京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2

《中国塑料》编辑部 ©2008-2024 版权所有

地址:北京市海淀区阜成路11号 邮编:100048

编辑部:010-68985541 联系信箱:cp@plaschina.com.cn

广告部/发行部:010-68985253 本系统由北京玛格泰克科技发展有限公司设计开发

中国塑料 ›› 2024, Vol. 38 ›› Issue (6): 105-110.DOI: 10.19491/j.issn.1001-9278.2024.06.016

牛荷, 吕明福, 张宗胤, 徐耀辉, 许巍, 张师军, 郭鹏( )

)

收稿日期:2023-10-18

出版日期:2024-06-26

发布日期:2024-06-20

通讯作者:

郭鹏,主要从事可降解材料加工技术研究,guopeng.bjhy@sinopec.com基金资助:

NIU He, LYU Mingfu, ZHANG Zongyin, XU Yaohui, XU Wei, ZHANG Shijun, GUO Peng( )

)

Received:2023-10-18

Online:2024-06-26

Published:2024-06-20

Contact:

GUO Peng

E-mail:guopeng.bjhy@sinopec.com

摘要:

综述了聚乙醇酸(PGA)加工技术中助剂的应用进展,包括抗氧剂、扩链剂、抗水解剂以及无机粒子。

中图分类号:

牛荷, 吕明福, 张宗胤, 徐耀辉, 许巍, 张师军, 郭鹏. 聚乙醇酸加工技术中助剂的应用进展[J]. 中国塑料, 2024, 38(6): 105-110.

NIU He, LYU Mingfu, ZHANG Zongyin, XU Yaohui, XU Wei, ZHANG Shijun, GUO Peng. Application progress in additives in polyglycolic acid processing[J]. China Plastics, 2024, 38(6): 105-110.

| 聚合物 | Tg/℃ | Tm/℃ | 拉伸强度/MPa | 弹性模量/GPa | 断裂伸长率/% |

|---|---|---|---|---|---|

| PGA | 35~40 | 220~230 | 115 | 7 | 1~3 |

| PHB | -1 | 160~170 | 40 | 1.7~3.5 | 3~6 |

| PBS | -32 | 110~120 | 32.1 | 0.33 | 321 |

| PLA | 50~60 | 140~180 | 28~50 | 1.2~2.7 | 5~9 |

| PTMC | -19~-27 | — | 1.8~2.4 | 0.005~0.006 | 610~670 |

| PCL | -60 | 60 | 16 | 0.4 | 120~800 |

| PHBV | 1.4~2.8 | 170 | 30~38 | 0.7~2.9 | 20 |

| PBAT | -30 | 110~120 | 11~20 | 0.04~0.08 | 500~800 |

| PBSA | -30~-40 | 89~97 | 15.6 | 0.16 | 408 |

| PBST[ | -24.5~17.5 | 99.7~195.2 | 23.2~42.5 | — | 88~752 |

| PLGA | 40~60 | 100~200 | 40~90 | 2~4 | <10 |

| PGC | -60~-12 | — | 0.6 | 0.4~1.7 | >250 |

| PLGC | -57.8~22 | — | 0.01~31.5 | 0.02 | 500~1 356 |

| 聚合物 | Tg/℃ | Tm/℃ | 拉伸强度/MPa | 弹性模量/GPa | 断裂伸长率/% |

|---|---|---|---|---|---|

| PGA | 35~40 | 220~230 | 115 | 7 | 1~3 |

| PHB | -1 | 160~170 | 40 | 1.7~3.5 | 3~6 |

| PBS | -32 | 110~120 | 32.1 | 0.33 | 321 |

| PLA | 50~60 | 140~180 | 28~50 | 1.2~2.7 | 5~9 |

| PTMC | -19~-27 | — | 1.8~2.4 | 0.005~0.006 | 610~670 |

| PCL | -60 | 60 | 16 | 0.4 | 120~800 |

| PHBV | 1.4~2.8 | 170 | 30~38 | 0.7~2.9 | 20 |

| PBAT | -30 | 110~120 | 11~20 | 0.04~0.08 | 500~800 |

| PBSA | -30~-40 | 89~97 | 15.6 | 0.16 | 408 |

| PBST[ | -24.5~17.5 | 99.7~195.2 | 23.2~42.5 | — | 88~752 |

| PLGA | 40~60 | 100~200 | 40~90 | 2~4 | <10 |

| PGC | -60~-12 | — | 0.6 | 0.4~1.7 | >250 |

| PLGC | -57.8~22 | — | 0.01~31.5 | 0.02 | 500~1 356 |

| 1 | 田虎虎, 曹鸿璋, 郭立影, 等. 完全生物降解聚乙醇酸研究进展 [J]. 橡塑技术与装备, 2021, 47(22): 9⁃15. |

| TIAN H H, CAO H Z, GUO L Y, et al. Research progress of completely biodegradable polyglycolic acid[J]. Rubber and Plastic Technology and Equipment, 2021, 47(22): 9⁃15. | |

| 2 | 王淑敏, 商宽祥, 谢鸿洲, 等. 聚乙醇酸产业现状及发展前景 [J]. 化肥设计, 2021, 59(04): 1⁃4,11. |

| WANG S M, SHANG K X, XIE H Z, et al. Present situation and development prospect of polyglicolic acid[J]. Fertilizer Design, 2021, 59(04): 1⁃4,11. | |

| 3 | 董露茜, 徐 芳, 翁云宣. 聚乙醇酸改性及其应用研究进展 [J]. 中国塑料, 2022, 36(04): 166⁃174. |

| DONG L Q, XU F, WENG Y X. Research progress in modification and application of poly(glycolic acid) [J]. China Plastics, 2022, 36(04): 166⁃174. | |

| 4 | de Beukelaer Herman, Marieke Hilhorst, Yarek Workala, et al. Overview of the mechanical, thermal and barrier properties of biobased and/or biodegradable thermoplastic materials [J]. Polym Test, 2022, 116. |

| 5 | Chen G P, Ushida T, Tateishi T. Scaffold design for tissue engineering [J]. Macromol Biosci, 2002, 2(2): 67⁃77. |

| 6 | Unalan Ilke Uysal, Wan Chaoying, Lukasz Figiel, et al. Exceptional oxygen barrier performance of pullulan nanocomposites with ultra⁃low loading of graphene oxide [J]. Nanotechnology, 2015, 26(27): 10. |

| 7 | Low Yan Jie, Andri Andriyana, Ang Bee Chin, et al. Bioresorbable and degradable behaviors ofPGA: Current state and future prospects [J]. Polym Eng Sci, 2020, 60(11): 2 657⁃2 675. |

| 8 | Ersen Göktürk, Pemba Alexander G, Miller Stephen A E. Polyglycolic acid from the direct polymerization of renewable C1 feedstocks [J]. Polym Chem, 2015, 6(21): 3 918⁃3 925. |

| 9 | Kamil Budak, Oguz Sogut, Sezer, Aydemir Umran. A review on synthesis and biomedical applications of polyglycolic acid [J]. J Polym Res, 2020, 27(8): 19. |

| 10 | Samantaray Paresh Kumar, Alastair Little, Haddleton David M., et al. Poly(glycolic acid) (PGA): a versatile building block expanding high performance and sustainable bioplastic applications [J]. Green Chem, 2020, 22(13): 4 055⁃4 081. |

| 11 | Kazuyuki Yamane, Hiroyuki Sato, Yukio Ichikawa, et al. Development of an industrial production technology for high⁃molecular⁃weight polyglycolic acid [J]. Polym J, 2014, 46(11): 769⁃775. |

| 12 | Jim Jem K, Tan Bowen. The Development and Challenges of Poly (lactic acid) and Poly (glycolic acid) [J]. Advanced Industrial and Engineering Polymer Research, 2020. |

| 13 | 谭博雯, 孙朝阳, 计 扬. 聚乙醇酸的合成、改性与性能研究综述 [J]. 中国塑料, 2021, 35(10): 137⁃146. |

| TAN B W, SUN Z Y, JI Y. A review in synthesis and modification of poly(glycolic acid) [J]. China Plastics, 2021, 35(10): 137⁃146. | |

| 14 | 郭 琳, 姚俊杰, 杨仁俊,等. 生物降解材料聚乙醇酸的产业化进程及展望 [J]. 合成纤维, 2022, 51(07): 13⁃18. |

| GUO L, YAO J J, YANG R J, et al. Industrialition progress and prospect of biodegridable materials polyglycolic acid [J]. Synthetic Fibre, 2022, 51(07): 13⁃18. | |

| 15 | Edyta Swider, Olga Koshkina, Jurjen Tel, et al. Customizing poly(lactic⁃co⁃glycolic acid) particles for biomedical applications [J]. Acta Biomater, 2018, 73:38⁃51. |

| 16 | Estelle Gautier, Patrick Fuertes, Philippe Cassagnau, et al. Synthesis and Rheology of Biodegradable Poly(glycolic acid) Prepared by Melt Ring⁃Opening Polymerization of Glycolide [J]. J Polym Sci Pol Chem, 2009, 47(5): 1 440⁃1 449. |

| 17 | Harumi Sato, Mai Miyada, Shigeki Yamamoto, et al. C⁃H•••O (ether) hydrogen bonding along the (110) direction in polyglycolic acid studied by infrared spectroscopy, wide⁃angle X⁃ray diffraction, quantum chemical calculations and natural bond orbital calculations [J]. RSC Adv, 2016, 6(20): 16 817⁃16 823. |

| 18 | Fumita Nishimura, Hiromichi Hoshina, Yukihiro Ozaki, et al. Isothermal crystallization of poly(glycolic acid) studied by terahertz and infrared spectroscopy and SAXS/WAXD simultaneous measurements [J]. Polym J, 2019, 51(2): 237⁃245. |

| 19 | 祝桂香, 叶文亮. 生物可降解共聚酯PBST的合成、结构性能及应用研究进展 [J]. 化工与医药工程, 2022, 43(05): 1⁃6. |

| ZHU G X, YE W L. Research progress in synthesis, structure, properties and application of biodegradable copolyester PBST[J]. Synthetic Fiber Chemical and Pharmaceutical Engineering, 2022, 43(05): 1⁃6. | |

| 20 | Xu Pengwu, Tan Shuai, Niu Deyu, et al. Highly Toughened Sustainable Green Polyglycolic Acid/Polycaprolactone Blends with Balanced Strength: Morphology Evolution, Interfacial Compatibilization, and Mechanism [J]. ACS Appl Polym Mater, 2022, 4(8): 5 772⁃5 780. |

| 21 | Christopher Ellingford, Samantaray Paresh Kumar, Stefano Farris, et al. Reactive extrusion of biodegradable PGA/PBAT blends to enhance flexibility and gas barrier properties [J]. J Appl Polym Sci, 2022, 139(6): 11. |

| 22 | Yee Bond Tee, Talib Rosnita A, Khalina Abdan, et al. Comparative study of chemical, mechanical, thermal and barrier properties of poly(lactic acid) plasticized with epoxidized soybean oil and epoxidized palm oil [J]. BioResources, 2016, 11(1): 1 518⁃1 540. |

| 23 | Celine Calvino, Nicholas Macke, Ryo Kato, et al. Development, processing and applications of bio⁃sourced cellulose nanocrystal composites [J]. Prog Polym Sci, 2020, 103:21. |

| 24 | M J Merritt Steven, Wemyss Alan Matheson, Stefano Farris, et al. Gas Barrier Polymer Nanocomposite Films Prepared by Graphene Oxide Encapsulated Polystyrene Microparticles [J]. ACS Appl Polym Mater, 2020, 2 (2) :725⁃731. |

| 25 | 谭博雯,孙朝阳,计 扬.聚乙醇酸的合成、改性与性能研究综述 [J]. 中国塑料,2021,35(10):137⁃146. |

| TAN B W, SUN C Y, JI Y. A review in synthesis and modification of poly(glycolic acid)[J]. China Plastics, 2021,35(10):137⁃146. | |

| 26 | Nair Lakshmi S, Laurencin Cato T. Biodegradable polymers as biomaterials[J]. Prog Polym Sci, 2007, 32(8/9): 762⁃798. |

| 27 | Gunatillake Pathiraja A, Adhikari Raju. Biodegradable synthetic polymers for tissue engineering[J]. Eur Cell Mater, 2003, 5(1): 1⁃16. |

| 28 | Tobias Standau, Mohammadreza Nofar, Dominik Dörr, et al. A Review on Multifunctional Epoxy⁃Based Joncryl® ADR Chain Extended Thermoplastics [J]. Polym Rev, 2022, 62(2): 296⁃350. |

| 29 | Xue Bin, He Hezhi, Huang Zhaoxia, et al. Fabrication of super⁃tough ternary blends by melt compounding of poly(lactic acid) with poly(butylene succinate) and ethylene⁃methyl acrylate⁃glycidyl methacrylate [J]. Compos Pt B⁃Eng, 2019, 172:743⁃749. |

| 30 | Wu Han, Wang Chunyu, Ning Zhenbo, et al. Ultra⁃toughened poly(glycolic acid)⁃based blends with controllable hydrolysis behavior fabricated via reactive compatibilization [J]. Eur Polym J, 2022, 181. |

| 31 | Wang Kai, Shen Jianing, Ma Zhao, et al. Preparation and Properties of Poly(ethylene glycol⁃co⁃cyclohexane-1,4⁃dimethanol terephthalate)/Polyglycolic Acid (PETG/PGA) Blends [J]. Polymers, 2021, 13(3): 20. |

| 32 | Shen Jianing, Wang Kai, Ma Zhao, et al. Biodegradable blends of poly(butylene adipate⁃co⁃terephthalate) and polyglycolic acid with enhanced mechanical, rheological and barrier performances [J]. J Appl Polym Sci, 2021, 138(43): 15. |

| 33 | Yang Fan, Zhang Caili, Ma Zhirui, et al. In Situ Formation of Microfibrillar PBAT in PGA Films: An Effective Way to Robust Barrier and Mechanical Properties for Fully Biodegradable Packaging Films [J]. ACS Omega, 2022, 7(24): 21 280⁃21 290. |

| 34 | Vincent Ojijo, Suprakas Sinha Ray. Super toughened biodegradable polylactide blends with non⁃linear copolymer interfacial architecture obtained via facile in⁃situ reactive compatibilization[J]. Polymer, 2015, 80: 1⁃17. |

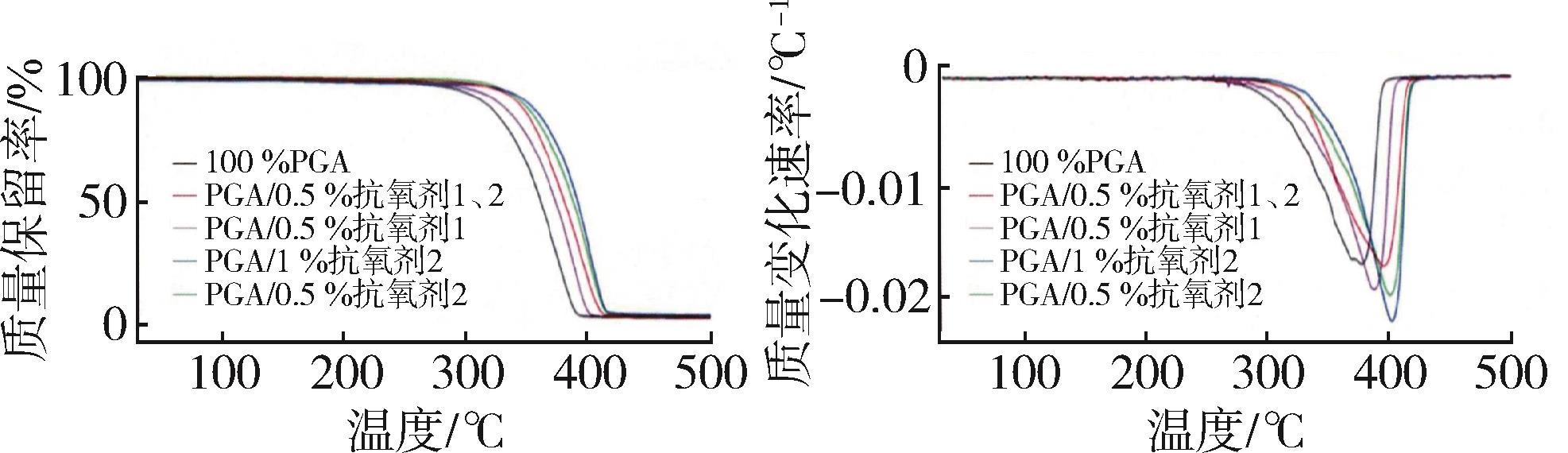

| 35 | 崔爱军,朱晨浩,祝龙生,等.抗氧剂对聚乙醇酸热稳定性能的影响[J].化工新型材料,2019,47(08):197⁃200. |

| CUI A J, ZHU C H, ZHU L S, et al. Influence of antioxidant on thermal stability of PGA [J]. New Chemical Materials, 2019, 47(08):197⁃200. | |

| 36 | 段雪蕾, 陈兰兰, 孙峤昳, 等. 改性PGA热稳定性及动力学研究 [J]. 化工新型材料, 2021, 49(S1): 210⁃214. |

| DUAN X L, CHEN L L, SUN Q Y, et al. Investigation on thermal stability and kinetics of modified PGA[J]. New Chemical Materials, 2021, 49(S1): 210⁃214. | |

| 37 | 陈启群. 助剂对生物降解高分子材料聚羟基乙酸的热稳定性的影响 [D].杭州:浙江大学, 2017. |

| 38 | Wei Chang, Guo Peng, Mingfu Lyu, et al. High Barrier Poly(Glycolic Acid) Modified Poly(Butylene Adipate⁃co⁃ terephthalate) Blown Films and Accelerated Ultraviolet Degradability Evaluation [J]. ACS Appl Polym Mater, 2023, 5(5): 3 457⁃3 467. |

| 39 | 陈兰兰, 孙小杰, 王 荣, 等. 助剂复配对聚乙醇酸性能的影响 [J]. 塑料工业, 2021, 49(02): 145⁃9. |

| CHEN L L, SUN X J, WANG R, et al. Efect of additive compound on the properties of polyglycolic acid[J]. Plastic Industry, 2021, 49(02): 145⁃149. | |

| 40 | Sun Xiaojie, Chen Lanlan, Wang, Rong, et al. Control of hydrolytic degradation of polyglycolic acid using chain extender and anti⁃hydrolysis agent [J]. J Appl Polym Sci, 2022, 139(25): 9. |

| 41 | 江 猛, 刘胜峰, 孙小杰, 等. PGA/PBAT复合材料抗水解性能研究 [J]. 塑料科技, 2022, 50(07): 32⁃37. |

| JIANG M, LIU S F, SUN X J, et al. Study on hydrolytoc resistance properties of PGA/PBAT composites[J]. Plastic Technology, 2022, 50(07): 32⁃37. | |

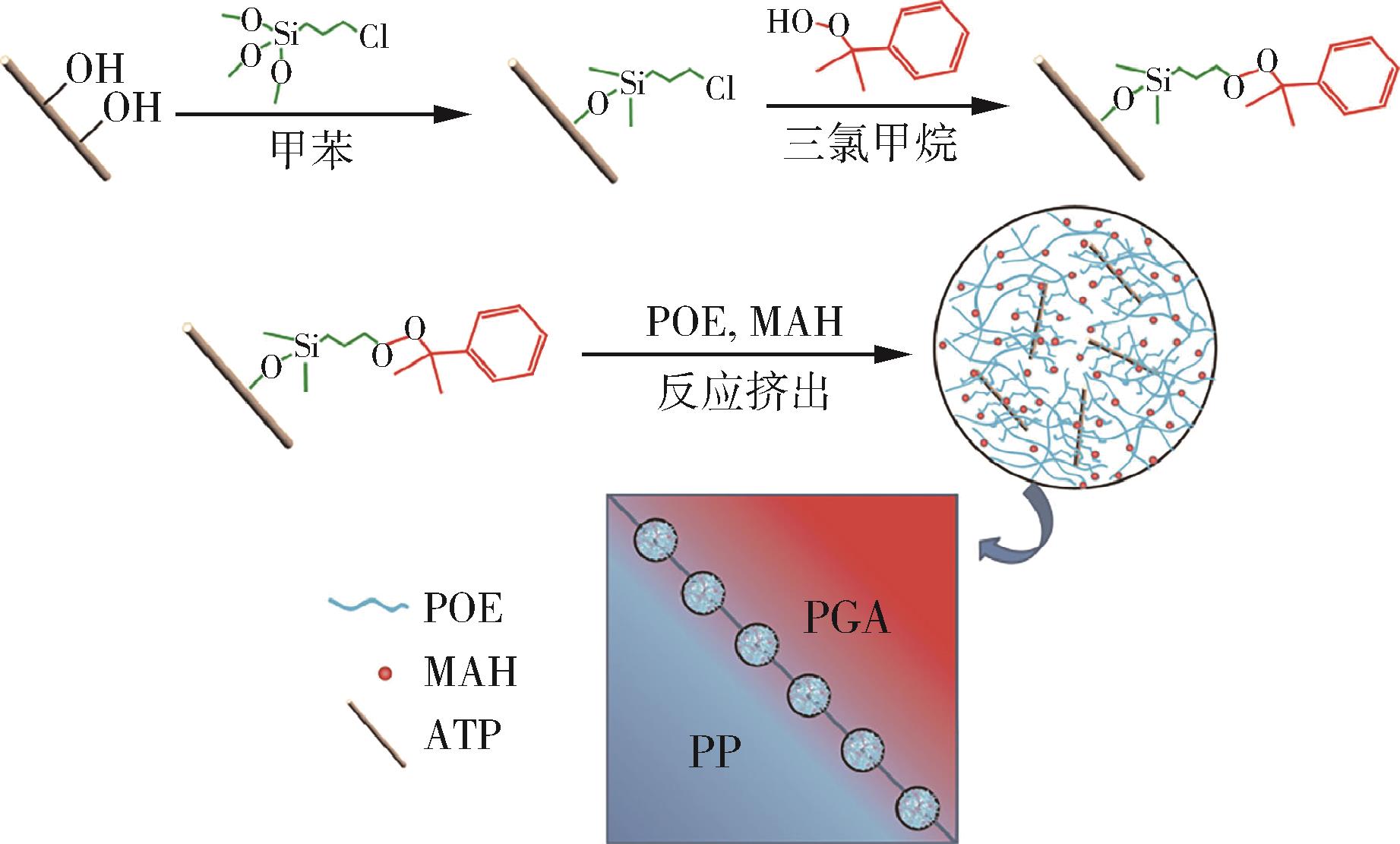

| 42 | Yang Haicun, Cai Zinan, Liu Haotian, et al. Compatibilization of polypropylene/poly(glycolic acid) blend with maleated poe/attapulgite hybrid compatibilizer: Evaluation of mechanical, thermal, rheological, and morphological characteristics [J]. J Polym Sci, 2020, 58(6): 903⁃913. |

| 43 | 杨光远, 彭三文, 王 闻, 等. 改性凹凸棒土增容 PP/PGA 复合材料及纤维的结构与性能 [J]. 塑料工业, 2022, 50(01): 119⁃123,141. |

| YANG G Y, PENG S W, WANG W, et al. Structure and properties of PP/PGA composites and fibers compatibilized by modified attapulgite[J]. Plastic Industry, 2022, 50(01): 119⁃123,141. | |

| 44 | 曹建军,郭 刚,段小平,等. 纳米 TiO2 及其改性塑料的研究进展 [C]// 2004 年中国工程塑料加工应用技术研讨会,2004. |

| 45 | Sakamoto M, Okuda H, Futamata H, et al. Influence of particle size of titanium dioxide on UV⁃ray shielding property[J]. Journal⁃Japan Society of Colour Material, 1995, 68: 203⁃203. |

| 46 | Fei Peng, Xiong Hanguo, Cai Jie, et al. Enhanced the weatherability of bamboo fiber⁃based outdoor building decoration materials by rutile nano⁃TiO2 [J]. Constr Build Mater, 2016, 114: 307⁃316. |

| 47 | 崔爱军,辛 健,蔡煜明,等.有机改性金红石型纳米TiO2对聚乙醇酸抗光老化性能的研究[J]. 化工进展, 2018,37(01):195⁃200. |

| CUI A J, XIN J, CAI Y M, et al. Study on photo⁃oxidative resistance of polyglycolic acid modified with organic nano⁃rutile⁃TiO2 [J]. Chemical Industry and Engineering Progress, 2018,37(01):195⁃200. |

| [1] | 王珅, 刘宣伯, 张艳芳, 贾雪飞, 祝桂香, 张龙贵. 生物可降解无纺布材料研究进展[J]. 中国塑料, 2024, 38(7): 86-92. |

| [2] | 马超, 马兰荣, 魏辽, 尹慧博, 林祥. 聚乙醇酸材料的加工改性及其水下降解特性的研究进展[J]. 中国塑料, 2022, 36(9): 74-84. |

| [3] | 董露茜, 徐芳, 翁云宣. 聚乙醇酸改性及其应用研究进展[J]. 中国塑料, 2022, 36(4): 166-174. |

| [4] | 冯珊, 蒋平平, 张萍波, 张哲铭, 张凯, 顾倩. 低挥发环保增塑剂对苯二甲酸二(2⁃丙基庚)酯的应用研究[J]. 中国塑料, 2022, 36(1): 135-141. |

| [5] | 韦代东, 曾娟娟, 陈海基. 高渗透性环氧树脂防水防腐涂料的制备及性能[J]. 中国塑料, 2021, 35(2): 8-13. |

| [6] | 谭博雯, 孙朝阳, 计扬. 聚乙醇酸的合成、改性与性能研究综述[J]. 中国塑料, 2021, 35(10): 137-146. |

| [7] | 冯申, 温亮, 孙朝阳, 计扬. PGA/PBAT复合材料的性能及应用研究[J]. 中国塑料, 2020, 34(11): 36-40. |

| [8] | 段景宽, 姚利辉, 程波, 王晓雄, 余志强. 一种新型多功能助剂在聚丙烯/滑石粉复合材料中的应用[J]. 中国塑料, 2017, 31(07): 114-120 . |

| [9] | 陈宇, 张春辉, 崔正. 法治环境下塑料技术的创新与发展[J]. 中国塑料, 2015, 29(08): 1-8 . |

| [10] | 刘学. 中国塑料工业(2013)[J]. 中国塑料, 2014, 28(04): 1-6 . |

| [11] | 中国塑料加工工业协会. 中国塑料工业(2012)[J]. 中国塑料, 2013, 27(05): 1-5 . |

| [12] | 中国塑料加工工业协会. 中国塑料工业(2011)[J]. 中国塑料, 2012, 26(04): 1-3 . |

| [13] | 冯发飞 钱立军. 无机纳米阻燃助剂的研究进展[J]. 中国塑料, 2012, 26(03): 1-9 . |

| [14] | 王家纯 苑梅菊. 高档棚膜专用料DFDC9088的研制与开发[J]. 中国塑料, 2011, 25(06): 60-64 . |

| [15] | 包红燕 孙绍刚 李润琳 王磊 王朝晖 陈宇. 环保安全法规环境下塑料助剂的应对策略[J]. 中国塑料, 2010, 24(05): 1-5 . |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2