京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2

《中国塑料》编辑部 ©2008-2024 版权所有

地址:北京市海淀区阜成路11号 邮编:100048

编辑部:010-68985541 联系信箱:cp@plaschina.com.cn

广告部/发行部:010-68985253 本系统由北京玛格泰克科技发展有限公司设计开发

中国塑料 ›› 2023, Vol. 37 ›› Issue (10): 24-33.DOI: 10.19491/j.issn.1001-9278.2023.10.004

马志蕊1, 尹甜2, 蒋志魁2, 杨璠1, 祝孟珂1, 杨洋1, 韩宇1, 翁云宣1, 张彩丽1( )

)

收稿日期:2023-04-28

出版日期:2023-10-26

发布日期:2023-10-23

通讯作者:

张彩丽(1989—),女,副教授,从事生物降解高分子材料的研究,zhangcaili@btbu.edu.cn基金资助:

MA Zhirui1, YIN Tian2, JIANG Zhikui2, YANG Fan1, ZHU Mengke1, YANG Yang1, HAN Yu1, WENG Yunxuan1, ZHANG Caili1( )

)

Received:2023-04-28

Online:2023-10-26

Published:2023-10-23

Contact:

ZHANG Caili

E-mail:zhangcaili@btbu.edu.cn

摘要:

综述了聚丁二酸丁二醇酯(PBS)及其共混物的制备及应用进展。目前国内外PBS的合成工艺主要有直接酯化法、酯交换法和扩链法。PBS的耐热性好、力学性能优良,是可完全生物降解的脂肪族聚酯,能从根本上解决塑料白色污染的重要材料之一。PBS与脆性可降解聚酯共混可以提高其韧性和生物降解性;通过与其他可再生资源如热塑性淀粉、木薯淀粉、开心果壳粉共混可以提高刚性和熔点,改善力学性能的同时降低成本;与少量无机填料如碳酸钙、二氧化硅等共混不仅可以降低PBS的价格还可以改善PBS的性能。PBS目前主要应用于包装材料、农林业用品、日用杂品、纺织业及医用制品中。PBS作为薄膜应用时其力学性能及气体阻隔性能是两项重要的指标,所以重点总结了对PBS复合膜的力学和阻隔性能的改善研究进展。最后对PBS未来的研究和发展方向进行了展望,指出PBS生产技术应该向综合性能高、成本低和绿色环保方向发展。

中图分类号:

马志蕊, 尹甜, 蒋志魁, 杨璠, 祝孟珂, 杨洋, 韩宇, 翁云宣, 张彩丽. PBS及其复合膜的制备及应用研究进展[J]. 中国塑料, 2023, 37(10): 24-33.

MA Zhirui, YIN Tian, JIANG Zhikui, YANG Fan, ZHU Mengke, YANG Yang, HAN Yu, WENG Yunxuan, ZHANG Caili. Research progress in preparation and applications of PBS and its blends[J]. China Plastics, 2023, 37(10): 24-33.

| 样品 | 玻璃化转变温度/℃ | 熔融温度/℃ | 热变形温度/℃ | 断裂拉伸强度/MPa | 断裂伸长率/% | 冲击强度/J·m-1 | 结晶度/% |

|---|---|---|---|---|---|---|---|

| PBS | -35 | 114 | 97 | 34 | 560 | 300 | 40 |

| PET | 80 | 250 | 98 | 71.6 | 70 | 110 | 35 |

| PLA | 60 | 175 | 58 | 53 | 6 | 13 | 50 |

| PP | -5 | 163 | 110 | 33 | 415 | 20 | 56 |

| PE⁃HD | -120 | 129 | 82 | 28 | 700 | 40 | 69 |

| PE⁃LD | -120 | 110 | 49 | 10 | 300 | 410 | 49 |

| 样品 | 玻璃化转变温度/℃ | 熔融温度/℃ | 热变形温度/℃ | 断裂拉伸强度/MPa | 断裂伸长率/% | 冲击强度/J·m-1 | 结晶度/% |

|---|---|---|---|---|---|---|---|

| PBS | -35 | 114 | 97 | 34 | 560 | 300 | 40 |

| PET | 80 | 250 | 98 | 71.6 | 70 | 110 | 35 |

| PLA | 60 | 175 | 58 | 53 | 6 | 13 | 50 |

| PP | -5 | 163 | 110 | 33 | 415 | 20 | 56 |

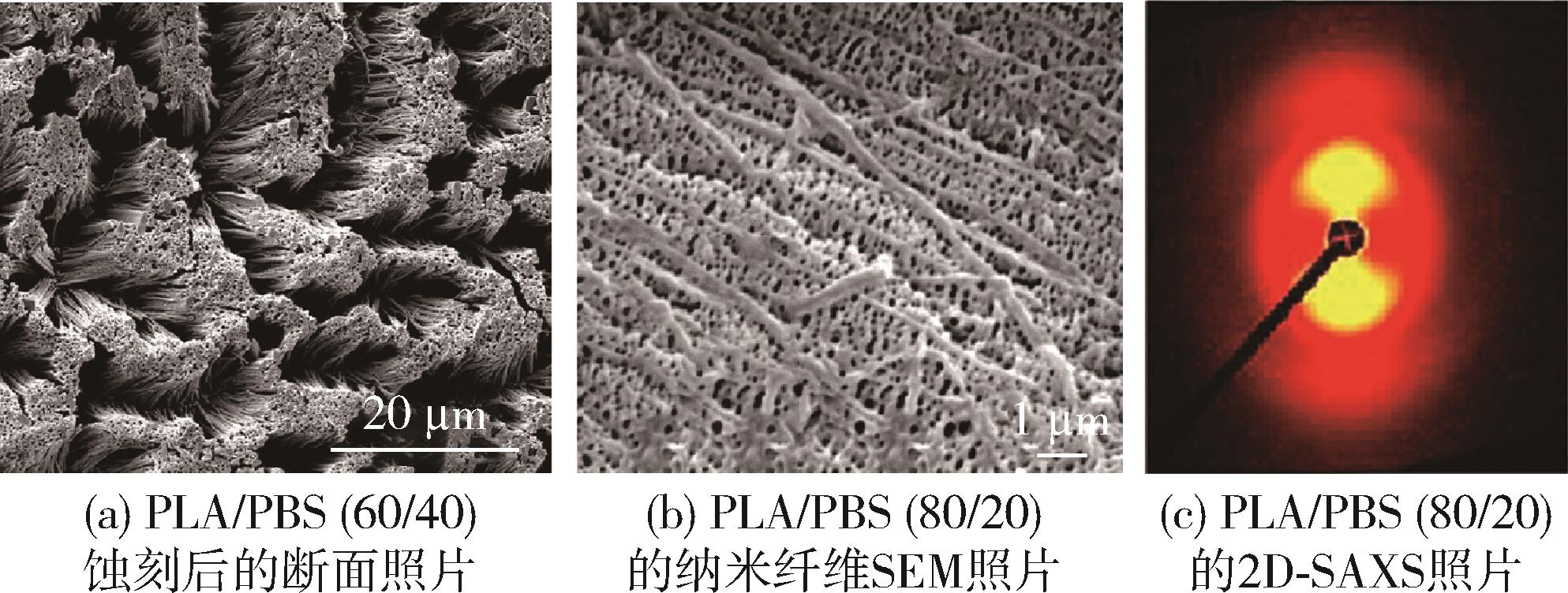

| PE⁃HD | -120 | 129 | 82 | 28 | 700 | 40 | 69 |

| PE⁃LD | -120 | 110 | 49 | 10 | 300 | 410 | 49 |

| 样品名称 | 相容剂/扩链剂 | 拉伸强度/MPa | 断裂伸长率/% | 参考文献 |

|---|---|---|---|---|

| PBS/PLA/EGMA(10/90/12) | 乙烯⁃丙烯酸甲酯⁃甲基丙烯酸缩水甘油酯(EGMA) | 23 | 460 | [ |

| PBS/PLA/EJ400(23/67/10) | 聚丙烯乙二醇二缩水甘油酯(EJ400) | 37 | 190 | [ |

| PBS/PLA/MFC⁃EPI(10/90/2) | 环氧微纤化纤维素(MFC⁃EPI) | 71 | 274 | [ |

| PBS/PLA/TDI(30/70/9) | 甲苯二异氰酸酯(TDI) | 36 | 285 | [ |

| PBS/PLA/rPBSL(20/80/5) | 丁二酸⁃乳酸共聚物(rPBSL) | 40 | 340 | [ |

| PBS/PLA/ISE(20/80/15) | 异山梨醇二元酸脂(ISE) | 22 | 260 | [ |

| PBS/PLA/ATBC(17/63/20) | 乙酰柠檬酸三丁酯(ATBC) | 33 | 580 | [ |

| PBS/PLA/TPP(20/80/0.5) | 亚磷酸三苯酯(TPP) | 34 | 455 | [ |

| 样品名称 | 相容剂/扩链剂 | 拉伸强度/MPa | 断裂伸长率/% | 参考文献 |

|---|---|---|---|---|

| PBS/PLA/EGMA(10/90/12) | 乙烯⁃丙烯酸甲酯⁃甲基丙烯酸缩水甘油酯(EGMA) | 23 | 460 | [ |

| PBS/PLA/EJ400(23/67/10) | 聚丙烯乙二醇二缩水甘油酯(EJ400) | 37 | 190 | [ |

| PBS/PLA/MFC⁃EPI(10/90/2) | 环氧微纤化纤维素(MFC⁃EPI) | 71 | 274 | [ |

| PBS/PLA/TDI(30/70/9) | 甲苯二异氰酸酯(TDI) | 36 | 285 | [ |

| PBS/PLA/rPBSL(20/80/5) | 丁二酸⁃乳酸共聚物(rPBSL) | 40 | 340 | [ |

| PBS/PLA/ISE(20/80/15) | 异山梨醇二元酸脂(ISE) | 22 | 260 | [ |

| PBS/PLA/ATBC(17/63/20) | 乙酰柠檬酸三丁酯(ATBC) | 33 | 580 | [ |

| PBS/PLA/TPP(20/80/0.5) | 亚磷酸三苯酯(TPP) | 34 | 455 | [ |

| 1 | Thurber H, Curtzwiler G W.Suitability of poly(butylene succinate) as a coating for paperboard convenience food packaging[J].International Journal of Biobased Plastics,2020,2:1⁃12. |

| 2 | Liminana P, Garcia⁃Sanoguera D, Quiles⁃Carrillo L,et al.Development and characterization of environmentally friendly composites from poly(butylene succinate) (PBS) and almond shell flour with different compatibilizers[J].Compos Part B⁃Eng,2018,144:153⁃162. |

| 3 | Pan P, Inoue Y.Polymorphism and isomorphism in biodegradable polyesters[J].Prog Polym Sci,2009,34:605⁃640. |

| 4 | Shih Y F, Chen L S, Jeng R J.Preparation and properties of biodegradable PBS/multi⁃walled carbon nanotube nanocomposites[J].Polymer,2008,48:4 602⁃4 611. |

| 5 | Zeng J B, Li Y D, Zhu Q Y,et al.A novel biodegradable multiblock poly(ester urethane) containing poly(L⁃lactic acid) and poly(butylene succinate) blocks[J]. Polymer,2009,50:1 178⁃1 186. |

| 6 | Suleyman H, Albayrak A, Bilici M,et al. Different mechanisms in formation and prevention of indomethacin⁃induced gastric ulcers[J]. Inflammation,2010,33:224⁃234. |

| 7 | Rudnik E.Compostable polymer materials:definitions,structures,and methods of preparation[J].Handbook of Biopolymers and Biodegradable Plastics,2013,20:189⁃211. |

| 8 | Rafiqah S A, Khalina A, Harmaen A S,et al.A review on properties and application of bio⁃based poly(butylene succinate) [J].Polymers(Basel),2021,13:1 309⁃1 436. |

| 9 | Zhou X X, Dou Q.Preparation of poly(butylene succinate)/soy protein isolate bio⁃composites by reactive compatibilization with peroxide and acrylate[J]. J Polym Environ, 2021,30:1 847⁃1 863. |

| 10 | Bautista M, Ilarduya A M, Alla A,et al. Poly(butylene succinate) ionomers with enhanced hydrodegradability[J].Polymers⁃Basel,2015,7:1 232⁃1 247. |

| 11 | Bautista M, Ilarduya A M, Alla A,et al. Cationic poly(butylene succinate) copolyesters[J]. Eur Polym J,2016,75:329⁃342. |

| 12 | Tokiwa Y, Calabia B P, Ugwu C U,et al.Biodegradability of plastics[J]. Int J Mol Sci, 2009,10:3 722⁃3 742. |

| 13 | Kanemura C, Nakashima S, Hotta A.Mechanical properties and chemical structures of biodegradable poly(butylene⁃succinate) for material reprocessing[J]. Polym Degrad Stabil,2012,97:972⁃980. |

| 14 | Yu L, Ke S M, Zhang Y H,et al. Dielectric relaxations of high⁃k poly(butylene succinate) based all⁃organic nanocomposite films for capacitor applications[J]. J Mater Res,2011,26:2 493⁃2 502. |

| 15 | Petchwattana N, Covavisaruch S, Wibooranawong S,et al. Antimicrobial food packaging prepared from poly(butylene succinate) and zinc oxide[J].Measurement,2016,93:442⁃448. |

| 16 | Saeng⁃on J, Aht⁃Ong D.Compatibility of banana starch nanocrystals/poly(butylene succinate) bio⁃nanocomposite packaging films[J]. Journal of Applied Polymer Science,2018,135: 46 836. |

| 17 | Jariyasakoolroj P, Makyarm K, Klairasamee K,et al.Crystallization behavior analysis and reducing thermal shrinkage of poly(lactic acid) miscibilized with poly(butylene succinate) film for food packaging[J]. Journal of Applied Polymer Science,2023,978:53915. |

| 18 | Xue B, He H, Zhu Z,et al.A facile fabrication of high toughness poly(lactic acid) via reactive extrusion with poly(butylene succinate) and ethylene⁃methyl acrylate⁃glycidyl methacrylate[J].Polymers (Basel),2018,10:1 012⁃1 401. |

| 19 | Mallegni N, Phuong T V, Coltelli M B,et al.Poly(lactic acid) (PLA) based tear resistant and biodegradable flexible films by blown film extrusion[J]. Materials (Basel),2018,11:148. |

| 20 | Deng Y, Thomas N L.Blending poly(butylene succinate) with poly(lactic acid):ductility and phase inversion effects[J].Eur Polym J,2015,71:534⁃546. |

| 21 | Phetwarotai W, Maneechot H, Kalkornsurapranee E,et al.Thermal behaviors and characteristics of polylactide/poly(butylene succinate) blend films via reactive compatibilization and plasticization[J].Polym Advan Technol,2018,29:2 121⁃2 133. |

| 22 | Supthanyakul R, Kaabbuathong N, Chirachanchai S.Random poly(butylene succinate⁃co⁃lactic acid) as a multi⁃functional additive for miscibility,toughness,and clarity of PLA/PBS blends[J]. Polymer,2016,105:1⁃9. |

| 23 | Fortunati E, Puglia D, Iannoni A,et al.Thermal and mechanical responses of stretchable poly (lactic acid)/poly (butylene succinate) films[J]. Materials (Basel),2017,10:10 070 809. |

| 24 | Gigante V, Coltelli M B, Vannozzi A,et al.Flat die extruded biocompatible poly(lactic acid) (PLA)/poly(butylene succinate) (PBS) based films[J]. Polymers (Basel),2019,11:1 111⁃1 857. |

| 25 | Ma M, Xu L, Liu K,et al.Effect of triphenyl phosphite as a reactive compatibilizer on the properties of poly(L‐lactic acid)/poly(butylene succinate) blends[J].Journal of Applied Polymer Science,2019,137:48646. |

| 26 | Wu F, Misra M, Mohanty A K.Novel tunable super⁃tough materials from biodegradable polymer blends: nano⁃structuring through reactive extrusion[J].RSC Adv,2019,9:2 836⁃2 847. |

| 27 | Ma P M, Hristova⁃Bogaerds D G, Lemstra P J,et al.Toughening of PHBV/PBS and PHB/PBS blends via in situ compatibilization using dicumyl peroxide as a free⁃radical grafting initiator[J].Macromol Mater Eng,2012,297:402⁃410. |

| 28 | Fahrngruber B,Fortea⁃Verdejo, Wimmer R,et al.Starch/poly(butylene succinate) compatibilizers: effect of different reaction⁃approaches on the properties of thermoplastic starch⁃based compostable films[J].J Polym Environ,2019,28:257⁃270. |

| 29 | Ayu R S, Khalina A, Harmaen A S,et al.Characterization study of empty fruit bunch (EFB) fibers reinforcement in poly(butylene) succinate (PBS)/starch/glycerol compo⁃site sheet[J]. Polymers (Basel),2020,12:1 207⁃1 571. |

| 30 | Rojas⁃Lema S, Arevalo J, Gomez⁃Caturla J,et al.Peroxide⁃induced synthesis of maleic anhydride⁃grafted poly(butylene succinate) and its compatibilizing effect on poly(butylene succinate)/pistachio shell flour composites[J].Molecules,2021,26:2 619⁃5 927. |

| 31 | Rasheed M, Jawaid M, Parveez B,et al.Morphology, structural, thermal, and tensile properties of bamboo microcrystalline cellulose/poly(lactic acid)/poly(butylene succinate) composites[J]. Polymers (Basel),2021,13:465. |

| 32 | Rasheed M, Jawaid M, Parveez B.Bamboo fiber based cellulose nanocrystals/poly(lactic acid)/poly(butylene succinate) nanocomposites:morphological, mechanical and thermal properties[J]. Polymers (Basel),2021,13:1 076. |

| 33 | Xu J, Manepalli P H, Zhu L,et al.Morphological,barrier and mechanical properties of films from poly (butylene succinate) reinforced with nanocrystalline cellulose and chitin whiskers using melt extrusion[J].Journal of Polymer Research,2019,26:191 783. |

| 34 | Zhang Y, Zhou S M, Fang X C,et al.Renewable and flexible UV⁃blocking film from poly(butylene succinate) and lignin[J].Eur Polym J,2019,116:265⁃274. |

| 35 | Zhou X, He T Z, Jiang Y K,et al.A novel network⁃structured compatibilizer for improving the interfacial behavior of PBS/lignin[J].Acs Sustain Chem Eng,2021,9:8 592⁃8 602. |

| 36 | Saffian H A, Yamaguchi M, Ariffin H,et al.Physical and mechanical properties of poly(butylene succinate)/kenaf core fibers composites reinforced with esterified lignin[J]. Polymers (Basel),2021,13:1 314⁃2 359. |

| 37 | Xiong L, Tu Z, Zhang S, Liu X,et al.Preparation of PBS and CaCO3 composite degradable materials based on melt blending[J].IOP Conference Series: Materials Science and Engineering,2020,730:012 012. |

| 38 | Jamnongkan T, Yosta A, Thanesthakul B,et al.Effect of ZnO nanoparticles on the physical properties of PLA/PBS biocomposite films[J].Materials Science Forum,2021,1033: 143⁃150. |

| 39 | Tan L C, He Y, Qu J R.Structure and properties of polylactide/poly(butylene succinate)/organically modified montmorillonite nanocomposites with high⁃efficiency intercalation and exfoliation effect manufactured via volume pulsating elongation flow[J].Polymer,2019,180:121656. |

| 40 | Karakehya N.Comparison of the effects of various reinforcements on the mechanical,morphological,thermal and surface properties of poly(butylene succinate) [J].Int J Adhes Adhes,2021,110:102949. |

| 41 | Aversa C, Barletta M, Gisario A,et al.Corotating twin⁃screw extrusion of poly(lactic acid) PLA/poly(butylene succinate) PBS/ micro⁃lamellar talc blends for extrusion blow molding of biobased bottles for alcoholic beverages[J].Journal of Applied Polymer Science,2021,138:51 294. |

| 42 | Ilsouk M, Raihane M, Rhouta B,et al.The relationship of structure,thermal and water vapor permeability barrier properties of poly(butylene succinate)/organomodified beidellite clay bionanocomposites prepared by in situ polycondensation[J].RSC Adv,2020,10:37 314⁃37 326. |

| 43 | Xie L, Xu H, Niu B,et al.Unprecedented access to strong and ductile poly(lactic acid) by introducing in situ nanofibrillar poly(butylene succinate) for green packaging[J].Biomacromolecules,2014,15:4 054⁃4 064. |

| 44 | Messin T, Marais S, Follain N,et al.Biodegradable PLA/PBS multinanolayer membrane with enhanced barrier performances[J].Journal of Membrane Science,2020,598:117777. |

| 45 | Bumbudsanpharoke N, Wongphan P, Promhuad K,et al.Morphology and permeability of bio⁃based poly(butylene adipate⁃co⁃terephthalate) (PBAT),poly(butylene succinate) (PBS) and linear low⁃density polyethylene (LLDPE) blend films control shelf⁃life of packaged bread[J].Food Control,2022,132:108541. |

| 46 | Sharma R, Jafari S M,Sharma.Antimicrobial bio⁃nanocomposites and their potential applications in food packaging[J].Food Control,2020,112:107086. |

| 47 | Aziman N, Kian L K, Jawaid M, al et,Morphological,structural,thermal,permeability, and antimicrobial activity of PBS and PBS/TPS films incorporated with biomaster⁃silver for food packaging application[J].Polymers (Basel),2021,13:126348. |

| 48 | Nanni A, Ricci A, Versari A,et al.Wine derived additives as poly(butylene succinate) (PBS) natural stabilizers for different degradative environments[J].Polym Degrad Stabil,2020,182:109381. |

| 49 | Lopusiewicz L, Zdanowicz M, Macieja S,et al.Development and characterization of bioactive poly(butylene⁃succinate) films modified with quercetin for food packaging applications[J].Polymers (Basel),2021,13:1 311⁃1 798. |

| 50 | Siracusa V, Rocculi P, Romani S,et al.biodegradable polymers for food packaging: a review[J].Trends Food Sci Tech,2008,19:634⁃643. |

| 51 | Yamamoto⁃Tamura K, Hoshino Y T, Tsuboi S,et al.Fungal community dynamics during degradation of poly(butylene succinate⁃co⁃adipate) film in two cultivated soils in Japan[J].Biosci Biotechnol Biochem,2020,84:1 077⁃1 087. |

| 52 | Bi S W, Pan H, Barinelli V,et al.Biodegradable polyester coated mulch paper for controlled release of fertilizer[J].Journal of Cleaner Production,2021,294:126⁃348. |

| 53 | Liu W J, Ren X.Study on the application of the narrow distribution and controlled molecular weight hindered amine lighter stabilizers in poly(butylene succinate) [J].J Macromol Sci A,2019,56:535⁃543. |

| [1] | 李丹, 赵彪, 陈轲, 王帆, 张靖宇, 张凤波, 潘凯. 中空聚丙烯纤维制备及应用研究进展[J]. 中国塑料, 2023, 37(9): 109-114. |

| [2] | 任国振, 王蒙蒙, 黄建建, 晋刚. 体积拉伸流场下PEEK/TLCP共混物的制备及性能研究[J]. 中国塑料, 2023, 37(8): 1-7. |

| [3] | 张文超 辛菲 刘昊育 王雪晶. 有机长余辉材料研究进展[J]. , 2023, 37(6): 131-140. |

| [4] | 孙菁, 熊发强, 邓汝辉, 陶雅娴, 陈兴刚. 智能高分子材料在医学监控中的研究进展[J]. 中国塑料, 2023, 37(10): 40-49. |

| [5] | 马志蕊 尹甜 蒋志魁 杨璠 祝孟珂 杨洋 韩宇 翁云宣 张彩丽. PBS及其复合膜的制备及应用研究进展[J]. , 2023, 37(10): 24-33. |

| [6] | 孙菁 熊发强 邓汝辉 陶雅娴 陈兴刚. 智能高分子材料在医学监控中的研究进展[J]. , 2023, 37(10): 40-49. |

| [7] | 马超, 马兰荣, 魏辽, 尹慧博, 林祥. 聚乙醇酸材料的加工改性及其水下降解特性的研究进展[J]. 中国塑料, 2022, 36(9): 74-84. |

| [8] | 冯凯, 李永青, 马秀清, 韩颖. 聚甲醛增韧改性的研究进展及应用[J]. 中国塑料, 2022, 36(7): 157-164. |

| [9] | 冯冰涛, 王晓珂, 张信, 孙国华, 汪殿龙, 侯连龙, 马劲松. 连续碳纤维增强热塑性复合材料制备与应用研究进展[J]. 中国塑料, 2022, 36(7): 165-173. |

| [10] | 杨小龙, 陈文静, 李永青, 闫晓堃, 王修磊, 谢鹏程, 马秀清. 导电型聚合物/石墨烯复合材料的研究进展[J]. 中国塑料, 2022, 36(6): 165-173. |

| [11] | 魏茂强. 农用塑料薄膜的发展与探讨[J]. 中国塑料, 2022, 36(6): 92-99. |

| [12] | 董露茜, 徐芳, 翁云宣. 聚乙醇酸改性及其应用研究进展[J]. 中国塑料, 2022, 36(4): 166-174. |

| [13] | 蒋森, 王立岩, 陈延明, 张乐, 翟桂法. MPO改性PBS共聚酯的合成及其热性能研究[J]. 中国塑料, 2022, 36(4): 24-29. |

| [14] | 黎玉山, 李杰. PDMS耐久性超疏水表面的研究进展[J]. 中国塑料, 2022, 36(3): 167-176. |

| [15] | 姚逸, 张尔杰, 卢昌利, 王超军, 焦建, 曾祥斌. 食品接触法规对PBS发展的影响浅析[J]. 中国塑料, 2022, 36(10): 125-130. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2