京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2

《中国塑料》编辑部 ©2008-2024 版权所有

地址:北京市海淀区阜成路11号 邮编:100048

编辑部:010-68985541 联系信箱:cp@plaschina.com.cn

广告部/发行部:010-68985253 本系统由北京玛格泰克科技发展有限公司设计开发

中国塑料 ›› 2024, Vol. 38 ›› Issue (7): 86-92.DOI: 10.19491/j.issn.1001-9278.2024.07.015

王珅( ), 刘宣伯(

), 刘宣伯( ), 张艳芳, 贾雪飞, 祝桂香, 张龙贵

), 张艳芳, 贾雪飞, 祝桂香, 张龙贵

收稿日期:2023-11-02

出版日期:2024-07-26

发布日期:2024-07-24

通讯作者:

刘宣伯(1981—),研究员,研究方向为合成树脂的表征和结构性能研究,liuxb.bjhy@sinopec.com作者简介:王珅(1995—),助理工程师,研究方向为合成树脂的表征和结构性能研究,wangsh.bjhy@sinopec.com

WANG Shen( ), LIU Xuanbo(

), LIU Xuanbo( ), ZHANG Yanfang, JIA Xuefei, ZHU Guixiang, ZHANG Longgui

), ZHANG Yanfang, JIA Xuefei, ZHU Guixiang, ZHANG Longgui

Received:2023-11-02

Online:2024-07-26

Published:2024-07-24

Contact:

LIU Xuanbo

E-mail:wangsh.bjhy@sinopec.com;liuxb.bjhy@sinopec.com

摘要:

随着人们对于绿色环保理念的重视,生物可降解无纺布材料因兼备性能优异、环境友好且用途广泛等优势,不仅是现阶段的研究热点,未来也极具发展潜力。本文按照天然高分子型、微生物型和化学合成型3种不同原料来源,对可降解聚合物无纺布的性能特点和国内外研究现状进行了概述和分析,重点介绍了几种常见的脂肪族聚酯类合成型可降解无纺布材料,并展望了未来发展趋势。

中图分类号:

王珅, 刘宣伯, 张艳芳, 贾雪飞, 祝桂香, 张龙贵. 生物可降解无纺布材料研究进展[J]. 中国塑料, 2024, 38(7): 86-92.

WANG Shen, LIU Xuanbo, ZHANG Yanfang, JIA Xuefei, ZHU Guixiang, ZHANG Longgui. Research progress in biodegradable nonwoven materials[J]. China Plastics, 2024, 38(7): 86-92.

| 1 | 黄逸伦.可生物降解的熔喷非织造材料研究现状[J].合成技术及应用,2021,36(3):17⁃21. |

| HUANG Y L. Research status of the biodegradable melt⁃blown nowoven materials[J]. Synthetic Technology and Application,2021,36(3):17⁃21. | |

| 2 | 周树照.论无纺布的现状及发展[J].山东工业技术,2017,20(20):273⁃273. |

| ZHOU S Z. On the present situation and development of nonwovens [J]. Shandong Industrial Technology, 2017, 20 (20): 273⁃273. | |

| 3 | 许新建.生物可降解脂肪族/芳香族共聚酯(PBST)纤维的制备及其性能研究[D].上海:东华大学,2007. |

| 4 | SHAARI M F, ISA, H M M, RASHID A H A, et al. Biodegradability characterization of cotton waste planting bag prototype[M]. Advances in Material Sciences and Engineering. Singapore: Springer, 2020: 453⁃464. |

| 5 | LIAO J B, ZHANG S Y, TANG X N, et al. Sound absorption of hemp fibers (cannabis sativa l.) based nonwoven fabrics and composites: a review[J]. Journal of Natural Fibers,2022,19(4):1 297⁃1 309. |

| 6 | TOSIN M, WEBER M, SIOTTO M, et al. Laboratory test methods to determine the degradation of plastics in marine environmental conditions[J]. Frontiers in Microbiology,2012,3:1⁃9. |

| 7 | 邵 岚.纯甲壳素湿法无纺布医用敷料制备技术的研究[J].纸和造纸,2018,37(5):34⁃37. |

| SHAO L. Study on pure chitin wet⁃laid non⁃woven medical dressing[J]. Paper and Paper Making, 2018,37(5):34⁃37. | |

| 8 | MAEVSKAIA E N, DRESVYANINA E N, SHABUNIN A S, et al. Preparation and study of hemostatic materials based on chitosan and chitin nanofibrils[J]. Nanotechnology in Russia, 2020,15(7⁃8):466⁃475. |

| 9 | NOMATA H, NAKAISHI M, TAKAKUDA K. Enhanced biological fixation of ligaments to bone tissues utilizingchitin fabrics[J]. Journal of Biomedical Materials Research Part B⁃Applied Biomaterials,2018,106(6):2 355⁃2 360. |

| 10 | 詹志城. 模拟自然环境下聚乳酸非织造布加速生物降解行为研究[D].广州:华南理工大学,2015. |

| 11 | SLEPICKA P, MALA Z, RIMPELOVA S, et al. Antibacterial properties of modified biodegradable PHB non⁃woven fabric[J]. Materials Science & Engineering C,2016,65:364⁃368. |

| 12 | DING Y P, LI W, SCHUBERT D W, et al. An organic⁃inorganic hybrid scaffold with honeycomb⁃like structures enabled by one⁃step self⁃assembly⁃driven electro⁃spinning[J].Materials Science and Engineering: C,2021,124:112 079⁃112 086. |

| 13 | MOROKOV E, ZYKOVA A, TYUBAEVA P. The influence of microstructure in PHB non⁃woven materials on mechanical behavior under tension[J]. Macromolecular Symposia,2021,396(1):1⁃4. |

| 14 | ANATOLY A O, ELENA E M, VASILY A O, et al. Biological and oxidative degradation of ultrathin⁃fibrous nonwovens based on poly(lactic acid)/poly(3⁃hydroxybutyrate) blends[J]. International Journal of Molecular Sciences,2023,24(9):7 979⁃7 993. |

| 15 | TERTYSHNAYA Y V, SKOROKHODOVA A N, SHIBRYEVA L S, et al. Nonwoven polylactide fibers: properties and application[J]. IOP Conference Series: Materials Science and Engineering,2020,971:052 052⁃052 057. |

| 16 | TERTYSHNAYA Y, LEVINA N, PODZOROVA M, et al. Promising agrofibers based on biodegradable polymers[J]. MATEC Web of Conferences,2019, 298:80⁃84. |

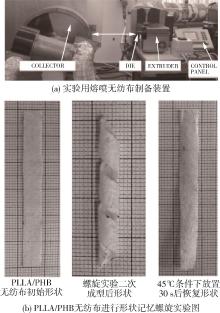

| 17 | WALCZAK J, SOBOTA M, CHRZANOWSKI M, et al. Application of the melt⁃blown technique in the production of shape⁃memory nonwoven fabrics from a blend of poly(l⁃lactide) and atactic poly[(r,s)⁃ 3⁃hydroxy butyrate][J]. Textile Research Journal,2018,88(18):2 141⁃2 152. |

| 18 | 宁波禾素纤维有限公司.一种PHBV与PLA共混生物基纤维生产工艺:中国,115012050A[P].2022⁃09⁃06. |

| 19 | 杨佩琴.聚乳酸纺熔非织造布的开发及应用前景[J].纺织导报,2021(11):76⁃78. |

| YANG P Q. Development and application prospects of polylactic acid spunmelt nonwovens[J]. Nonwovens Technology,2021(11):76⁃78. | |

| 20 | 朱斐超,张宇静,张 强,等.聚乳酸基生物可降解熔喷非织造材料的研究进展与展望[J].纺织学报,2022,43(1): 49⁃57. |

| ZHU F C, ZHANG Y J, ZHANG Q, et al. Research progress and prospect on biodegradable polylactic acid⁃based melt⁃blown nonwovens[J]. Journal of Textile Research,2022,43(1): 49⁃57. | |

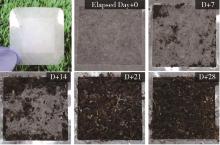

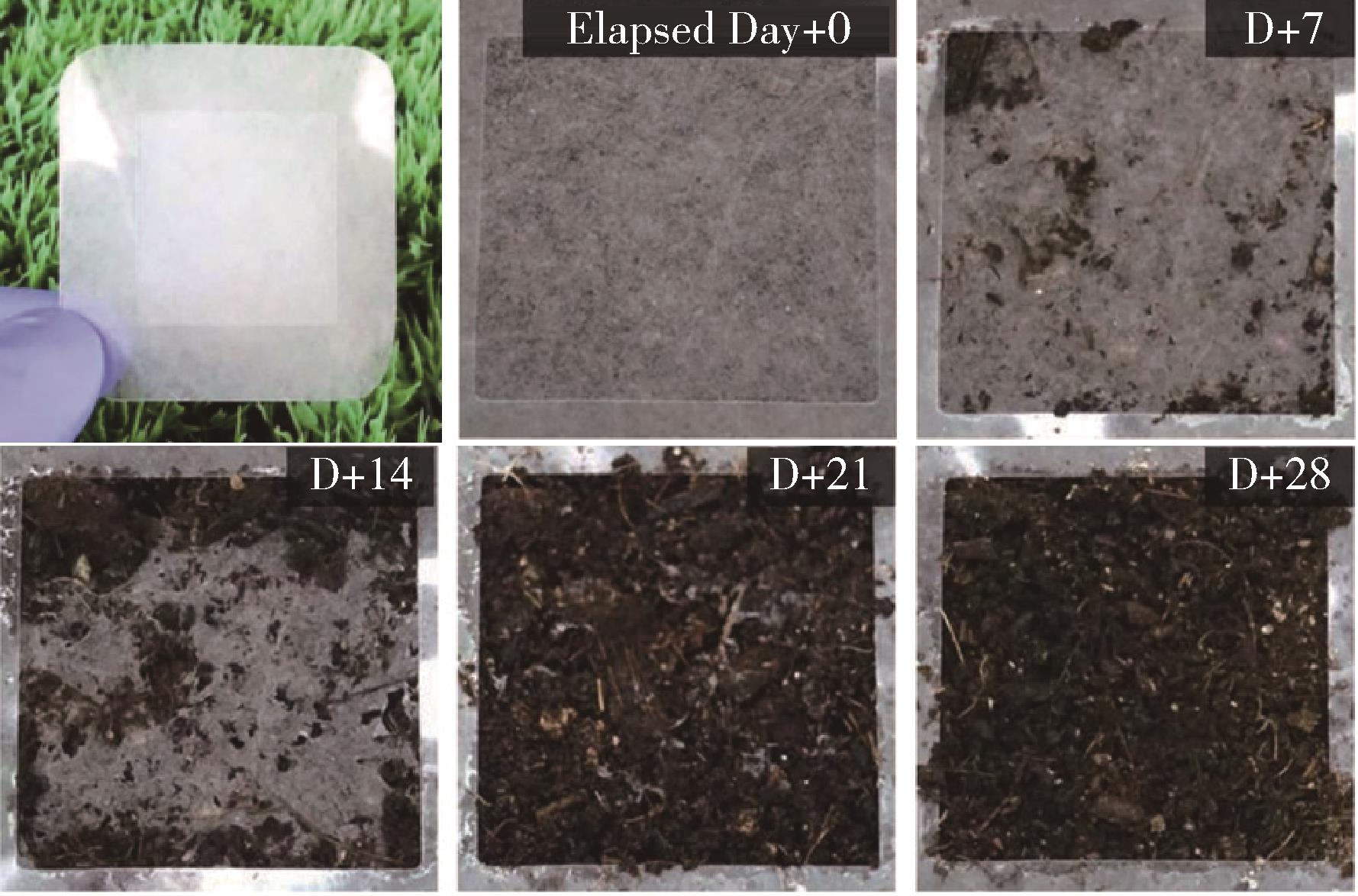

| 21 | SATHISKUMAR D. Biodegradation and photodegradation of polylactic acid and polylactic acid/polyhydroxyalkanoate blends nonwoven agricultural mulches in ambient soil conditions[D]. Knoxville:University of Tennessee,2014. |

| 22 | 一特尔探索(北京)科技有限公司.一种抗病毒可降解无纺布及其制备方法:中国,116536849[P].2023⁃08⁃04. |

| 23 | PARK T H, PARK S G. Manufacture method of band using material with PLA:KR,1020190030185[P].2019⁃06⁃12. |

| 24 | LI J X, NIU D Y, XU P W, et al. Tailoring the crystallization behavior and mechanical property of poly (glycolic acid) by self⁃nucleation[J]. Chinese Journal of Polymer Science,2022,40(4): 365⁃372. |

| 25 | 冯 申, 温 亮, 孙朝阳,等. PGA/PBAT复合材料的性能及应用研究[J]. 中国塑料, 2020, 34(11):36⁃40. |

| FENG S, WEN L, SUN Z Y, et al. Properties and applications of PGA/PBAT composites[J]. China Plastics, 2020, 34(11):36⁃40. | |

| 26 | YANG M, LIU G X, YING Q. Study on protein nanomarker combined with vascular endothelial growth factor to improve vascularization of rabbit urethral defect tissue engineering[J]. Journal of Biomaterials and Tissue Engineering,2022,12(4):673⁃680. |

| 27 | Wu Y, XIA H B, ZHANG B, et al. Assessment of polyglycolic acid scaffolds for periodontal ligament regeneration[J]. Biotechnology & Biotechnological Equipment,2018,32(3):701⁃706. |

| 28 | CAROLINA S, TERESA M C, DANIA N, et al. Reducing post⁃operative alveolo⁃pleural fistula by applying PGA⁃sheets (Neoveil) after major lung resection: a historical case⁃control study[J]. Journal of Clinical Medicine,2023,12(7):2 719⁃2 726. |

| 29 | 谢朝政. “富矿精开”:转型发展逐绿而行[J]. 当代贵州, 2023 (30): 16⁃17. |

| 30 | 陈 玲. 抓好大项目 激发新动能——贵州加快重大项目建设推动高质量发展[J]. 当代贵州, 2023(22): 8⁃9. |

| 31 | 陈韶辉,李 涛.生物降解塑料的产业现状及其发展前景[J].现代塑料加工应用,2020,32(2):50⁃54. |

| CHEN S H, LI T. Industry statue and development prospects of biodegradable plastics[J]. Modern Plastics Processing and Applications,2020,32(2):50⁃54. | |

| 32 | CHOI S, JEON H, JANG M, et al. Biodegradable, efficient, and breathable multi⁃use face mask filter[J]. Advanced Science, 2021,8(6): 2 003 155⁃2 003 162. |

| 33 | HAN Q Q, ZHAO L, Lin P L, et al. Poly(butylene succinate) biocomposite modified by amino functionalized ramie fiber fabric towards exceptional mechanical performance and biodegradability[J]. Reactive and Functional Polymers,2019,146(C):104 443⁃104 452. |

| 34 | 钱伯章.蓝山屯河24万t PBAT项目进入施工冲刺阶段[J].聚酯工业,2023,36(1):65. |

| 35 | 刘佳祺. PBAT改性技术及其发展现状[J]. 炼油与化工, 2023, 34 (5): 13⁃17. |

| LIU J Q. PBAT modification technology and its development status[J]. Refining and Chemical Industry, 2023, 34 (5): 13⁃17. | |

| 36 | 钱伯章.仪征化纤PBAT获欧盟通行证[J].合成材料老化与应用,2023,52(1):150. |

| 37 | 林建云.抗氧化剂对PBAT/PLA/TPS全生物降解塑料性能和外观的影响[J].广东化工,2023,50(22):18⁃20,17. |

| LIN J Y. The effect of antioxidants on the properties and appearance of PBAT/PLA/TPS biodegradable plastics[J].Guangdong Chemical Industry,2023,50(22):18⁃20,17. | |

| 38 | 六安载丰新材料有限公司. 一种PBAT熔喷可降解无纺布及其制备方法:中国,105586712A[P],2016⁃05⁃18. |

| 39 | 阚瑞俊. 聚羟基丁酸戊酸共聚酯(PHBV)的改性及其熔喷无纺布制备初探[D].上海:东华大学,2010. |

| 40 | ZHENG C, ZHU G X, SHI Y, et al. Crystallization, structures and properties of biodegradable poly (butylene succinate⁃co⁃butylene terephthalate) with a symmetric composition[J].Materials Chemistry And Physics,2021, 260(1):124 183⁃124 191. |

| 41 | 李发学. 成纤用生物降解性聚丁二酸丁二醇⁃共⁃对苯二甲酸丁二醇酯(PBST)的合成及结构性能研究[D].上海:东华大学,2006. |

| 42 | 东华大学. 一种可生物降解非织造材料的制造方法:中国,101775705[P]. 2010⁃07⁃14. |

| 43 | 鲁伟涛,靳向煜.PBST纺黏土工排水板滤膜的可降解性能[J].东华大学学报(自然科学版),2014,40(2):213⁃219,243. |

| LU W T, JIN X Y. Degradable properties of PBST spun⁃bonded filter membrane for geotextile drainage board[J]. Journal of Donghua University (NaturalScience), 2014, 40(2):213⁃219,243. | |

| 44 | 中国石油化工股份有限公司. 聚酯组合物和无纺布及其制备方法和应用:中国,109401215[P]. 2022⁃07⁃12. |

| 45 | 潘亚男, 刘 旸. 北化院:创新,从不止步[J]. 中国石化, 2023,(7): 90⁃91. |

| 46 | SEOL Y J, KIM K H, KIM I A, et al. Osteoconductive and degradable electrospun nonwoven poly(e⁃caprolactone)/CaO⁃SiO2 gel composite fabric[J].Journal of Biomedical Materials Research Part A,2010, 94A(2):649⁃659. |

| 47 | HARDT J C, GALDIOLI P, MICHELLY C, et al. Potential wound dressings from electrospun medicated poly(butylene⁃adipate⁃co⁃terephthalate)/poly⁃(ε⁃caprolactone) microfibers[J]. Journal of Molecular Liquids,2021,339:1 166 694⁃1 166 704. |

| 48 | ZANELLA H G, ROSSIN A R S, HARDT J C, et al. Electrospinning PBAT (poly (butylene⁃adipate⁃co⁃terephthalate)/PCL (poly(e⁃caprolactone) blend containing propolis for the preparation of a smart wound dressing[J]. Química Nova.2021,44(10):1 245⁃1 251. |

| 49 | INOUE S, KOINUMA H, TSURUTA T. Copolymerization of carbon dioxide and epoxide with organometallic compounds[J]. Journal of Polymer Science Part A Polymer Chemistry,1969,42(42):5 561⁃5 573. |

| 50 | 陶 剑, 胡 丹, 刘 莉, 等. PLA, PPC和PHBV共混物的热性能、力学性能和生物降解性能研究[J].离子交换与吸附, 2010, 26 (1) :59⁃67. |

| TAO J, HU D, LIU L, et al. Thermal characteristics, mechanical properties, and degradability of PLA/ PPC/PHBV blends[J]. Ion Exchange and Adsorption, 2010, 26 (1) :59⁃67. | |

| 51 | 王格侠,黄 丹,张 维,等.典型生物降解聚酯在海水中的降解性能[J].功能高分子学报,2020,33(5):492⁃499. |

| WANG G X, HUANG D, ZHANG W, et al. Degradation performance of typical biodegradable polyester in seawater[J].Journal of Functional Polymers,2020,33(5): 492⁃499. |

| [1] | 何和智, 黄宗海, 赖文, 熊华威. PLA/PBAT/CB防静电包装材料的制备及其性能研究[J]. 中国塑料, 2024, 38(7): 1-8. |

| [2] | 牛荷, 吕明福, 张宗胤, 徐耀辉, 许巍, 张师军, 郭鹏. 聚乙醇酸加工技术中助剂的应用进展[J]. 中国塑料, 2024, 38(6): 105-110. |

| [3] | 邵琳颖, 郗悦玮, 翁云宣. 可降解聚乳酸复合材料研究进展[J]. 中国塑料, 2022, 36(6): 155-164. |

| [4] | 冀峰, 龚炜华, 张艳, 罗水源, 于庆雨, 朱君秋, 郭江彬. 超临界二氧化碳釜压发泡法制备生物可降解PBAT发泡颗粒[J]. 中国塑料, 2022, 36(5): 122-126. |

| [5] | 夏云霞, 李磊, 罗章生, 朱倩沁, 何力军. 基于闪蒸法制备再生聚乙烯无纺布及其性能研究[J]. 中国塑料, 2022, 36(5): 14-18. |

| [6] | 李向阳, 杨林柱, 翟国强, 高婉琴, 王克智, 李训刚. 成核剂对聚丁二酸丁二醇酯结晶与性能的影响[J]. 中国塑料, 2021, 35(8): 146-151. |

| [7] | 李磊, 朱倩沁, 夏云霞, 张俊峰, 何力军. 聚乙烯瞬时释压纺丝法无纺布制备及其性能研究[J]. 中国塑料, 2021, 35(2): 41-45. |

| [8] | 马城华, 陈延明, 吴佩华, 林妍妍, 王立岩. PPET共聚酯的结构表征及其结晶和热性能研究[J]. 中国塑料, 2017, 31(04): 30-34 . |

| [9] | 陈颖, 徐大志, 马城华, 王文娟, 王立岩. 聚碳酸酯/1,2丙二醇改性共聚酯合金的流变性能研究[J]. 中国塑料, 2017, 31(03): 23-27 . |

| [10] | 王立岩, 王菲, 赵丹, 陈君, 刘洪. 三羟甲基丙烷改性共聚酯的结晶性能和流变行为[J]. 中国塑料, 2016, 30(01): 61-67 . |

| [11] | 许乾慰. 我国新材料轻型输送带的发展现状与趋势[J]. 中国塑料, 2010, 24(11): 6-10 . |

| [12] | 肖峰 王庭慰 丁培. PBS基共聚酯降解性能的研究概述[J]. 中国塑料, 2009, 23(09): 12-15 . |

| [13] | 钱立军, 董宇平. 含磷酰杂菲共聚酯的聚集态和热性能研究[J]. 中国塑料, 2008, 22(08): 17-21 . |

| [14] | 李梅, 李志强. 聚(3一羟基丁酸和4一羟基丁酸酯)共聚物性能研究[J]. 中国塑料, 2007, 21(1): 48-51. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2