京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2

《中国塑料》编辑部 ©2008-2024 版权所有

地址:北京市海淀区阜成路11号 邮编:100048

编辑部:010-68985541 联系信箱:cp@plaschina.com.cn

广告部/发行部:010-68985253 本系统由北京玛格泰克科技发展有限公司设计开发

中国塑料 ›› 2022, Vol. 36 ›› Issue (9): 167-179.DOI: 10.19491/j.issn.1001-9278.2022.09.022

收稿日期:2022-08-26

出版日期:2022-09-26

发布日期:2022-09-26

通讯作者:

张玉霞(1965—),女,副教授,从事高性能塑料薄膜、聚烯烃发泡材料及可生物降解塑料等相关研究工作,zhangyux@th.btbu.edu.cn

YANG Chaoyong, GUO Jinqiang, WANG Fuyu, ZHNAG Yuxia( )

)

Received:2022-08-26

Online:2022-09-26

Published:2022-09-26

Contact:

ZHNAG Yuxia

E-mail:zhangyux@th.btbu.edu.cn

摘要:

概述了6种高性能树脂——聚醚醚酮(PEEK)、聚苯硫醚(PPS)、液晶聚合物(LCP)、聚醚酰亚胺(PEI)、聚砜(PSF)和聚酰亚胺(PI)等的性能及应用,详细介绍了以这6种高性能树脂分别为原料制备高性能薄膜的方法(挤出吹塑法、挤出流延法、溶液流延法等)和改性方法,最后对不同高性能薄膜的应用进行了讨论和展望。

中图分类号:

杨超永, 郭金强, 王富玉, 张玉霞. 高性能塑料薄膜制备方法及改性研究进展[J]. 中国塑料, 2022, 36(9): 167-179.

YANG Chaoyong, GUO Jinqiang, WANG Fuyu, ZHNAG Yuxia. Research progress in preparation and modification methods of high-performance plastic films[J]. China Plastics, 2022, 36(9): 167-179.

| 材料 | 频率/GHz | 屏蔽效能/dB | 特定的电磁屏蔽效能/mm | 厚度/mm | 拉伸强度/MPa | |

|---|---|---|---|---|---|---|

| PEEK/包裹MWCNT/GPPS1.0 | 8.2~12.4 | ~10.5 | 58.3 | 0.18 | 101 | 586 |

| 40 | 16.2 | 90.0 | 0.18 | |||

| PEEK/包裹MWCNT | 12.0~18.0 | ~55 | ~27.5 | 2 | 91 | 583 |

| 2.0~18.0 | ~10 | 5 | 2 | 11.17 | 300 | |

| PC/MWCNT | 17.5 | 27.2 | 9 | 3 | 72 | — |

| 材料 | 频率/GHz | 屏蔽效能/dB | 特定的电磁屏蔽效能/mm | 厚度/mm | 拉伸强度/MPa | |

|---|---|---|---|---|---|---|

| PEEK/包裹MWCNT/GPPS1.0 | 8.2~12.4 | ~10.5 | 58.3 | 0.18 | 101 | 586 |

| 40 | 16.2 | 90.0 | 0.18 | |||

| PEEK/包裹MWCNT | 12.0~18.0 | ~55 | ~27.5 | 2 | 91 | 583 |

| 2.0~18.0 | ~10 | 5 | 2 | 11.17 | 300 | |

| PC/MWCNT | 17.5 | 27.2 | 9 | 3 | 72 | — |

| 项目 | PPS | PI | PET | |

|---|---|---|---|---|

| 拉伸强度 (纵向/横向)/ MPa | 300/250 | 180/180 | 250/270 | |

| 熔点/℃ | 285 | 不融化 | 265 | |

| 热膨胀系数/ | 3 | 2 | 1.7 | |

| 吸水率/%(湿度为75 %) | 0.05 | 22 | 0.4 | |

| 电阻/ | 0.5 | 1 | 1 | |

| 介电常数 | 1 kHz | 3.0 | 3.5 | 3.3 |

| 1 MHz | 3.0 | 3.4 | 3.2 | |

| 1 GHz | 3.0 | — | 3.1 | |

| 介电损耗角正切 | 1 kHz | 0.0006 | 0.003 | 0.002 |

| 1 MHz | 0.0018 | 0.01 | 0.01 | |

| 1 GHz | 0.0015 | — | 0.01 | |

| 项目 | PPS | PI | PET | |

|---|---|---|---|---|

| 拉伸强度 (纵向/横向)/ MPa | 300/250 | 180/180 | 250/270 | |

| 熔点/℃ | 285 | 不融化 | 265 | |

| 热膨胀系数/ | 3 | 2 | 1.7 | |

| 吸水率/%(湿度为75 %) | 0.05 | 22 | 0.4 | |

| 电阻/ | 0.5 | 1 | 1 | |

| 介电常数 | 1 kHz | 3.0 | 3.5 | 3.3 |

| 1 MHz | 3.0 | 3.4 | 3.2 | |

| 1 GHz | 3.0 | — | 3.1 | |

| 介电损耗角正切 | 1 kHz | 0.0006 | 0.003 | 0.002 |

| 1 MHz | 0.0018 | 0.01 | 0.01 | |

| 1 GHz | 0.0015 | — | 0.01 | |

| 性能 | 电击穿强度/MV | |

|---|---|---|

| 室温 | 150℃ | |

| 未经处理的 PI | 547 | 468 |

| 单面处理的PI | 615 | 467 |

| 双面处理的PI | 609 | 467 |

| 性能 | 电击穿强度/MV | |

|---|---|---|

| 室温 | 150℃ | |

| 未经处理的 PI | 547 | 468 |

| 单面处理的PI | 615 | 467 |

| 双面处理的PI | 609 | 467 |

| 1 | 王占杰,加强创新,奋发图强,促进塑料薄膜行业高质量发展[EB/OL].(2022⁃07⁃22)[2022⁃08⁃04].. |

| 2 | G·卢克斯,蒋明,叶培森.高性能热塑性塑料薄膜[J].国外塑料,1991(1):26⁃30. |

| G·LU K S, JIANG M, YE P S, High performance thermoplastic film[J]. Foreign Plastics, 1991(1):26⁃30. | |

| 3 | 顾有伟.聚醚醚酮——一种新型耐热绝缘材料[J].绝缘材料通讯,1986(6):37⁃42. |

| GU Y W. Polyetheretherketone—A new type of heat⁃resistant insulating material[J]. Insulation Newsletter, 1986(6):37⁃42. | |

| 4 | 张维.特种工程塑料PEEK薄膜的发展与应用[J].化工新型材料,2007(4):82⁃83. |

| ZHANG W. Development and application of special engineering plastic PEEK film[J].New Chemical Materials, 2007(04):82⁃83. | |

| 5 | 王睦铿.PEEK薄膜[J].化工新型材料,1991(10):17⁃20,7. |

| WANG M Q. PEEK films[J]. New Chemical Materials,1991(10):17⁃20,7. | |

| 6 | WEN L L, GUI B W, ZHEN H J, et al. Preparation and characterization of high⁃strength poly(ether ether ketone) films[J].Journal of Applied Polymer Science,2014,131(9):40172. |

| 7 | RUI Q N, JIN Y L, GUI B W, et al. Light weight and flexible poly(ether ether ketone) based composite film with excellent thermal stability and mechanical properties for wide⁃band electromagnetic interference shielding[J].RSC Advances,2017,8(6):3 296⁃3 303. |

| 8 | 孙江华,张敏.聚醚醚酮薄膜的性能研究[J].中国塑料,2020,34(2):43⁃48. |

| SUN J H, ZHANG M. Properties of PEEK films[J]. China Plastics,2020,34(2):43⁃48. | |

| 9 | 李文雷.多壁碳纳米管/聚醚醚酮复合薄膜的制备及性能研究[D].吉林大学,2014. |

| 10 | 高正春. 一种复合薄膜及其制备方法和应用,CN109334192A [P].2019⁃02⁃15. |

| 11 | 朱冠南,李强,谭宗尚,等.一种各向同性PEEK吹塑薄膜的制备方法,CN113234301A [P].2021⁃08⁃10. |

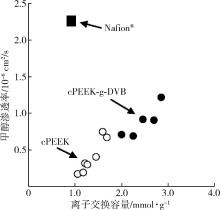

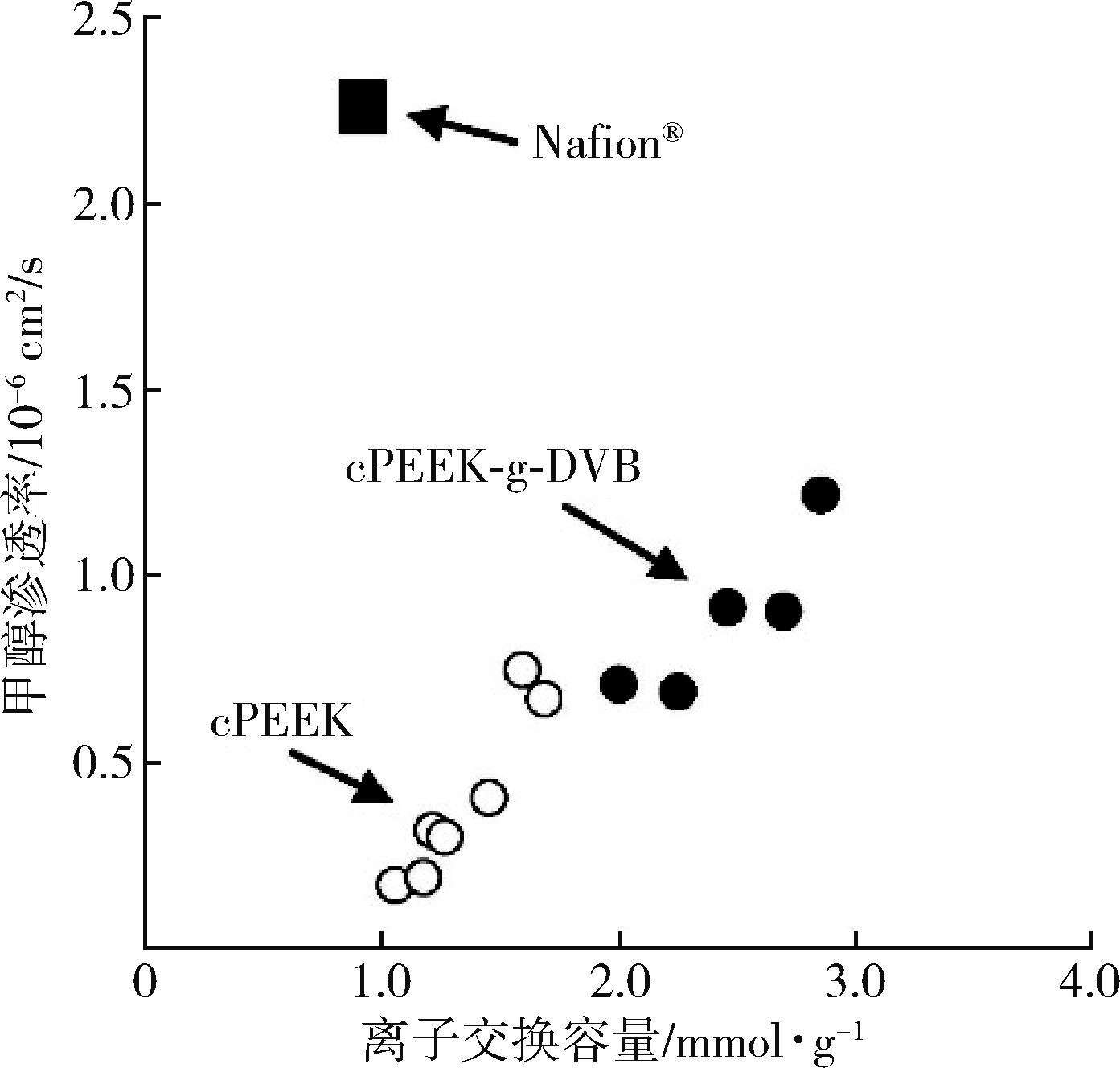

| 12 | 宋文生,李磊,王宇新,等.磺化聚醚醚酮与聚砜共混膜导电与传质特性研究[J].膜科学与技术,2004(3):15⁃19. |

| SONG W S, LI L, WANG Y X, et al. Conductivity and mass transfer properties of sulfonated polyetheretherketone and polysulfone blend membranes[J]. Membrane Science and Technology, 2004(3):15⁃19. | |

| 13 | 薛松,尹鸽平.磺化聚醚醚酮/磷钨酸复合膜的导电和甲醇渗透性能[J].高分子学报,2006(9):1 083⁃1 087. |

| XUE S, YIN G P. Conductivity and methanol permeability of sulfonated polyetheretherketone/phosphotungstic acid composite membranes[J]. Acta Polymerica Sinica,2006(9):1 083⁃1 087. | |

| 14 | INAGAKI N, TASAKA S, HORIUCHI T, et al. Surface modification of poly(aryl ether etherketone) film by remote oxygen plasma[J]. Journal of Applied Polymer Science,1998,68(2):271⁃279. |

| 15 | 杜鹏,杨雪梅,李明.聚醚醚酮薄膜的离子注入表面改性[J].材料科学与工程学报,2010,28(4):481⁃485. |

| DU P, YANG X M, LI M. Ion implantation surface modi⁃fication of polyetheretherketone thin films[J]. Journal of Materials Science and Engineering,2010,28(4):481⁃485. | |

| 16 | JIN H C, DENG R L, KOSHIKAWAHIROSHI, et al. Modification of ultrathin polyetheretherketone film for application in direct methanol fuel cells[J]. Journal of Membrane Science,2009,344(1/2):266⁃274. |

| 17 | JIN H C, DENG R L, KOSHIKAWAHIROSHI, et al. Crosslinking and grafting of polyetheretherketone film by radiation techniques for application in fuel cells[J]. Journal of Membrane Science,2010,362(1/2):488⁃494. |

| 18 | KIEPFERHENDRIK, OMARWAID, SCHRÖDERTIMO, et al. Polymer film heat transfer surfaces in seawater desalination: fouling layer formation and technology[J]. Chemical Engineering & Technology,2020, 43(6): 1 205⁃1 213. |

| 19 | HAMADATAKASHI, FUKASAWAHIDEYUKI, HA⁃SEGAWASHIN, et al. Graft⁃type polymer electrolyte membranes based on poly(ether ether ketone)/nanosilica hybridfilms for fuel cell applications[J]. International Journal of Hydrogen Energy, 2016,41(41):18 621⁃18 630. |

| 20 | 王德禧.聚苯硫醚的特性及应用[J].塑料,2002(2):34⁃38. |

| WANG D X. Properties and applications of polyphenylene sulfide[J]. Plastics,2002(2):34⁃38. | |

| 21 | 高勇,戴厚益.聚苯硫醚薄膜的研究进展[J].塑料工业,2010,38(S1):6⁃8. |

| GAO Y, DAI H Y. Research progress of polyphenylene sulfide films[J].China Plastics Industry, 2010,38(S1):6⁃8. | |

| 22 | 黄宝奎,马百钧,王孝军,等.聚苯硫醚吹塑薄膜的结构与性能[J].塑料工业,2010,38(5):75⁃77. |

| HUANG B K, MA B J, WANG X J, et al. Structure and properties of polyphenylene sulfide blown films[J]. China Plastics Industry,2010,38(5):75⁃77. | |

| 23 | RANGHO JONG, WHITEJAMES L. A double bubble tubular film process to produce biaxially oriented poly(p⁃phenylene sulfide) (PPS) film[J]. Polymer Engineering and Science,1990,30(19):1 228⁃1 236. |

| 24 | 夏超华.一种 5G PPS薄膜及其制备方法,CN110791096B [P].2022⁃05⁃27. |

| 25 | 一种5G PPS薄膜及其制备方法,CN110698864A [P].2020⁃01⁃17. |

| 26 | YOOTAE JONG, HWANGEUN⁃BYEOL, JEONGYOUNG GYU. Thermal and electrical properties of poly(phenylene sulfide)/carbon nanotube nanocomposite films with a segregated structure[J].Composites Part A: Applied Science and Manufacturing,2016,91(1):77⁃84. |

| 27 | 唐荣芝,董林,马雅琳,等. 一种共挤双向拉伸PET/PPS复合薄膜及其制备方法,CN109648976B[P]. 2021⁃03⁃16. |

| 28 | SHOU Y Z, GUANG S H, XIAO J W, et al. Effect of air plasma treatment on the mechanical properties of polyphenylene sulfide/glass fiber cloth composites[J]. Journal of Reinforced Plastics and Composites,2013,32(11):786⁃793. |

| 29 | INAGAKINORIHIRO, NARUSHIMAKAZUO, MORI⁃TAMASAHIRO. Plasma surface modification of poly(phenylene sulfide) films for copper metallization[J]. Journal of Adhesion Science and Technology,2006,20(9):917⁃938. |

| 30 | 王新民.聚苯硫醚(PPS)薄膜[J].绝缘材料通讯,1989(5):40⁃45. |

| WANG X M. Polyphenylene sulfide (PPS) film[J]. Insulation Newsletter,1989(5):40⁃45. | |

| 31 | 张静茜,陈萌,陈东志,等.聚硅氧烷/聚苯硫醚无纺布复合电池隔膜的制备与性能[J].复合材料学报,2019,36(9):1 995⁃2 001. |

| ZHANG J Q, CHEN M, CHEN D Z, et al. Preparation and properties of polysiloxane/polyphenylene sulfide nonwoven composite battery separator[J]. Journal of Composite Materials,2019,36(9):1 995⁃2 001. | |

| 32 | 朱沛隽,濮实.一种新型电容器薄膜——聚苯硫醚[J].电子元件与材料,1991(1):51⁃57. |

| ZHU P X, PU S. A new type of capacitor film⁃polypheny⁃lene sulfide[J]. Electronic Components and Materials, 1991(1):51⁃57. | |

| 33 | 唐荣芝,罗春明,唐安斌,等.液晶聚合物薄膜加工及应用进展[J].印制电路信息,2021,29(3):13⁃17. |

| TANG R Z, LUO C M, TANG A B, et al. Progress in processing and application of liquid crystal polymer films[J]. Printed Circuit Information,2021,29(3):13⁃17. | |

| 34 | SULLIVANANTHONY, SAIGALANIL, ZIMMERMANMICHAEL A. Structure⁃property⁃processing relationships in extruded liquid crystal polymer film[J]. Polymers and Polymer Composites,2021(11):450⁃463. |

| 35 | LUSIGNEARICHARD W.. Orientation of LCP blown film with rotating dies[J]. Polymer Engineering and Science,1999,39(12):2 326⁃2 334. |

| 36 | ZHI T Y, JIA J Z, ZHAO Y, et al. Rotational blow molding of thermotropic liquid crystal polymers and resul⁃ting orientational structure and mechanical properties[J]. Polymer,2022,255:125 144⁃125 152. |

| 37 | MEI S Z, WEN L Z, DONG Y D, et al. The effect of pretreatment on adhesive strength of cu⁃plated liquid crystal polymer (LCP)[J]. Applied Surface Science,2012,258(7):2 643⁃2 647. |

| 38 | WEN L Z, DONG Y D. Electroless copper plating on liquid crystal polymer films using dimethylamine borane as reducing agent[J]. Journal of the Chinese Chemical Society, 2016,63(2):222⁃228. |

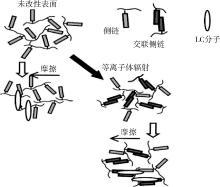

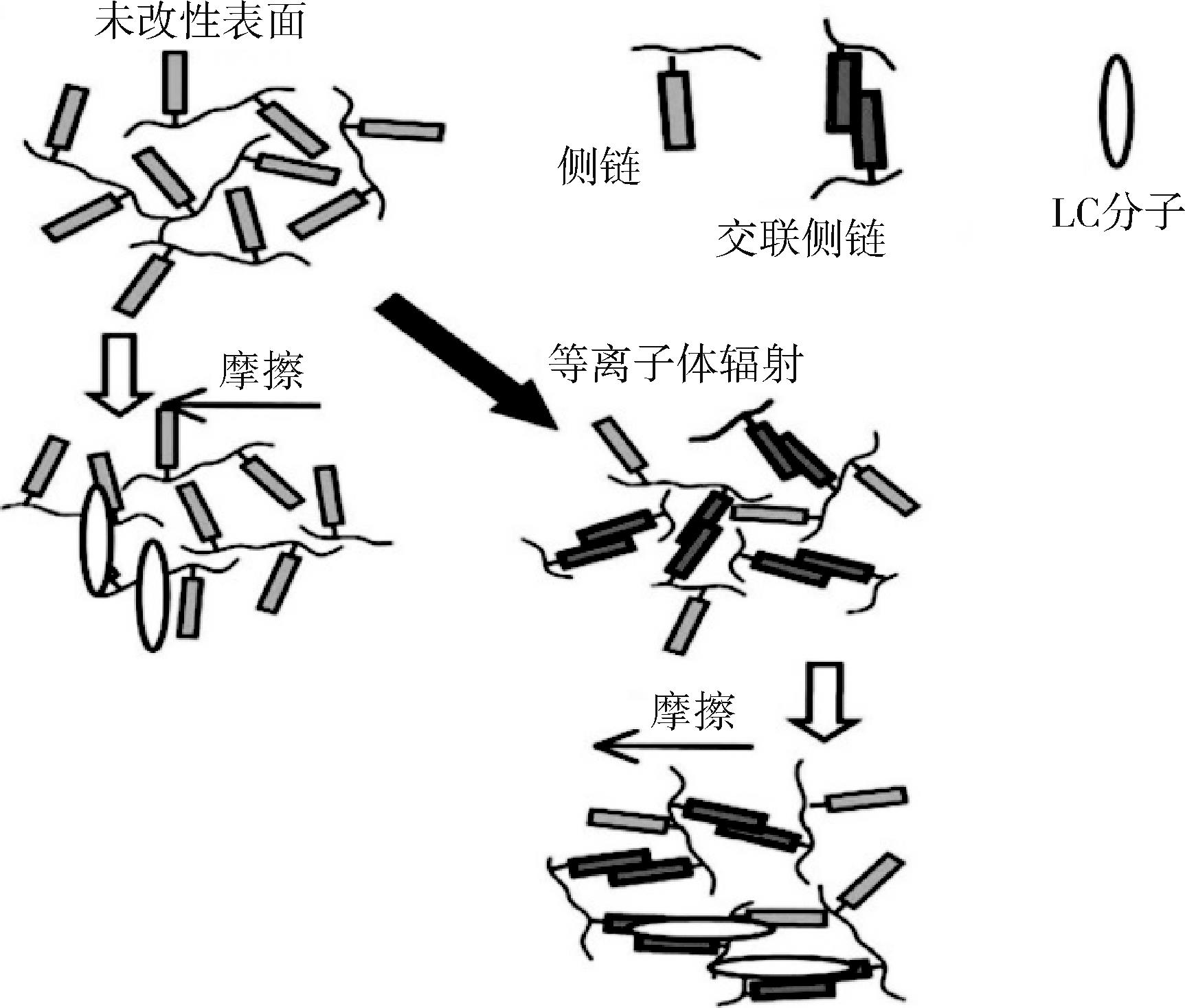

| 39 | RUMIKOYAMAGUCHI, YASUHIROSATO, SUSUMUSATO. Liquid crystal alignment properties on crosslinkable polymer films with plasma surface modification[J]. Molecular Crystals and Liquid Crystals,2005,438(1):109⁃116. |

| 40 | ASANOTOMOHARU, KOSHIBAYASUKO, UEDAYASUKIYO,et al. Formation of circuit pattern on liquid⁃crystalline polymer film by electroless copper plating[J]. Molecular Crystals and Liquid Crystals,2007,464(1):187⁃194. |

| 41 | TSUCHIYAA., SUGAMAH., SUNAMOTOT., et al. Low⁃loss and high⁃speed transmission flexible printed circuits based on liquid crystal polymer films[J]. Electro⁃nics Letters,2012, 48(19):1 216⁃1 217. |

| 42 | 梁立,茹敬宏,伍宏奎.涂布法液晶聚合物挠性覆铜板的制备[J].印制电路信息,2020,28(1):15⁃17. |

| LIANG L, RU J H, WU H K. Preparation of liquid crystal polymer flexible copper clad laminate by coating method[J]. Printed Circuit Information,2020,28(1):15⁃17. | |

| 43 | 王新威,胡祖明,刘兆峰.聚醚酰亚胺的性能、聚合与纺丝研究[J].材料导报,2007(S1):408⁃412. |

| WANG X W, HU Z M, LIU Z F. Properties,polymeri⁃zation and spinning of polyetherimide[J]. Material Guide,2007(S1):408⁃412. | |

| 44 | GE先进材料集团推出在X GENTM树脂技术上开发的第一代PEI薄膜产品目标进军全球电子产品行业[J].上海化工,2004(3):24. |

| GE advanced materials launches first⁃generation pei film products developed on X GENTM resin technology to target global electronics industry[J]. Shanghai Chemical, 2004(3):24. | |

| 45 | HUANG W, DRZALLAWRENCE T.. Multifunctional highly aligned graphite nanoplatelet⁃polyether imide composite in film form[J]. Materials Chemistry and Physics,2016,182:110⁃118. |

| 46 | LOPEZVIRGINIA, PATON⁃CARRERO A, ROMERO⁃AMAYA, et al. Improvement of the mechanical and flame⁃retardant properties of polyetherimide membranes modified with graphene oxide[J]. Polymer⁃Plastics Technology and Engineering, 2019,58(11):1⁃8. |

| 47 | WEN H L, JIN L Z, YAN R C, et al. Surface modification of h⁃BN and preparation of h⁃BN/PE thermally conductive flexible films[J]. Polymer Composites, 2022,43(6):3 846⁃3 857. |

| 48 | 曲绍宁,汪叶舟,刘继龙,等.聚醚酰亚胺/改性钛酸钡复合材料制备及介电储能性能[J].工程塑料应用,2022,50(5):21⁃26. |

| QU S N, WANG Y Z, LIU J L, et al. Preparation and dielectric energy storage properties of polyetherimide/modi⁃fied barium titanate composites[J]. Engineering Plastics Application,2022,50(5):21⁃26. | |

| 49 | TIAN D Z, LIAN Y Y, JIN Y R, et al. Improved high⁃temperature energy storage performance of PEI dielectric films by introducing an S i O 2 insulating layer[J]. Macromolecular Materials and Engineering,2021,306(12):2100514. |

| 50 | TIAN X L, YUE J T, WEI D Z. Preparation and characterization of carbon nanotube/polyetherimide nanocompo⁃site films[J]. Composites Science and Technology,2007, 67(3/4):406⁃412. |

| 51 | EDGESTEPHEN, JAMES FEAST W, PACYNKO WITOLD F, et al. The surface modification of poly(ether⁃imide) by photochemical grafting[J]. Polymer Bulletin, 1992,27(4):441⁃445. |

| 52 | WEI J M, HAN X C, ZHONG B P, et al. Enhancement thermal stability of polyetherimide⁃based nanocomposites for applications in energy storage[J].Composites Science and Technology,2021,201:108 501⁃108 511. |

| 53 | 李琳,程敏,刘文元,等.紫外辐照对聚醚酰亚胺薄膜介电性能的影响[J].强激光与粒子束,2016,28(6):186⁃190. |

| LI L, CHNEG M, LIU W Y, et al. Effects of UV irradiation on dielectric properties of polyetherimide films[J]. Intense Lasers and Particle Beams,2016,28(6):186⁃190. | |

| 54 | KIMSANGHOON, JOON⁃SUK OH, KIMMYEONG⁃GI, et al. Electromagnetic interference (EMI) transparent shielding of reduced graphene oxide (RGO) interleaved structure fabricated by electrophoretic deposition[J]. ACS Applied Materials & Interfaces, 2014,6(20):17 647⁃17 653. |

| 55 | MONDALSUBHADIP, KUMARASHAVANI. Multifunctional silanized silica nanoparticle functionalized grapheneoxide: polyetherimide composite film for EMI shielding applications[J]. Journal of Materials Science: Materials in Electronics,2018, 29:14 122⁃14 131. |

| 56 | 温变英,段磊.PEI/Ni梯度电磁屏蔽薄膜材料耐腐蚀性研究[J].材料导报,2019,33(6):1 065⁃1 069. |

| WEN B Y, DUAN L. Study on corrosion resistance of PEI/Ni gradient electromagnetic shielding film materials[J]. Material Guide,2019,33(6):1 065⁃1 069. | |

| 57 | 胡任之.聚砜树脂的发展动态[J].上海化工,2013,38(4):22⁃26. |

| HU R Z. Development trend of polysulfone resin[J]. Shanghai Chemical,2013,38(4):22⁃26. | |

| 58 | 聚砜薄膜及其金属化电容器试制简介[J].绝缘材料通讯,1973(5):20⁃21. |

| Brief introduction of trial production of polysulfone film and its metallized capacitor[J]. Insulation Newsletter, 1973(5):20⁃21. | |

| 59 | BAUTISTA⁃QUIJANO J R, AVILÉS F, AGUILAR J O, et al. Strain sensing capabilities of a piezoresistive MWCNT⁃polysulfone film[J]. Sensors and Actuators A: Physical,2010, 159(2):135⁃140. |

| 60 | LI L J, YI M M, SU X, et al. Preparation and gas separation performance of polysulfone mixed matrix membrane[J]. Journal of Nanomaterials, 2021:1⁃10. |

| 61 | JURCZUKKINGA, GALESKIANDRZEJ, MACKEYMATTHEW, et al. Orientation of PVDF α and γ crystals in nanolayered films[J]. Colloid and Polymer Science,2015,293:1 289⁃1 297. |

| 62 | RUI K D, BAO J G, YAN B L. Hydrophilic polysulfone film prepared from polyethylene glycol monomethylether via coupling graft[J]. Applied Surface Science,2013, 274:288⁃294. |

| 63 | MING M T, JING J X, YUN R Q. Surface hemocompatible modification of polysulfone membrane via covalently grafting acrylic acid and sulfonated hydroxypropyl chitosan[J]. RSC Advances, 2019,9(11):6 254⁃6 266. |

| 64 | AJITH JAMES JOSE, ALAGARM, SELVIN PAND THOMAS. Preparation and characterization of organoclay filled polysulfone nanocomposites[J]. Materials and Manufacturing Processes,2012,27(3):247⁃254. |

| 65 | SUWANWONG S, YUENYAO C, HUTEM A. Efficiency of supercapacitor with C a T i O 3 ⁃filled polysulfone separators[J]. Journal of Physics:Conference Series,2021:2145. |

| 66 | VINODHRAJANGAM, PURUSHOTHAMANMUTHUKRISHNAN, SANGEETHADHARMALINGAM. Novel quaternized polysulfone/ Z r O 2 composite membranes for solid alkaline fuel cell applications[J]. International Journal of Hydrogen Energy,2011,36 (12):7 291⁃7 302. |

| 67 | 杜瑞奎,高保娇,李延斌,等.聚砜阴离子交换膜的制备及结构与性能研究[J].高分子学报,2010(7):924⁃931. |

| DU R K, GAO B J, LI Y B, et al. Preparation, structure and properties of polysulfone anion exchange membrane[J]. Acta Polymerica Sinica,2010(7):924⁃931. | |

| 68 | 刘金刚,倪洪江,高鸿,等.超薄聚酰亚胺薄膜研究与应用进展[J].航天器环境工程,2014,31(5):470⁃475. |

| LIU J G, NI H J, GAO H, et al. Research and application progress of ultrathin polyimide films[J]. Spacecraft Environmental Engineering,2014,31(5):470⁃475. | |

| 69 | 卢小闯,余文涛,翁梦蔓,等.电子器件用低膨胀聚酰亚胺薄膜研究进展[J].绝缘材料,2021,54(11):11⁃22. |

| LU X C, YU W T, WENG M M, et al. Research progress of low expansion polyimide films for electronic devices[J]. Insulation Materials, 2021,54(11):11⁃22. | |

| 70 | 王伟,来育梅,孙琳,等.流延法制备聚酰亚胺薄膜工艺研究[J].塑料工业,2006(1):15⁃17. |

| WANG W, LAI Y M, SUN L, et al. Study on the technology of preparing polyimide film by casting method[J]. China Plastics Industry,2006(1):15⁃17. | |

| 71 | 赵伟涛,邢爱,许剑,等.高性能聚酰亚胺薄膜制备方法[J].信息记录材料,2015,16(4):37⁃41. |

| ZHAO W T, XING A, XU J, et al. Preparation method of high⁃performance polyimide film[J]. Information Recording Material,2015,16(4):37⁃41. | |

| 72 | 蒋里锋,董云飞,沈鹏飞,等.流延法制备聚酰亚胺薄膜的热膨胀系数表征[J].塑料工业,2020,48(S1):128⁃131. |

| JIANG L F, DONG Y F, SHEN P F, et al. Characteri⁃zation of thermal expansion coefficient of polyimide films prepared by casting[J]. China Plastics Industry, 2020,48(S1):128⁃131. | |

| 73 | YA J W, XIAO J W, CHANG G F, et al. Improved dielectric properties of surface modified B a T i O 3 /polyimide composite films[J]. Microelectronic Engineering,2016,154:17⁃21. |

| 74 | JING D, MENG M Z, LING L M, et al. Preparation and characterization of high dielectric calcium copper titanate/polyimide composite films[J]. High Performance Polymers,2016,28(8):908⁃914. |

| 75 | 徐萌,安钊,王野,等.低温等离子体处理对聚酰亚胺纳米复合薄膜表面特性的影响[J].绝缘材料,2021,54(5):47⁃53. |

| XU M, AN Z, WANG Y, et al. Effects of low temperature plasma treatment on surface properties of polyimide nanocomposite films[J]. Insulation Materials,2021,54(5):47⁃53. | |

| 76 | YUNG S L, HUANG M L, CHUNG WEI TSAI. Nitrogen plasma modification on polyimide films for copper metallization on microelectronic flex substrates[J]. Journal of Polymer Science,2005,43(15):2 023⁃2 038. |

| 77 | MEDDEBA.BARHOUMI, OUNAIESZ, LanaganM. Enhancement of Electrical Properties of Polyimide Films by Plasma Treatment[J]. Chemical Physics Letters,2016,649:111⁃114. |

| 78 | 苏桂明,姜海健,马宇良.聚酰亚胺薄膜材料的制备和应用探究[J].中国新技术新产品,2015(5):40. |

| SU G M, JIANG H J, MA Y L. Preparation and application of polyimide film materials[J]. China’s New Technology and New products,2015(5):40. | |

| 79 | NISAR ALI, FARMAN ALI, KHANSABOOR, et al. Novel sulfonated polyimide⁃nafion nanocomposite membranes: fabrication, morphology and physiochemical investigations for fuel cell applications[J]. Journal of Molecular Structure,2021,1231:129940. |

| 80 | JUN L, HAO R D, WEN J X, et al. Branched sulfonated polyimide/s⁃MWCNTs composite membranes for vanadium redox flow battery application[J]. International Journal of Hydrogen Energy,2021,46(70):34 767⁃34 776. |

| [1] | 张林, 夏章川, 何亚东, 信春玲, 王瑞雪, 任峰. 等离子体射流载气流量大小对玻璃纤维改性效果影响的研究[J]. 中国塑料, 2022, 36(9): 7-15. |

| [2] | 马超, 马兰荣, 魏辽, 尹慧博, 林祥. 聚乙醇酸材料的加工改性及其水下降解特性的研究进展[J]. 中国塑料, 2022, 36(9): 74-84. |

| [3] | 董玥, 董霄, 朱德兆, 杨延翔, 罗琛, 李阳, 李锦山. 聚酰亚胺发展概况与应用展望[J]. 中国塑料, 2022, 36(9): 85-95. |

| [4] | 马国成, 何圳, 陈少军. 醋酸纤维素的降解性研究进展[J]. 中国塑料, 2022, 36(9): 111-121. |

| [5] | 余大荣, 辛勇. 超高分子量聚乙烯改性研究进展[J]. 中国塑料, 2022, 36(8): 135-145. |

| [6] | 汤小明, 曹宁, 蒋岳航, 王倩, 王志彦, 李建华, 王亚涛, 连慧琴, 汪晓东, 崔秀国. 聚砜类燃料电池质子交换膜研究进展[J]. 中国塑料, 2022, 36(8): 146-158. |

| [7] | 喻九阳, 王众浩, 陈琦, 夏亚忠. 基于阀体制造的先进树脂基复合材料性能研究[J]. 中国塑料, 2022, 36(8): 16-22. |

| [8] | 陈佰全, 郑友明, 田际波, 张磊, 王金松, 林夏洁, 段亚鹏. 高含量玻璃纤维增强阻燃聚酰胺材料的制备与性能[J]. 中国塑料, 2022, 36(8): 42-48. |

| [9] | 王倩, 杨康宁, 翟绍雄, 尹立坤, 何少剑, 林俊. 高质子传导率及尺寸稳定性复合质子交换膜制备及性能研究[J]. 中国塑料, 2022, 36(8): 62-68. |

| [10] | 熊一鸣, 宋季岭, 秦舒浩, 龙雪彬, 鲁显睿. 改性热塑性淀粉的制备及其与PBAT复合薄膜的性能[J]. 中国塑料, 2022, 36(8): 69-72. |

| [11] | 李果, 朱惠豪, 马玉录, 王玉, 吉华建, 谢林生. 导热型微孔透气薄膜的制备及性能研究[J]. 中国塑料, 2022, 36(7): 14-20. |

| [12] | 冯凯, 李永青, 马秀清, 韩颖. 聚甲醛增韧改性的研究进展及应用[J]. 中国塑料, 2022, 36(7): 157-164. |

| [13] | 陈轲, 刘鸣飞, 赵彪, 潘凯. 有机硅改性高分子材料阻燃及耐烧蚀性能研究进展[J]. 中国塑料, 2022, 36(6): 149-154. |

| [14] | 王帅, 张玉迪, 杨富凯, 徐新宇. 聚酰亚胺/多壁碳纳米管泡沫材料的制备及性能研究[J]. 中国塑料, 2022, 36(6): 39-45. |

| [15] | 黄素媛, 曹琳, 李卫, 林志丹, 张鹏. 硼化钽增强聚醚醚酮复合涂层的制备及性能评价[J]. 中国塑料, 2022, 36(6): 60-68. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2