京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2

《中国塑料》编辑部 ©2008-2024 版权所有

地址:北京市海淀区阜成路11号 邮编:100048

编辑部:010-68985541 联系信箱:cp@plaschina.com.cn

广告部/发行部:010-68985253 本系统由北京玛格泰克科技发展有限公司设计开发

中国塑料 ›› 2020, Vol. 34 ›› Issue (6): 80-86.DOI: 10.19491/j.issn.1001-9278.2020.06.013

于翔, 李如洋, 翟静雯, 谭缓缓

收稿日期:2020-01-06

出版日期:2020-06-26

发布日期:2020-06-26

Xiang YU, Ruyang LI, Jingwen ZHAI, Huanhuan TAN

Received:2020-01-06

Online:2020-06-26

Published:2020-06-26

摘要:

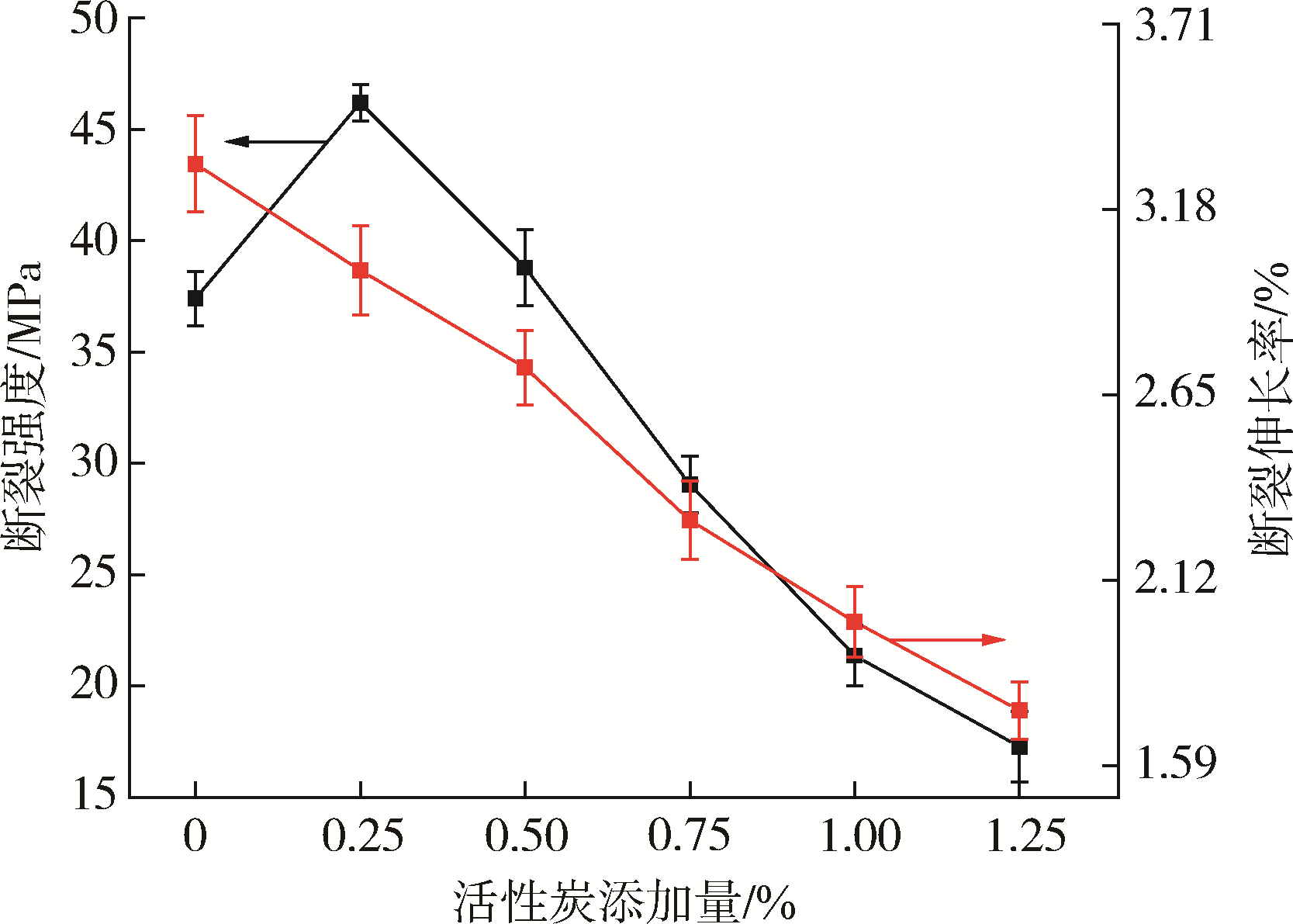

通过机械共混法制备了聚对苯二甲酸乙二醇酯(PET)/聚丙烯酸钠(PAAS)/活性炭复合材料,并通过差示扫描量热仪(DSC)、X射线衍射仪(XRD)和高效液相色谱仪(HPLC)对复合材料的热性能、晶体结构和挥发性有机化合物(VOC)含量等进行研究与分析。结果表明,活性炭的加入能提高PET/PAAS/活性炭复合材料的结晶度,降低复合材料中的VOC含量;随着活性炭的加入,PET/PAAS/活性炭复合材料的熔点先降低后升高,断裂强度呈先升高后降低,且分别在活性炭添加量为0.75 %与0.2 5%时达到最大值;当活性炭含量为1.25 %时,复合材料的甲醛去除率达到94.4 %,乙醛去除率达到92.1 %,丙酮去除率达到80.2 %。

中图分类号:

于翔, 李如洋, 翟静雯, 谭缓缓. 低VOC含量的PET/PAAS/活性炭复合材料的制备及性能研究[J]. 中国塑料, 2020, 34(6): 80-86.

Xiang YU, Ruyang LI, Jingwen ZHAI, Huanhuan TAN. Preparation and Properties of PET/PAAS/Activated Carbon Composites with Low VOC Content[J]. China Plastics, 2020, 34(6): 80-86.

| 编号 | PET含量/份 | PAAS含量/份 | 活性炭含量*/份 |

|---|---|---|---|

| 1# | 100 | 0 | 0 |

| 2# | 97 | 3 | 0 |

| 3# | 97 | 3 | 0.25 |

| 4# | 97 | 3 | 0.50 |

| 5# | 97 | 3 | 0.75 |

| 6# | 97 | 3 | 1.00 |

| 7# | 97 | 3 | 1.25 |

| 编号 | PET含量/份 | PAAS含量/份 | 活性炭含量*/份 |

|---|---|---|---|

| 1# | 100 | 0 | 0 |

| 2# | 97 | 3 | 0 |

| 3# | 97 | 3 | 0.25 |

| 4# | 97 | 3 | 0.50 |

| 5# | 97 | 3 | 0.75 |

| 6# | 97 | 3 | 1.00 |

| 7# | 97 | 3 | 1.25 |

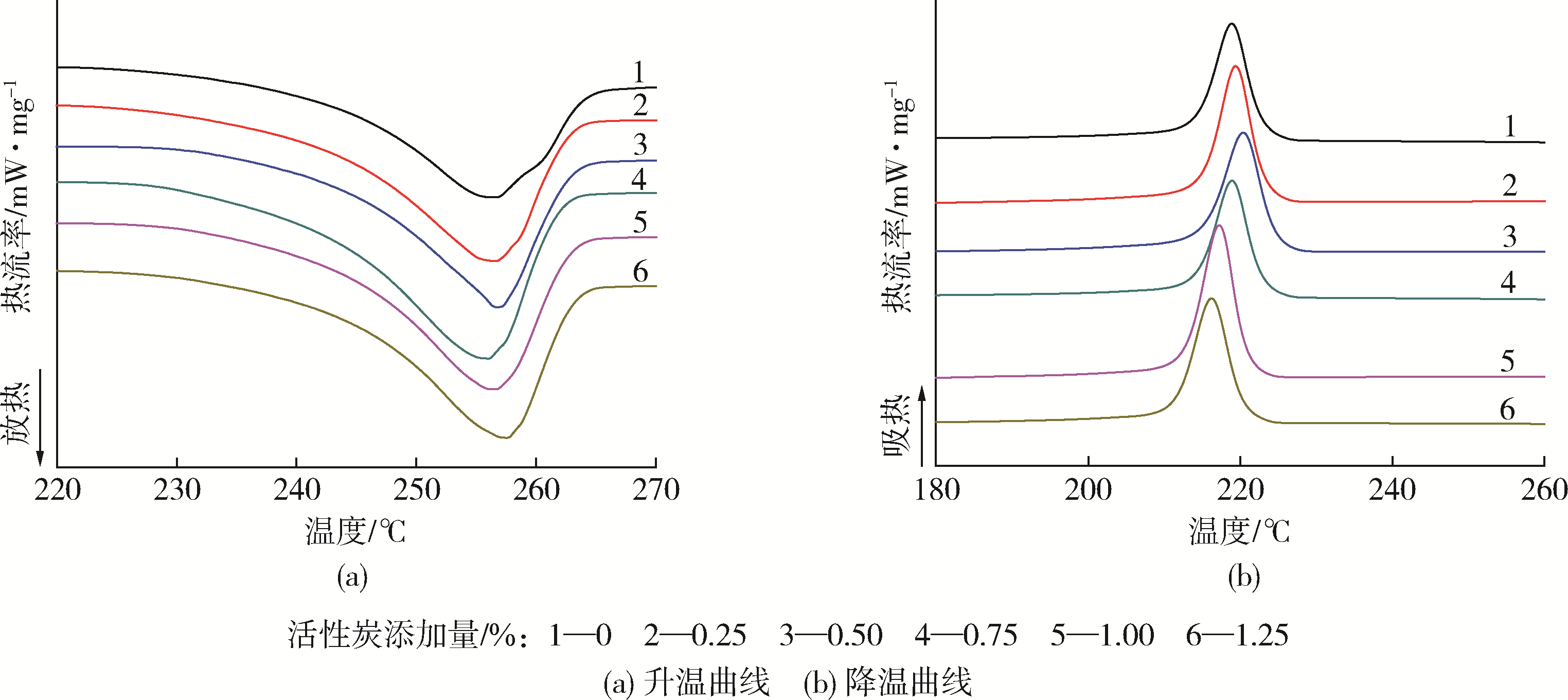

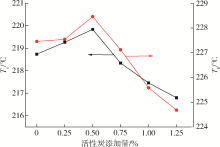

| 活性炭添加量/% | Tm/℃ | ΔHm/J·g?1 | Xc/% | T0/℃ | Tc/℃ |

|---|---|---|---|---|---|

| 0 | 257.16 | 50.04 | 45.71 | 226.94 | 219.30 |

| 0.25 | 256.21 | 49.84 | 47.29 | 227.42 | 219.39 |

| 0.50 | 256.04 | 48.43 | 48.55 | 227.94 | 220.40 |

| 0.75 | 255.92 | 52.21 | 51.50 | 226.58 | 218.93 |

| 1.00 | 256.41 | 49.12 | 49.83 | 225.78 | 217.24 |

| 1.25 | 256.84 | 50.67 | 48.19 | 225.18 | 216.25 |

| 活性炭添加量/% | Tm/℃ | ΔHm/J·g?1 | Xc/% | T0/℃ | Tc/℃ |

|---|---|---|---|---|---|

| 0 | 257.16 | 50.04 | 45.71 | 226.94 | 219.30 |

| 0.25 | 256.21 | 49.84 | 47.29 | 227.42 | 219.39 |

| 0.50 | 256.04 | 48.43 | 48.55 | 227.94 | 220.40 |

| 0.75 | 255.92 | 52.21 | 51.50 | 226.58 | 218.93 |

| 1.00 | 256.41 | 49.12 | 49.83 | 225.78 | 217.24 |

| 1.25 | 256.84 | 50.67 | 48.19 | 225.18 | 216.25 |

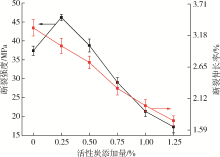

| 活性炭添加量/% | 初始模量/MPa |

|---|---|

| 0 | 1 145 |

| 0.25 | 1 695 |

| 0.50 | 1 671 |

| 0.75 | 1 403 |

| 1.00 | 1 357 |

| 1.25 | 1 583 |

| 活性炭添加量/% | 初始模量/MPa |

|---|---|

| 0 | 1 145 |

| 0.25 | 1 695 |

| 0.50 | 1 671 |

| 0.75 | 1 403 |

| 1.00 | 1 357 |

| 1.25 | 1 583 |

| 活性炭添加量/% | 甲醛 | 乙醛 | 丙酮 | |||

|---|---|---|---|---|---|---|

| 峰面积之比 | 含量/μg·g-1 | 峰面积之比 | 含量/μg·g-1 | 峰面积之比 | 含量/μg·g-1 | |

| 0 | 2.402 5 | 2.285 | 0.947 3 | 1.321 | 0.315 8 | 0.581 |

| 0.25 | 1.554 9 | 1.479 | 0.735 2 | 1.025 | 0.273 6 | 0.503 |

| 0.50 | 1.052 8 | 1.001 | 0.462 4 | 0.645 | 0.201 6 | 0.371 |

| 0.75 | 0.823 6 | 0.783 | 0.367 8 | 0.513 | 0.143 5 | 0.264 |

| 1.00 | 0.647 8 | 0.616 | 0.213 5 | 0.298 | 0.104 1 | 0.191 |

| 1.25 | 0.135 4 | 0.128 | 0.075 4 | 0.105 | 0.062 4 | 0.115 |

| 活性炭添加量/% | 甲醛 | 乙醛 | 丙酮 | |||

|---|---|---|---|---|---|---|

| 峰面积之比 | 含量/μg·g-1 | 峰面积之比 | 含量/μg·g-1 | 峰面积之比 | 含量/μg·g-1 | |

| 0 | 2.402 5 | 2.285 | 0.947 3 | 1.321 | 0.315 8 | 0.581 |

| 0.25 | 1.554 9 | 1.479 | 0.735 2 | 1.025 | 0.273 6 | 0.503 |

| 0.50 | 1.052 8 | 1.001 | 0.462 4 | 0.645 | 0.201 6 | 0.371 |

| 0.75 | 0.823 6 | 0.783 | 0.367 8 | 0.513 | 0.143 5 | 0.264 |

| 1.00 | 0.647 8 | 0.616 | 0.213 5 | 0.298 | 0.104 1 | 0.191 |

| 1.25 | 0.135 4 | 0.128 | 0.075 4 | 0.105 | 0.062 4 | 0.115 |

| 1 | VIRENDRA S, TEJVIR S, AMITA C, et al. Swift Heavy Ion Induced Modification in PET: Structural and Thermal Properties[J]. Nuclear Instruments and Methods in Physics Research B, 2006, 244(1): 243⁃247. |

| 2 | 杨 挺. 高性能工程塑料在汽车领域中的应用与发展[J]. 中国石油和化工经济分析, 2010, (12): 20⁃24. |

| YANF T, Application and Development of High⁃performance Engineering Plastics in the Automotive Field[J]. Economic Analysis of China Petroleum and Chemical Industry, 2010, (12): 20⁃24. | |

| 3 | 牛 茜, 蒋 琼, 俞 雁. 浅谈国内外汽车VOC法规和检测方法[J]. 材料应用, 2018, 4: 50⁃60. |

| NIU X, JINAG Q, YU Y. Talking about Domestic and Foreign Automobile VOC Regulations and Testing Methods[J]. Material Application, 2018, 4: 50⁃60. | |

| 4 | 吕国会. 浅谈降低汽车内饰件用聚氨酯材料VOC的措施[J]. 化学推进剂与高分子材料, 2018, 16(1): 1⁃12. |

| LV G H. Talking about Means to Reduce VOC of Polyurethane Materials for Automotive Interior Parts[J]. Chemical Propellants & Polymeric Materials, 2018, 16(1): 1⁃12. | |

| 5 | 陈振斌, 马应霞, 张安杰, 等. 聚丙烯酸钠高吸水性树脂的改性研究进展[J]. 应用化工, 2009, 38(11): 1 656⁃1 661. |

| CHEN Z B, MA Y X, ZHANG A J, et al. Advanced Development of Modification of Superabsorbent Polymer Based on Sodium Polyacrylate[J]. Applied Chemical Industry, 2009, 38(11): 1 656⁃1 661. | |

| 6 | 刘 琴, 程存喜, 张铎严. 聚丙烯酸钠吸水树脂的合成及性能研究[J]. 广州化工, 2017, 45(11): 62⁃64. |

| LIU Q, CHENG C X, ZHANG D Y. Synthesis and Properties of Sodium Polyacrylate Hydrogel[J]. Guangzhou Chemical Industry, 2017, 45(11): 62⁃64. | |

| 7 | 李本刚, 范玉曼, 张严丹, 等. 聚丙烯酸钠/纳米纤维素晶体⁃g⁃聚丙烯酰胺复合高吸水性树脂的制备与表征[J]. 高分子材料科学与工程, 2018, 34(7): 156⁃161. |

| LI B G, FAN Y M, ZHANG Y D, et al. Preparation and Characterization of Sodium Polyacrylate/(Nanicrysatlline Cellulose)⁃g⁃Polyacrylamide Superabsorbent Composites[J]. Polymer Materials Science & Engineering, 2018, 34(7): 156⁃161. | |

| 8 | 刘宝成, 赵晓明. 活性炭吸附去除室内甲醛的研究进展[J]. 成都纺织高等专科学校学报, 2017, 34(1): 224⁃229. |

| LIU B C, ZHAO X M, Research Progress of Activated Carbon Adsorption Removal of Indoor Formaldehyde[J]. Journal of Chengdu Textile College, 2017, 34(1): 224⁃229. | |

| 9 | 高丁丁, 蒙冕武, 谢君梁, 等. 改性活性炭纤维协同等离子体去除甲醛[J]. 环境工程, 2018, 36(12): 125⁃129. |

| GAO D D, MENG M W, XIE J L, et al. Formaldehyde Removal by Modified Activated Carbon Fiber Combined with Plasma[J]. Environmental Engineering, 2018, 36(12): 125⁃129. | |

| 10 | 徐 伏, 王 莉, 曹云丽. PET/碳纳米管复合材料的结晶性能和力学性能研究[J]. 塑料科技, 2016, 44(11): 21⁃25. |

| XU F, WANG L, CAO Y L. Study on Crystallization and Mechanical Properties of PET/Carbon Nanotubes Composites[J]. Plastics Science and Technology, 2016, 44(11): 21⁃25. | |

| 11 | 王迪然, 罗发亮, 赵阿龙. 柠檬酸钠对PET结晶性能及力学性能的调控[J]. 合成树脂及塑料, 2018, 35(1): 23⁃29. |

| WANG D R, LUO F L, ZHAO A L. Effect of SC on Crystallization and Mechanical Properties of PET[J]. China Synthetic Resin and Plastics, 2018, 35(1): 23⁃29. | |

| 12 | 程勇锋, 庄 辉, 戴干策. 热处理对玻璃纤维增强PET力学性能的影响[J]. 工程塑料应用, 2005, 33(10): 20⁃23. |

| CHENG Y F, ZHUANG H, DAI G C. Influence of Heat⁃Treatment on Mechanical Property of Glass Fiber Reinforced Poly(ethylene terephthalate) [J]. Engineering Plastics Application, 2005, 33(10): 20⁃23. | |

| 13 | 黄 山, 刘炳艳, 田秀娟, 等. 聚磷酸酯阻燃剂对PET结晶行为及形态结构的影响[J]. 山东科技大学学报, 2018, 37(5): 50⁃56. |

| HUANG S, LIU B Y, TIAN X J, et al. Effect of Polyphosphoester Flame Retardant on Crystallization Behavior and Morphology of PET[J]. Journal of Shangong University of Science and Technology, 2018, 37(5): 50⁃56. |

| [1] | 冯冰涛, 王晓珂, 张信, 孙国华, 汪殿龙, 侯连龙, 马劲松. 连续碳纤维增强热塑性复合材料制备与应用研究进展[J]. 中国塑料, 2022, 36(7): 165-173. |

| [2] | 宋银宝, 杨建军, 李传敏. PDMS/SiC功能梯度复合材料性能与制造精度研究[J]. 中国塑料, 2022, 36(7): 30-36. |

| [3] | 杨小龙, 陈文静, 李永青, 闫晓堃, 王修磊, 谢鹏程, 马秀清. 导电型聚合物/石墨烯复合材料的研究进展[J]. 中国塑料, 2022, 36(6): 165-173. |

| [4] | 王轲, 龙春光. PE⁃UHMW/海泡石纤维复合材料的力学性能与摩擦学性能研究[J]. 中国塑料, 2022, 36(5): 19-23. |

| [5] | 陈胜, 梁颖超, 吴方娟, 方辉, 范新凤, 陈晖, 王永刚. 聚酰胺6/双向经编玻璃纤维复合材料的制备及其界面改性研究[J]. 中国塑料, 2022, 36(5): 24-28. |

| [6] | 刘文, 师文钊, 刘瑾姝, 陆少锋, 周红娟. 电致形状记忆复合材料研究进展[J]. 中国塑料, 2022, 36(4): 175-189. |

| [7] | 阮芳涛, 夏成龙, 张宝根, 曹叶, 刘志, 徐珍珍, 章劲草. 芳纶包覆碳纤维增强环氧树脂的轴向压缩性能研究[J]. 中国塑料, 2022, 36(4): 19-23. |

| [8] | 彭博, 肖运彬, 顾家宝, 陈梓钧, 唐雁煌, 朱刚, 徐焕翔. 聚合物/石墨烯复合材料制备与性能研究进展[J]. 中国塑料, 2022, 36(4): 190-197. |

| [9] | 宋立健, 张有忱, 左夏华, 张政和, 安瑛, 杨卫民, 谭晶, 程礼盛. 自组装单分子层调控界面热输运的研究进展[J]. 中国塑料, 2022, 36(4): 60-69. |

| [10] | 何毅, 赵广慧. 复合材料增强修复油气管道的研究进展[J]. 中国塑料, 2022, 36(4): 70-82. |

| [11] | 宋仁达, 武高健, 陈俊翔, 张有忱, 杨卫民, 谢鹏程. 微孔发泡PP/PET/CNTs复合材料的制备及其电磁屏蔽效能研究[J]. 中国塑料, 2022, 36(2): 1-7. |

| [12] | 刘延宽, 顾子琛, 王志平. 连续纤维增强热塑性预浸料制备工艺与发展趋势[J]. 中国塑料, 2022, 36(2): 172-181. |

| [13] | 何明峰, 王珂, 王启扬, 杨肖, 郭红, 胡泊洋, 李保安. 聚偏氟乙烯/类基体基团修饰石墨烯导热复合材料研究[J]. 中国塑料, 2022, 36(2): 41-48. |

| [14] | 李琪微, 王翠翠, 郑海军, 陈季荷, 王戈, 程海涛. 挤出循环对聚丙烯/竹粉复合材料力学及发泡性能的影响[J]. 中国塑料, 2022, 36(2): 56-60. |

| [15] | 李波, 龚军, 金学义, 孟晓宇. 碳纳米管改性方法对聚酰胺11性能影响研究[J]. 中国塑料, 2022, 36(2): 61-66. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2