京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2

《中国塑料》编辑部 ©2008-2024 版权所有

地址:北京市海淀区阜成路11号 邮编:100048

编辑部:010-68985541 联系信箱:cp@plaschina.com.cn

广告部/发行部:010-68985253 本系统由北京玛格泰克科技发展有限公司设计开发

中国塑料 ›› 2025, Vol. 39 ›› Issue (12): 119-126.DOI: 10.19491/j.issn.1001-9278.2025.12.019

• 机械与模具 • 上一篇

李明华1, 薛平1( ), 王斌2, 赵荣2, 韩民园2, 张帅2, 韩京京2

), 王斌2, 赵荣2, 韩民园2, 张帅2, 韩京京2

收稿日期:2025-01-07

出版日期:2025-12-26

发布日期:2025-12-22

通讯作者:

薛平,教授,从事高分子材料/特种材料加工成型的研究,xueping@mail.buct.edu.cn

LI Minghua1, XUE Ping1( ), WANG Bin2, ZHAO Rong2, HAN Minyuan2, ZHANG Shuai2, HAN Jingjing2

), WANG Bin2, ZHAO Rong2, HAN Minyuan2, ZHANG Shuai2, HAN Jingjing2

Received:2025-01-07

Online:2025-12-26

Published:2025-12-22

Contact:

XUE Ping

E-mail:xueping@mail.buct.edu.cn

摘要:

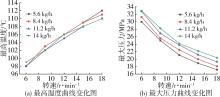

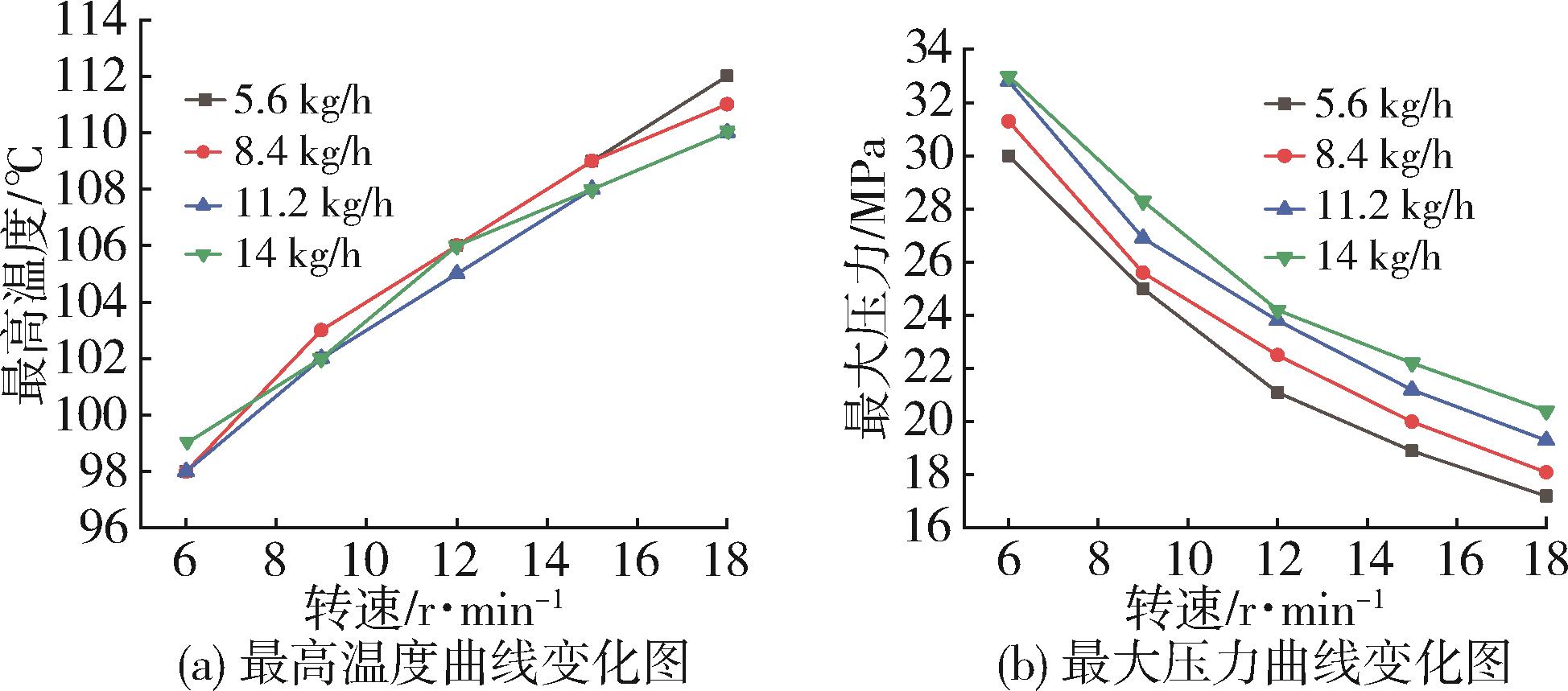

为了提高含能材料在双螺杆挤出机生产过程中的安全性和加工效率,通过EDEM、Ludovic和Polyflow仿真软件对设计的平行同向双螺杆挤出过程进行模拟仿真,开展工艺条件对工艺过程安全性影响模拟仿真研究,得到含能材料在双螺杆挤出机混合塑化过程中的温度、压力和平均停留时间等参数,进而分析加工过程的安全性。结果表明,当螺杆转速为12 r/min时,加料速率推荐范围为5.6~8.4 kg/h;当螺杆转速为15 r/min时,加料速率推荐范围为5.6~11.2 kg/h,在此范围内有利于提高加工过程的安全性;物料的物性参数(幂律指数、稠度系数)对挤出的安全性影响较明显,因此实际试验中,需根据不同的工艺阶段,采用适当范围水分含量的物料,以提高加工的安全性。

中图分类号:

李明华, 薛平, 王斌, 赵荣, 韩民园, 张帅, 韩京京. 平行同向双螺杆加工含能材料挤出安全特性研究[J]. 中国塑料, 2025, 39(12): 119-126.

LI Minghua, XUE Ping, WANG Bin, ZHAO Rong, HAN Minyuan, ZHANG Shuai, HAN Jingjing. Study on extrusion safety characteristics of parallel coaxial twin⁃screws for processing energetic materials[J]. China Plastics, 2025, 39(12): 119-126.

| 参数 | 涵义 | 数值 |

|---|---|---|

| 固相物性参数 | 颗粒直径/mm | 5 |

| 泊松比 | 0.23 | |

| 密度/kg·m-3 | 600 | |

| 杨氏模量/Pa | 6.96×109 | |

| 设备 | 泊松比 | 0.3 |

| 密度/kg·m-3 | 7 850 | |

| 杨氏模量/Pa | 2×1011 | |

| 塑化物料物性参数 | 比热容/J·(kg·K)-1 | 2 790 |

| 密度/kg·m-3 | 1 670 | |

| 导热系数/W·(m·K)-1 | 0.34 |

| 参数 | 涵义 | 数值 |

|---|---|---|

| 固相物性参数 | 颗粒直径/mm | 5 |

| 泊松比 | 0.23 | |

| 密度/kg·m-3 | 600 | |

| 杨氏模量/Pa | 6.96×109 | |

| 设备 | 泊松比 | 0.3 |

| 密度/kg·m-3 | 7 850 | |

| 杨氏模量/Pa | 2×1011 | |

| 塑化物料物性参数 | 比热容/J·(kg·K)-1 | 2 790 |

| 密度/kg·m-3 | 1 670 | |

| 导热系数/W·(m·K)-1 | 0.34 |

| 工艺温度 | 加料段/℃ | 混合塑化段/℃ | 均化段/℃ | |||

|---|---|---|---|---|---|---|

| GYWD⁃1 | 50 | 50 | 70 | 70 | 80 | 80 |

| GYWD⁃2 | 55 | 55 | 65 | 65 | 75 | 75 |

| GYWD⁃3 | 60 | 60 | 70 | 70 | 80 | 80 |

| GYWD⁃4 | 60 | 60 | 65 | 65 | 75 | 75 |

| GYWD⁃5 | 65 | 65 | 75 | 75 | 85 | 85 |

| 工艺温度 | 加料段/℃ | 混合塑化段/℃ | 均化段/℃ | |||

|---|---|---|---|---|---|---|

| GYWD⁃1 | 50 | 50 | 70 | 70 | 80 | 80 |

| GYWD⁃2 | 55 | 55 | 65 | 65 | 75 | 75 |

| GYWD⁃3 | 60 | 60 | 70 | 70 | 80 | 80 |

| GYWD⁃4 | 60 | 60 | 65 | 65 | 75 | 75 |

| GYWD⁃5 | 65 | 65 | 75 | 75 | 85 | 85 |

| 工艺温度 | 最高温度/ ℃ | 最大压力/ MPa | 平均停留时间/ s | 比机械能/ kWh·t-1 |

|---|---|---|---|---|

| GYWD⁃1 | 103 | 25.0 | 253.7 | 134 |

| GYWD⁃2 | 103 | 25.9 | 252.3 | 142 |

| GYWD⁃3 | 104 | 24.4 | 253.9 | 133 |

| GYWD⁃4 | 103 | 25.7 | 252.4 | 141 |

| GYWD⁃5 | 106 | 22.5 | 256.1 | 122 |

| 工艺温度 | 最高温度/ ℃ | 最大压力/ MPa | 平均停留时间/ s | 比机械能/ kWh·t-1 |

|---|---|---|---|---|

| GYWD⁃1 | 103 | 25.0 | 253.7 | 134 |

| GYWD⁃2 | 103 | 25.9 | 252.3 | 142 |

| GYWD⁃3 | 104 | 24.4 | 253.9 | 133 |

| GYWD⁃4 | 103 | 25.7 | 252.4 | 141 |

| GYWD⁃5 | 106 | 22.5 | 256.1 | 122 |

| [1] | 姚昕. ASRM实现推进剂连续混合[J].固体火箭技术,1991(4):6. |

| [2] | 张方宇. 我国弹药生产技术和装备发展现状及发展对策初探[J].兵工自动化,2008(4):1⁃4+7. |

| ZHANG F Y. Research on National Ammunition Technology, Current Equipment Situation and Development Strategy.[J].military⁃industrial automation,2008(4):1⁃4+7. | |

| [3] | Keating J W, Sage F, Klager K, et al. 复合推进剂连续混合工艺述评[J].国外固体火箭技术,1981,(04):117⁃128. |

| [4] | US) C M (US) J B (US) S R M.Co⁃extrusion of energetic materials using multiple twin screw extruders[P].US 20020307535,2006⁃6⁃20. |

| [5] | 李建军,朱晋生. 双螺杆技术用于火药生产中的安全分析[J].兵工安全技术,1997(4):21⁃23. |

| [6] | 孟红伟. 单基药代料的双螺杆挤出工艺研究[D].北京理工大学,2016. |

| [7] | 王浩男. NE62型双螺杆挤出机共混挤出ABS/ABS和PC/ABS工艺与优化[D].北京理工大学,2016. |

| [8] | 林群章. 含能材料同向双螺杆连续混合过程的安全性分析[D].北京化工大学,2018. |

| [9] | 丁学良,何 红,王克俭,等. 单螺杆挤出过程固体粒子输送的离散单元法模拟[J].塑料,2012,41(5):92⁃95. |

| DING X L, HE H, WANG K J,et al. Discrete element method simulation of solid particle conveying in single screw extrusion process[J]. Plastics,2012,41(5):92⁃95. | |

| [10] | 夏同友. 含能粉体材料自动过筛装置研制[D].华中科技大学,2021.DOI:10.27157/d.cnki.ghzku.2021.004549 . |

| [11] | 钟婷婷. 双基推进剂螺压挤出成型工艺流变特性的数值模拟研宄[D].南京理工大学,2015. |

| [12] | Ji D, Xiao Y, Huang Q, et al. Safety design and numerical simulation of twin screw extruder for energetic materials[J].Journal of Physics: Conference Series,2020,1507(2). |

| [13] | 傅陈超. 推进剂代料用双螺杆挤出机混合塑化过程模拟及验证研究[D].北京化工大学,2024.DOI:10.26939/d.cnki.gbhgu.2024.001677 . |

| [14] | 王晓倩. CL-20基发射药(代料)界面性质及双螺杆挤出工艺数值模拟研究[D].北京理工大学,2016.DOI:10.26948/d.cnki.gbjlu.2016.000830 . |

| [15] | Dombe G, Mehilal D, Bhongale C, et al. Application of Twin Screw Extrusion for Continuous Processing of Energetic Materials[J]. Central European Journal of Energetic Materials, 2015,12(3):507⁃522. |

| [1] | 张勋, 刘翔, 方梅, 郭攀, 冯跃战, 黄明, 刘春太. 基于动态高分子基复合材料的一体化T型加筋壁板力学性能仿真研究[J]. 中国塑料, 2025, 39(3): 53-59. |

| [2] | 林高明, 张国辉, 宗胡曾, 王重阳, 贺有凤, 王苏炜. 聚合物基高黏浆料立式螺旋挤注装填装备关键元件结构的仿真优化[J]. 中国塑料, 2024, 38(5): 107-112. |

| [3] | 姜曙, 王阳, 翟孟雷, 李庆涛, 黄明, 刘春太. 连续碳纤增强B柱加强板结构设计与铺覆仿真[J]. 中国塑料, 2024, 38(4): 73-78. |

| [4] | 张莉彦, 杜翔宇, 丁玉梅, 杨卫民, 焦志伟, 何伟. 聚合物微纳层叠挤出过程无机粒子混合效果的仿真分析[J]. 中国塑料, 2024, 38(11): 70-75. |

| [5] | 苏英霞, 乔蒙, 欧相麟. 汽车薄壁门板结构优化[J]. 中国塑料, 2024, 38(10): 67-69. |

| [6] | 刘学军. 制造氢气瓶内胆的电加热滚塑工艺参数的优化研究[J]. 中国塑料, 2024, 38(1): 79-85. |

| [7] | 刘学军. 电加热滚塑工艺的模具表面和模内温度的仿真计算[J]. , 2023, 37(7): 53-61. |

| [8] | 欧阳宇 刘泓滨 李振淼 巫兴悦 李虎 易伟锋. 基于Moldflow和Ansys联合仿真对进气歧管注射成型及进气性能优化的研究[J]. , 2023, 37(3): 71-76. |

| [9] | 潘宏阳, 陈宗勇, 廖廷茂, 袁鸿. 聚烯烃弹性体的力学性能及对床垫体压分布的影响[J]. 中国塑料, 2023, 37(11): 24-34. |

| [10] | 刘学军. 在加热阶段滚塑模具内表面传热系数的两种研究方法[J]. 中国塑料, 2023, 37(1): 82-89. |

| [11] | 张响, 闫振昊, 孔小亚, 朱建晓, 关国涛, 赵娜, 李倩. 盘式螺杆微注塑机动盘结构优化研究[J]. 中国塑料, 2022, 36(2): 147-156. |

| [12] | 孙国华, 崔佳齐, 汪杨, 张信, 马劲松, 侯连龙. 耐热型聚合物锂离子电池隔膜的研究进展[J]. 中国塑料, 2022, 36(10): 190-194. |

| [13] | 查燕, 郑方莉, 肖剑, 杨卫民, 谢鹏程. 多尺度联合仿真在汽车注塑零件减量化设计中的应用研究[J]. 中国塑料, 2021, 35(8): 112-116. |

| [14] | 蔡小芳, 袁航, 刁晓倩, 李字义, 封棣. 食品接触聚乳酸杯盖中的滑石粉迁移分析[J]. 中国塑料, 2021, 35(7): 91-96. |

| [15] | 关天民, 李钰, 翟贇, 雷蕾. 熔融沉积工艺成型材料的力学性能研究[J]. 中国塑料, 2021, 35(6): 68-73. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2