京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2

《中国塑料》编辑部 ©2008-2024 版权所有

地址:北京市海淀区阜成路11号 邮编:100048

编辑部:010-68985541 联系信箱:cp@plaschina.com.cn

广告部/发行部:010-68985253 本系统由北京玛格泰克科技发展有限公司设计开发

中国塑料 ›› 2021, Vol. 35 ›› Issue (7): 115-125.DOI: 10.19491/j.issn.1001-9278.2021.07.019

收稿日期:2020-12-10

出版日期:2021-07-26

发布日期:2021-07-21

基金资助:

ZHANG Ting1, ZHANG Caili1,2, SONG Xinyu2, WENG Yunxuan1,2( )

)

Received:2020-12-10

Online:2021-07-26

Published:2021-07-21

Contact:

WENG Yunxuan

E-mail:wyxuan@th.btbu.edu.cn

摘要:

综述了聚己二酸?对苯二甲酸丁二酯(PBAT)及其复合膜在食品活性包装膜和地膜中应用的研究进展;详细介绍了提高PBAT膜性能的主要方法,包括与聚合物共混、与无机填料共混、与其他可再生资源共混等;阐述了PBAT及其复合膜的降解性能;并对PBAT膜未来的研究方向进行了展望。

中图分类号:

张婷, 张彩丽, 宋鑫宇, 翁云宣. PBAT薄膜的制备及应用研究进展[J]. 中国塑料, 2021, 35(7): 115-125.

ZHANG Ting, ZHANG Caili, SONG Xinyu, WENG Yunxuan. Research Progress in Preparation and Applications of PBAT Films[J]. China Plastics, 2021, 35(7): 115-125.

| 样品 | 薄膜厚度/μm | 断裂伸长率/% | 弹性模量/MPa | 拉伸强度/MPa | 水蒸气透过率/10-11·g m·m-2·Pa-1·s-1 | 水接触角/(°) |

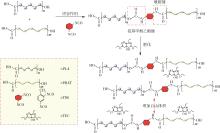

|---|---|---|---|---|---|---|

| PBAT | 51.9 | 126.7 | 107.3 | 4.1 | 6.50 | 70.7 |

| PBAT/TP | 52.7 | 125.5 | 107.4 | 6.5 | 5.95 | 72.5 |

| PBAT/AgNPs | 51.4 | 121.6 | 108.6 | 7.8 | 5.35 | 77.9 |

| 样品 | 薄膜厚度/μm | 断裂伸长率/% | 弹性模量/MPa | 拉伸强度/MPa | 水蒸气透过率/10-11·g m·m-2·Pa-1·s-1 | 水接触角/(°) |

|---|---|---|---|---|---|---|

| PBAT | 51.9 | 126.7 | 107.3 | 4.1 | 6.50 | 70.7 |

| PBAT/TP | 52.7 | 125.5 | 107.4 | 6.5 | 5.95 | 72.5 |

| PBAT/AgNPs | 51.4 | 121.6 | 108.6 | 7.8 | 5.35 | 77.9 |

| 样品名称 | 相容剂/交联剂 | 拉伸强度/MPa | 断裂伸长率/% | 撕裂强度/kN·m-1 | 参考文献 | ||||

|---|---|---|---|---|---|---|---|---|---|

| 名称 | 含量/份 | MD | TD | MD | TD | MD | TD | ||

| PBAT/PLA(60/40) | BIBP | 0.1 | 43.9 | 48.7 | 382.8 | 364.6 | 197.0 | 159.1 | [ |

| PBAT/PLA(50/50) | ADR?4370F | 0.15 | 40.7 | 36.7 | 264.6 | 300.3 | 163.8 | 168.5 | [ |

| PBAT | — | — | 31.3 | 21.7 | 2 001 | 1 401 | 93.2 | 100.7 | [ |

| PBAT/PPC(90/10) | — | — | 27.6 | 12.4 | 1 768 | 702 | 94.7 | 99.4 | [ |

| PBAT/PPC(70/30) | — | — | 20.4 | 12.6 | 1 464 | 699 | 102.6 | 109.7 | [ |

| 样品名称 | 相容剂/交联剂 | 拉伸强度/MPa | 断裂伸长率/% | 撕裂强度/kN·m-1 | 参考文献 | ||||

|---|---|---|---|---|---|---|---|---|---|

| 名称 | 含量/份 | MD | TD | MD | TD | MD | TD | ||

| PBAT/PLA(60/40) | BIBP | 0.1 | 43.9 | 48.7 | 382.8 | 364.6 | 197.0 | 159.1 | [ |

| PBAT/PLA(50/50) | ADR?4370F | 0.15 | 40.7 | 36.7 | 264.6 | 300.3 | 163.8 | 168.5 | [ |

| PBAT | — | — | 31.3 | 21.7 | 2 001 | 1 401 | 93.2 | 100.7 | [ |

| PBAT/PPC(90/10) | — | — | 27.6 | 12.4 | 1 768 | 702 | 94.7 | 99.4 | [ |

| PBAT/PPC(70/30) | — | — | 20.4 | 12.6 | 1 464 | 699 | 102.6 | 109.7 | [ |

| 样品 | 弹性模量/MPa | 断裂伸长率/% | 拉伸强度/ MPa |

|---|---|---|---|

| 76PBAT/24PLA | 373 ± 94 | 32 ± 13 | 11 ± 2 |

| 66PBAT/24PLA/10 CaCO3 | 544± 58 | 87± 2 | 14.0 ± 0.6 |

| 56PBAT/24PLA/20 CaCO3 | 584± 9 | 22 ± 3 | 11.2± 0.8 |

| 62PBAT/28PLA/10 CaCO3 | 782 ± 85 | 80 ± 12 | 15 ± 2 |

| 样品 | 弹性模量/MPa | 断裂伸长率/% | 拉伸强度/ MPa |

|---|---|---|---|

| 76PBAT/24PLA | 373 ± 94 | 32 ± 13 | 11 ± 2 |

| 66PBAT/24PLA/10 CaCO3 | 544± 58 | 87± 2 | 14.0 ± 0.6 |

| 56PBAT/24PLA/20 CaCO3 | 584± 9 | 22 ± 3 | 11.2± 0.8 |

| 62PBAT/28PLA/10 CaCO3 | 782 ± 85 | 80 ± 12 | 15 ± 2 |

| 1 | 宁晓琴. 塑料包装行业发展现状及趋势分析[J]. 塑料包装, 2014, 24(3): 1⁃4. |

| NING X Q. Analysis of Current Situation and Trend of Plastic Packaging Industry Development[J]. Plastic Packaging, 2014, 24(3): 1⁃4. | |

| 2 | 马兆嵘, 刘有胜, 张芊芊, 等.农用塑料薄膜使用现状与环境污染分析[J]. 生态毒理学报, 2020,15(4): 1⁃22. |

| MA Z R, LIU Y S, ZHANG Q Q, et al. Application Status and Environmental Pollution Analysis of Agricultural Plastic Film[J]. Journal of Ecotoxicology, 2020,15(4): 1⁃22. | |

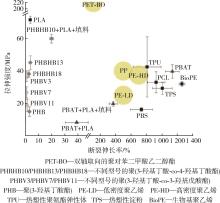

| 3 | JOST V. Packaging Related Properties of Commercially Available Biopolymers⁃An Overview of the Status Quo[J]. Express Polymer Letters, 2018,12(5): 429⁃435. |

| 4 | 张双双, 李仁海, 高 甲, 等. PBAT合成方法及其应用的研究现状[J]. 现代塑料加工应用, 2018, 30(5): 59⁃63. |

| ZHANG S S, LI H R, GAO J, et al. Research status of synthesis methods and applications of PBAT[J]. Modern Plastic Processing and Application, 2018, 30(5): 59⁃63. | |

| 5 | ROCHA D B, JESSIKA S D C, SUELI A D O, et al. A New Approach for Flexible PBAT/PLA/CaCO3 Films into Agriculture[J]. Journal of Applied Polymer Science, 2018, 135(35): 46660. |

| 6 | 钟淦基, 杨彪, 李忠明, 等. 一种抗紫外高阻水PBAT薄膜及其制备方法: 中国,CN107936495A[P]. 2018⁃04⁃20. |

| 7 | 叶士娟. 一种高强度改性PBAT光催化抗菌薄膜及其制法: 中国,CN202010334770.5[P]. 2020⁃08⁃07. |

| 8 | SERAY M, SKENDER A and HADJ⁃HAMOU A S. Kinetics and Mechanisms of Zn2+ Release From Antimicrobial Food Packaging Based on Poly (butylene adipate⁃co⁃terephthalate) and Zinc Oxide Nanoparticles[J]. Polymer Bull, 2021,78: 1 021⁃1 040. |

| 9 | VENKATESAN R, RAJESWARI N. ZnO/PBAT Nanocomposite Films: Investigation on the Mechanical and Biological Activity for Food Packaging[J]. Polymers for Advanced Technologies, 2017, 28(1): 20⁃27. |

| 10 | LUO S, ZHANG P, GAO D. Preparation and Properties of Antimicrobial Poly(butylene adipate⁃co⁃terephthalate)/TiO2 Nanocomposites Films[J]. Journal of Macromolecular Science, Part B, 2020, 59(4):1⁃14. |

| 11 | VENKATESAN R, RAJESWARI N. TiO2 Nanoparticles/Poly(butylene adipate⁃co⁃terephthalate) Bionanocomposite Films for Packaging Applications[J]. Polymers for Advanced Technologies, 2017, 28(12): 1 699⁃1 706. |

| 12 | VENKATESAN R, RAJESWARI N. Nanosilica⁃reinforced Poly(butylene adipate⁃co⁃terephthalate) Nanocomposites: Preparation, Characterization and Properties[J]. Polymer Bulletin, 2018, 76(9): 4 785⁃4 801. |

| 13 | VENKATESAN R, RAJESWARI N, TAMILSELVI A. Antimicrobial, Mechanical, Barrier and Thermal Pro⁃perties of Bio⁃based Poly(butylene adipate⁃co⁃terephthalate)(PBAT)/Ag2O Nanocomposite Films for Packaging Application[J]. Polymers for Advanced Technologies, 2018, 29(1): 61⁃68. |

| 14 | SHANKAR S ,RHIM J W. Tocopherol⁃Mediated Synthesis of Silver Nanoparticles and Preparation of Antimicrobial PBAT/Silver Nanoparticles Composite Films[J]. LWT ⁃ Food Science and Technology, 2016, 72: 149⁃156. |

| 15 | SOUSA G M., YAMASHITA F,SOARES J M S. Application of Biodegradable Films Made from Rice Flour, Poly(butylene adipate⁃co⁃terphthalate), Glycerol and Potassium Sorbate in the Preservation of Fresh Food Pastas[J]. LWT ⁃ Food Science and Technology, 2016, 65: 39⁃45. |

| 16 | LEAL I L, SILVA ROSA D Y C, SILVA PENHA D J, et al. Development and Application Starch Films:PBAT with Additives for Evaluating the Shelf Life of Tommy Atkins Mango in the Fresh⁃cut State[J]. Journal of Applied Polymer Science, 2019, 136(1): 48150. |

| 17 | SHANKAR S, RHIM J W. Preparation of Antibacterial Poly(lactide)/Poly(butylene adipate⁃co⁃terephthalate) Composite Films Incorporated with Grapefruit Seed Extract[J]. Biol Macromol, 2018, 120(Part A): 846⁃852. |

| 18 | ZHAO H, LI L, ZHANG Q, et al. Manipulation of Chain Entanglement and Crystal Networks of Biodegradable Poly(butylene adipate⁃co⁃butylene terephthalate) During Film Blowing through the Addition of a Chain Extender: An In Situ Synchrotron Radiation X⁃ray Scattering Study[J]. Biomacromolecules, 2019, 20(10): 3 895⁃3 907. |

| 19 | XIE J, WANG Z, ZHAO Q, et al. Scale⁃Up Fabrication of Biodegradable Poly(butylene adipate⁃co⁃terephthalate)/Organophilic⁃Clay Nanocomposite Films for Potential Packaging Applications[J]. ACS Omega, 2018, 3(1): 1 187⁃1 196. |

| 20 | REN P G, LIU X H, REN F, et al. Biodegradable Graphene Oxide Nanosheets/Poly⁃(butylene adipate⁃co⁃terephthalate) Nanocomposite Film with Enhanced Gas and Water Vapor Barrier Properties[J]. Polymer Testing, 2017, 58: 173⁃180. |

| 21 | LEE K M. Biodegradable⁃Agriculture Mulching Film:Korea, KR101823409[P].2018⁃01⁃31. |

| 22 | TOUCHALEAUME F, MARTIN⁃CLOSAS L, ANGELLIER⁃COUSSY H, et al. Performance and Environmental Impact of Biodegradable Polymers as Agricultural Mulching Films[J]. Chemosphere, 2016, 144: 433⁃439. |

| 23 | SOUZA P M S, MORALES A R, SANCHEZ E M S, et al. Study of PBAT Photostabilization with Ultraviolet Absorber in Combination with Hindered Amine Light Stabilizer and Vitamin E, Aiming Mulching Film Application[J]. Journal of Polymers and the Environment, 2018, 26(8): 3 422⁃3 436. |

| 24 | LI J, LAI L, WU L, et al. Enhancement of Water Vapor Barrier Properties of Biodegradable Poly(butylene adipate⁃co⁃terephthalate) Films with Highly Oriented Organomontmorillonite[J]. ACS Sustainable Chemistry & Engineering, 2018, 6(5): 6 654⁃6 662. |

| 25 | FALCÃO G A M, ALMEIDA T G, BARDI M A G, et al. PBAT/Organoclay Composite Films—Part 2: Effect of UV Aging on Permeability, Mechanical Properties and Biodegradation[J]. Polymer Bulletin, 2018, 76(1): 291⁃301. |

| 26 | ARRUDA L C, MAGATON M, BRETAS R E S, et al. Influence of Chain Extender on Mechanical, Thermal and Morphological Properties of Blown Films of PLA/PBAT Blends[J]. Polymer Testing, 2015,43: 27⁃37. |

| 27 | PHETWAROTAI W, PHUSUNTI N, AHT⁃ONG D. Preparation and Characteristics of Poly(butylene adipate⁃co⁃terephthalate)/Polylactide Blend Films via Synergistic Efficiency of Plasticization and Compatibilization[J]. Polymer Science, 2019,37(1): 68⁃78. |

| 28 | AI X, LI X, YU Y, et al. The Mechanical, Thermal, Rheological and Morphological Properties of PLA/PBAT Blown Films by Using Bis(tert⁃butyl dioxy isopropyl) Benzene as Crosslinking Agent[J]. Polymer Engineering & Science, 2019, 59(S1): 227⁃236. |

| 29 | SCHNEIDER J, MANJURE S, NARAYAN R. Reactive Modification and Compatibilization of Poly(lactide) and Poly(butylene adipate⁃co⁃terephthalate) Blends with Epoxy Functionalized⁃Poly(lactide) for Blown Film Applications[J]. Journal of Applied Polymer Science, 2016, 133(16): 43310. |

| 30 | LI X, YAN X, YANG J, et al. Improvement of Compatibility and Mechanical Properties of the Poly(lactic acid)/Poly(butylene adipate⁃co⁃terephthalate) Blends and Films by Reactive Extrusion with Chain Extender[J]. Polymer Engineering & Science, 2018, 58(10): 1 868⁃1 878. |

| 31 | LI X, AI X, PAN H, et al. The Morphological, Mechani⁃cal, Rheological, and Thermal Properties of PLA/PBAT Blown Films with Chain Extender[J]. Polymers for Advanced Technologies, 2018, 29(6): 1 706⁃1 717. |

| 32 | PAN H, HAO Y, ZHAO Y, et al. Improved Mechanical Properties, Barrier Properties and Degradation Behavior of Poly(butylenes adipate⁃co⁃terephthalate)/Poly(propyle⁃ne carbonate) Films[J]. Korean Journal of Chemical Engineering, 2017, 34(5): 1 294⁃1 304. |

| 33 | JIANG G, WANG F, ZHANG S, et al. Structure and Improved Properties of PPC/PBAT Blends via Controlling Phase Morphology Based on Melt Viscosity[J]. Journal of Applied Polymer Science, 2020, 137(31): 48924. |

| 34 | HOFFMANN R, MORAIS D D S, Braz C J F, et al. Impact of the Natural Filler Babassu on the Processing and Properties of PBAT/PHB Films[J]. Composites Part A: Applied Science and Manufacturing, 2019,124:105472. |

| 35 | LAGARÓN J M, LÓPEZRUBIO A, JOSÉ FABRA M. Film Blowing of PHBV Blends and PHBV⁃Based Multilayers for the Production of Biodegradable Packages[J]. Journal of Applied Polymer Science, 2016, 133(2): 356⁃365. |

| 36 | CORREA J P, BACIGALUPE A, MAGGI J, et al. Biodegradable PLA/PBAT/Clay Nanocomposites: Morphological, Rheological and Thermomechanical Behavior[J]. Journal of Renewable Materials, 2016, 4(4): 258⁃265. |

| 37 | MONDAL D, BHOWMICK B, MOLLICK M M R, et al. Antimicrobial Activity And Biodegradation Behavior of Poly(butylene adipate⁃co⁃terephthalate)/Clay Nanocomposites[J]. Journal of Applied Polymer Science, 2014, 131(7):40079. |

| 38 | ZHANG S, LIN Z, LI J, et al. Elevated Ductility, Optical, and Air Barrier Properties of Poly (butyleneadipate⁃co⁃terephthalate) Bio⁃based Films via Novel Thermoplastic Starch Feature[J]. Polymers for Advanced Technologies, 2019, 30(4): 852⁃862. |

| 39 | SILVA T B V D, MOREIRA T F M, OLIVEIRA D A, et al. Araucaria Angustifolia (Bertol.) Kuntze Extract as A Source of Phenolic Compounds in TPS/PBAT Active Films[J]. Food & Function, 2019, 10(12): 7 697⁃7 706. |

| 40 | XING Q, BUONO P, RUCH D, et al. Biodegradable UV⁃Blocking Films through Core⁃Shell Lignin⁃Melanin Nanoparticles in Poly(butylene adipate⁃co⁃terephthalate)[J]. CS Sustainable Chemistry & Engineering, 2019, 7(4): 4 147⁃4 157. |

| 41 | XING Q, RUCH D, DUBOIS P, et al. Biodegradable and High⁃Performance Poly(butylene adipate⁃co⁃terephthalate)–Lignin UV⁃Blocking Films[J]. ACS Sustaina⁃ble Chemistry & Engineering, 2017, 5(11): 10 342⁃10 351. |

| 42 | MUROI F, TACHIBANA Y, SOULENTHONE P, et al. Characterization of A Poly(butylene adipate⁃co⁃terephthalate) Hydrolase From the Aerobic Mesophilic Bacterium Bacillus Pumilus[J]. Polymer Degradation and Stability, 2017, 137: 11⁃22. |

| 43 | DE HOE G X, ZUMSTEIN M T, GETZINGER G J, et al. Photochemical Transformation of Poly(butylene adipate⁃ co⁃terephthalate) and Its Effects on Enzymatic Hydrolyzability[J]. Environmental Science and Technology, 2019, 53(5): 2 472⁃2 481. |

| 44 | OLIVEIRA T A, OLIVEIRA MOTA I, MOUSINHO F E P, et al. Biodegradation of Mulch Films from Poly(butylene adipate co‐terephthalate), Carnauba Wax, and Sugarcane Residue[J]. Journal of Applied Polymer Science, 2019, 136(47):48240. |

| 45 | WANG X W, WANG G X, HUANG D, et al. Degrada⁃bility Comparison of Poly(butylene adipate terephthalate) and Its Composites Filled with Starch and Calcium Carbonate in Different Aquatic Environments[J]. Journal of Applied Polymer Science, 2019, 136(2): 46916. |

| [1] | 张宗胤, 吕明福, 郭鹏, 徐耀辉, 张师军. 紫外线吸收剂对PBST薄膜耐候性的影响[J]. 中国塑料, 2022, 36(5): 110-115. |

| [2] | 隋振全, 毛金超, 范金石. 壳聚糖/聚乙烯醇液态地膜的制备与应用[J]. 中国塑料, 2022, 36(3): 21-25. |

| [3] | 管彤晖, 付烨, 翁云宣. PBAT全生物降解地膜在土壤试验中的降解行为研究[J]. 中国塑料, 2022, 36(1): 67-72. |

| [4] | 冯玉红, 姚文清, 尚超男, 谢艳丽, 张名楠, 周雪晴, 王桂振, 于文辉, 窦智峰. 一次性塑料制品污染防治的法律法规及检测标准研究进展[J]. 中国塑料, 2021, 35(8): 55-63. |

| [5] | 李攀, 李东峰, 陆新焱, 彭麒桦, 卢波, 季君晖. 回收PE地膜残膜在高性能沥青路面新材料中应用[J]. 中国塑料, 2021, 35(8): 84-87. |

| [6] | 王智勤, 李慧, 朱冰玉, 陈厂. 废旧地膜的回收与应用[J]. 中国塑料, 2021, 35(12): 108-113. |

| [7] | 谭博雯, 孙朝阳, 计扬. 聚乙醇酸的合成、改性与性能研究综述[J]. 中国塑料, 2021, 35(10): 137-146. |

| [8] | 毕昕媛, 姚建民. 聚碳酸亚丙酯生物降解渗水地膜的研制及性能分析[J]. 中国塑料, 2021, 35(10): 21-25. |

| [9] | 周大纲, 谢胜利. 我国农膜行业现状的分析及发展对策(2020年)[J]. 中国塑料, 2020, 34(7): 104-108. |

| [10] | 薛颖昊, 孙占祥, 居学海, 习斌, 靳拓, 贾涛. 可降解农用地膜的材料研究与应用现状[J]. 中国塑料, 2020, 34(5): 87-96. |

| [11] | 贾璇, 傅晨星, 张军平, 李鸣晓, 李雪琪, 刘晓佩. 可降解液体地膜的研究现状及应用展望[J]. 中国塑料, 2020, 34(12): 110-118. |

| [12] | 朱城业;刘鸣;孙琦岳;何梦娇;章宇冲;孙瑞泽;高山俊. 聚丁二酸丁二醇酯/淀粉共混物阻燃改性的研究[J]. 中国塑料, 2016, 30(01): 52-55 . |

| [13] | 姜李龙;孙靖尧;杨昆晓;余东泉;信春玲;何亚东. 三螺杆挤出机中剪切拉伸交变流场对PP/PE-HD[J]. 中国塑料, 2016, 30(01): 86-91 . |

| [14] | 申慧雁;王彦鸿;曹莉苏志强. 等规聚丙烯与液晶成核剂的共混改性研究[J]. 中国塑料, 2015, 29(03): 26-32 . |

| [15] | 黄安荣 朱永军 秦舒浩 韦良强 罗筑. 原位微纤增强复合材料的结构与性能[J]. 中国塑料, 2013, 27(09): 37-40 . |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2