京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2

《中国塑料》编辑部 ©2008-2024 版权所有

地址:北京市海淀区阜成路11号 邮编:100048

编辑部:010-68985541 联系信箱:cp@plaschina.com.cn

广告部/发行部:010-68985253 本系统由北京玛格泰克科技发展有限公司设计开发

中国塑料 ›› 2021, Vol. 35 ›› Issue (12): 154-165.DOI: 10.19491/j.issn.1001-9278.2021.12.024

收稿日期:2021-04-06

出版日期:2021-12-26

发布日期:2021-12-22

基金资助:

FANG Yunfeng1, MA Biao1( ), WANG Xiaoqing1, KANG Xingxiang1, TANG Yuting2

), WANG Xiaoqing1, KANG Xingxiang1, TANG Yuting2

Received:2021-04-06

Online:2021-12-26

Published:2021-12-22

Contact:

MA Biao

E-mail:mabiaochd@163.com

摘要:

对国内外有关单组分环氧树脂用固化剂进行了梳理,介绍了潜伏型单组分环氧树脂用固化剂(热致型、湿致型、光致型以及微胶囊型),并对其制备合成方法及固化机理进行详细的综述,指出了单组分环氧树脂用固化剂所存在的问题,并明确未来的研究思路。

中图分类号:

方云峰, 马骉, 王小庆, 康兴祥, 汤宇婷. 单组分环氧树脂用潜伏型固化剂研究进展[J]. 中国塑料, 2021, 35(12): 154-165.

FANG Yunfeng, MA Biao, WANG Xiaoqing, KANG Xingxiang, TANG Yuting. Research progress in latent curing agent for one⁃component epoxy resin[J]. China Plastics, 2021, 35(12): 154-165.

反应 体系 | 环氧 树脂/份 | DICY/ 份 | 促进剂/ 份 | 反应起始 温度/℃ | 反应峰值 温度/℃ |

|---|---|---|---|---|---|

| ED | 100 | 8 | 0.15 | 192 | 199 |

| EDP | 100 | 8 | 0.15 | 154 | 176 |

| EDM | 100 | 8 | 0.15 | 145 | 170 |

| EDA | 100 | 8 | 0.15 | 135 | 167 |

| EDY | 100 | 8 | 0.15 | 131 | 161 |

反应 体系 | 环氧 树脂/份 | DICY/ 份 | 促进剂/ 份 | 反应起始 温度/℃ | 反应峰值 温度/℃ |

|---|---|---|---|---|---|

| ED | 100 | 8 | 0.15 | 192 | 199 |

| EDP | 100 | 8 | 0.15 | 154 | 176 |

| EDM | 100 | 8 | 0.15 | 145 | 170 |

| EDA | 100 | 8 | 0.15 | 135 | 167 |

| EDY | 100 | 8 | 0.15 | 131 | 161 |

| 酰肼 | 熔点/ ℃ | 储存 时间/月 | DTA | |

|---|---|---|---|---|

反应起始 温度/℃ | 反应峰值 温度/℃ | |||

| 丁二酸二酰肼(SuADH) | 163 | 4 | 161 | 165 |

| 己二酸二酰肼(AADH) | 180 | 4 | 161 | 167 |

| 间苯二甲酸二酰肼(IPADH) | 212 | 4~5 | 154 | 160 |

| 对羟基苯甲酸酰肼(POBH) | 248 | 4 | 153 | 161 |

| 水杨酸酰肼(SaAH) | 151~2 | (4 d) | 96(175) | 130(196) |

| 苯基氨基丙酸酰肼(PAPAH) | 93~5 | (2 d) | 75(115) | 150 |

| 酰肼 | 熔点/ ℃ | 储存 时间/月 | DTA | |

|---|---|---|---|---|

反应起始 温度/℃ | 反应峰值 温度/℃ | |||

| 丁二酸二酰肼(SuADH) | 163 | 4 | 161 | 165 |

| 己二酸二酰肼(AADH) | 180 | 4 | 161 | 167 |

| 间苯二甲酸二酰肼(IPADH) | 212 | 4~5 | 154 | 160 |

| 对羟基苯甲酸酰肼(POBH) | 248 | 4 | 153 | 161 |

| 水杨酸酰肼(SaAH) | 151~2 | (4 d) | 96(175) | 130(196) |

| 苯基氨基丙酸酰肼(PAPAH) | 93~5 | (2 d) | 75(115) | 150 |

| 1 | MAYCHAHAL C, VERSCHUREN C A, TANAKA G Y. Epoxy resins: chemistry and technology[M]. America: Dekker, 2018: 35. |

| 2 | DODIUK H, GOODMAN S H. Handbook of thermoset plastics[M]. Britain: Noyes Publications, 2014: 77. |

| 3 | ZHANG Z, LI J, WANG Z, et al. Preparation and performance characterization of a novel high⁃performance epoxy resin modified reactive liquid asphalt[J]. Construction and Building Materials, 2020, 263: 120113. |

| 4 | PHAM V H, HA Y W, KIM S H, et al. Synthesis of epoxy encapsulated organoclay nanocomposite latex via phase inversion emulsification and its gas barrier property[J]. Journal of Industrial & Engineering Chemistry, 2014, 20(1): 108⁃112. |

| 5 | WANG C, FU Y, CHEN Q, et al. Application and research advances in epoxy asphalt concrete serving as deck pavement material[J]. Materials Review, 2018, 32(9A): 2 992⁃3 009. |

| 6 | QI H Z, ZHAO Y H, ZHU K Y, et al. Research progresses in self⁃healing polymer materials[J]. Progress in Chemi⁃stry, 2011, 23(12): 2 560⁃2 567. |

| 7 | ZHOU XY, MA B, WANG X Q, et al. Study of the interlocking filling⁃graded composition design method of an asphalt mixture mixed with shape⁃memory epoxy resin fibers[J]. Journal of Materials in Civil Engineering, 2020, 32(7): 11.10.1061/(asce)mt.1943⁃5533.0003249. |

| 8 | WANG Y, LIU W, QIU Y, et al. A one⁃component, fast⁃cure, and economical epoxy resin system suitable for liquid molding of automotive composite parts[J]. Materials, 2018, 11(5): 1⁃8. |

| 9 | QUAN D, IVANKOVIC A. Effect of core⁃shell rubber (CSR) nano⁃particles on mechanical properties and fracture toughness of an epoxy polymer[J]. Polymer, 2015, 66: 16⁃28. |

| 10 | JIN F L, LI X, PARK S J. Synthesis and application of epoxy resins: A review[J]. Journal of Industrial and Engineering Chemistry, 2015, 29: 1⁃11. |

| 11 | SHIN Y J, KIM M, HWANG S W, et al. One⁃component epoxy adhesive for repair of cell phone board[J]. Journal of Adhesion Science and Technology, 2018, 32(12): 1278⁃1286.10.1080/01694243.2017.1408547. |

| 12 | DE B, KARAK N. Novel high performance tough hyperbranched epoxy by an A2 + B3 polycondensation reaction[J]. Journal of Materials Chemistry A, 2013, 1(2): 348⁃353,DOI:10.1039/c2ta00011c. |

| 13 | FEDTKE M, DOMARATIUS F, PFITZMANN A. Curing of epoxy resins with dicyandiamide⁃reaction behaviour of glycidyl ethers[J]. Polymer Bulletin, 1990, 23(4): 381⁃388. |

| 14 | HAGNAUER G L, DUNN D A. Dicyandiamide analysis and solubility in epoxy resins[J]. Journal of Applied Polymer ence, 1981, 26(6): 1 837⁃1 846. |

| 15 | GÜTHNER T, HAMMER B. Curing of epoxy resins with dicyandiamide and urones[J]. Journal of Applied Polymer Science, 2010, 50(8): 1 453⁃1 459. |

| 16 | HONG S G, WU C S. DSC and FTIR analysis of the curing behaviors of epoxy/DICY/solvent open systems[J]. Thermochimica Acta, 1998, 316(2): 167⁃175. |

| 17 | 刘巧燕. 环氧树脂用潜伏型固化剂的合成及性能[D]. 广州: 华南理工大学, 2013. |

| 18 | GU X, ZHANG J. Study on the Curing Mechanism of epoxy/DICY system by FT⁃IR[J]. Polymer Materials Science & Engineering, 2006, 22(5): 182⁃184. |

| 19 | GAUKLER J C. Oligomer formation in epoxy⁃dicyandiamide systems[J]. The Journal of Adhesion, 2012, 88(8): 720⁃750. |

| 20 | LIU, XD, KIMURA, M, SUDO, A, et al. Accelera⁃ting effects of N⁃aryl⁃N′,N′⁃dialkyl ureas on epoxy‐dicyandiamide curing system[J]. Journal of Polymer Science Part A:Polymer Chemistry, 2010, 48(23).,doi: 10.1002/pola.24329. |

| 21 | HAYATY M, HONARKAR H, BEHESHTY M H. Curing behavior of dicyandiamide/epoxy resin system using different accelerators[J]. Iranian Polymer Journal, 2013, 22(8): 591⁃598. |

| 22 | HESABI M, SALIMI A, BEHESHTY M H. Effect of tertiary amine accelerators with different substituents on curing kinetics and reactivity of epoxy/dicyandiamide system[J]. Polymer Testing, 2017, 59: 344⁃354. |

| 23 | DING L, YANG J, CHEN G, et al. Preparation and properties of latent moderate⁃temperature curing epoxy resin system[J]. Acta Materiae Compositae Sinica, 2017, 34(10): 2 150⁃2 155. |

| 24 | CHEN L, TIAN H, LIU Q, et al. Curing reaction kine⁃tics of epoxy resin using dicyandiamide modified by aromatic amines[J]. Wuhan University Journal of Natural ences, 2007(6): 1 105. |

| 25 | FENG L, WANG Y, WANG Y, et al. Study on reaction kinetics of epoxy resin cured by a modified dicyandiamide[J]. Journal of Applied Polymer ence, 2012, 127(3): 1 895⁃1 900. |

| 26 | WANG Q, SHI T, YU F, et al. Synthesis and properties of novel latent curing agent[J]. CIESC Journal, 2014, 65(9): 3 712⁃3 717. |

| 27 | WANG Q, SHI T, ZHANG Y, et al. Latent curing of polybiguanide/epoxy resin[J]. CIESC Journal, 2015, 66(1): 464⁃470. |

| 28 | DANNELS B F, KARL W G. Preparation of dihydrazides of dicarboxylic acids: USA, US3061642A[P].(1962⁃10⁃30) [2020⁃12⁃2] . |

| 29 | FAN Y L. N, N'⁃bis(isomaleimide) polyhydrazides: USA, US3631005A[P].(1971⁃12⁃28) [2020⁃12⁃03] . |

| 30 | 胡玉明. 环氧固化剂及添加剂[M]. 化学工业出版社, 2011:216⁃217. |

| 31 | 李 固, 桂文娟, 张玉兰. 潜伏固化剂癸二酸二酰肼的合成[J]. 热固性树脂, 1987(4): 25⁃27. |

| 32 | TOMUTA A M, RAMIS X, FERRANDO F, et al. The use of dihydrazides as latent curing agents in diglycidyl ether of bisphenol A coatings[J]. Progress in Organic Coatings, 2012, 74(1): 59⁃66. |

| 33 | TOMUTA A M. Influence of end groups in hyperbranched polyesters used as modifiers in the characteristics of epoxy thermosets cured by adipic dihydrazide[J]. eXPRESS Polymer Letters, 2013, 7(7): 595. |

| 34 | GEORGE N, KURIAN T. Sodium carbonate catalyzed aminolytic degradation of PET[J]. Progress in Rubber Plastics and Recycling Technology, 2016, 32(3): 153⁃168,DOI:10.1177/147776061603200304. |

| 35 | GEORGE N, SHARMILA T K B, KURIAN T. Preparation of a one⁃component epoxy adhesive using PET bottle waste derived terephthalic dihydrazide as latent curing agent[J]. International Journal of Adhesion and Adhesives, 2020, 98: 6,DOI:10.1016/j.ijadhadh.2019.102524. |

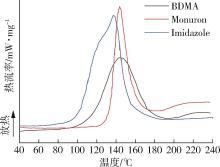

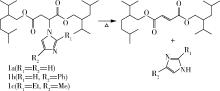

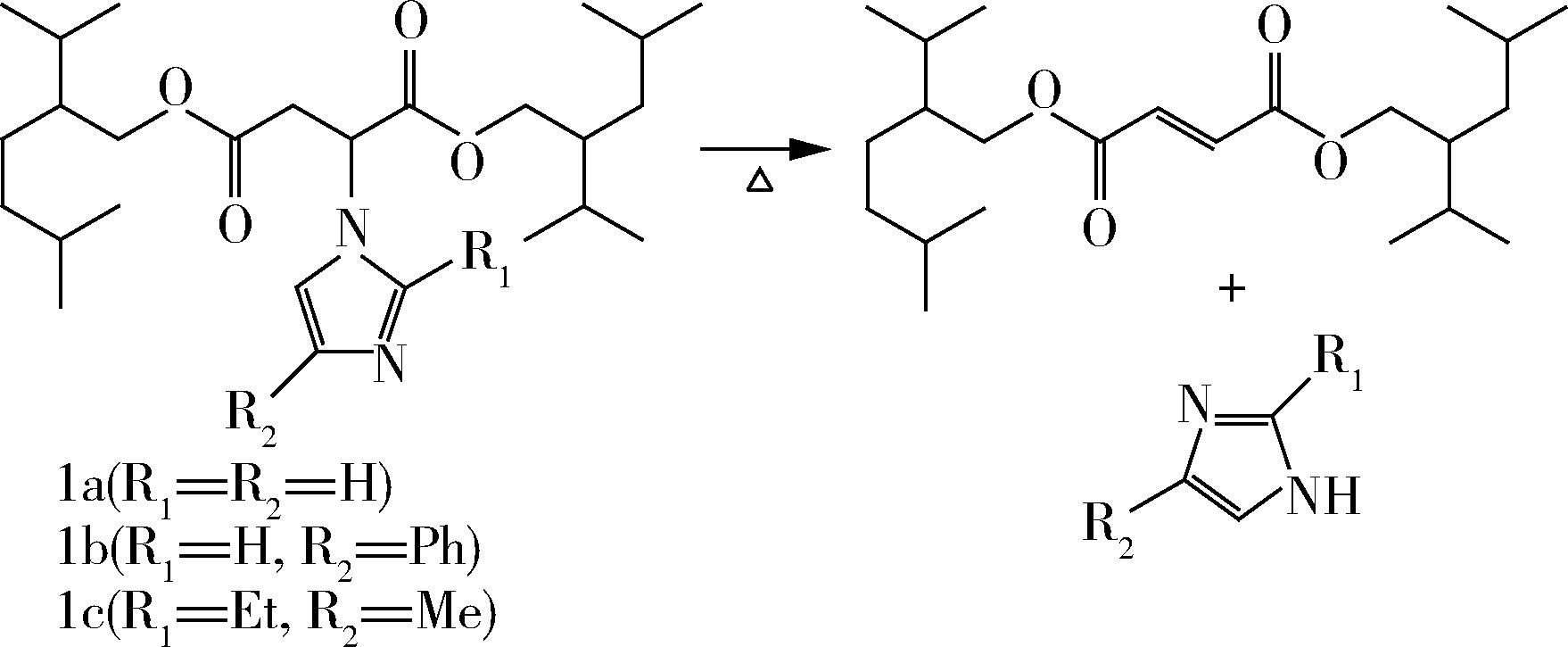

| 36 | HAM Y R, KIM S H, SHIN Y J, et al. A comparison of some imidazoles in the curing of epoxy resin[J]. Journal of Industrial and Engineering Chemistry, 2010, 16(4): 556⁃559. |

| 37 | DEARLOVET J. A comparison of some imidazole catalysts as epoxy curing agents[J]. Journal of Applied Polymer Science, 1970, 14(6): 1 615⁃1 626. |

| 38 | GHAEMY M, SADJADY S. Kinetic analysis of curing behavior of diglycidyl ether of bisphenol A with imidazoles using differential scanning calorimetry techniques[J]. Journal of Applied Polymer Science, 2006, 100(4): 2 634⁃2 641,10.1002/app.22716. |

| 39 | FARKAS A, STROHM P F. Imidazole catalysis in the curing of epoxy resins[J]. Journal of Applied Polymer Science, 1968, 12(1): 159⁃168. |

| 40 | ARIMITSU K, FUSE S, KUDO K, et al. Imidazole derivatives as latent curing agents for epoxy thermosetting resins[J]. Materials Letters, 2015, 161: 408⁃410. |

| 41 | LEI D F, MA W S, WANG L F, et al. Preparation of 2⁃ethyl⁃4⁃methylimidazole derivatives as latent curing agents and their application in curing epoxy resin[J]. Journal of Applied Polymer Science, 2015, 132(38),doi: 10.1002/app.42563. |

| 42 | YANG S, ZHANG Q, HUA Y, et al. Synthesis of maleimide modified imidazole derivatives and their application in one⁃component epoxy resin systems[J]. Materials Letters, 2018, 234: 379⁃383. |

| 43 | SHI K, SHEN Y, YANG Y, et al. Novel imidazole derivatives with recoverable activity as latent curing agents for epoxy[J]. Journal of Applied Polymer Science, 2021, 138. |

| 44 | 雷定锋. 咪唑类潜伏型固化剂的制备及其在环氧导热涂料中的应用[D]. 广州: 华南理工大学, 2015. |

| 45 | MOTAMEDI M, RAMEZANZADEH M, RAMEZANZADEH B, et al. One⁃pot synthesis and construction of a high performance metal⁃organic structured nano pigment based on nanoceria decorated cerium (III)⁃imidazole network (NC/CIN) for effective epoxy composite coating anti⁃corrosion and thermo⁃mechanical properties improvement[J]. Chemical Engineering Journal, 2020, 382: 14.10.1016/j.cej.2019.122820. |

| 46 | LIU L, LI M. Curing mechanisms and kinetic analysis of DGEBA cured with a novel imidazole derivative curing agent using DSC techniques[J]. Journal of Applied Polymer Science, 2010, 117(6),doi: 10.1002/app.32196. |

| 47 | SUN X, WANG Y M, TANG Y T, et al. Synthesis of isocyanurate⁃based imidazole carboxylate as thermal latent curing accelerator for thermosetting epoxy resins[J]. Journal of Applied Polymer Science, 2020,doi: 10.1002/app.49221. |

| 48 | OKUHIRA H, KII T, OCHI M, et al. Novel moisture⁃curable epoxy resins and their characterization[J]. Journal of Applied Polymer Science, 2010, 89(1): 91⁃95. |

| 49 | 刘佳欣. 室温固化单组份建筑结构胶的制备与性能研究[D]. 大连: 大连理工大学, 2012. |

| 50 | ZAVATSKY J, BORDOLOI B K, INC E, et al. Moisture activated latent curing adhesive or sealant[J].2009 |

| 51 | 杨 国. 酮醛树脂的合成及其在潜伏型固化剂中的应用[D]. 郑州: 郑州大学, 2014. |

| 52 | 李三妹, 陕绍云, 贾庆明, 等 分子筛改性研究进展[J]. 材料导报, 2013(13): 46⁃49. |

| LI S M, SHAN S Y, JIA Q M, et al. Research progress on modification of molecular sieve[J]. Materials Reports,2013(13): 46⁃49. | |

| 53 | 包建文, 刘 刚, 张 晖, et al. 一种环氧树脂的缓释固化方法: 中国, CN201410545350.6[P].(2014⁃10⁃15) [2020⁃12⁃6] . |

| 54 | 彭长征, 余湘平, 佘万能. 三芳基硫Wong六氟锑酸盐引发环氧树脂阳离子光固化的研究[J]. 功能高分子学报, 1997, 10(3): 393⁃398. |

| 55 | SHANG Q, HAO S, ZHANG J, et al. Investigation on constitution of electrical conductive adhesives fitting for UV⁃thermal dual curing[J]. Journal of Adhesion ence & Technology, 2015, 29(9): 910⁃923. |

| 56 | ARIMITSU K, AMANO S, FURUTANI M. Acid⁃amplifying microcapsules: preparation, characterization, and application to cationic UV curing[J]. Rsc Advances, 2016, 6(10): 7 893⁃7 896,DOI:10.1039/c5ra26008f. |

| 57 | VÁZQUEZ C P, JOLY⁃DUHAMEL C, BOUTEVIN B. Photopolymerization without photoinitiator of bismaleimide⁃containing oligo(oxypropylene)s: effect of oligoethers chain length[J]. Macromolecular Chemistry & Physics, 2009, 210(3/4): 269⁃278. |

| 58 | FAN S L. UV curing of a liquid based bismaleimide⁃containing polymer system[J]. Express Polymer Letters, 2007, 1(6): 397⁃405. |

| 59 | BONGIOVANNI R, SANGERMANO M, MALUCELLI G, et al. UV curing of photoinitiator⁃free systems containing bismaleimides and diacrylate resins: bulk and surface properties[J]. Progress in Organic Coatings, 2005, 53(1): 46⁃49. |

| 60 | CHEN C F, IWASAKI S, KANARI M, et al. High performance UV and thermal cure hybrid epoxy adhesive[J]. IOP Conference Series Materials Scince and Engineering, 2017, 213(1): 012032. |

| 61 | AHANGARAN F,NAVARCHIAN A H,HAYATY M, et al. Effect of mixing mode and emulsifying agents on micro/nanoencapsulation of low viscosity self⁃healing agents in polymethyl methacrylate shell[J]. Smart Materials & Structures, 2016,10.1088/0964⁃1726/25/9/095035. |

| 62 | MISHRA A K, KIM N H, KUILA T, et al. Effects of processing conditions of poly(methylmethacrylate) encapsulated liquid curing agent on the properties of self⁃healing composites[J]. Composites Part B: Engineering, 2013, 49: 6⁃15. |

| 63 | LEE D H, YANG M, KIM S H, et al. Microencapsulation of imidazole curing agents by spray⁃drying method[J]. Journal of Applied Polymer Science, 2011, 122(2): 782⁃788. |

| 64 | 韩丽颖. 三聚氰胺尿素甲醛共聚物包覆环氧树脂微胶囊自修复复合材料的制备及性能[D]. 苏州: 江苏大学, 2016. |

| 65 | CAI X, PAN M. Progress on preparation and application of microencapsulated ammonium polyphosphate by in⁃situ polymerization[J]. Polymer Bulletin, 2016(1): 47⁃47. |

| 66 | BROWN E N, KESSLER M R, SOTTOS N R, et al. In situ poly(urea⁃formaldehyde) microencapsulation of dicyclopentadiene[J]. Journal of Microencapsulation, 2003, 20(6): 719⁃730. |

| 67 | BLAISZIK J B, CARUSO M M, ILROY M, et al. Microcapsules filled with reactive solutions for self⁃healing materials[J]. Polymer, 2009, 50(4): 990⁃997. |

| 68 | JIN H, MANGUN C L, STRADLEY D S, et al. Self⁃healing thermoset using encapsulated epoxy⁃amine healing chemistry[J]. Polymer, 2012, 53(2): 581⁃587. |

| 69 | YUAN Y C. Preparation and characterization of microencapsulated polythiol[J]. Polymer London, 2008:10.1016/j.polymer.2008.03.044. |

| 70 | TIAN R,FU X, ZHENG Y, et al. The preparation and characterization of double⁃layer microcapsules used for the self⁃healing of resin matrix composites[J]. Journal of Materials Chemistry, 2012, 22(48): 25 437⁃25 446. |

| 71 | 邢素丽, 曾竟成, 王 遵, 等. 新型潜伏型M⁃DDM微胶囊固化剂的制备及表征[J]. 高分子材料科学与工程, 2006, 22(4): 196⁃196. |

| XING S L, ZENG J C, WANG Z, et al. The Fabrication and characterization of a novel M⁃DDM/microcapsule⁃type latent curing agent[J]. Polymeric Materials Science and Engineering, 2006, 22(4): 196⁃196. | |

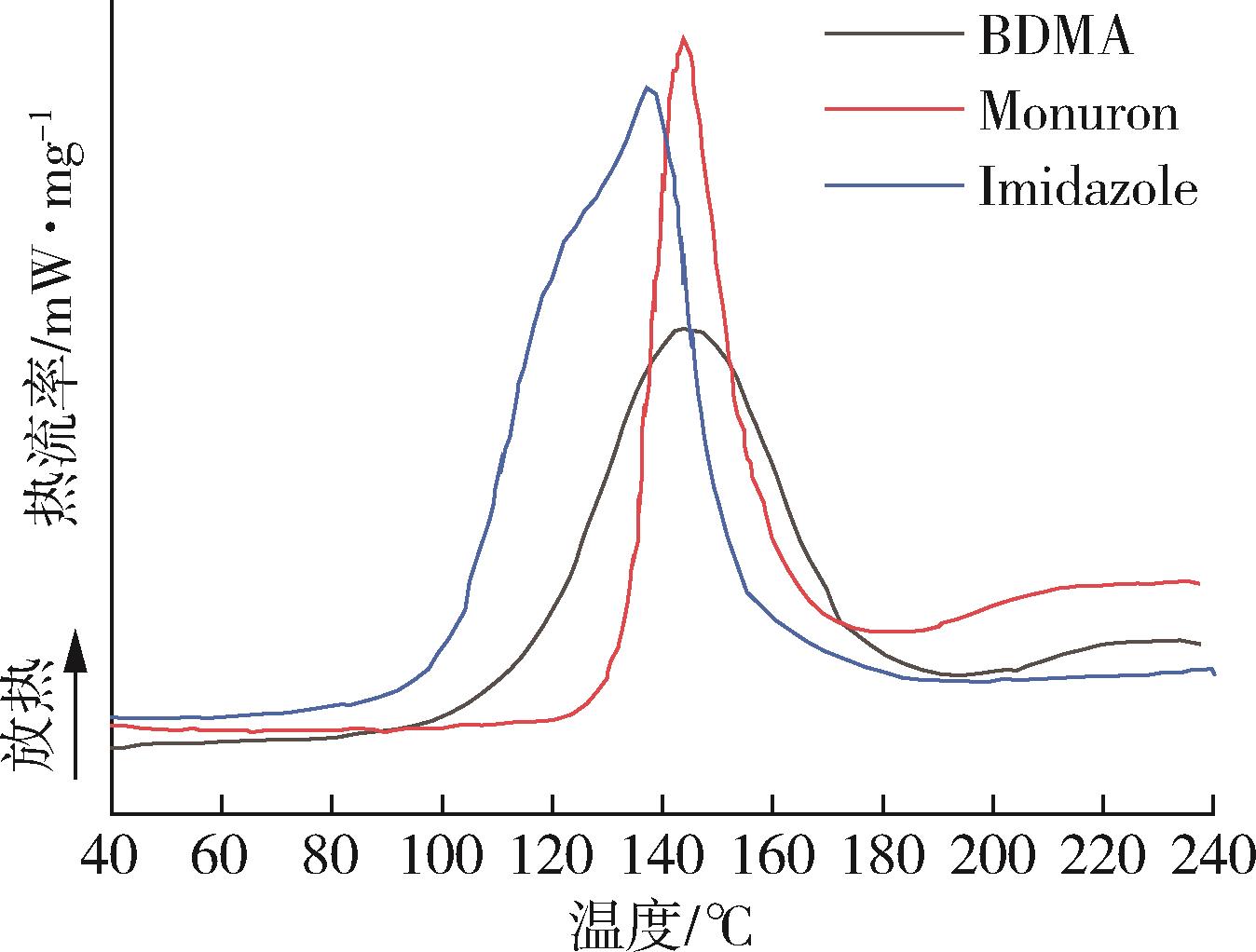

| 72 | ZHAO L, YANG X, MA L, et al. Preparation of imidazole embedded polyurea microcapsule for latent curing agent[J]. Journal of Applied Polymerence, 2020, 137(43):10.1002/app.49340. |

| 73 | TAN X Y, ZHANG J P, GUO D, et al. Preparation, characterization and repeated repair ability evaluation of asphalt⁃based crack sealant containing microencapsulated epoxy resin and curing agent[J]. Construction and Building Materials, 2020, 256,DOI: 10.1016/j.conbuildmat.2020.119433. |

| 74 | FAN J S, ZHENG Y D, XIE Y J, et al. Effect of solvent evaporation technique on the characteristics of curing agent microcapsules and the curing process[J]. Compo⁃sites ence and Technology, 2017, 138: 80⁃90. |

| 75 | 唐欣欣. 环氧树脂阴离子催化剂型固化剂微胶囊的制备及性能表征[D]. 哈尔滨:哈尔滨工业大学, 2011. |

| 76 | SHIN M J, SHIN Y J, HWANG S W, et al. Microencapsulation of imidazole curing agent by solvent evaporation method using W/O/W emulsion[J]. Journal of Applied Polymer Science, 2013, 129(3): 1 036⁃1 044. |

| 77 | ZHAO L Y, YANG X J, LI Q T, et al. Latent curing agent DDM‐PMMA microcapsule for epoxy resin[J]. Journal of Applied Polymer Science, 2019, 136(28):10.1002/app.47757. |

| 78 | WANG F, XIAO J, WANG J W, et al. Study on curing kinetics of a diglycidyl ether of bisphenol A epoxy resin/microencapsulated curing agent system[J]. High Performance Polymers, 2012, 24(8): 730⁃737. |

| [1] | 杨小龙, 陈文静, 李永青, 闫晓堃, 王修磊, 谢鹏程, 马秀清. 导电型聚合物/石墨烯复合材料的研究进展[J]. 中国塑料, 2022, 36(6): 165-173. |

| [2] | 刘文, 师文钊, 刘瑾姝, 陆少锋, 周红娟. 电致形状记忆复合材料研究进展[J]. 中国塑料, 2022, 36(4): 175-189. |

| [3] | 张周雅, 白世建, 张玉霞, 周洪福, 宫芳芳, 唐雪古丽, 王斌. 高分子材料导热性能影响因素研究进展[J]. 中国塑料, 2021, 35(9): 156-165. |

| [4] | 张一辉, 王从龙, 陈士宏, 王向东. 聚醚酰亚胺发泡技术研究进展[J]. 中国塑料, 2021, 35(4): 124-132. |

| [5] | 杨小龙, 李永青, 闫晓堃, 陈文静, 马秀清. 聚合物/石墨烯阻气型复合材料的研究进展[J]. 中国塑料, 2021, 35(12): 145-153. |

| [6] | 于翔, 谭缓缓, 王卓, 张玉坤, 安彦飞, 赵俊杰. 溶剂沉淀法制备具有相变功能的PA6/AG复合粉体及其性能分析[J]. 中国塑料, 2020, 34(8): 71-77. |

| [7] | 王翔;王惠明;许忠斌. 医用塑料管道产品的制备加工及其力学性能研究进展[J]. 中国塑料, 2015, 29(10): 1-6 . |

| [8] | 何小芳 贺超峰 刘玉飞 张 崇 曹新鑫. 聚丙烯基石墨导电复合材料研究进展[J]. 中国塑料, 2012, 26(05): 17-21 . |

| [9] | 应宗荣;刘海生;陈仁康;朱磊;陈帆. 聚合物/石墨导电纳米复合材料制备方法进展[J]. 中国塑料, 2008, 22(11): 9-14 . |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2