京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2

《中国塑料》编辑部 ©2008-2024 版权所有

地址:北京市海淀区阜成路11号 邮编:100048

编辑部:010-68985541 联系信箱:cp@plaschina.com.cn

广告部/发行部:010-68985253 本系统由北京玛格泰克科技发展有限公司设计开发

中国塑料 ›› 2025, Vol. 39 ›› Issue (7): 49-55.DOI: 10.19491/j.issn.1001-9278.2025.07.009

收稿日期:2024-12-23

出版日期:2025-07-26

发布日期:2025-07-22

作者简介:胡砚磊(1992-),工程师,主要从事高分子材料及制品测试评价新方法的研究工作,huyl.bjhy@sinopec.com

HU Yanlei( ), SUN Jin, HU Fa, WU Zhijun, LI Yue, WU Xiaohan

), SUN Jin, HU Fa, WU Zhijun, LI Yue, WU Xiaohan

Received:2024-12-23

Online:2025-07-26

Published:2025-07-22

摘要:

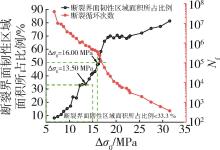

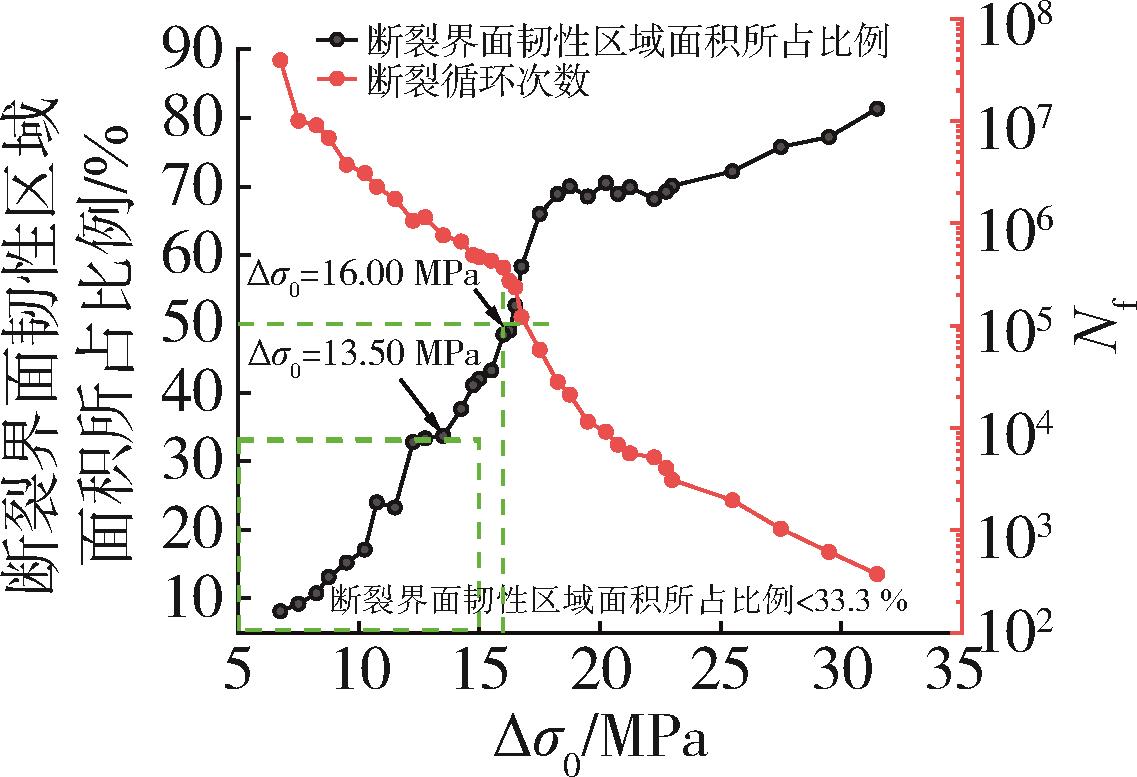

采用循环载荷缺口圆棒(CRB)试验方法研究了聚乙烯(PE)管材料的耐疲劳失效性能,并考察了不同样品制备方式、样品尺寸、应力范围、频率、载荷比和温度等因素对材料失效结果的影响。结果表明,采用压塑制样的PE管材料在CRB试验中的耐疲劳性能优于管材挤出样品;随着样品直径的增加,断裂循环次数显著减少;应力范围增大也会导致断裂循环次数减少,并在应力范围达到16 MPa时出现脆韧转变现象;试验频率的提高使试样断裂循环次数减少;而载荷比的增加则导致样品断裂循环次数上升;温度升高会引起试样断裂循环次数的下降。

中图分类号:

胡砚磊, 孙晋, 胡法, 武志军, 李玉娥, 吴孝翰. 循环载荷法评价聚乙烯管材料耐疲劳失效性能的研究[J]. 中国塑料, 2025, 39(7): 49-55.

HU Yanlei, SUN Jin, HU Fa, WU Zhijun, LI Yue, WU Xiaohan. Study on fatigue failure resistance of polyethylene pipe materials evaluated by cyclic loading method[J]. China Plastics, 2025, 39(7): 49-55.

| 样品 | 应力范围(Δσ0)/MPa | 循环次数 Nf | R2 | 应力范围Δσ0=12.5 MPa时的循环次数(Nf) |

|---|---|---|---|---|

| 压塑制样 | 11.50 | 1 919 915 | 0.947 09 | 1 314 258 |

| 12.25 | 1 321 413 | |||

| 12.75 | 1 246 994 | |||

| 13.50 | 971 701 | |||

管材机 加工制样 | 11.50 | 1 565 000 | 0.922 80 | 1 043 217 |

| 12.25 | 1 234 136 | |||

| 12.75 | 857 081 | |||

| 13.50 | 754 160 |

| 样品 | 应力范围(Δσ0)/MPa | 循环次数 Nf | R2 | 应力范围Δσ0=12.5 MPa时的循环次数(Nf) |

|---|---|---|---|---|

| 压塑制样 | 11.50 | 1 919 915 | 0.947 09 | 1 314 258 |

| 12.25 | 1 321 413 | |||

| 12.75 | 1 246 994 | |||

| 13.50 | 971 701 | |||

管材机 加工制样 | 11.50 | 1 565 000 | 0.922 80 | 1 043 217 |

| 12.25 | 1 234 136 | |||

| 12.75 | 857 081 | |||

| 13.50 | 754 160 |

| 制备方式 | 结晶峰温/℃ | 熔融焓/J·g-1 | 结晶度/% |

|---|---|---|---|

| 压塑制样 | 132.06 | 197.88 | 68.4 |

| 管材机加工制样 | 128.43 | 179.36 | 62.0 |

| 制备方式 | 结晶峰温/℃ | 熔融焓/J·g-1 | 结晶度/% |

|---|---|---|---|

| 压塑制样 | 132.06 | 197.88 | 68.4 |

| 管材机加工制样 | 128.43 | 179.36 | 62.0 |

| 样品 | 应力范围Δσ0/MPa | 循环次数 Nf | R2 | 应力范围Δσ0=12.5 MPa的循环次数Nf |

|---|---|---|---|---|

溢料式 模具 | 11.50 | 1 800 561 | 0.986 45 | 1 245 850 |

| 12.25 | 1 427 605 | |||

| 12.75 | 1 128 993 | |||

| 13.50 | 845 598 | |||

| 非溢料式模具 | 11.50 | 1 471 394 | 0.977 82 | 1 137 159 |

| 12.25 | 1 193 262 | |||

| 12.75 | 1 108 537 | |||

| 13.50 | 874 047 |

| 样品 | 应力范围Δσ0/MPa | 循环次数 Nf | R2 | 应力范围Δσ0=12.5 MPa的循环次数Nf |

|---|---|---|---|---|

溢料式 模具 | 11.50 | 1 800 561 | 0.986 45 | 1 245 850 |

| 12.25 | 1 427 605 | |||

| 12.75 | 1 128 993 | |||

| 13.50 | 845 598 | |||

| 非溢料式模具 | 11.50 | 1 471 394 | 0.977 82 | 1 137 159 |

| 12.25 | 1 193 262 | |||

| 12.75 | 1 108 537 | |||

| 13.50 | 874 047 |

| 样品 | 结晶峰温度/℃ | 熔融焓/J·g-1 | 结晶度/% |

|---|---|---|---|

| 溢料式模具 | 132.16 | 189.80 | 65.6 |

| 非溢料式模具 | 131.68 | 189.54 | 65.5 |

| 样品 | 结晶峰温度/℃ | 熔融焓/J·g-1 | 结晶度/% |

|---|---|---|---|

| 溢料式模具 | 132.16 | 189.80 | 65.6 |

| 非溢料式模具 | 131.68 | 189.54 | 65.5 |

直径/ mm | 应力范围Δσ0 /MPa | 循环次数 Nf | R2 | 应力范围Δσ0=12.5 MPa 时循环次数Nf |

|---|---|---|---|---|

| 10 | 11.50 | 4 000 591 | 0.996 67 | 2 792 593 |

| 12.25 | 3 046 124 | |||

| 12.75 | 2 493 142 | |||

| 13.50 | 2 005 398 | |||

| 12 | 11.50 | 2 245 255 | 0.997 84 | 1 676 279 |

| 12.25 | 1 788 561 | |||

| 12.75 | 1 549 468 | |||

| 13.50 | 1 223 300 | |||

| 14 | 11.50 | 1 919 915 | 0.947 09 | 1 314 258 |

| 12.25 | 1 321 413 | |||

| 12.75 | 1 246 994 | |||

| 13.50 | 971 701 | |||

| 15 | 11.50 | 1 861 143 | 0.952 61 | 1 109 790 |

| 12.25 | 1 136 585 | |||

| 12.75 | 980 985 | |||

| 13.50 | 791 540 | |||

| 16 | 11.50 | 1 305 413 | 0.868 22 | 926 766 |

| 12.25 | 1 167 283 | |||

| 12.75 | 889 912 | |||

| 13.50 | 566 550 |

直径/ mm | 应力范围Δσ0 /MPa | 循环次数 Nf | R2 | 应力范围Δσ0=12.5 MPa 时循环次数Nf |

|---|---|---|---|---|

| 10 | 11.50 | 4 000 591 | 0.996 67 | 2 792 593 |

| 12.25 | 3 046 124 | |||

| 12.75 | 2 493 142 | |||

| 13.50 | 2 005 398 | |||

| 12 | 11.50 | 2 245 255 | 0.997 84 | 1 676 279 |

| 12.25 | 1 788 561 | |||

| 12.75 | 1 549 468 | |||

| 13.50 | 1 223 300 | |||

| 14 | 11.50 | 1 919 915 | 0.947 09 | 1 314 258 |

| 12.25 | 1 321 413 | |||

| 12.75 | 1 246 994 | |||

| 13.50 | 971 701 | |||

| 15 | 11.50 | 1 861 143 | 0.952 61 | 1 109 790 |

| 12.25 | 1 136 585 | |||

| 12.75 | 980 985 | |||

| 13.50 | 791 540 | |||

| 16 | 11.50 | 1 305 413 | 0.868 22 | 926 766 |

| 12.25 | 1 167 283 | |||

| 12.75 | 889 912 | |||

| 13.50 | 566 550 |

频率/ Hz | 应力范围Δσ0/ MPa | 循环次数 Nf | R2 | 应力范围Δσ0=12.5 MPa 时循环次数Nf |

|---|---|---|---|---|

| 5 | 11.50 | 1 136 159 | 0.981 30 | 671 237 |

| 12.25 | 772 580 | |||

| 12.75 | 617 217 | |||

| 13.50 | 368 895 | |||

| 10 | 11.50 | 970 261 | 0.980 13 | 660 281 |

| 12.25 | 455 669 | |||

| 12.75 | 643 314 | |||

| 13.50 | 737 814 | |||

| 15 | 11.50 | 378 228 | 0.908 32 | 84 056 |

| 12.25 | 205 645 | |||

| 12.75 | 41 594 | |||

| 13.50 | 18 065 | |||

| 20 | 11.50 | 60 251 | 0.994 76 | 34 811 |

| 12.25 | 40 331 | |||

| 12.75 | 31 494 | |||

| 13.50 | 20 135 |

频率/ Hz | 应力范围Δσ0/ MPa | 循环次数 Nf | R2 | 应力范围Δσ0=12.5 MPa 时循环次数Nf |

|---|---|---|---|---|

| 5 | 11.50 | 1 136 159 | 0.981 30 | 671 237 |

| 12.25 | 772 580 | |||

| 12.75 | 617 217 | |||

| 13.50 | 368 895 | |||

| 10 | 11.50 | 970 261 | 0.980 13 | 660 281 |

| 12.25 | 455 669 | |||

| 12.75 | 643 314 | |||

| 13.50 | 737 814 | |||

| 15 | 11.50 | 378 228 | 0.908 32 | 84 056 |

| 12.25 | 205 645 | |||

| 12.75 | 41 594 | |||

| 13.50 | 18 065 | |||

| 20 | 11.50 | 60 251 | 0.994 76 | 34 811 |

| 12.25 | 40 331 | |||

| 12.75 | 31 494 | |||

| 13.50 | 20 135 |

| 载荷比 | 应力范围Δσ0/MPa | 循环次数 Nf | R2 | 应力范围Δσ0=12.50 MPa时 循环次数Nf | 应力强度因子KImax(MPa*m0.5) |

|---|---|---|---|---|---|

| 0.01 | 11.50 | 849 023 | 0.896 93 | 633 877 | 0.669 21 |

| 12.25 | 752 194 | 0.713 26 | |||

| 12.75 | 548 061 | 0.743 34 | |||

| 13.50 | 480 158 | 0.788 10 | |||

| 0.05 | 11.50 | 1 205 147 | 0.997 34 | 829 941 | 0.671 17 |

| 12.25 | 924 713 | 0.714 94 | |||

| 12.75 | 756 185 | 0.744 12 | |||

| 13.50 | 604 753 | 0.787 90 | |||

| 0.1 | 11.50 | 1 565 000 | 0.922 80 | 1 043 217 | 0.669 06 |

| 12.25 | 1 234 136 | 0.715 31 | |||

| 12.75 | 857 081 | 0.743 73 | |||

| 13.50 | 754 160 | 0.785 83 |

| 载荷比 | 应力范围Δσ0/MPa | 循环次数 Nf | R2 | 应力范围Δσ0=12.50 MPa时 循环次数Nf | 应力强度因子KImax(MPa*m0.5) |

|---|---|---|---|---|---|

| 0.01 | 11.50 | 849 023 | 0.896 93 | 633 877 | 0.669 21 |

| 12.25 | 752 194 | 0.713 26 | |||

| 12.75 | 548 061 | 0.743 34 | |||

| 13.50 | 480 158 | 0.788 10 | |||

| 0.05 | 11.50 | 1 205 147 | 0.997 34 | 829 941 | 0.671 17 |

| 12.25 | 924 713 | 0.714 94 | |||

| 12.75 | 756 185 | 0.744 12 | |||

| 13.50 | 604 753 | 0.787 90 | |||

| 0.1 | 11.50 | 1 565 000 | 0.922 80 | 1 043 217 | 0.669 06 |

| 12.25 | 1 234 136 | 0.715 31 | |||

| 12.75 | 857 081 | 0.743 73 | |||

| 13.50 | 754 160 | 0.785 83 |

温度/ ℃ | 应力范围Δσ0/ MPa | 循环次数 Nf | R2 | 应力范围Δσ0=12.50 MPa时循环次数Nf |

|---|---|---|---|---|

| 23 | 11.50 | 1 800 561 | 0.986 45 | 1 246 507 |

| 12.25 | 1 427 605 | |||

| 12.75 | 1 128 993 | |||

| 13.50 | 845 598 | |||

| 30 | 11.50 | 1 672 136 | 0.998 43 | 1 144 491 |

| 12.25 | 1 268 948 | |||

| 12.75 | 1 031 517 | |||

| 13.50 | 806 407 | |||

| 40 | 11.50 | 1 240 420 | 0.993 77 | 843 909 |

| 12.25 | 939 837 | |||

| 12.75 | 782 993 | |||

| 13.50 | 568 835 | |||

| 50 | 11.50 | 747 610 | 0.998 78 | 559 275 |

| 12.25 | 604 589 | |||

| 12.75 | 516 202 | |||

| 13.50 | 424 841 | |||

| 60 | 11.50 | 16 021 | 0.951 41 | 8 294 |

| 12.25 | 9 147 | |||

| 12.75 | 6 564 | |||

| 13.50 | 5 245 |

温度/ ℃ | 应力范围Δσ0/ MPa | 循环次数 Nf | R2 | 应力范围Δσ0=12.50 MPa时循环次数Nf |

|---|---|---|---|---|

| 23 | 11.50 | 1 800 561 | 0.986 45 | 1 246 507 |

| 12.25 | 1 427 605 | |||

| 12.75 | 1 128 993 | |||

| 13.50 | 845 598 | |||

| 30 | 11.50 | 1 672 136 | 0.998 43 | 1 144 491 |

| 12.25 | 1 268 948 | |||

| 12.75 | 1 031 517 | |||

| 13.50 | 806 407 | |||

| 40 | 11.50 | 1 240 420 | 0.993 77 | 843 909 |

| 12.25 | 939 837 | |||

| 12.75 | 782 993 | |||

| 13.50 | 568 835 | |||

| 50 | 11.50 | 747 610 | 0.998 78 | 559 275 |

| 12.25 | 604 589 | |||

| 12.75 | 516 202 | |||

| 13.50 | 424 841 | |||

| 60 | 11.50 | 16 021 | 0.951 41 | 8 294 |

| 12.25 | 9 147 | |||

| 12.75 | 6 564 | |||

| 13.50 | 5 245 |

| [1] | 周建斌, 吴 欣. 聚乙烯管道材料的慢速裂纹增长性能研究[J]. 材料研究学报, 2014, 28(6): 516-522. |

| ZHOU J B, WU X. Study on slow crack growth performance of polyethylene pipeline materials[J]. Chinese Journal of Materials Research, 2014, 28(6): 516-522. | |

| [2] | 朱 建, 杨 勇, 张建中. 聚乙烯燃气管道材料的慢速裂纹增长特性[J]. 塑料工业, 2012, 40(8): 67-72. |

| ZHU J, YANG Y, ZHANG J Z. Slow crack growth characteristics of polyethylene gas pipeline materials[J]. China Plastics Industry, 2012,40(8): 67-72. | |

| [3] | Brown N, Lu. Slow crack growth in polyethylene resins[J]. Polymer, 1997, 38(22): 5 739-5 746. |

| [4] | Leeming A, Porter D. Stress rupture and slow crack growth behaviour of polyethylene[J]. Polymer Testing, 2000, 19(3): 291-297. |

| [5] | Spychala J G, Hill M A, Harris K R. The influence of surfactants on the slow crack growth of polyethylene[J].Polymer Engineering & Science, 2003, 43(3):503-509. |

| [6] | Nishimura H, Narisawa I. Fatigue Behavior of Medium-Density Polythylene Pipes[J]. Polym Eng Sci, 1991, 31(6):399-403. |

| [7] | Shah A, Stepanov E V, Capaccio G, et al. Correlation of fatigue crack propagation in polyethylene pipe specimens of different geometries[J].International Journal of Fracture,1997,84: 159-173. |

| [8] | Parsons M, Stepanov E V, Hiltner A, et al.Correlation of fatigue and creep slow crack growth in a medium density polyethylene pipe material[J].Journal of Materials Science,2000,35:2 659-2 674. |

| [9] | Favier V, Giroud T, Strijko E, et al. Slow crack propagation in polyethylene under fatigue at controlled stress intensity[J].Polymer,2002,43:1 375-1 382. |

| [10] | Gerald P, Markus H, Werner B. Cyclic crack growth tests with CRB specimens for the evaluation of the long-term performance of PE pipe grades[J]. Polymer Testing, 2007(26):180-188. |

| [11] | 中国国家标准化管理委员会. 塑料 差示扫描量热法(DSC) 第3部分:熔融和结晶温度及热焓的测定: [S].北京:中国标准出版社,2004. |

| [12] | 李 军, 周 超, 王 悦. 冷却速度对聚乙烯结晶行为的影响[J].高分子材料科学与工程, 2016, 32(5): 88-93. |

| LI J, ZHOU C, WANG Y. Effect of cooling rate on crystallization behavior of polyethylene[J]. Polymer Materials Science and Engineering, 2016, 32(5): 88-93. | |

| [13] | 赵丽萍, 王 林. 挤出和压塑对聚乙烯结晶行为的影响[J].塑料工业, 2018, 46(8): 55-59. |

| ZHAO L P, WANG L. Effects of extrusion and compression molding on crystallization behavior of polyethylene[J]. China Plastics Industry, 2018, 46(8):55-59. | |

| [14] | Lazzarin P, Tovo R, Meneghettit G. Fatigue crack initiation and propagation phases near notches in metals with low notch sensitivity[J], Int J Fatigue, 1997,19:647. |

| [15] | 李 明, 王大伟, 刘 锋. 加载频率对聚乙烯材料动态疲劳寿命的影响[J].材料科学与工程学报, 2015, 33(2): 45-50. |

| LI M, WANG D W, LIU F. Effect of loading frequency on dynamic fatigue life of polyethylene material[J]. Journal of Materials Science and Engineering, 2015, 33(2):45-50. | |

| [16] | 朱英杰, 赵 伟. 疲劳加载频率对聚合物材料缺陷敏感性的影响[J].高分子学报, 2018, 49(8): 1 234-1 239. |

| ZHU Y J, ZHAO W. Influence of fatigue loading frequency on defect sensitivity in polymeric materials[J]. Acta Polymerica Sinica, 2018,49(8): 1 234-1 239. | |

| [17] | Paris P C, Erdogan F. A critical analysis of crack propagation laws[J]. Journal of Basic Engineering, 1963, 85(4):528-534. |

| [18] | Zhang Yu T. Effect of temperature on creep crack growth in polyethylene[J]. Polymer Testing, 2000, 19(3): 283-289. |

| [19] | Plummer, Jerome, Leblan J. Crazing and shear deformation in polyethylene and polypropylene[J]. Journal of Materials Science, 1998, 33(16): 4 065-4 076. |

| [20] | 王 琳, 张 建, 黄明辉. 温度对聚乙烯断裂韧性及裂纹扩展影响的研究[J]. 塑料科技, 2008, 36(5): 42-46. |

| WANG L, ZHANG J, HUANG M H. Effect of temperature on fracture toughness and crack propagation of polyethylene[J]. Plastics Science and Technology, 2008, 36(5): 42-46. |

| [1] | 徐传浩, 石振武, 池波. BMH型温拌剂对废塑/SBS复合改性沥青疲劳性能的影响[J]. 中国塑料, 2024, 38(8): 94-99. |

| [2] | 李明昆, 林荣涛. PC/ABS高温下耐疲劳性能的影响因素研究[J]. 中国塑料, 2024, 38(12): 77-80. |

| [3] | 李岩, 唐晓旭, 张伟杰, 黄瑞鹏, 张杉. 基于应变硬化模量方法评价聚乙烯管材耐慢速裂纹增长性能研究进展[J]. 中国塑料, 2022, 36(9): 148-159. |

| [4] | 李亚飞, 孙小杰, 任月庆, 张寅灵. 阻燃抗静电聚烯烃板材的制备与性能研究[J]. 中国塑料, 2022, 36(8): 23-27. |

| [5] | 孙永涛, 卢道胜, 刘练, 张海龙, 刘明泰. 氟橡胶纳米复合材料的应用研究进展[J]. 中国塑料, 2022, 36(12): 167-174. |

| [6] | 李文婷, 李明鹏, 陈季荷, 苑之童, 程海涛. 加捻植物纤维增强聚氨酯复合材料的力学特性与疲劳性能[J]. 中国塑料, 2022, 36(11): 41-50. |

| [7] | 王志刚, 杨波, 李茂东, 林金梅李仕平, 翟伟. 聚乙烯管材耐慢速裂纹增长性能的加速评价方法研究进展[J]. 中国塑料, 2017, 31(07): 121-125 . |

| [8] | 李劲松, 李美, 梅烨. 玻璃纤维增强聚丙烯水箱支架的结构优化[J]. 中国塑料, 2016, 30(04): 99-101 . |

| [9] | 盛永华 李力. 短碳纤维增强热塑性树脂复合材料的制备及其疲劳性能研究[J]. 中国塑料, 2012, 26(05): 54-57 . |

| [10] | 赵启辉. 聚乙烯承压管道及原料耐慢速裂纹增长测试标准及实验要求[J]. 中国塑料, 2008, 22(10): 90-94 . |

| [11] | 朱利平. 塑料阀门国际标准的介绍与问题探讨[J]. 中国塑料, 2005, 19(7): 82-86. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2