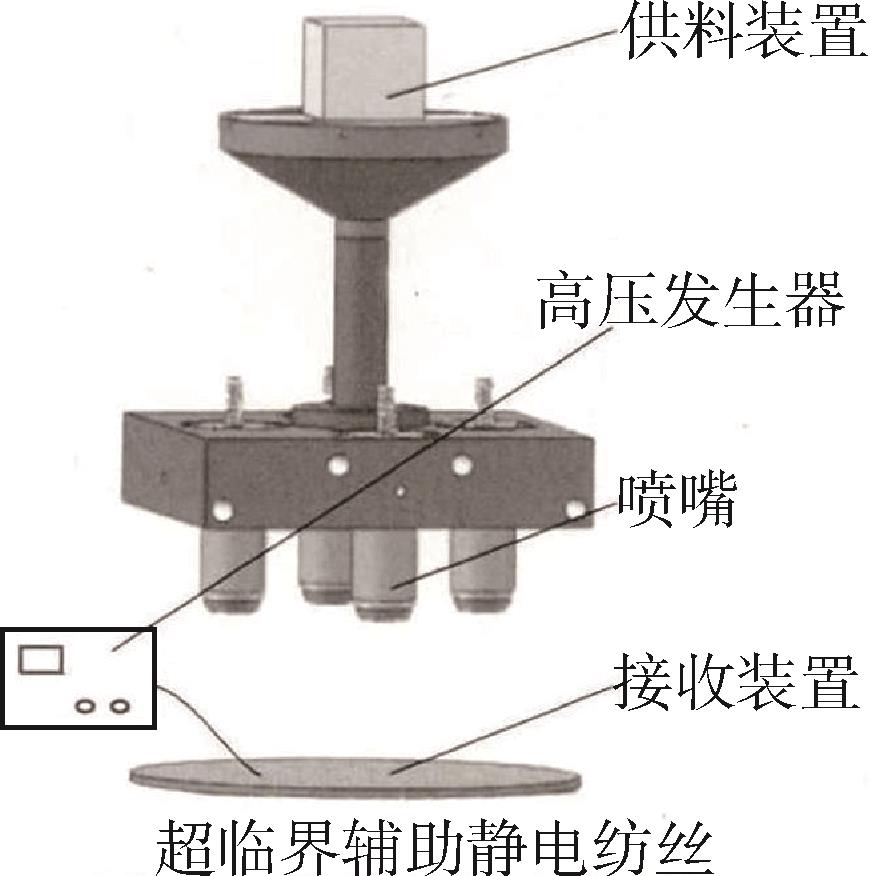

| 主要包括超临界釜、供料装置和静电纺丝模头3部分,物料在超临界注入釜内完成材料的超临界流体注入,通过供料装置输送到静电纺丝模头,在高压静电的作用下在接收电极板纺丝成纤。 优点:不使用任何溶剂无污染,生产效率较高。 缺点:控制工艺较复杂,无溶剂限制材料的适用范围。 适用性:适用于PP、PLA等黏度较低的可熔性塑料纺丝加工。 | [ |

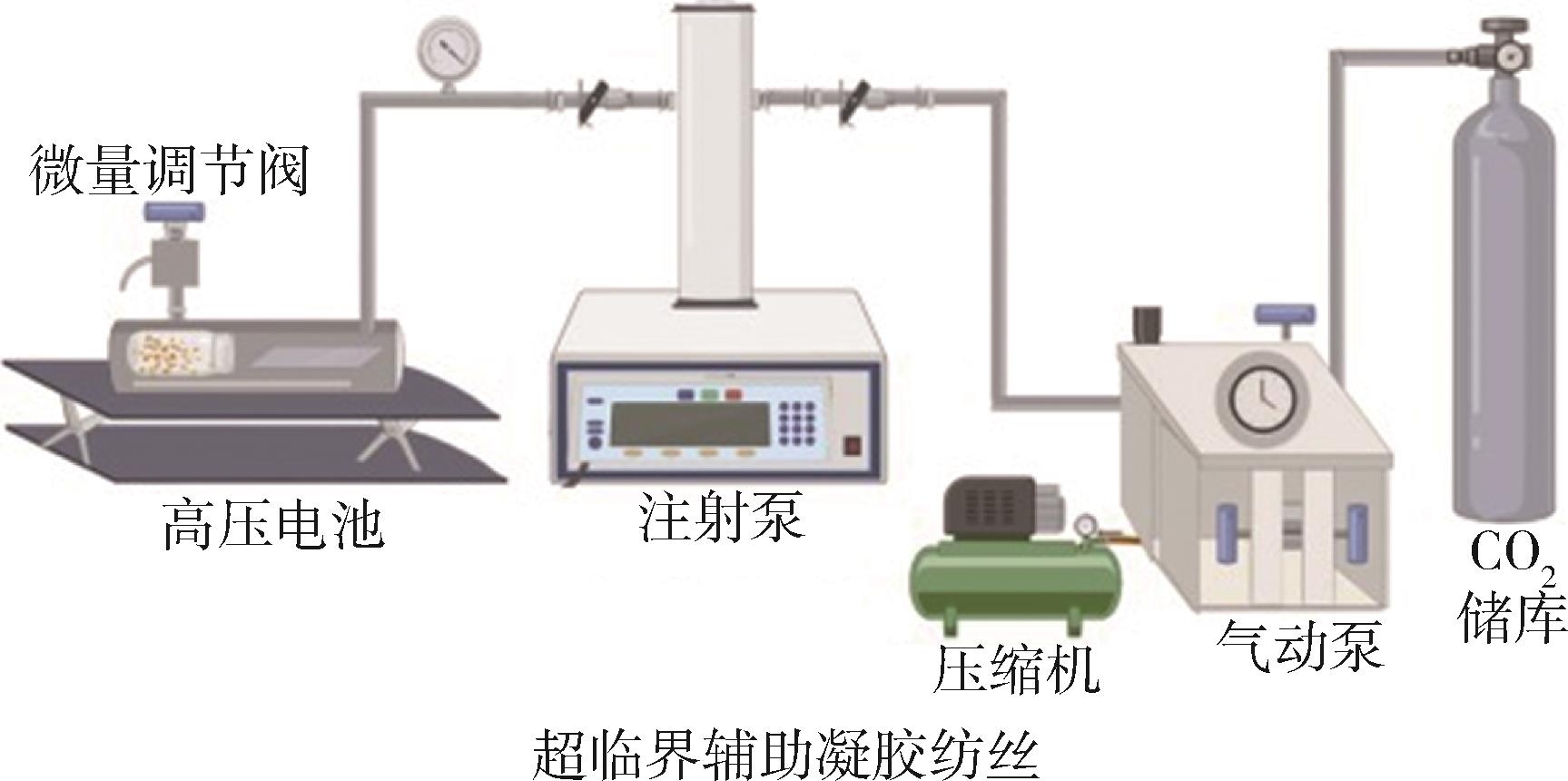

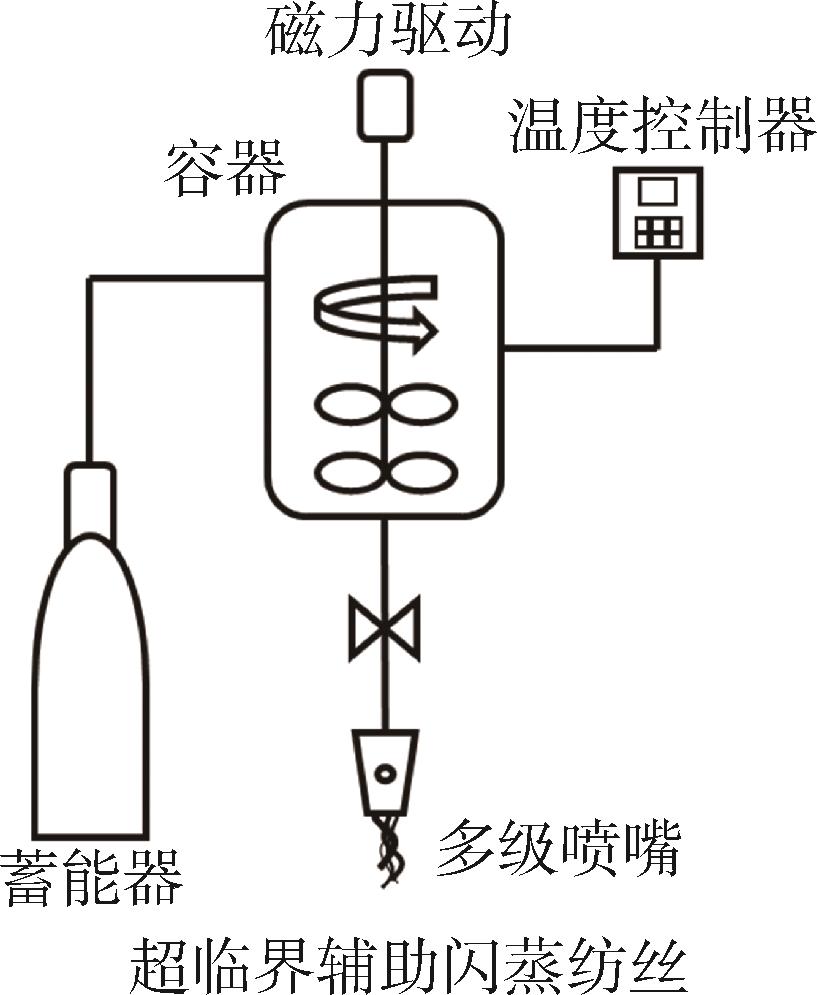

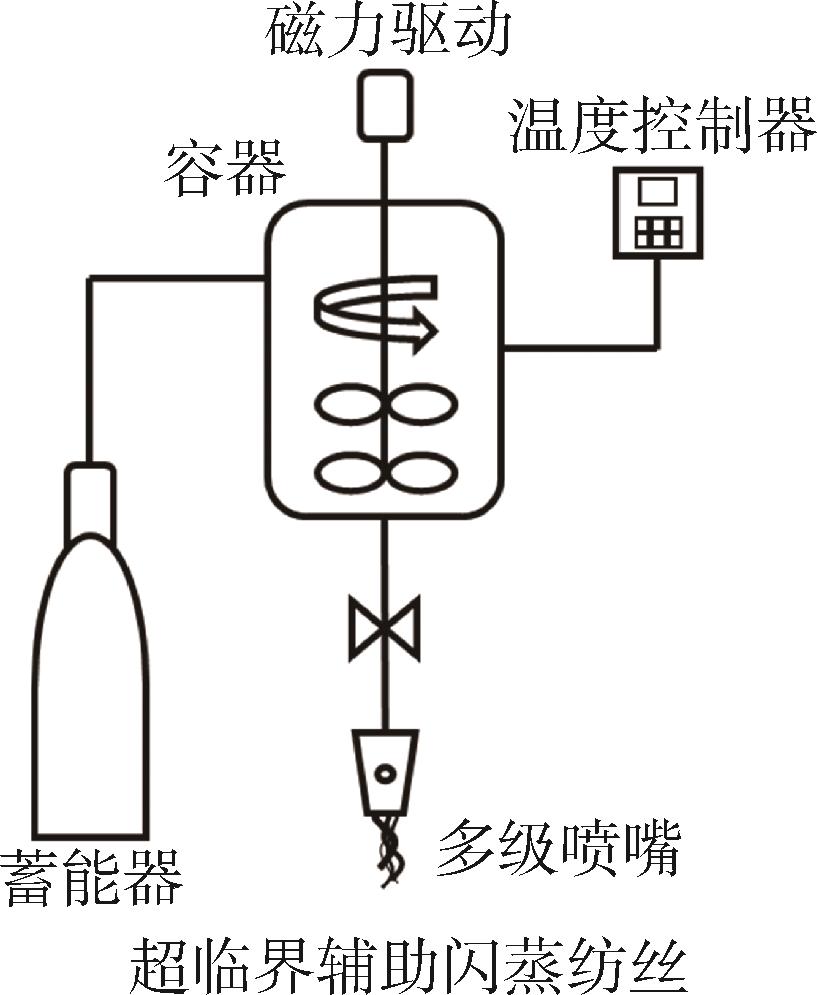

| 主要包括超临界发生器、超临界混合釜、相分离室、喷丝头四部分,超临界流体通过发生器注入到混合釜内,在高温高压下与物料、超临界流体、溶剂一起完成均相化混合,经过减压室进行预分相,输送到喷丝头,超临界流体与少量溶剂在常压条件下瞬间蒸发,纤维固化成纤。 优点:纤维强度高,可连续制备,溶剂挥发彻底。 缺点:控制工艺复杂,相关研究少。 适用性:适用于PP、PLA、PET、UHMWPE等各类可溶解于有机溶剂的塑料纺丝加工。 | [ |

| 成型工艺及装置示意图 | 主要介绍 | 参考文献 |

|---|---|---|

| 主要包括超临界注入釜、挤出机和熔喷模头3部分,物料在超临界注入釜内完成材料的超临界流体注入,输送到挤出机进行塑化均相化并通过熔喷模头喷丝固化成纤。 优点:工艺操作简便,生产连续,纤维铺网较易。 缺点:制备纤维的力学性能较差。 适用性:适用于PP、PE、PLA等各类黏度适中的可熔性塑料纺丝加工。 | — |

| 通过在挤出机熔融塑化段充入超临界气体形成均相体系,在机头模腔通过压力条件变化实现泡孔的成核、生长及定型。 优点:周期短,效率高,可连续化生产。 缺点:生产工艺较为复杂,设备成本高。 适用性:适用于PP、PE、PLA等各类黏度适中的可熔性塑料纺丝加工。 | [ |

| 主要包括超临界釜、供料装置和静电纺丝模头3部分,物料在超临界注入釜内完成材料的超临界流体注入,通过供料装置输送到静电纺丝模头,在高压静电的作用下在接收电极板纺丝成纤。 优点:不使用任何溶剂无污染,生产效率较高。 缺点:控制工艺较复杂,无溶剂限制材料的适用范围。 适用性:适用于PP、PLA等黏度较低的可熔性塑料纺丝加工。 | [ |

| 主要包括超临界发生器、超临界混合釜、相分离室、喷丝头四部分,超临界流体通过发生器注入到混合釜内,在高温高压下与物料、超临界流体、溶剂一起完成均相化混合,经过减压室进行预分相,输送到喷丝头,超临界流体与少量溶剂在常压条件下瞬间蒸发,纤维固化成纤。 优点:纤维强度高,可连续制备,溶剂挥发彻底。 缺点:控制工艺复杂,相关研究少。 适用性:适用于PP、PLA、PET、UHMWPE等各类可溶解于有机溶剂的塑料纺丝加工。 | [ |

| 成型工艺及装置示意图 | 主要介绍 | 参考文献 |

|---|---|---|

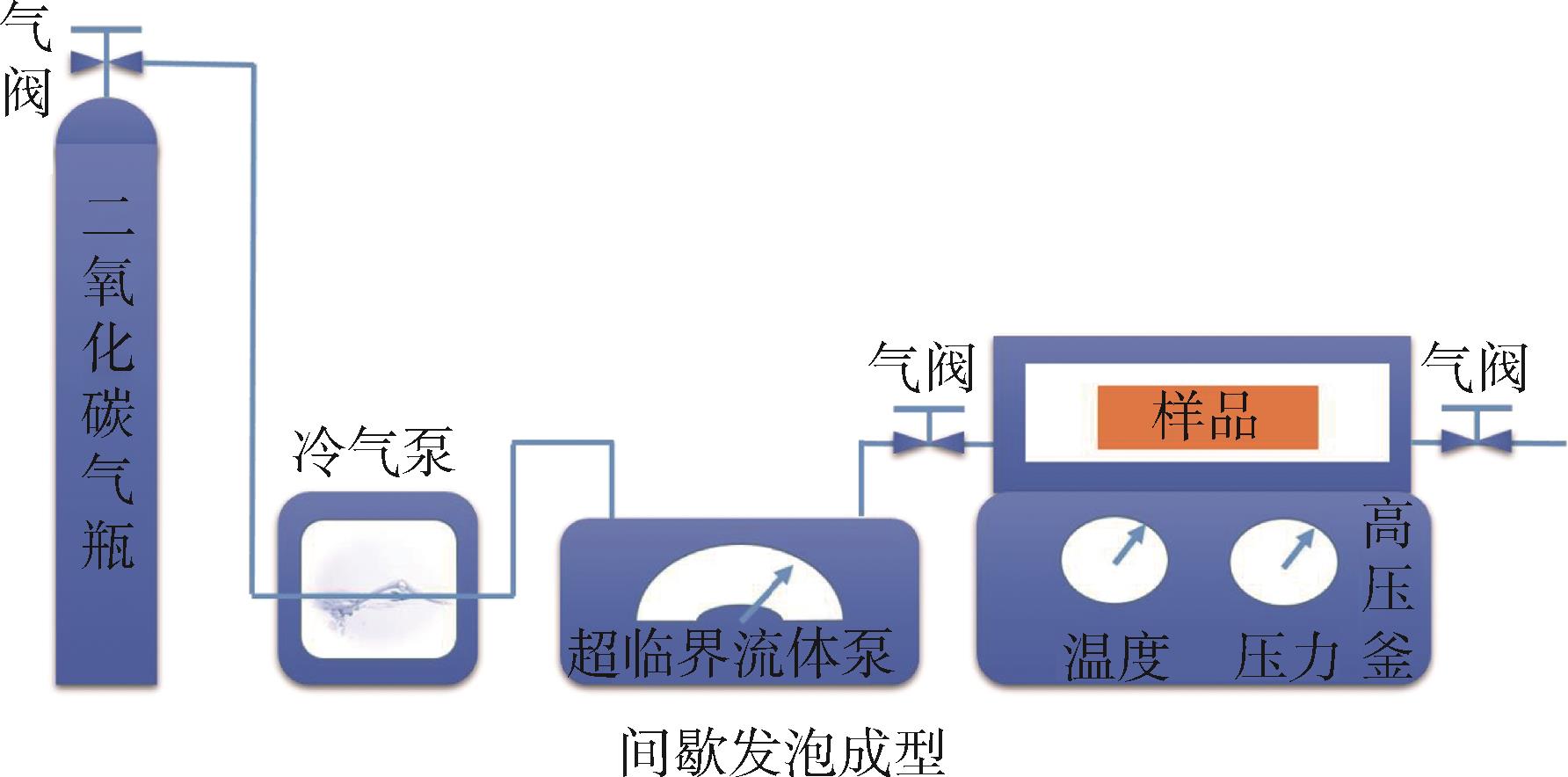

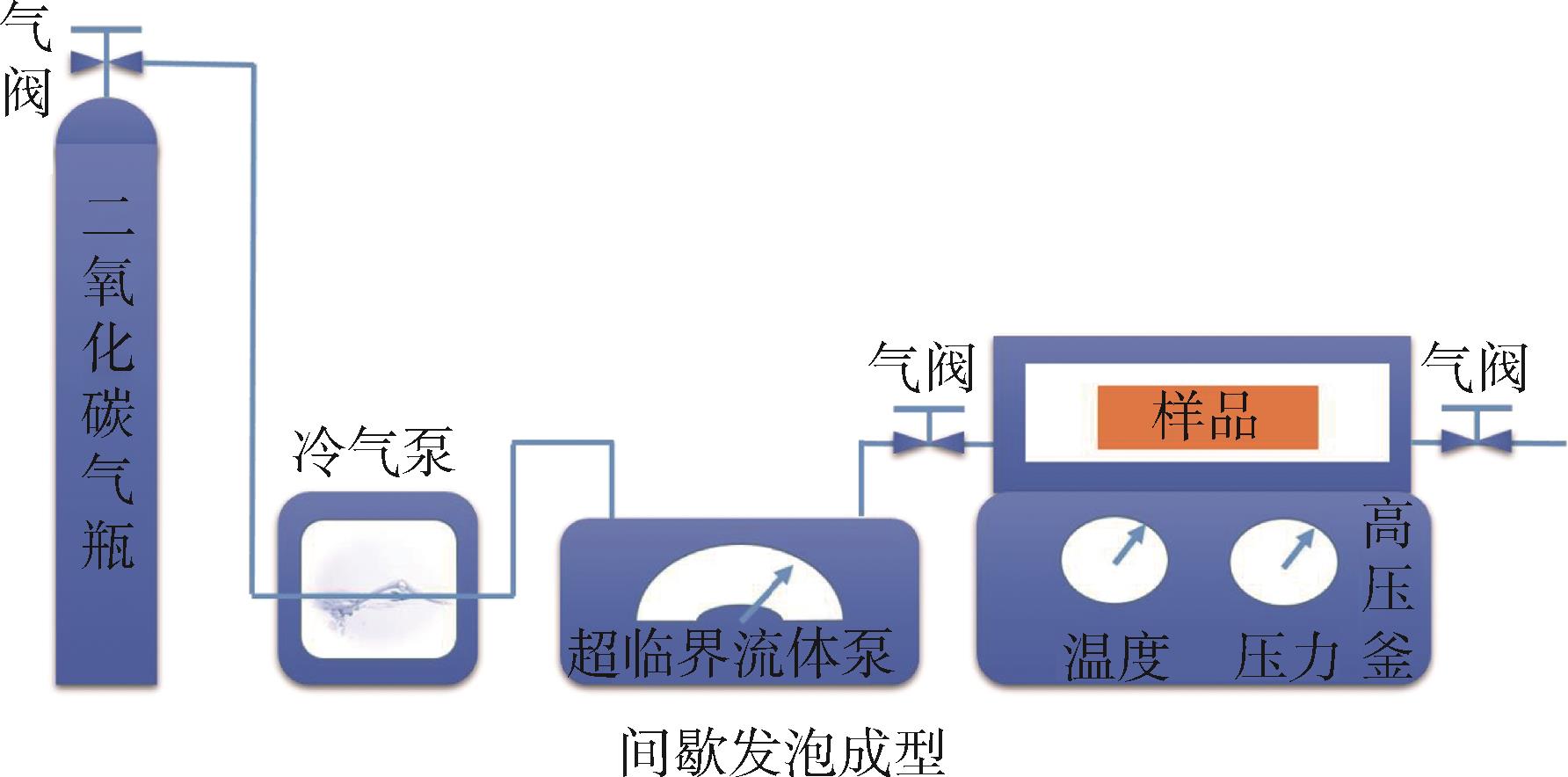

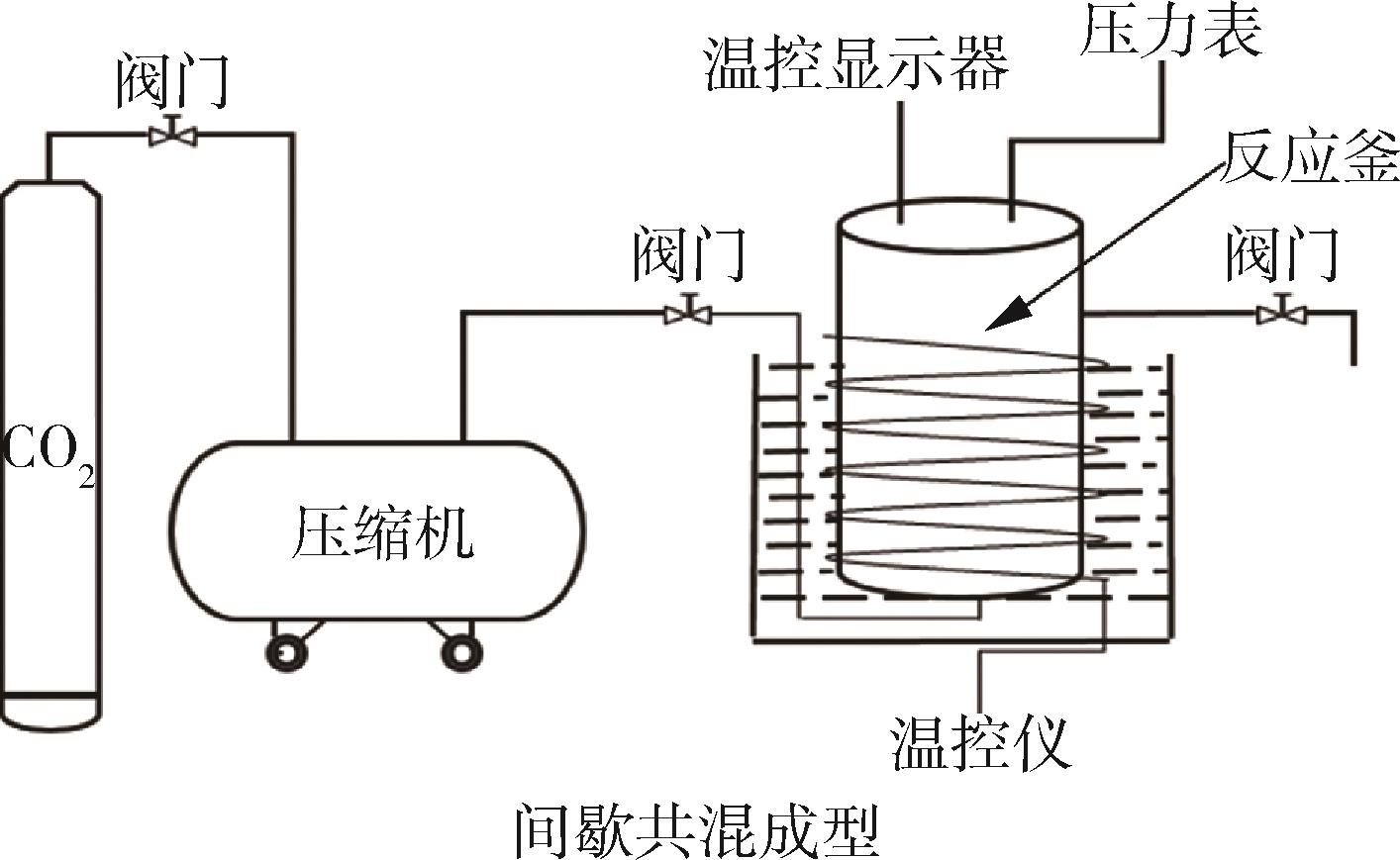

| 通过对高压釜充放超临界气体,控制体系内压力条件的变化,实现均相体系的形成、泡孔的生长以及定型。 优点:工艺操作简便,成孔率高,质量均匀。 缺点:无法连续化生产。 适用性:适用于全品类塑料的发泡成型。 | [ |

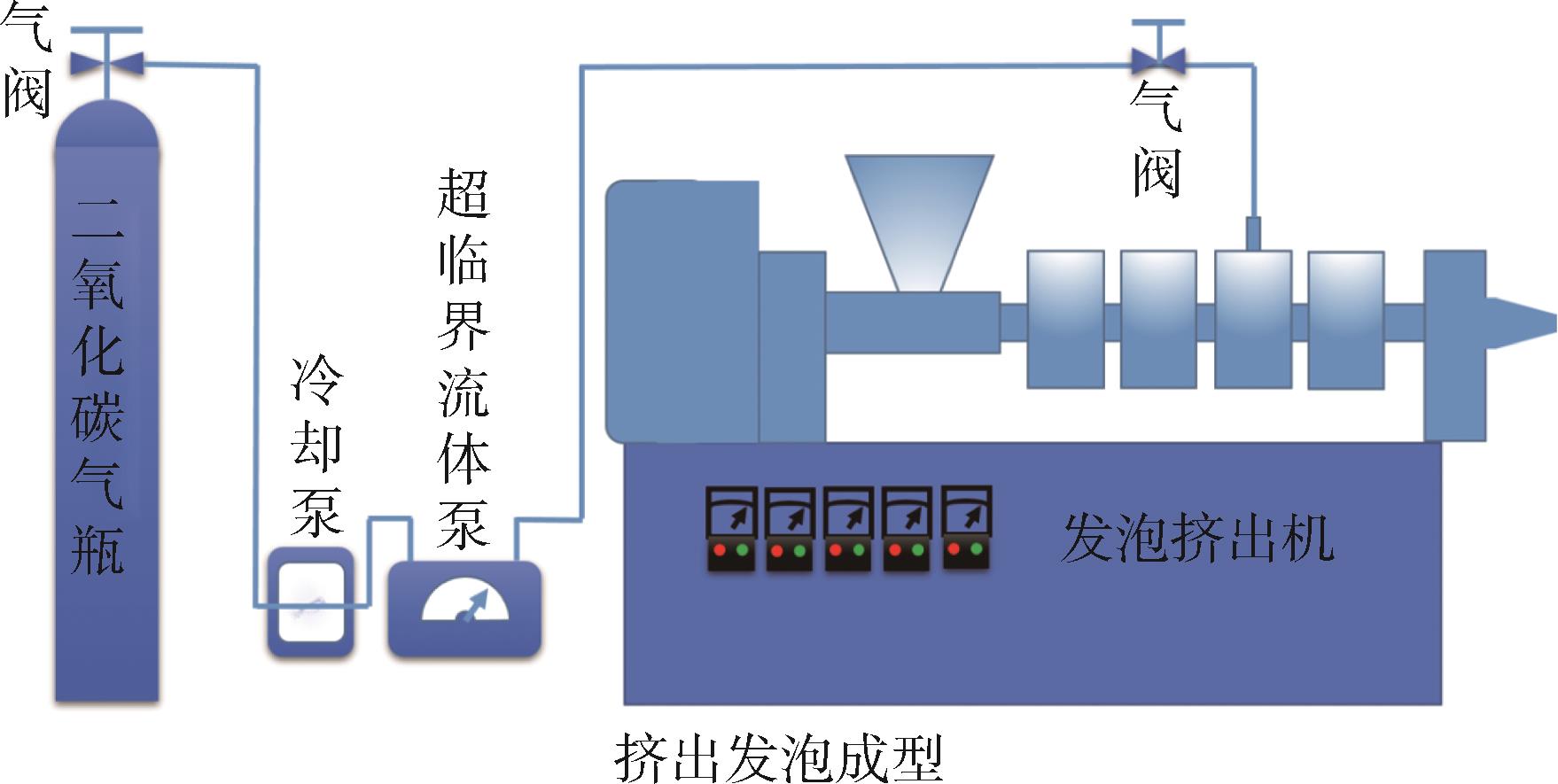

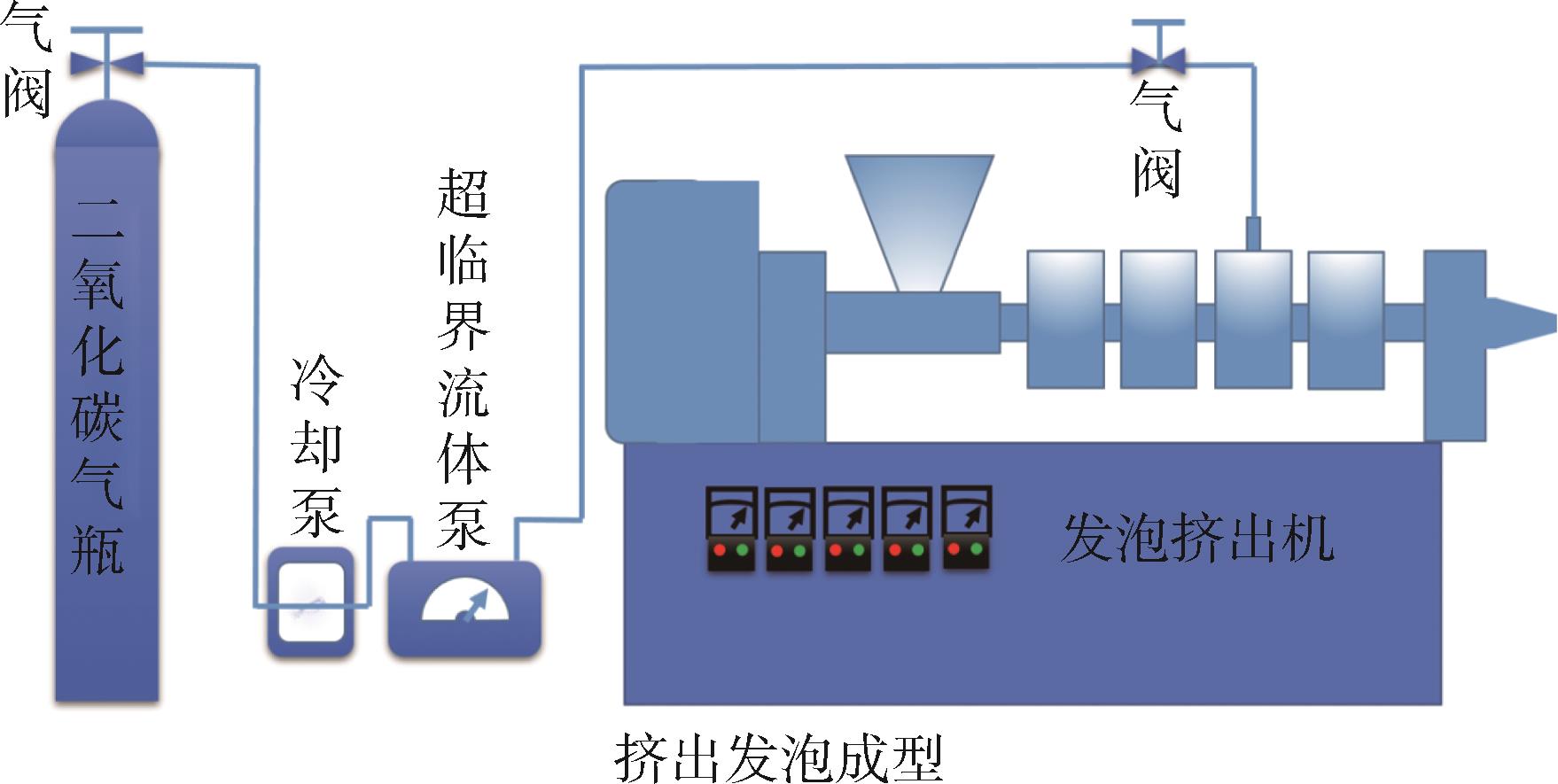

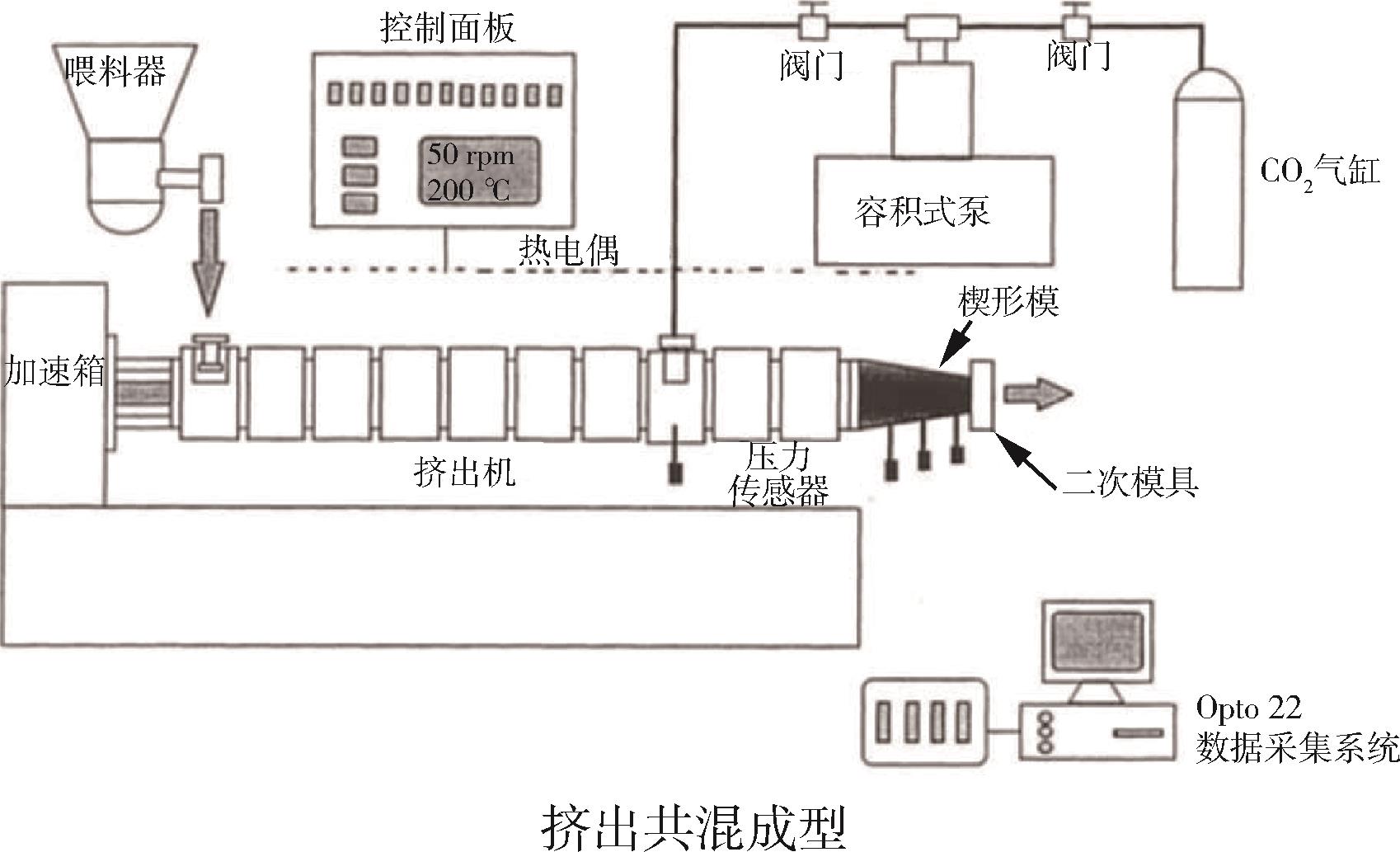

| 通过在挤出机熔融塑化段充入超临界气体形成均相体系,在机头模腔通过压力条件变化实现泡孔的成核、生长及定型。 优点:周期短,效率高,可连续化生产。 缺点:生产工艺较为复杂,设备成本高。 适用性:适用于PP、PE、PLA等各类黏度适中的可熔性塑料的发泡成型。 | [ |

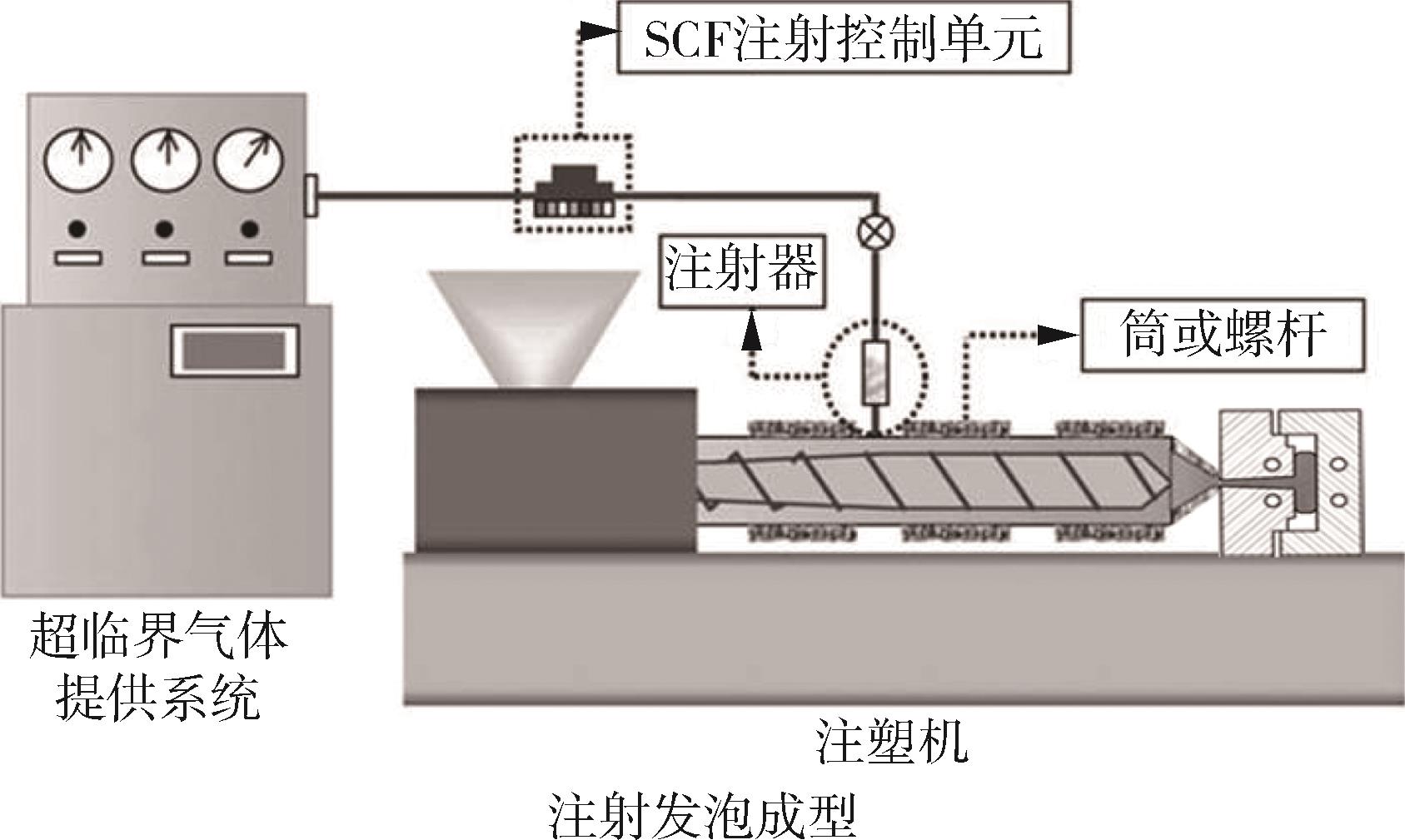

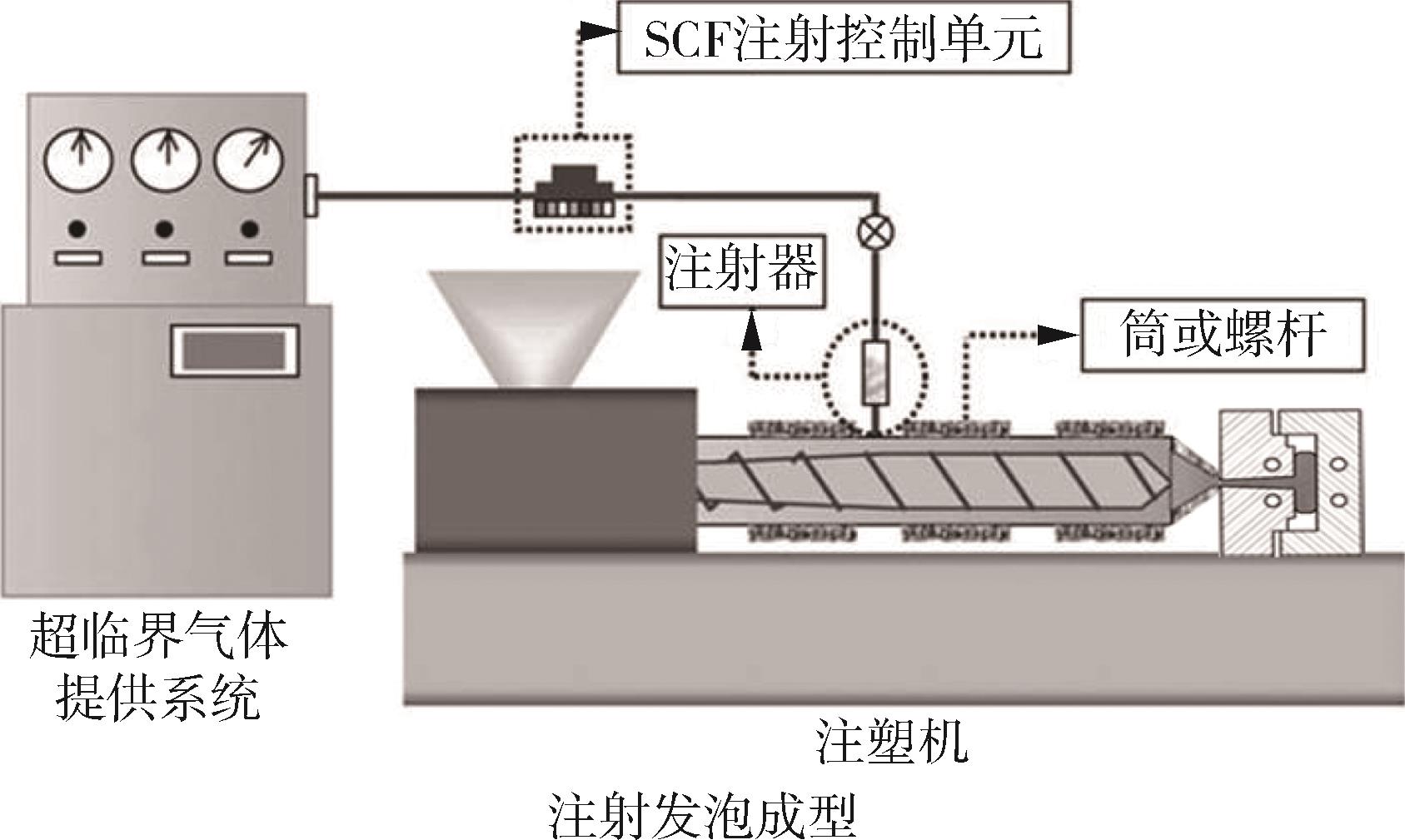

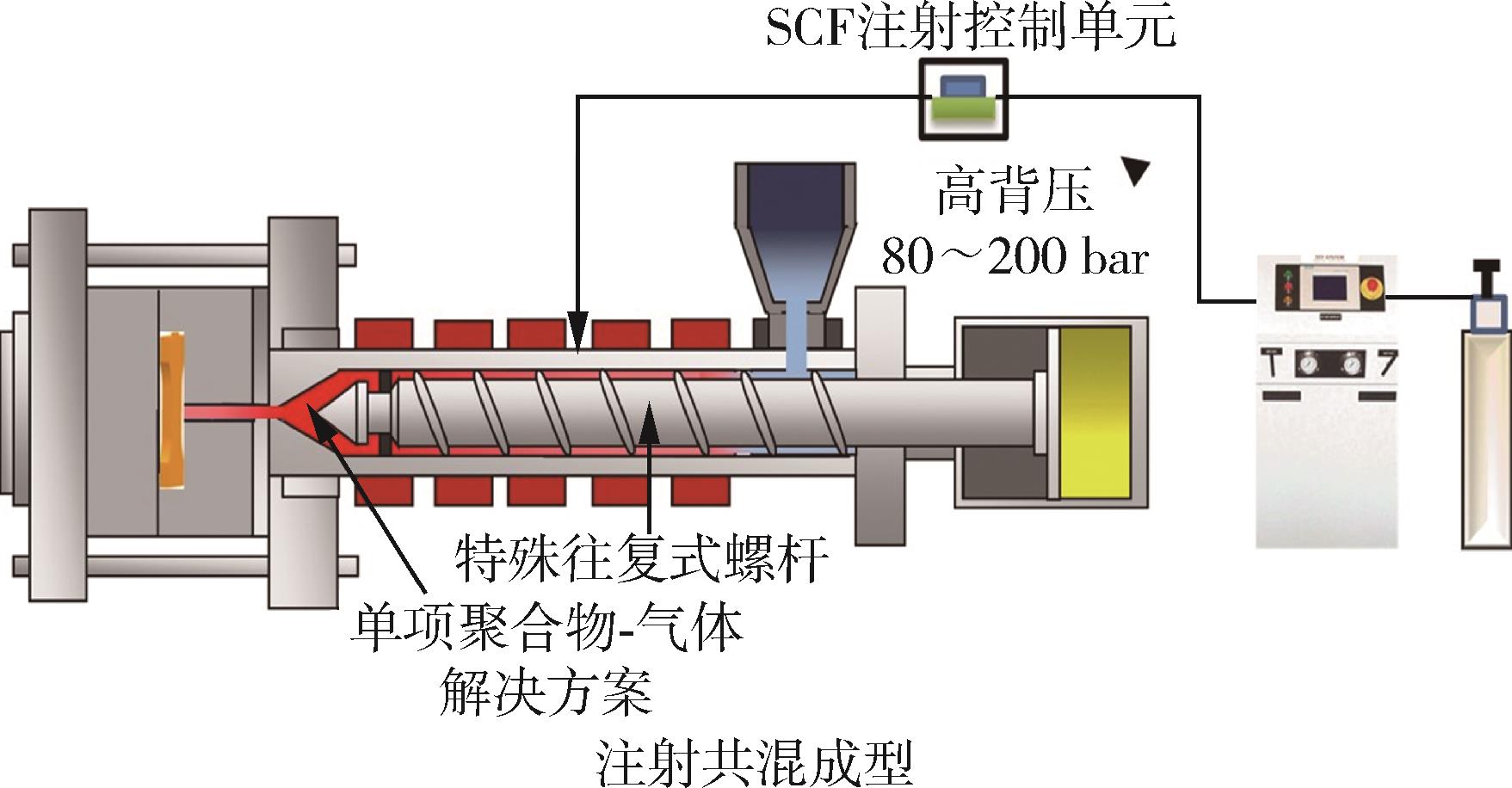

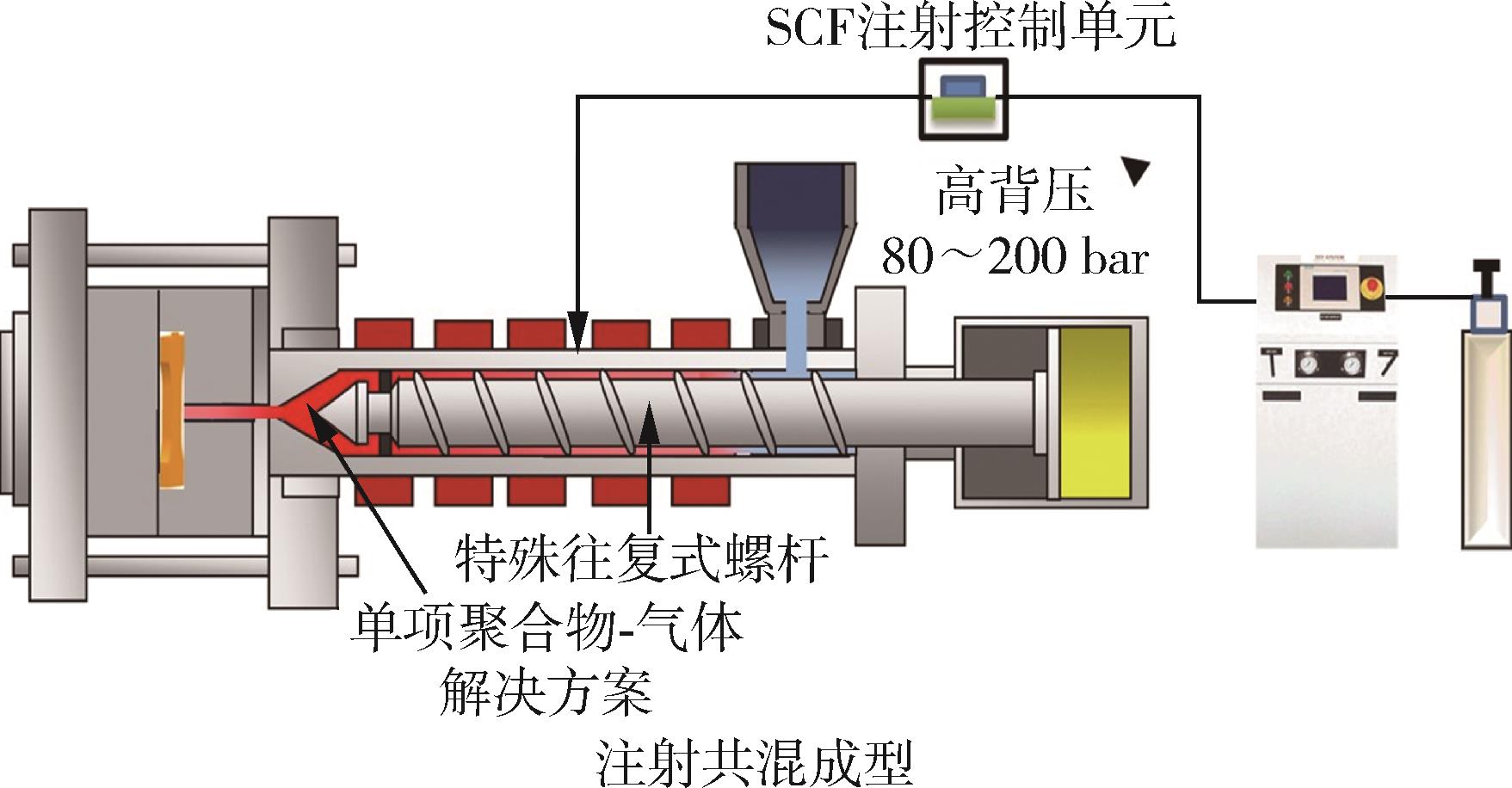

| 通过在注射机熔融塑化段充入超临界气体形成均相体系,注射到模具内,通过模具温度压力条件变化实现泡孔的成核、生长及定型。 优点:可成型复杂制品,生产效率及精度高。 缺点:控制工艺复杂,制品易产生缺陷。 适用性:适用于PP、PE、PLA等各类黏度适中的可熔性塑料的发泡成型。 | [ |

| 成型工艺及装置示意图 | 主要介绍 | 参考文献 |

|---|---|---|

| 通过对高压釜充放超临界气体,控制体系内压力条件的变化,实现均相体系的形成、泡孔的生长以及定型。 优点:工艺操作简便,成孔率高,质量均匀。 缺点:无法连续化生产。 适用性:适用于全品类塑料的发泡成型。 | [ |

| 通过在挤出机熔融塑化段充入超临界气体形成均相体系,在机头模腔通过压力条件变化实现泡孔的成核、生长及定型。 优点:周期短,效率高,可连续化生产。 缺点:生产工艺较为复杂,设备成本高。 适用性:适用于PP、PE、PLA等各类黏度适中的可熔性塑料的发泡成型。 | [ |

| 通过在注射机熔融塑化段充入超临界气体形成均相体系,注射到模具内,通过模具温度压力条件变化实现泡孔的成核、生长及定型。 优点:可成型复杂制品,生产效率及精度高。 缺点:控制工艺复杂,制品易产生缺陷。 适用性:适用于PP、PE、PLA等各类黏度适中的可熔性塑料的发泡成型。 | [ |

| 成型工艺及装置示意图 | 主要介绍 | 参考文献 |

|---|---|---|

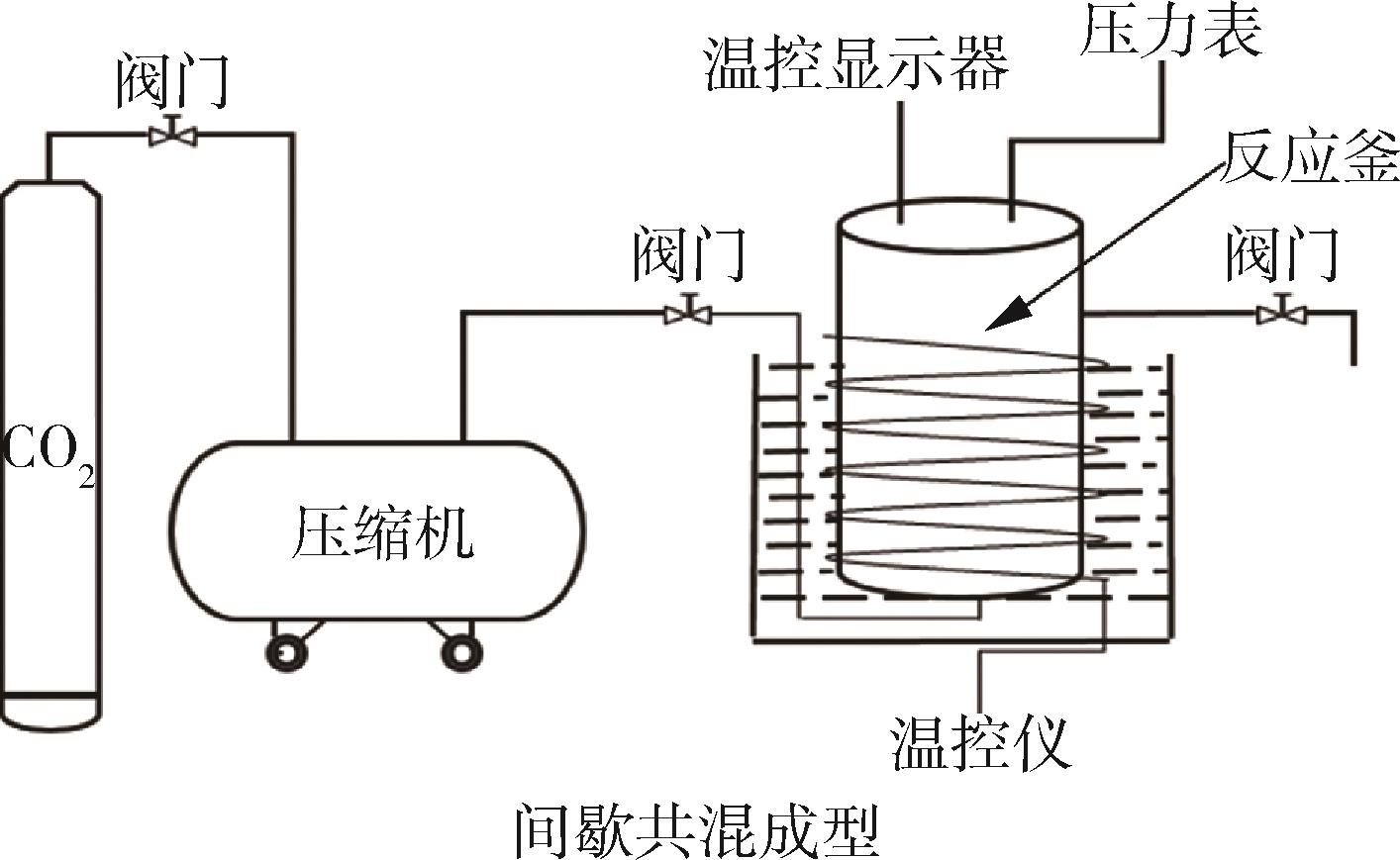

| 将聚合物和填料与超临界流体一起放入反应釜中,通过对釜内的温度和压力进行精确控制,使超临界流体溶解并渗透到聚合物基体中,从而实现共混与改性。 优点:更高的精度和灵活性,适用于小规模的研究和特殊材料的制备。 缺点:无法连续化生产。 适用性:适用于PP、PLA、PET、PE⁃UHMW等各类可熔性塑料的共混成型加工。 | [ |

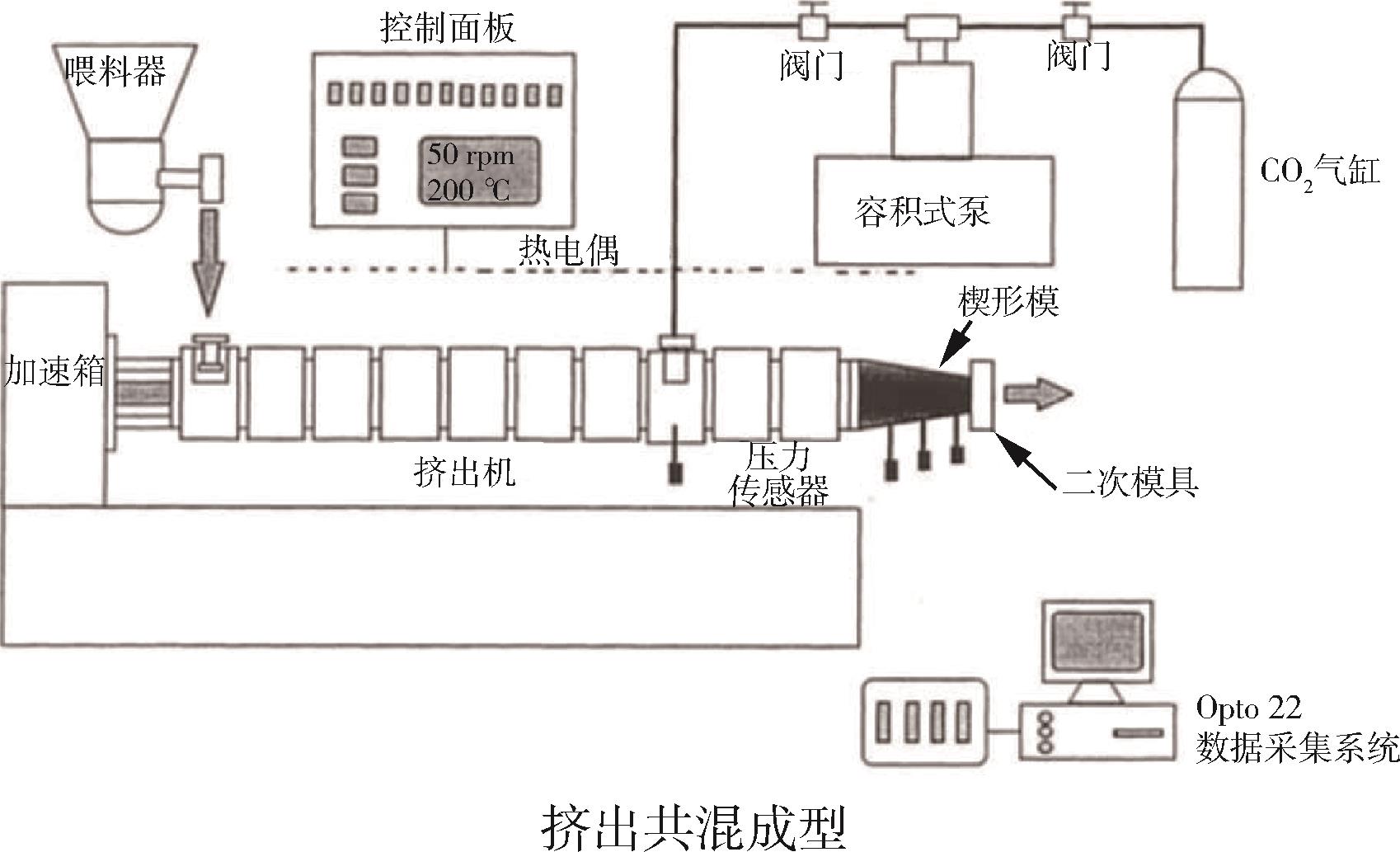

| 挤出共混改性是一种连续化的工艺,超临界流体通过高压注入装置直接注入到挤出机中,与聚合物熔体和填料充分混合。 优点:精度高,效率高,可大规模生产。 缺点:能耗较高,设备成本高。 适用性:适用于PP、PE、PLA等各类黏度适中的可熔性塑料的共混成型加工。 | [ |

| 注射共混过程中,超临界CO₂被引入到聚合物熔体中,通过快速注射成型,可以使填料在注射成型件中均匀分布,从而提升材料的力学性能和表面质量。 优点:有助于增强材料的均匀性,适用于制造复杂形状的高性能工程塑料件。 缺点:设备要求高,控制工艺复杂。 适用性:适用于PP、PE、PLA等各类黏度适中的可熔性塑料的共混成型加工。 | [ |

| 成型工艺及装置示意图 | 主要介绍 | 参考文献 |

|---|---|---|

| 将聚合物和填料与超临界流体一起放入反应釜中,通过对釜内的温度和压力进行精确控制,使超临界流体溶解并渗透到聚合物基体中,从而实现共混与改性。 优点:更高的精度和灵活性,适用于小规模的研究和特殊材料的制备。 缺点:无法连续化生产。 适用性:适用于PP、PLA、PET、PE⁃UHMW等各类可熔性塑料的共混成型加工。 | [ |

| 挤出共混改性是一种连续化的工艺,超临界流体通过高压注入装置直接注入到挤出机中,与聚合物熔体和填料充分混合。 优点:精度高,效率高,可大规模生产。 缺点:能耗较高,设备成本高。 适用性:适用于PP、PE、PLA等各类黏度适中的可熔性塑料的共混成型加工。 | [ |

| 注射共混过程中,超临界CO₂被引入到聚合物熔体中,通过快速注射成型,可以使填料在注射成型件中均匀分布,从而提升材料的力学性能和表面质量。 优点:有助于增强材料的均匀性,适用于制造复杂形状的高性能工程塑料件。 缺点:设备要求高,控制工艺复杂。 适用性:适用于PP、PE、PLA等各类黏度适中的可熔性塑料的共混成型加工。 | [ |

| [1] | 赵一权,董婧晗,张铜柱,等.汽车外饰用再生聚丙烯材料性能研究[J].中国塑料,2023,37(01):112⁃118. |

| [2] | 李守成.阻燃塑料在电气控制系统中的应用[J].塑料工业,2024,52(10):186. |

| [3] | 任 森,庞利霞,周 迪,等.储能聚合物复合方式的研究进展[J].功能材料,2023,54(09):9 070⁃9 079+9 099. |

| [4] | 王镕琛,张 恒,孙焕惟,等.医疗卫生用聚乳酸非织造材料的制备及其亲水改性研究进展[J].中国塑料,2022,36(05):158⁃166. |

| [5] | 刘小平,赵吉敏,周 屹.浅析高分子材料在军品包装上的应用[J].中国塑料,2019,33(02):119⁃122. |

| [6] | 张守海.特种高性能工程塑料产业化技术研究[J].中国科技成果, 2024, 25(15):7⁃10. |

| [7] | Chang B, Li Y, Wang W, et al. Impacts of chain extenders on thermal property, degradation, and rheological performance of poly (butylene adipate⁃co⁃terephthalate)[J]. Journal of Materials Research, 2021, 36: 3 134⁃3 144. |

| [8] | 徐兴家 甄卫军 赵 玲.超临界CO2发泡制备聚氯乙烯微孔材料研究进展[J].中国塑料, 2019, 33(7):117⁃129. |

| [9] | 万 辰. 超临界CO2环境下聚乙烯的流变特性及其影响发泡行为的作用机制[D]. 上海, 2017. |

| [10] | 张 正,李长金,郑 萃,等.闪蒸纺丝法制备医用包装材料的研究进展[J].中国塑料,2024,38(10):60⁃66. |

| [11] | 何亚东,信春玲,任 峰,等.超临界流体挤出发泡系列成套装备技术[J].中国科技成果, 2023, 24(4):75⁃76. |

| [12] | 张 骞,李 冰,智怿擎.可降解泡沫塑料生产技术及其在物流包装领域的应用[J].合成树脂及塑料, 2023, 40(2):68⁃71. |

| [13] | 王淑敏.超临界流体萃取技术在化工生产中的应用[J].聚酯工业,2024,37(6):89⁃91. |

| [14] | 吕正阳,邱 健,邢海平,等.超临界二氧化碳制备高强度阻燃聚苯醚复合发泡材料[J].中国塑料,2024,38(11):21⁃26. |

| [15] | 车秋凌.涤纶的N2⁃CO2混合流体超临界染色技术探索[J].针织工业,2024(9):54⁃57. |

| [16] | Reverchon, Ernesto. Supercritical fluids processing of polymers for pharmaceutical and medical applications[J]. The Journal of Supercritical Fluids, 2009,47(3): 484⁃492. |

| [17] | Subramanian A, Bhat G S. Supercritical CO₂ as a green solvent for polymer processing[J]. Journal of Applied Polymer Science, 2014,131 (9): 40014. |

| [18] | Kazarian S G.Polymer processing with supercritical fluids[J].Polymer Science: A Comprehensive Reference, 2012,1016(10): 503⁃517. |

| [19] | Lu Y. Nanofibrous scaffolds prepared by electrospinning and supercritical CO₂ technology for tissue engineering applications[J]. Journal of Biomedical Materials Research Part A, 2015,103 (1): 21⁃28. |

| [20] | Rivera, Patricia.Development of PLA suture materials by extrusion, electrospinning and supercritical CO2 impregnation of ibuprofen and naproxen[J]. The Journal of Supercritical Fluids, 2023,194: 105854. |

| [21] | 陈明钟,杨卫民,李好义,等.基于超临界CO2制备熔体微分静电纺聚丙烯纤维[J].中国塑料,2016,30(6):70⁃73. |

| [22] | Jae⁃Hyung Wee.Enhancing mechanical properties of flash⁃spun filaments by pressure⁃induced phase separation control in supercritical high⁃density polyethylene solution[J].Scientific Reports, 2022,12 (1): 18030. |

| [23] | Li Lu.Producing polymer fibers by electrospinning in supercritical fluids[J]. Journal of Chemistry, 2013(1): 508905. |

| [24] | Zhou Mengnan. Porous polyetherimide fiber fabricated by a facile micro⁃extrusion foaming for high temperature thermal insulation[J]. Journal of CO2 Utilization, 2022,65: 102247. |

| [25] | GAVANDE V, SHAIKH V, LEE W. Nanofibers: Preparation, Challenges, and Applications[J]. Sustainable Green Nanomaterials: Synthesis, Characterization, and Engineering Applications, 2024: 1. |

| [26] | Sasikala, Padmajan Suchithra, et al. An effective in situ reduction strategy assisted by supercritical fluids for the preparation of graphene⁃polymer composites[J].Carbon, 2018,139: 572⁃580. |

| [27] | Ye Sihong. Supercritical CO2 Assisted TiO2 Preparation to Improve the UV Resistance Properties of Cotton Fiber[J]. Polymers, 2022,14(24): 5513. |

| [28] | Xu Y Y, Zheng L J, Ye F,et al. Water/Oil Repellent Property of Polyester Fabrics After Supercritical Carbon Dioxide Finishing[J].Thermal Science, 2015(4).DOI:10.2298/TSCI1504273X . |

| [29] | Munj, Hrishikesh. CO2 Assisted Processing of Biocompatible Electrospun Polymer Blends[D]. The Ohio State University, 2014. |

| [30] | Jelena Pajnik.Utilization of supercritical carbon dioxide for development of antibacterial surgical sutures[J].The Journal of Supercritical Fluids, 2022,181: 105490. |

| [31] | Meng Zhi⁃Yuan. Supercritical carbon dioxide assisted fabrication of biomimetic sodium alginate/silk fibroin nanofibrous scaffolds[J].Journal of Applied Polymer Science, 2021,138 (44): 51421. |

| [32] | Park C B, Baldwin D F.Polystyrene microcellular foam processing with carbon dioxide[J].Polymer Engineering & Science, 1996,36 (1): 34⁃48. |

| [33] | Colton J S, Suh N P. Nucleation of microcellular foam: theory and practice[J]. Polymer Engineering and Science, 1987, 27(7): 500⁃503. |

| [34] | DeSimone J M. Practical approaches to green solvents[J]. Science, 2002,5582 (297): 799⁃803. |

| [35] | Xanthos M. Foam extrusion: principles and practice[J].Hanser Publishers,2010. |

| [36] | 陈剑泽,王亚桥,陈士宏,等.超临界二氧化碳辅助TPU硬段结晶与发泡行为研究[J].中国塑料, 2019, 33(4):4.DOI:CNKI:SUN:ZGSU.0.2019-04-009 . |

| [37] | 况太荣.超临界二氧化碳发泡制备高性能结晶型聚合物泡沫材料及其应用研究[D].华南理工大学.[2024⁃09⁃21].DOI:CNKI:CDMD:1.1017.734226 . |

| [38] | Jeon B, Kim H K, Cha S W, et al. Microcellular foam processing of biodegradable polymers ⁃ review[J]. International Journal of Precision Engineering and Manufacturing, 2013, 14(4): 679⁃690. |

| [39] | 米皓阳. 医用聚合物组织工程支架的制备方法及其结构性能研究[D]. 华南理工大学, 2015. |

| [40] | Zhang X. Influence of temperature on the cellular structure of PLA foamed using supercritical CO₂[J].Polymer Engineering & Science, 2018,58 (4): 634⁃642. |

| [41] | Chen L.In⁃situ observation of CO₂ diffusion and cell growth in supercritical CO₂ foamed polystyrene using synchrotron X⁃ray imaging[J].Polymer, 2019,167: 35⁃42. |

| [42] | Siripurapu S, Gay Y J, Royer J R,et al. Generation of microcellular foams of PVDF and its blends using supercritical carbon dioxide in a continuous process[J].Polymer, 2002, 43(20):5 511⁃5 520. |

| [43] | Song H.Supercritical CO₂⁃assisted preparation of graphene nanoplatelet/polypropylene composite foams with enhanced electromagnetic interference shielding effectiveness[J].Composites Science and Technology, 2019,174: 31⁃39. |

| [44] | Huang Z.Preparation and thermal conductivity of polystyrene foams containing multi⁃walled carbon nanotubes by supercritical CO₂ foaming[J].Composites Part B: Engineering, 2019,178: 107471. |

| [45] | Zhao Y.Supercritical CO₂ foaming of polyetheretherketone/carbon fiber composites: Morphology, thermal, and mechanical properties[J].Journal of Supercritical Fluids, 2020,159: 104772. |

| [46] | Wang S.Biodegradable PLA/starch composite foams prepared by supercritical CO₂ foaming[J]. Carbohydrate Polymers, 2019,224: 115171. |

| [47] | Liu W.Supercritical CO₂ foaming of polycaprolactone (PCL) for bone tissue engineering scaffolds with enhanced porosity and biocompatibility[J].Polymers, 2020,12 (3): 654. |

| [48] | Yang F.Supercritical CO₂⁃assisted preparation of PLA/hydroxyapatite porous composites for tissue engineering[J].Journal of Applied Polymer Science, 2020,137 (28): 48715. |

| [49] | Xu B.3D printed PEEK scaffolds with gradient pore structure for bone tissue engineering applications. |

| [50] | Zhang H. Fabrication of high⁃strength polypropylene/carbon fiber composite foams by supercritical CO₂⁃assisted hot pressing[J]. Composites Science and Technology, 2021,199: 108388. |

| [51] | Sun Z.Supercritical CO₂⁃assisted electrospinning: A novel method for preparing nanofiber⁃reinforced polymer foams[J].Journal of Applied Polymer Science, 2021,138 (12): 50321. |

| [52] | Zhao Y.Supercritical CO₂ foaming of polyetheretherketone/carbon fiber composites: Morphology, thermal, and mechanical properties[J].Journal of Supercritical Fluids, 2020,159: 104772. |

| [53] | Liu W.Supercritical CO₂ foaming of polycaprolactone (PCL) for bone tissue engineering scaffolds with enhanced porosity and biocompatibility[J]. Polymers, 2020,12 (3): 654. |

| [54] | Wang X.Online monitoring and control system for supercritical CO₂ foaming process of polymer materials[J].Journal of Manufacturing Processes, 2021(60): 487⁃495. |

| [55] | Nalawade S P, Picchioni F, Janssen L P B M. Supercritical carbon dioxide as a green solvent for processing polymer melts: Processing aspects and applications[J]. Progress in Polymer Science, 2006, 31: 19⁃43. |

| [56] | Yadav P, Agrawal M, Alexander A, et al. Polymer production and processing using supercritical carbon dioxide[J]. Green Sustainable Process for Chemical and Environmental Engineering and Science: Supercritical Carbon Dioxide as Green Solvent, 2020: 1⁃16. |

| [57] | Tutek K, Masek A, Kosmalska A, et al. Application of fluids in supercritical conditions in the polymer industry[J]. Polymers, 2021, 13(5): 729. |

| [58] | 薄 扩, 李志义, 魏 炜, 等. 超临界法制备PVDF⁃HFP⁃PEO共混聚合物电解质及其性能研究[J]. 现代化工, 2022, 42(12): 229⁃232. |

| [59] | Lee M, Tzoganakis C, Park C B. Extrusion of PE/PS blends with supercritical carbon dioxide[J]. Polymer Engineering and Science, 1998, 38(7): 1 112⁃1 120. |

| [60] | Zhao H, Yan X, Zhao G,et al. Microcellular injection molded polylactic acid/poly(ε⁃caprolactone) blends with supercritical CO₂: Correlation between rheological properties and their foaming behavior[J]. Polymer Engineering and Science, 2016, 56(8): 939⁃946. |

| [61] | 时静雅, 武培怡. 傅里叶变换红外光谱技术在超临界CO₂作用聚合物体系中的应用[J]. 化学进展, 2009, 21(5): 2 101⁃2 330. |

| [62] | Zeinolebadi A, Schwaderer J, Beuermann S, et al. Effects of supercritical carbon dioxide sorption on the microstructure of poly(vinylidene fluoride)[J]. The Journal of Supercritical Fluids, 2021, 177: 105347. |

| [63] | 崔文豪, 顾瑞星, 米皓阳. 超临界二氧化碳流场作用下线型聚乙烯剪切塑化行为的分子动力学模拟研究[J]. 高分子学报, 2024, 55(10), 1 414⁃1 429. |

| [64] | 郑晓莉. 超临界CO2辅助制备碳纳米管及石墨烯基纳米杂化材料的研究[D]. 河南:郑州大学,2012. |

| [65] | 陈 丹. 改性纳米纤维素/聚乳酸复合材料的制备及超临界CO2发泡研究[D]. 浙江:浙江理工大学,2014. |

| [66] | 张理卿.超临界流体制备石墨烯基无机纳米复合材料及其应用的初步研究[D].青岛科技大学,2014. |

| [67] | Lee S H, Park S, Kim M, et al. Supercritical Carbon Dioxide Assisted Process for Well⁃Dispersed Silicon/Graphene Composite as a Li ion Battery Anode[J]. Scientific Reports, 2016, 6: 32011. |

| [68] | Xu Q Q, Ma Y L, Xu G, et al. Synthesis of highly dispersed silver nanoparticles or nano⁃network modified KIT-6 using supercritical carbon dioxide[J]. Journal of Materials Science, 2015, 50(3): 855⁃862. |

| [69] | Xue J, Li X, Zhao Y,et al. Rapid and selective extraction of silver from complex aqueous matrices using metal⁃organic framework oligomer composites constructed by supercritical CO₂[J]. Journal of Environmental Chemical Engineering, 2022, 10(5): 108456. |

| [70] | Zhou Y, Tian Y, Zhang M. Technical development and application of supercritical CO₂ foaming technology in PCL foam production[J]. Scientific Reports, 2024, 14: 6 825. |

| [71] | Tessanan W, Phinyocheep P, Daniel P,et al. Microcellular natural rubber using supercritical CO₂ technology[J]. The Journal of Supercritical Fluids, 2019, 149: 70⁃78. |

| [1] | WANG Shuo, YUAN Wenbo, CHENG Yichong, ZANG Yuntao, LENG Dongliang, LI Haiyan, ZHAO Ling, HU Dongdong. Mechanical performance of branched polypropylene foams fabricated via supercritical CO₂ molding [J]. China Plastics, 2025, 39(9): 1-6. |

| [2] | LIU Wenlong, ZHOU Xiang, LOU Shuang, MA Xiuqing, LI Haoyi, LI Changjin, YANG Weimin. Research progress in refinement mechanism and influencing factors of melt⁃blown fibers [J]. China Plastics, 2025, 39(5): 118-122. |

| [3] | LI Changjin, LIU Wenlong, YANG Weimin, GUO Zifang, LI Haoyi. Preparation and performance of electrostatic melt⁃blown low⁃density polyethylene microfibers [J]. China Plastics, 2025, 39(5): 25-29. |

| [4] | LI Wanlong, YANG Weimin, WANG Shuo, LI Changjin, ZHANG Yang, TAN Jing, YAN Hua, LI Haoyi. Study on enhancement modification of melt⁃differential electrospun poly(lactic acid) fiber with CH⁃S04 [J]. China Plastics, 2025, 39(2): 1-5. |

| [5] | ZHANG Liyan, YIN Rongzheng, TAN Jing, HOU Qinzheng, LI Changjin, YANG Tao, YANG Weimin, LI Haoyi. Research progress in nonwoven technology of polyethylene ultrafine fibers [J]. China Plastics, 2025, 39(2): 100-105. |

| [6] | ZHANG Zheng, LI Fangquan, ZHU Guixiang, GUO Min, WANG Ying. Study on preparation technology of ultrafine biodegradable electrospun PBST nanofibers [J]. China Plastics, 2025, 39(2): 32-39. |

| [7] | WANG Yong, SUN Xiaojie, WANG Rong, SUN Miaomiao. Advances in modification of poly(glycolic acid) [J]. China Plastics, 2025, 39(11): 142-152. |

| [8] | WANG Suwei, HU Ping, ZONG Huzeng, XUE Ping. Thermal decomposition behavior of foaming agent and its influence of gas yield on properties of microporous PP⁃based wood⁃plastic composites [J]. China Plastics, 2025, 39(11): 27-31. |

| [9] | XIE Mingdong, QIN Liu, SI Daoxing, LIU Jiaxin, YANG Weimin. Structure and properties of rigid low⁃density open⁃cell polyimide foam prepared by vacuum⁃assisted foaming [J]. China Plastics, 2025, 39(11): 7-12. |

| [10] | QUAN Shumiao, ZHANG Zhe, YU Dan, DU Runping. Carbon emission accounting of typical organic solid waste treatment and disposal processes in context of carbon peak and neutrality [J]. China Plastics, 2025, 39(10): 113-120. |

| [11] | LI Yan, WANG Xinyan, ZHUANG Chuanlong, CHEN Jie, LIU Ye. Research progress in electrospinning technology for polymer⁃based radiative cooling materials [J]. China Plastics, 2025, 39(10): 151-157. |

| [12] | CUI Bao, YANG Jianjun, WU Qingyun, WU Mingyuan, ZHANG Jianan, LIU Jiuyi. Research Progress in blending modification of polylactic acid composites and their applications [J]. China Plastics, 2024, 38(9): 129-136. |

| [13] | HU Lingxiao, JIANG Huihui. The relationship between the defoaming process after PET film bonding and pressure based on visual experiments [J]. China Plastics, 2024, 38(9): 82-87. |

| [14] | SUN He, HE Xin, LUO Tongyu, JI Xin, LIAO Qiling, ZHANG Yuxia, ZHOU Hongfu. Study on electromagnetic interference shielding properties of ABS/CNTs/Fe3O4 composite and its bimodal foam [J]. China Plastics, 2024, 38(8): 46-52. |

| [15] | SHEN Qiangfeng, LYU Mingfu, XU Yaohui. Study on autoclave foaming properties of metallocene polypropylene [J]. China Plastics, 2024, 38(7): 55-61. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||