京ICP备13020181号-2

© 《China Plastics》

© 《China Plastics》

China Plastics ›› 2024, Vol. 38 ›› Issue (6): 12-18.DOI: 10.19491/j.issn.1001-9278.2024.06.002

• Materials and Properties • Previous Articles Next Articles

YANG Lian1,2, JIANG Jing1,2( ), JIA Caiyi1,2, XIE Yuehan1, WANG Xiaofeng2, LI Qian2

), JIA Caiyi1,2, XIE Yuehan1, WANG Xiaofeng2, LI Qian2

Received:2023-11-17

Online:2024-06-26

Published:2024-06-20

CLC Number:

YANG Lian, JIANG Jing, JIA Caiyi, XIE Yuehan, WANG Xiaofeng, LI Qian. Preparation of polyamide 6 microfiber reinforced polypropylene composite and its property of chemical foam injection molding[J]. China Plastics, 2024, 38(6): 12-18.

Add to citation manager EndNote|Ris|BibTeX

URL: https://www.plaschina.com.cn/EN/10.19491/j.issn.1001-9278.2024.06.002

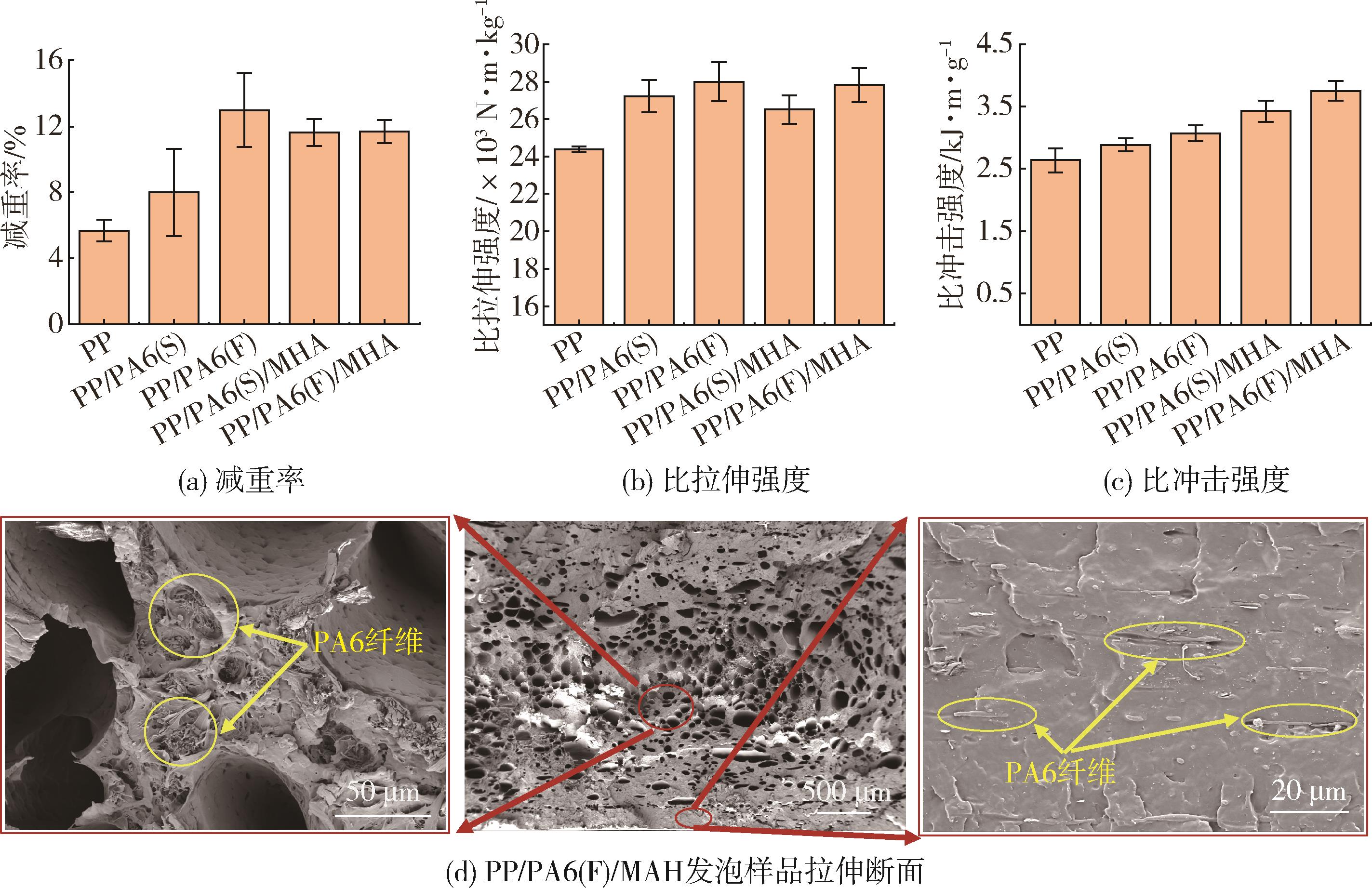

| 样品 | PP含量/% | PA6含量/% | PP⁃g⁃MAH含量/% | 备注 |

|---|---|---|---|---|

| PP | 100 | 0 | 0 | — |

| PP/PA6(S) | 95 | 5 | 0 | 球形PA6 分散相的两相共混物 |

| PP/PA6(F) | 95 | 5 | 0 | PP/PA6两相微纤复合材料 |

| PP/PA6(S)/MAH | 94 | 5 | 1 | 球形PA6分散相的三相共混物 |

| PP/PA6(F)/MAH | 94 | 5 | 1 | PP/PA6/MAH三相微纤复合材料 |

| 样品 | PP含量/% | PA6含量/% | PP⁃g⁃MAH含量/% | 备注 |

|---|---|---|---|---|

| PP | 100 | 0 | 0 | — |

| PP/PA6(S) | 95 | 5 | 0 | 球形PA6 分散相的两相共混物 |

| PP/PA6(F) | 95 | 5 | 0 | PP/PA6两相微纤复合材料 |

| PP/PA6(S)/MAH | 94 | 5 | 1 | 球形PA6分散相的三相共混物 |

| PP/PA6(F)/MAH | 94 | 5 | 1 | PP/PA6/MAH三相微纤复合材料 |

| 1 | Penumakala P K, Santo J, Thomas A. A Critical Review On the Fused Deposition Modeling of Thermoplastic Polymer Composites[J]. Composites Part B: Engineering, 2020, 201: 108336. |

| 2 | 袁洪跃, 金章勇, 蒋 晶, 等. 聚丙烯/碳纳米管微孔注塑发泡行为及力学性能[J]. 中国塑料, 2020, 34(06): 20⁃26. |

| YUAN H Y, JIN Z Y, JIANG J, et al. Microcellular injection foaming behaviors and mechanical properties of polypropylene/carbon nanotubes composites[J]. China Plastics, 2020, 34(06): 20⁃26. | |

| 3 | Cui Y, Luo J, Deng Y, et al. Effect of Acetylated Cellulose Nanocrystals On Solid‐State Foaming Behaviors of Chain‐Extended Poly(Butylene Adipate‐Co‐Terephthalate)[J]. Journal of Vinyl and Additive Technology, 2021, 27(4): 722⁃735. |

| 4 | Zhu N, Shen C, Zeng X, et al. Enhancing the Foaming Properties of Polypropylene/Basalt Fiber Composites by Altering their Rheological and Crystallization Behavior Via Polyethylene–Octene Blending Modification[J]. Polymer Composites, 2023, 44(11): 7 631⁃7 642. |

| 5 | Wang G, Zhao G, Zhang L, et al. Lightweight and Tough Nanocellular PP/PTFE Nanocomposite Foams with Defect⁃Free Surfaces Obtained Using in Situ Nanofibrillation and Nanocellular Injection Molding[J]. Chemical Engineering Journal, 2018, 350: 1⁃11. |

| 6 | Zhao J, Zhao Q, Wang L, et al. Development of High Thermal Insulation and Compressive Strength BPP Foams Using Mold⁃Opening Foam Injection Molding with in⁃Situ Fibrillated PTFE Fibers[J]. European Polymer Journal, 2018, 98: 1⁃10. |

| 7 | Jiang J, Li Z, Yang H, et al. Microcellular injection molding of polymers: A review of process know⁃how, emerging technologies, and future directions[J]. Current Opinion in Chemical Engineering, 2021, 33: 100694. |

| 8 | Zhao J, Wang G, Zhang L, et al. Lightweight and Strong Fibrillary PTFE Reinforced Polypropylene Composite Foams Fabricated by Foam Injection Molding[J]. European Polymer Journal, 2019, 119: 22⁃31. |

| 9 | Wang G, Zhao G, Dong G, et al. Lightweight and Strong Microcellular Injection Molded PP/Talc Nanocomposite[J]. Composites Science and Technology, 2018, 168: 38⁃46. |

| 10 | Zhao J, Qiao Y, Wang G, et al. Lightweight and Tough PP/Talc Composite Foam with Bimodal Nanoporous Structure Achieved by Microcellular Injection Molding[J]. Materials & Design, 2020, 195: 109051. |

| 11 | 孙俊威, 蒋 晶, 赵 娜, 等. 原位成纤复合泡沫材料的研究进展[J]. 复合材料学报, 2023, 40(4): 1 951⁃1 965. |

| SUN J W, JIANG J, ZHAO N, et al. Research progress of in⁃situ fibrous composite foamed material[J]. Acta Materiae Compositae Sinica, 2023, 40(4): 1 951⁃1 965. | |

| 12 | Ahmadlouydarab M, Chamkouri M, Chamkouri H. Compatibilization of Immiscible Polymer Blends (R⁃PET/PP) by Adding Pp⁃G⁃Ma as Compatibilizer: Analysis of Phase Morphology and Mechanical Properties[J]. Polymer Bulletin, 2020, 77(11): 5 753⁃5 766. |

| 13 | Wang X, Li Y, Jiao Y, et al. Microcellular Foaming Behaviors of Poly (Lactic Acid)/Low⁃Density Polyethylene Blends Induced by Compatibilization Effect[J]. Journal of Polymers and the Environment, 2019, 27(8): 1 721⁃1 734. |

| 14 | Su B, Zhou Y, Dong B, et al. Effect of Compatibility On the Foaming Behavior of Injection Molded Polypropylene and Polycarbonate Blend Parts[J]. Polymers, 2019, 11(2): 300. |

| 15 | Wang B, Sun C, Wang Y, et al. Improved Mechanical Properties of in Situ Microfibrillar Polypropylene/Polyamide6 Composites through Constructing Strong Interfacial Adhesion[J]. Polymers for Advanced Technologies, 2021, 32(8): 3 343⁃3 357. |

| 16 | Qiao Y, Li Q, Jalali A, et al. In⁃Situ Microfibrillated Poly(Ε⁃Caprolactone)/ Poly(Lactic Acid) Composites with Enhanced Rheological Properties, Crystallization Kinetics and Foaming Ability[J]. Composites Part B: Engineering, 2021, 208: 108594. |

| 17 | Friedrich K. Microfibrillar Reinforced Composites From PET/PP Blends: Processing, Morphology and Mechanical Properties[J]. Composites Science and Technology, 2005, 65(1): 107⁃116. |

| 18 | Qiao Y, Li Q, Jalali A, et al. Effect of Polyethylene Glycol On the Crystallization, Rheology and Foamability of Poly (Lactic Acid) Containing in Situ Generated Polyamide 6 Nanofibrils[J]. Frontiers of Chemical Science and Engineering, 2023: 1⁃14. |

| 19 | Jiang Y, Jiang J, Yang L, et al. In Situ Nanofibrillar Polypropylene⁃Based Composite Microcellular Foams with Enhanced Mechanical and Flame⁃Retardant Performances[J]. Polymers, 2023, 15(6): 1 497. |

| 20 | 徐云飞, 赵在胜, 邢雅静, 等. 聚乳酸/聚氨酯复合多孔材料制备及吸油性能研究[J]. 中国塑料, 2021, 35(11): 24⁃31. |

| XU Y F, ZHAO Z S, XING Y J, et al. Preparation and oil absorption performance of porous polylactide/polyurethane composites[J]. China Plastics, 2021, 35(11): 24⁃31. | |

| 21 | Sun S, Li Q, Zhao N, et al. Preparation of Highly Interconnected Porous Poly(Ε‐Caprolactone)/Poly(Lactic Acid) Scaffolds Via Supercritical Foaming[J]. Polymers for Advanced Technologies, 2018, 29(12): 3 065⁃3 074. |

| 22 | Sun J, Li Q, Jiang Y, et al. Lightweight and High Impact Toughness PP/PET/POE Composite Foams Fabricated by in Situ Nanofibrillation and Microcellular Injection Molding[J]. Polymers, 2023, 15(1): 227. |

| 23 | Zhang G, Wang Y, Xing H, et al. Interplay Between the Composition of LLDPE/PS Blends and their Compatibilization with Polyethylene⁃Graft⁃Polystyrene in the Foaming Behaviour[J]. Rsc Advances, 2015, 5(34): 27 181⁃27 189. |

| [1] | SONG Wenlan, SONG Wenxing, LI Bing, LIU Qian, OUYANG Yuge, TIAN Huafeng, GUO Gaiping. Research progress in BOPP films of capacitors for enhancing dielectric and electric energy storage [J]. China Plastics, 2024, 38(7): 138-143. |

| [2] | HU Yongxiang, XIE Jiling, LI Weiming, ZHANG Lu, TANG Xianggang, LYU Yitong, SHEN Hongwang, JU Guannan. Effect of maleic anhydride graft⁃modified ground tire rubber on properties of poly(lactic acid) [J]. China Plastics, 2024, 38(7): 20-24. |

| [3] | WANG Jie, XIN Dehua, LI Hui, JIANG Hongshi, ZHOU Hongfu, ZHAO Jianguo. Effect of hybrid reinforcement of nanoclay and silica on properties of poly(lactic acid) [J]. China Plastics, 2024, 38(7): 43-48. |

| [4] | SHEN Qiangfeng, LYU Mingfu, XU Yaohui. Study on autoclave foaming properties of metallocene polypropylene [J]. China Plastics, 2024, 38(7): 55-61. |

| [5] | XU Chen, LUO Bofei, LIU Tengteng, XING Jingkai. Research progress in modification of polypropylene with nucleating agent [J]. China Plastics, 2024, 38(7): 79-85. |

| [6] | LIU Ying, SUN Hao, YANG Yong, JIANG Kaiyu, YU Tongmin, MA Sai, ZHU Tieli. Effect of ultrasonic vibration on mechanical properties of injection⁃molded parts of glass⁃fiber⁃reinforced polyamide 6 [J]. China Plastics, 2024, 38(7): 9-14. |

| [7] | . Effect of ultrasonic vibration on mechanical properties of injection-molded parts of glass-fiber-reinforced polyamide 6 [J]. , 2024, 38(7): 9-14. |

| [8] | . Effect of maleic anhydride graft-modified ground tire rubber on properties of poly(lactic acid) [J]. , 2024, 38(7): 20-24. |

| [9] | . Study on autoclave foaming properties of metallocene polypropylene [J]. , 2024, 38(7): 55-61. |

| [10] | ZHOU Ziyi, WANG Yangyang, SUN Tao, JIANG Wei, DONG Tungalag, YUN Xunyan. Properties and applications of poly(butylene adipate⁃co⁃terephthalate)⁃based self⁃regulating gas film [J]. China Plastics, 2024, 38(6): 31-38. |

| [11] | DONG Yapeng, ZHAO Tianjiao, WANG Meizhen, CUI Wenju, LIN Fuhua, WANG Bo. Effect of long chain fatty acid sodium/sodium arylamide fatty acid compounding nucleating agent on properties of polypropylene [J]. China Plastics, 2024, 38(6): 60-65. |

| [12] | XIE Bo, TU Zhigang, ZHOU Xianjin, ZHAG Shangxian, XIONG Ligui, YANG Ting. Development of heat shrinkable BOPP packaging film with low friction coefficient [J]. China Plastics, 2024, 38(6): 78-81. |

| [13] | WANG Han, LIANG Jinhua, GAO Zhenguo, JIANG Wei, ZHOU Hao. Mechanical properties and repair efficiency of self⁃repairing microencapsulated epoxy resin [J]. China Plastics, 2024, 38(5): 40-46. |

| [14] | ZHANG Zhiqi, WANG Xiangdong, LIU Haiming, CHEN Shihong. Study on toughening modification and foaming behavior of biobased polyamide 56/polyamide 66 blends by polyamide elastomer [J]. China Plastics, 2024, 38(5): 55-60. |

| [15] | ZHANG Yi, HUANG Yating, WEI Yongbao, TANG Wei, QIAN Lijun. Study on pyrolysis mechanism of intumescent flame⁃retardant system based on reaction force field [J]. China Plastics, 2024, 38(5): 66-72. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||