京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2

《中国塑料》编辑部 ©2008-2024 版权所有

地址:北京市海淀区阜成路11号 邮编:100048

编辑部:010-68985541 联系信箱:cp@plaschina.com.cn

广告部/发行部:010-68985253 本系统由北京玛格泰克科技发展有限公司设计开发

中国塑料 ›› 2021, Vol. 35 ›› Issue (11): 111-119.DOI: 10.19491/j.issn.1001-9278.2021.11.017

唐巧林, 赵雨, 张凯鑫, 余燕莉, 李年玲, 张雨衡, 胡佳玲, 钟柳( ), 陈明军, 刘治国

), 陈明军, 刘治国

收稿日期:2021-04-10

出版日期:2021-11-26

发布日期:2021-11-23

基金资助:

TANG Qiaolin, ZHAO Yu, ZHANG Kaixin, YU Yanli, LI Nianling, ZHANG Yuheng, HU Jialing, ZHONG Liu( ), CHEN Mingjun, LIU Zhiguo

), CHEN Mingjun, LIU Zhiguo

Received:2021-04-10

Online:2021-11-26

Published:2021-11-23

Contact:

ZHONG Liu

E-mail:12619831@qq.com

摘要:

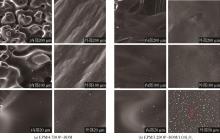

采用自制的阻燃剂双{4-[4-(4-氨基苄基)苯氨基] [(6-氧二苯并[c,e][1,2]氧磷菲?6?基)甲基]苯基}苯基膦酸酯(DOP-DDM),以及DOP?DDM与金属氧化物复合,分别用于制备高效阻燃环氧树脂(EPM)。通过极限氧指数(LOI)、垂直燃烧(UL 94)和锥形量热燃烧试验评价了阻燃性能,利用热失重分析和动态热机械分析研究了热性能,热失重与红外光谱仪联用、扫描电子显微和拉曼光谱分析了阻燃机理。结果表明,DOP-DDM的引入会降低阻燃EPM的起始降解温度,但不会影响其玻璃化转变温度,提高了残炭率、储能模量、损耗模量和阻燃性能;DOP?DDM添加量为4.7 %(质量分数,下同),磷含量仅0.37 %,阻燃EPM的LOI 值为33.5 %,UL 94达V-0 级,热释放速率峰值、总热释放量和总烟释放量分别降低了23.2 %、17.8 %和12.4 %;3.7 %的DOP-DDM与1.0 %的Al2O3复合,阻燃EPM达UL 94 V-0级,不仅热释放速率峰值和总烟释放量进一步降低,而且CO和CO2毒气分别降低了7.7 %和17.2 %。

中图分类号:

唐巧林, 赵雨, 张凯鑫, 余燕莉, 李年玲, 张雨衡, 胡佳玲, 钟柳, 陈明军, 刘治国. 自制高效无卤含磷阻燃剂阻燃环氧树脂研究[J]. 中国塑料, 2021, 35(11): 111-119.

TANG Qiaolin, ZHAO Yu, ZHANG Kaixin, YU Yanli, LI Nianling, ZHANG Yuheng, HU Jialing, ZHONG Liu, CHEN Mingjun, LIU Zhiguo. Study on Self⁃made High Efficiency Halogen⁃free Phosphorus⁃containing Flame⁃retardant Epoxy Resin[J]. China Plastics, 2021, 35(11): 111-119.

| 样品编号 | 组分含量/% | |||||

|---|---|---|---|---|---|---|

| EP | DDM | DOP?DDM | Al2O3 | CuO | Cu2O | |

| EPM | 82 | 18 | 0 | 0 | 0 | 0 |

| EPM/3.2DOP?DDM | 82 | 18 | 3.2 | 0 | 0 | 0 |

| EPM/3.9DOP?DDM | 82 | 18 | 3.9 | 0 | 0 | 0 |

| EPM/4.7DOP?DDM | 82 | 18 | 4.7 | 0 | 0 | 0 |

| EPM/3.2DOP?DDM/1.0Al2O3 | 82 | 18 | 3.2 | 1.0 | 0 | 0 |

| EPM/3.2DOP?DDM/1.0CuO | 82 | 18 | 3.2 | 0 | 1.0 | 0 |

| EPM/3.2DOP?DDM/1.0Cu2O | 82 | 18 | 3.2 | 0 | 0 | 1.0 |

| 样品编号 | 组分含量/% | |||||

|---|---|---|---|---|---|---|

| EP | DDM | DOP?DDM | Al2O3 | CuO | Cu2O | |

| EPM | 82 | 18 | 0 | 0 | 0 | 0 |

| EPM/3.2DOP?DDM | 82 | 18 | 3.2 | 0 | 0 | 0 |

| EPM/3.9DOP?DDM | 82 | 18 | 3.9 | 0 | 0 | 0 |

| EPM/4.7DOP?DDM | 82 | 18 | 4.7 | 0 | 0 | 0 |

| EPM/3.2DOP?DDM/1.0Al2O3 | 82 | 18 | 3.2 | 1.0 | 0 | 0 |

| EPM/3.2DOP?DDM/1.0CuO | 82 | 18 | 3.2 | 0 | 1.0 | 0 |

| EPM/3.2DOP?DDM/1.0Cu2O | 82 | 18 | 3.2 | 0 | 0 | 1.0 |

| 样品 | DOP?DDM/% | P/% | LOI/% | UL 94 (3.2 mm) | |

|---|---|---|---|---|---|

| t1/t2(s)* | 级别 | ||||

| EPM | 0 | 0 | 26.0 | ?? | 无 |

| EPM/3.2DOP?DDM | 3.2 | 0.26 | 32.0 | 6.5/2.6 | V?1 |

| EPM/3.9DOP?DDM | 3.9 | 0.31 | 32.3 | 5.1/2.5 | V?1 |

| EPM/4.7DOP?DDM | 4.7 | 0.37 | 33.5 | 3.9/3.2 | V?0 |

| EPM/3.2DOP?DDM/1.0Al2O3 | 3.2 | 0.26 | 33.2 | 4.6/2.1 | V?0 |

| EPM/3.2DOP?DDM/1.0CuO | 3.2 | 0.26 | 32.8 | 5.1/3.8 | V?1 |

| EPM/3.2DOP?DDM/1.0Cu2O | 3.2 | 0.26 | 32.7 | 5.4/3.7 | V?1 |

| 样品 | DOP?DDM/% | P/% | LOI/% | UL 94 (3.2 mm) | |

|---|---|---|---|---|---|

| t1/t2(s)* | 级别 | ||||

| EPM | 0 | 0 | 26.0 | ?? | 无 |

| EPM/3.2DOP?DDM | 3.2 | 0.26 | 32.0 | 6.5/2.6 | V?1 |

| EPM/3.9DOP?DDM | 3.9 | 0.31 | 32.3 | 5.1/2.5 | V?1 |

| EPM/4.7DOP?DDM | 4.7 | 0.37 | 33.5 | 3.9/3.2 | V?0 |

| EPM/3.2DOP?DDM/1.0Al2O3 | 3.2 | 0.26 | 33.2 | 4.6/2.1 | V?0 |

| EPM/3.2DOP?DDM/1.0CuO | 3.2 | 0.26 | 32.8 | 5.1/3.8 | V?1 |

| EPM/3.2DOP?DDM/1.0Cu2O | 3.2 | 0.26 | 32.7 | 5.4/3.7 | V?1 |

| 样品 | TTI/s | pHRR /kW?m-2 | THR/MJ?m-2 | pSPR/m2?s-1 | TSP/m2 | pCOP/g?s-1 | pCO2P/g?s-1 |

|---|---|---|---|---|---|---|---|

| EPM | 64±1 | 1 015 | 90 | 0.313 | 3 811 | 0.026 | 0.64 |

| EPM/4.7DOP?DDM | 54±1 | 780 | 74 | 0.276 | 3 338 | 0.030 | 0.58 |

| EPM/3.2DOP?DDM/1.0Al2O3 | 54±1 | 744 | 75 | 0.259 | 3 199 | 0.024 | 0.53 |

| 样品 | TTI/s | pHRR /kW?m-2 | THR/MJ?m-2 | pSPR/m2?s-1 | TSP/m2 | pCOP/g?s-1 | pCO2P/g?s-1 |

|---|---|---|---|---|---|---|---|

| EPM | 64±1 | 1 015 | 90 | 0.313 | 3 811 | 0.026 | 0.64 |

| EPM/4.7DOP?DDM | 54±1 | 780 | 74 | 0.276 | 3 338 | 0.030 | 0.58 |

| EPM/3.2DOP?DDM/1.0Al2O3 | 54±1 | 744 | 75 | 0.259 | 3 199 | 0.024 | 0.53 |

| 样品 | T5%/°C | Tmax1/°C | Tmax2/°C | p1?DTG/%?°C?1 | p2?DTG/%?°C?1 | R700℃/% |

|---|---|---|---|---|---|---|

| EPM | 364 | 381 | - | - | -16.5 | 17.0 |

| DOP?DDM | 306 | 347 | 491 | -4.6 | -2.0 | 48.7 |

| EPM/4.7DOP?DDM | 335 | 378 | - | - | -9.7 | 21.8 |

| EPM/3.2DOP?DDM/1.0Al2O3 | 331 | 377 | - | - | -10.1 | 20.5 |

| 样品 | T5%/°C | Tmax1/°C | Tmax2/°C | p1?DTG/%?°C?1 | p2?DTG/%?°C?1 | R700℃/% |

|---|---|---|---|---|---|---|

| EPM | 364 | 381 | - | - | -16.5 | 17.0 |

| DOP?DDM | 306 | 347 | 491 | -4.6 | -2.0 | 48.7 |

| EPM/4.7DOP?DDM | 335 | 378 | - | - | -9.7 | 21.8 |

| EPM/3.2DOP?DDM/1.0Al2O3 | 331 | 377 | - | - | -10.1 | 20.5 |

| 样品 | E′(80 °C)/MPa | E′′/MPa | Tg/°C |

|---|---|---|---|

| EPM | 896 | 148 | 164 |

| EPM/4.7DOP?DDM | 1 485 | 218 | 170 |

| EP/3.2DOP?DDM/1.0Al2O3 | 1 320 | 149 | 156 |

| 样品 | E′(80 °C)/MPa | E′′/MPa | Tg/°C |

|---|---|---|---|

| EPM | 896 | 148 | 164 |

| EPM/4.7DOP?DDM | 1 485 | 218 | 170 |

| EP/3.2DOP?DDM/1.0Al2O3 | 1 320 | 149 | 156 |

| 1 | 陈平, 刘胜平, 王德中. 环氧树脂及其应用[M]. 北京: 化学工业出版社, 2011:5⁃8. |

| 2 | 董金伟, 李丽娟. 2015—2016年国外环氧树脂应用进展[J]. 热固性树脂, 2017, 32(4): 47⁃55. |

| DONG J W, LI L J. The Progress of Foreign Epoxy Resin Applications from 2015 to 2016[J]. Thermosetting Re⁃sins, 2017, 32(4): 47⁃55. | |

| 3 | 张祯, 王斌, 吕钓炜. 提高PBO纤维/环氧树脂界面相容性的研究进展[J]. 玻璃钢/复合材料, 2018, (11): 104⁃108. |

| ZHANG Z, WANG B, LU D W. Research Progress on Improving the Interface Compatibility of PBO Fiber/Epoxy Resin[J]. FRP/Composite Materials, 2018, (11): 104⁃108. | |

| 4 | 张谦, 王涵, 毕治功. 环氧树脂的应用及市场分析[J]. 弹性体, 2019, 29(1): 76⁃80. |

| ZHANG Q, WANG H, BI Z G. Application and Market Analysis of Epoxy Resin[J]. Elastomers, 2019, 29(1): 76⁃80. | |

| 5 | 邹政平, 肖啸, 田杰, 等. 无卤阻燃型环氧树脂的研究进展[J]. 合成树脂及塑料, 2020, 37(1): 97⁃102. |

| ZOU Z P, XIAO X, TIAN J, et al. Research Progress of Halogen⁃free Flame⁃retardant Epoxy Resins[J]. Synthetic Resins and Plastics, 2020, 37(1): 97⁃102. | |

| 6 | 贺梦, 张冲, 郭晓东, 等. 含硫功能聚磷腈微纳米球的合成及其在环氧树脂阻燃中的应用[J]. 复合材料学报, 2019, 36(3): 584⁃591. |

| HE M, ZHANG C, GUO X D, et al. Synthesis of Sulfur⁃containing Functional Polyphosphazene Micro/Nanospheres and Its Application in Epoxy Resin Flame Retardant[J]. Journal of Composite Materials, 2019, 36(3): 584⁃591. | |

| 7 | QU L J, SUI Y L, ZHANG C L, et al. Improved Flame Retardancy of Epoxy Resin Composites Modified with a Low Additive Content of Silica⁃microencapsulated Phosphazene Flame Retardant[J]. Reactive & Functional Polymers, 2020, 148: 104485. |

| 8 | MORGAN A B , GILMAN J W. An Overview of Flame Retardancy of Polymeric Materials: Application, Technology, and Future Directions[J]. Fire & Materials, 2013, 37(4):259⁃279. |

| 9 | 魏柯, 张道海, 秦舒浩, 等. 反应型和添加型磷杂菲类阻燃剂在聚合物中的应用进展[J].高分子材料科学与工程, 2019, 35(5): 184⁃190. |

| WEI K, ZHANG D H, QIN S H, et al. Application Progress of Reactive and Additive Phosphaphenanthrene Flame Retardants in Polymers[J]. Polymer Materials Science & Engineering, 2019, 35(5): 184⁃190. | |

| 10 | 刘建华, 史铁钧, 李明, 等. 含双 DOPO 的双酚 A⁃单苯并嗪合成、表征及其与环氧树脂共聚物的阻燃性能[J]. 化工学报, 2015, 66(2): 820⁃826. |

| LIU J H, SHI T J, LI M, et al. Synthesis, Characterization and Flame Retardant Properties of Bisphenol A⁃monobenzoxazine Containing bisDOPO and Its Copolymer with Epoxy Resin[J]. CIESC Journal, 2015, 66(2): 820⁃826. | |

| 11 | ZHANG Y, YU B, WANG B B, et al. Highly Effective P⁃P Synergy of a Novel DOPO⁃based Flame Retardant for Epoxy Resin[J]. Industrial & Engineering Chemistry Research, 2017, 56(5): 1 245⁃1 255. |

| 12 | ZHANG W C, LI X M, and YANG R J. Novel Flame Retardancy Effects of DOPO⁃POSS on Epoxy Resins[J]. Polymer Degradation and Stability, 2011, 96(12): 2 167⁃ 2 173. |

| 13 | WANG P, CHEN L, and XIAO H. Flame Retardant Effect and Mechanism of a Novel DOPO Based Tetrazole Derivative on Epoxy Resin[J]. Journal of Analytical and Applied Pyrolysis, 2019, 139: 104⁃113. |

| 14 | QIAN L J, QIU Y, SUN N, et al. Pyrolysis Route of a Novel, Flame Retardant Constructed by Phosphaphenanthrene and Triazine⁃trione Groups and Its Flame⁃retardant Effect on Epoxy Resin[J]. Polymer Degradation and Stability, 2014, 107: 98⁃105. |

| 15 | ZHANG W C, LI X M, YANG R J. Pyrolysis and Fire Behaviour of Epoxy Resin Composites Based on a Phosphorus⁃containing Polyhedral Oligomeric Silsesquioxane (DOPO⁃POSS)[J]. Polymer Degradation and Stability, 2011, 96(10): 1 821⁃1 832. |

| 16 | WIRASAPUTRA A, YAO X H, ZHU Y M, et al. Flame⁃retarded Epoxy Resins with a Curing Agent of DOPO⁃triazine Based Anhydride[J]. Macromolecular Materials and Engineering, 2016, 301: 982⁃991. |

| 17 | XU W H, WIRASAPUTRA A, LIU S M, et al. Highly Effective Flflame Retarded Epoxy Resin Cured by DOPO Based Co⁃curing Agent[J]. Polymer Degradation and Stability, 2015, 122: 44⁃51. |

| 18 | 王鹏, 刘家豪. 磷杂菲三氮唑双基化合物高效阻燃环氧树脂[J]. 复合材料学报, . |

| WANG P, LIU J H. Phosphaphenanthrenetriazole Double Base Compound High⁃efficiency Flame⁃retardant Epoxy Resin[J]. Chinese Journal of Composites, . | |

| 19 | ROY E D. Phosphorus Recovery and Recycling with Ecological Engineering: A Review[J]. Ecol Eng, 2017, 98: 213⁃227. |

| 20 | EHMANN A, BACH I M, LAOPEAMTHONG S, et al. Can Phosphate Salts Recovered from Manure Replace Conventional Phosphate Fertilizer[J]. Agriculture, 2017, 7(1). |

| 21 | SHEN D, XU Y J, LONG J W, et al. Epoxy Resin Flameretarded via a Novel Melamine⁃organophosphinic Acid Salt: Thermal Stability, Flame Retardance and Pyrolysis Behavior[J]. Journal of Analytical and Applied Pyrolysis, 2017, 128: 54⁃63. |

| 22 | ZHANG Q Q, WANG J, YANG S, et al. Synthesis of a P/N/S⁃based Flame Retardant and Its Flame Retardant Effect on Epoxy Resin[J]. Fire Safety Journal, 2020, 113: 102994. |

| 23 | SUN Z Z, HOU Y B, HU Y, et al. Effect of Additive Phosphorus⁃nitrogen Containing Flame Retardant on Char Formation and Flame Retardancy of Epoxy Resin[J]. Materials Chemistry and Physics, 2018, 214: 154⁃164. |

| 24 | 卢林刚, 程哲, 丘新铭, 等. 星型绿色磷腈阻燃剂的制备及阻燃环氧树脂性能[J].高等学校化学学报, 2018, 39(12): 2 789⁃2 796. |

| LU L G, CHENG Z, QIU X M, et al. Preparation of Star⁃shaped Green Phosphazene Flame Retardant and Properties of Flame Retardant Epoxy Resin[J].Chemical Journal of Chinese Universities, 2018, 39(12): 2 789⁃2 796. | |

| 25 | MONGE S, DAVID G, TANG B Z, et al. Phosphorus⁃Based Polymers: From Synthesis to Applications[M]. London:Royal Society of Chemistry, 2014. |

| 26 | Braun U, Balabanovich A I, Schartel B, et al. Influence of the Oxidation State of Phosphorus on the Decomposition and Fire Behaviour of Flame⁃retarded Epoxy Resin Composites[J]. Polymer, 2006, 47(26): 8 495⁃8 508. |

| 27 | 钟柳,张凯鑫,刘治国,等.一种化合物及其制备方法、用途和阻燃材料:ZL 201710779926.9 [P]. 2019⁃11⁃08. |

| [1] | 田保政. 烷基次膦酸盐阻燃剂复配体系的研究进展[J]. 中国塑料, 2022, 36(2): 197-208. |

| [2] | 樊晓玲, 辛菲, 蔡丽云. 金属有机骨架材料多功能阻燃聚合物应用研究进展[J]. 中国塑料, 2021, 35(6): 130-140. |

| [3] | 宋昆朋, 王银杰, 刘吉平, 方祝青, 杨威威, 郑东森. 磷腈化合物在阻燃聚合物领域的研究进展[J]. 中国塑料, 2021, 35(2): 107-118. |

| [4] | 张亚斌 李响 王露蓉 郭军红 田力 崔锦峰. 石墨烯阻燃聚合物的研究进展[J]. 中国塑料, 2018, 32(09): 17-24. |

| [5] | 彭民乐;岑茵;何继辉;佟伟. 聚碳酸酯无卤阻燃剂阻燃机理及其发展趋势[J]. 中国塑料, 2017, 31(03): 1-6 . |

| [6] | 姜定;杨成志;秦军;田瑶珠. UF/MPOP与PEA/MPOP对木材燃烧性能的影响[J]. 中国塑料, 2016, 30(10): 32-35 . |

| [7] | 刘燕琴;李建厂;丁雪佳;朱杰克;张龙. 阻燃双酚A型聚碳酸酯/丙烯腈-丁二烯-苯乙烯共聚物合金研究进展[J]. 中国塑料, 2014, 28(05): 11-15 . |

| [8] | 路琴 杨明. 热塑性聚合物/木纤维复合材料的阻燃研究进展[J]. 中国塑料, 2013, 27(09): 11-16 . |

| [9] | 汤朔 靳玉娟 钱立军. 膨胀型阻燃剂的研究进展[J]. 中国塑料, 2012, 26(08): 1-8 . |

| [10] | 张翔 张帆. 无卤膨胀阻燃剂在低密度聚乙烯中的应用研究[J]. 中国塑料, 2012, 26(07): 80-84 . |

| [11] | 张翔 张帆. 新型磷-氮膨胀阻燃剂在改性聚丙烯中的应用研究[J]. 中国塑料, 2012, 26(04): 92-96 . |

| [12] | 陈晓平 张胜 杨伟强 崔正 陈小随. 膨胀阻燃体系概述[J]. 中国塑料, 2010, 24(10): 1-8 . |

| [13] | 屈红强 武伟红 武红娟 徐建中. 聚磷酸铵为主的膨胀型阻燃剂的协效研究进展[J]. 中国塑料, 2010, 24(07): 7-12 . |

| [14] | 叶龙健 钱立军 佟芍朋 许国志. 无卤阻燃含磷环氧树脂的研究进展[J]. 中国塑料, 2010, 24(03): 11-18 . |

| [15] | 叶龙健 钱立军 王澜 许国志. 硅系阻燃剂研究进展[J]. 中国塑料, 2009, 23(11): 7-14 . |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2