京ICP备13020181号-2

© 《China Plastics》

© 《China Plastics》

China Plastics ›› 2024, Vol. 38 ›› Issue (7): 79-85.DOI: 10.19491/j.issn.1001-9278.2024.07.014

• Additive • Previous Articles Next Articles

XU Chen( ), LUO Bofei, LIU Tengteng, XING Jingkai

), LUO Bofei, LIU Tengteng, XING Jingkai

Received:2024-10-23

Online:2024-07-26

Published:2024-07-24

CLC Number:

XU Chen, LUO Bofei, LIU Tengteng, XING Jingkai. Research progress in modification of polypropylene with nucleating agent[J]. China Plastics, 2024, 38(7): 79-85.

Add to citation manager EndNote|Ris|BibTeX

URL: https://www.plaschina.com.cn/EN/10.19491/j.issn.1001-9278.2024.07.014

| 种类 | 示例 | 特点 |

|---|---|---|

| 无机类 | 碳酸钙、氧化钇 | 价格低廉但成核效率较低且分散性差 |

| 稠环芳烃类 | 三酚二噻嗪 | 成核性能较好但对产品外观影响大 |

| 第IIA族复合物类 | 庚二酸钙 | 能显著提高PP韧性但加工过程中易分解,影响成核效率 |

| 芳香族二酰胺类 | N,N′⁃二环己基对苯二甲酰胺 | 与PP有较好相容性且成核效率高、耐热性能好,综合性能优良 |

| 稀土化合物 | 稀土有机配合物 | 成核效率显著且对PP增韧效果明显 |

| 种类 | 示例 | 特点 |

|---|---|---|

| 无机类 | 碳酸钙、氧化钇 | 价格低廉但成核效率较低且分散性差 |

| 稠环芳烃类 | 三酚二噻嗪 | 成核性能较好但对产品外观影响大 |

| 第IIA族复合物类 | 庚二酸钙 | 能显著提高PP韧性但加工过程中易分解,影响成核效率 |

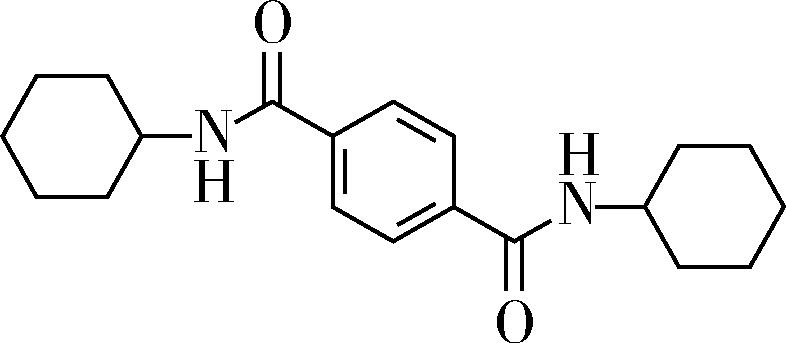

| 芳香族二酰胺类 | N,N′⁃二环己基对苯二甲酰胺 | 与PP有较好相容性且成核效率高、耐热性能好,综合性能优良 |

| 稀土化合物 | 稀土有机配合物 | 成核效率显著且对PP增韧效果明显 |

| 名称 | 结构式 | 参考文献 |

|---|---|---|

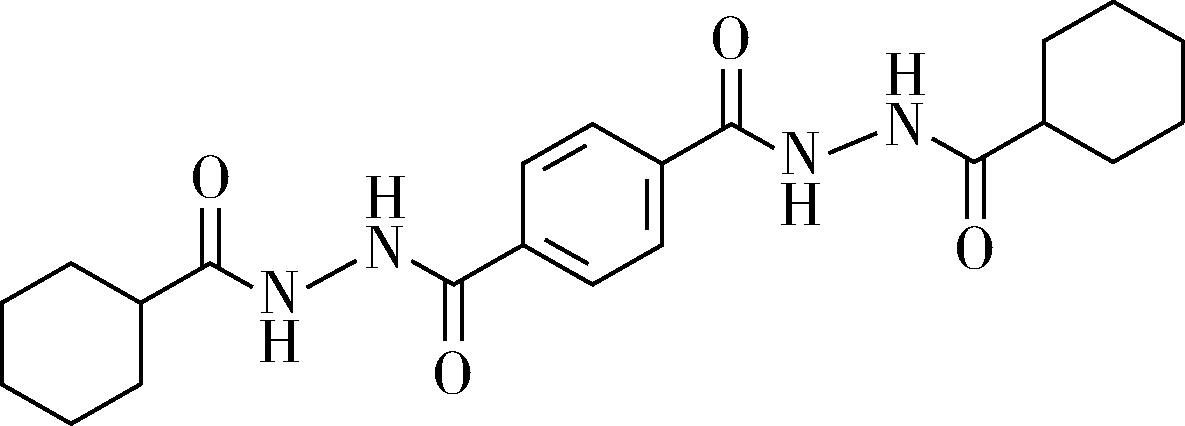

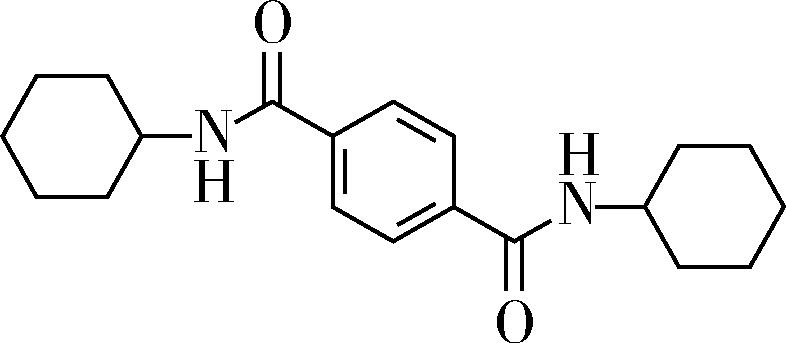

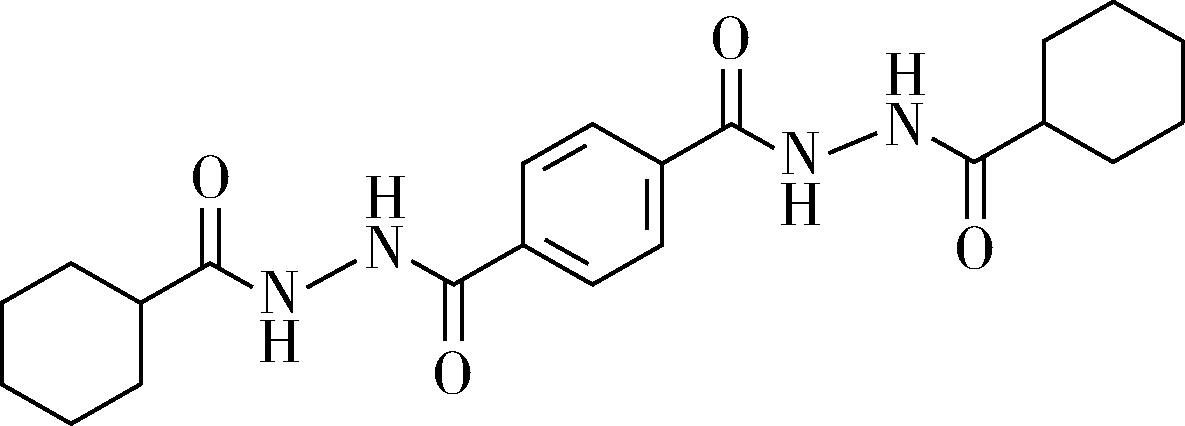

| N,N'⁃二环己基对苯二甲酸二酰肼 |  | [ |

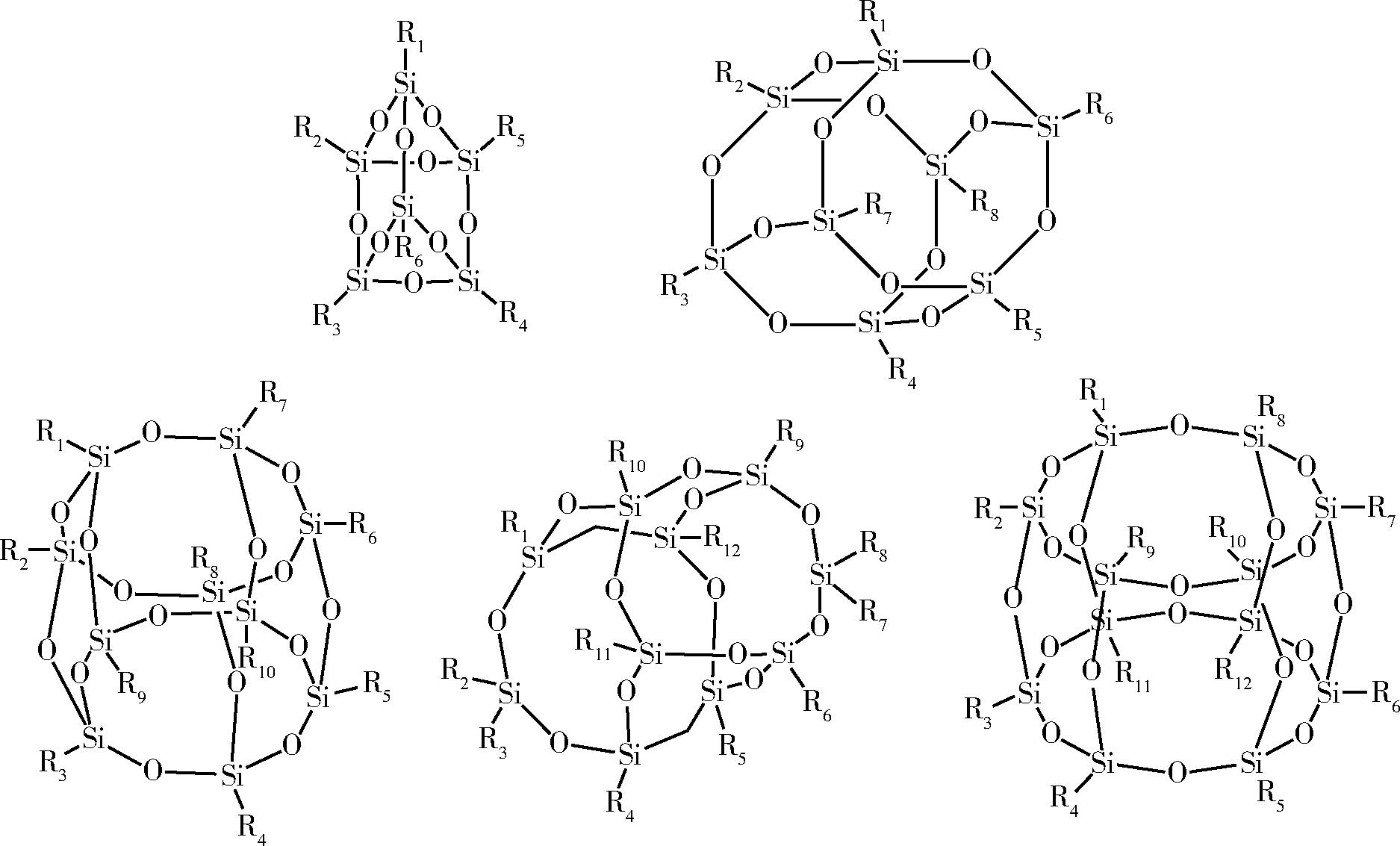

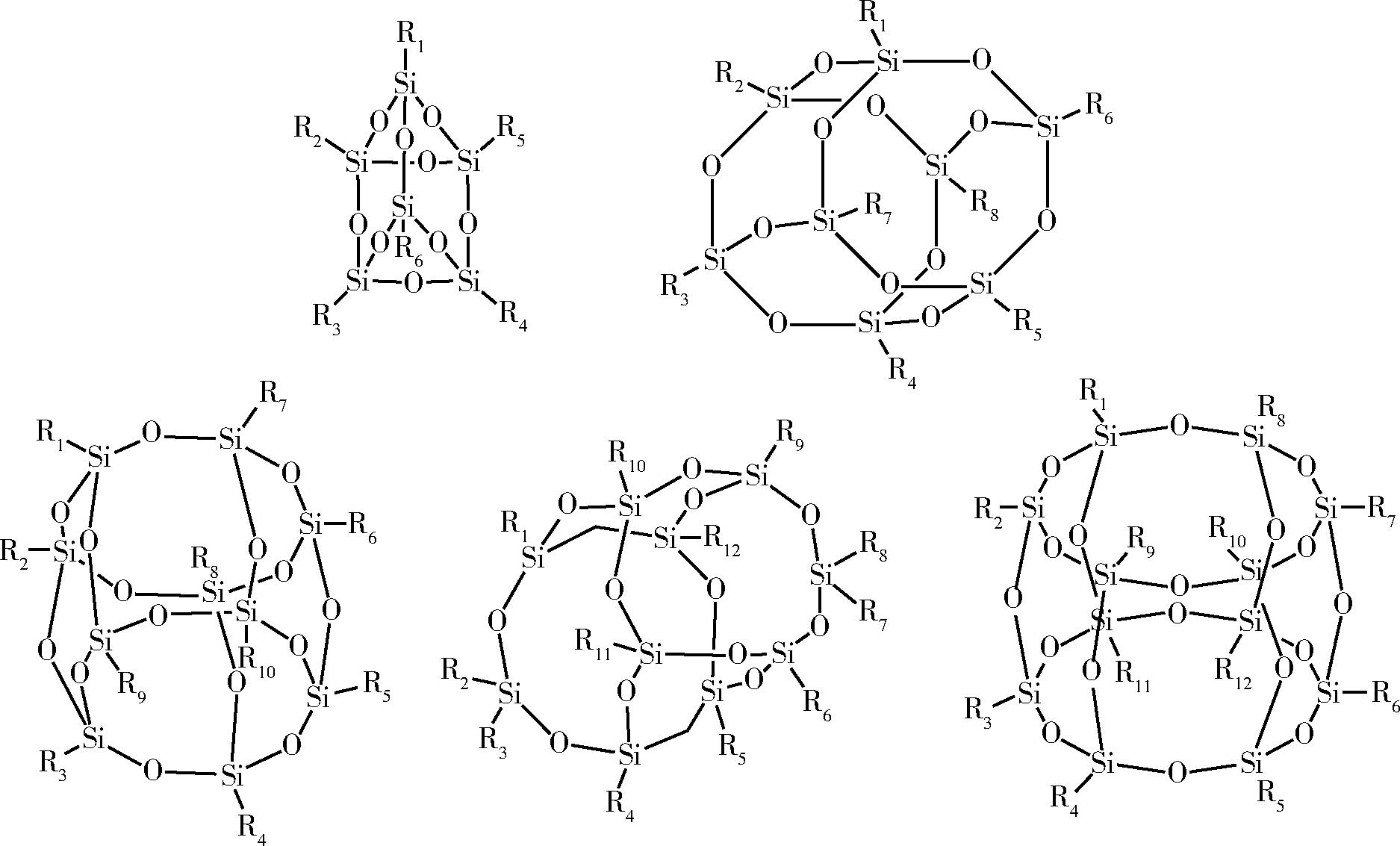

| 笼型倍半硅氧烷 |  | [ |

| 纳米氧化锌 |  | [ |

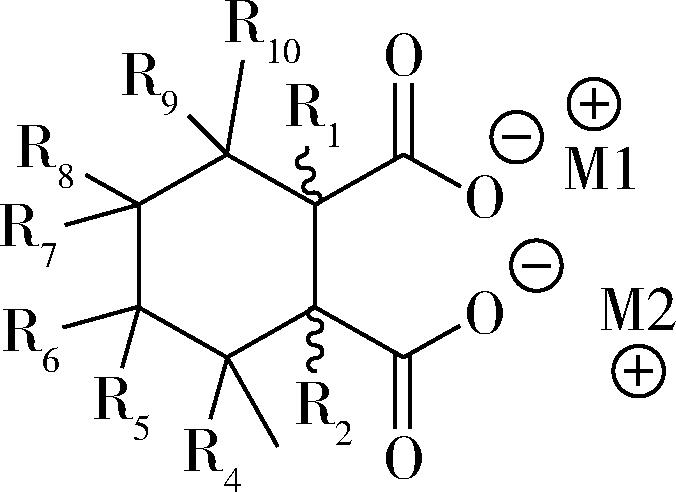

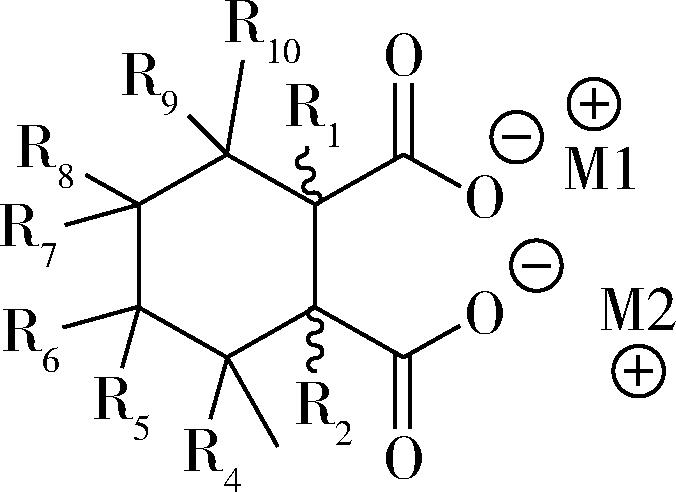

| 成核剂结构通式 |  | [ |

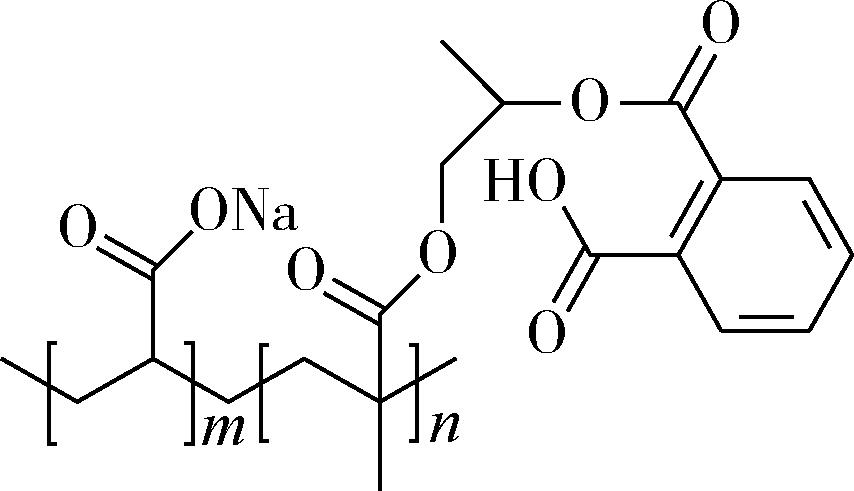

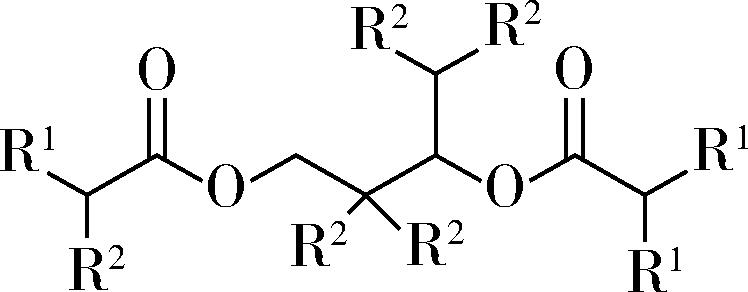

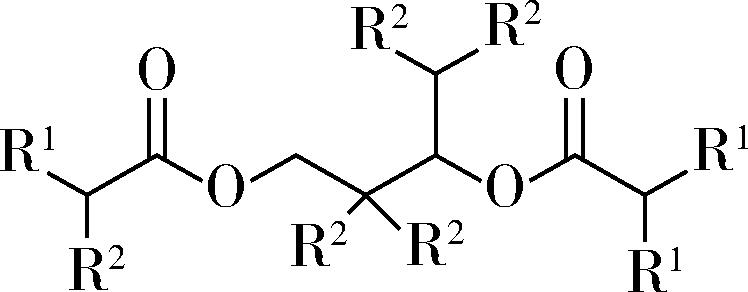

| 二醇二烯酸双酯 |  | [ |

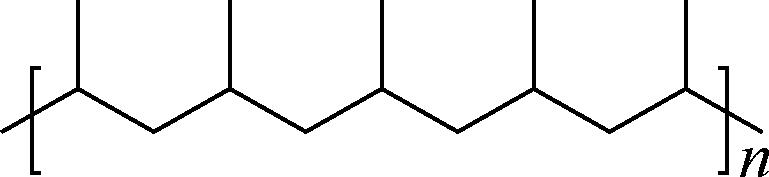

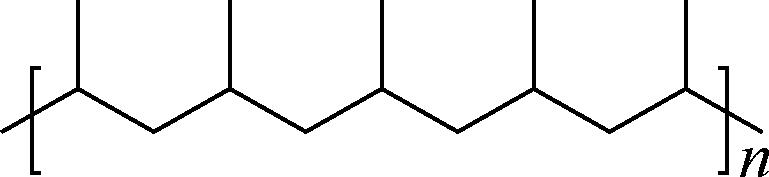

| PP |  | [ |

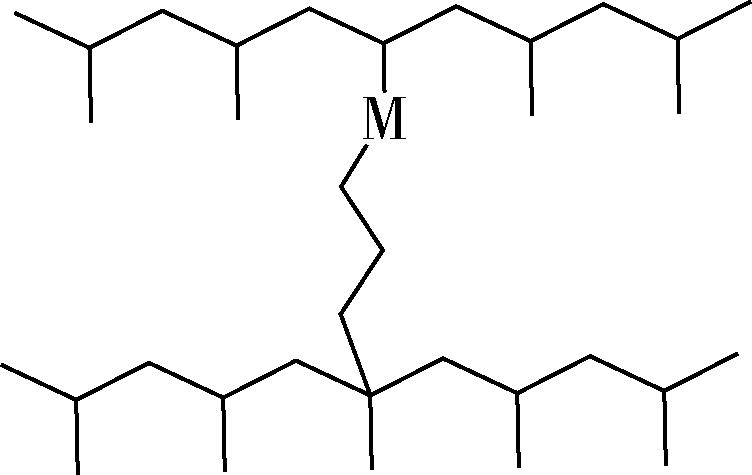

| 长链支化聚丙烯 |  | [ |

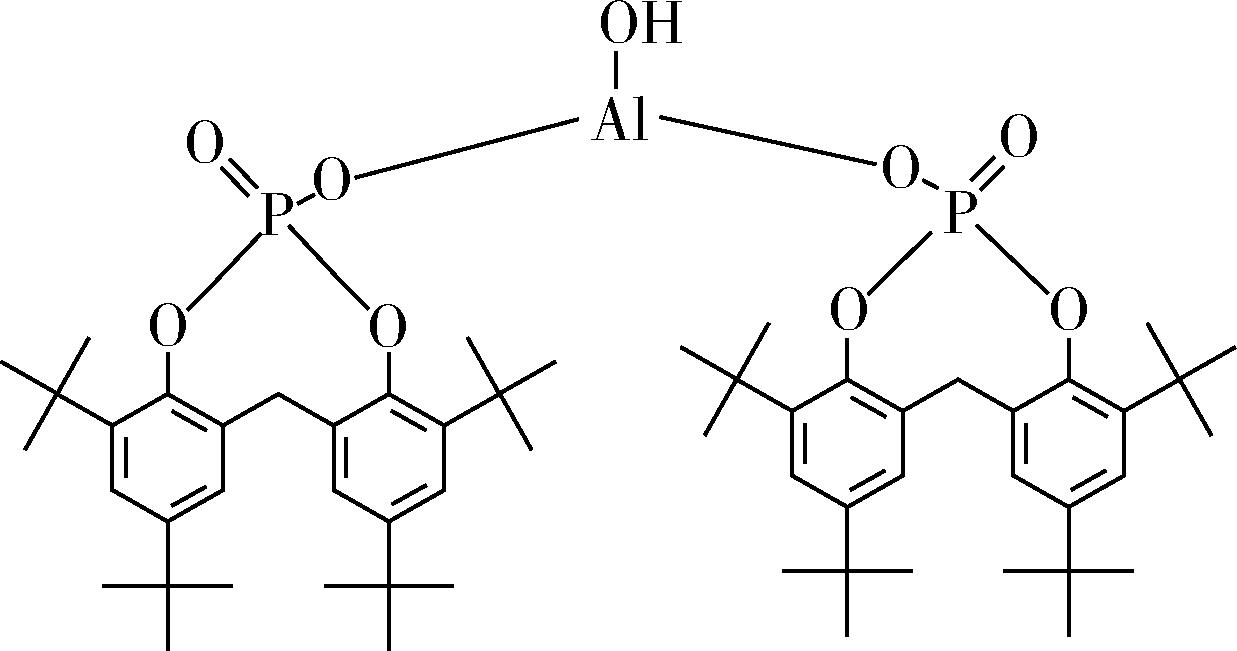

| 有机磷酸盐成核剂 |  | [ |

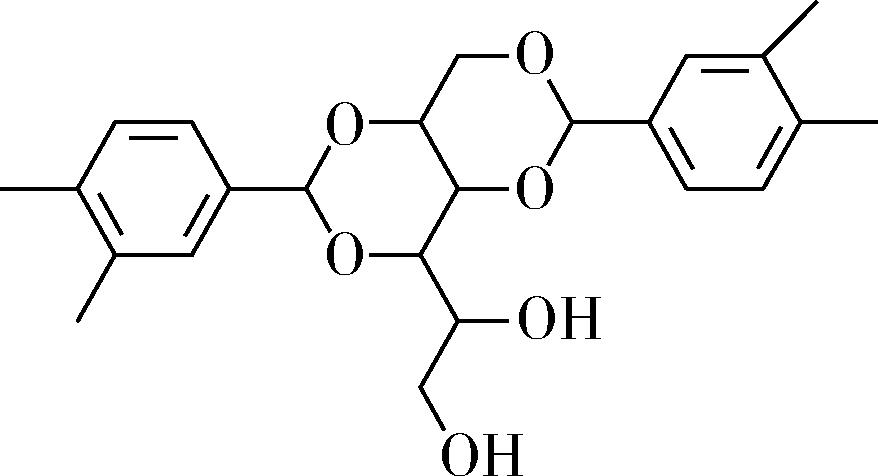

| 山梨醇成核剂 |  | [ |

| 稀土成核剂 | La+3Ca2+P m X n Q x | [ |

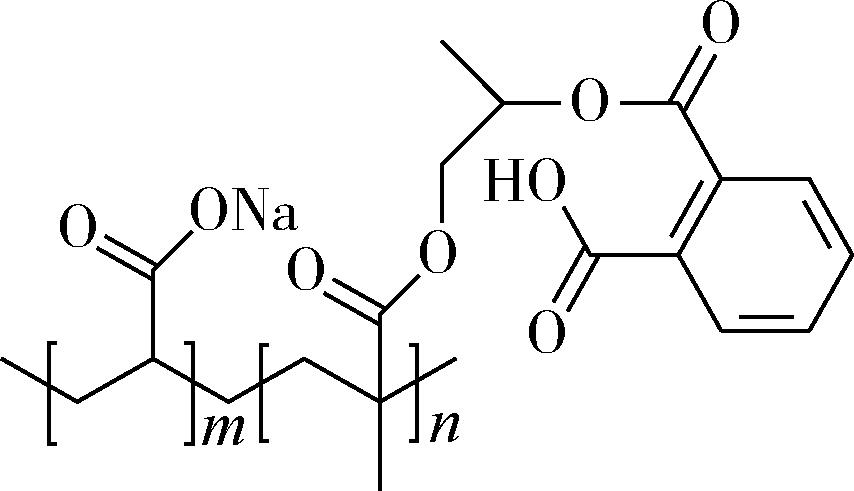

| 酰胺基成核剂 |  | [ |

| 名称 | 结构式 | 参考文献 |

|---|---|---|

| N,N'⁃二环己基对苯二甲酸二酰肼 |  | [ |

| 笼型倍半硅氧烷 |  | [ |

| 纳米氧化锌 |  | [ |

| 成核剂结构通式 |  | [ |

| 二醇二烯酸双酯 |  | [ |

| PP |  | [ |

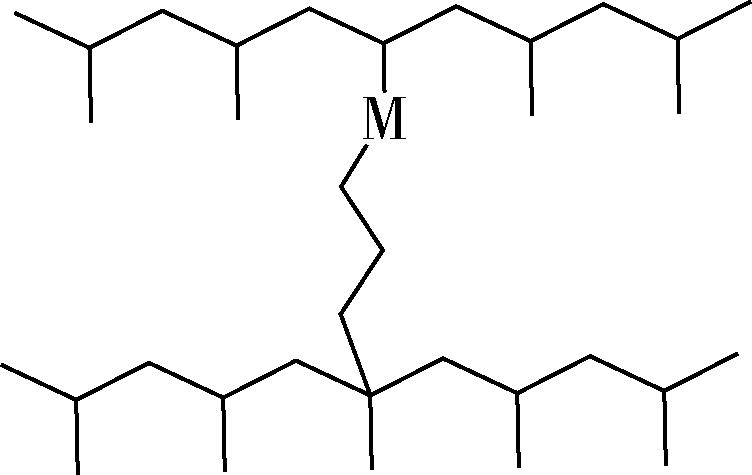

| 长链支化聚丙烯 |  | [ |

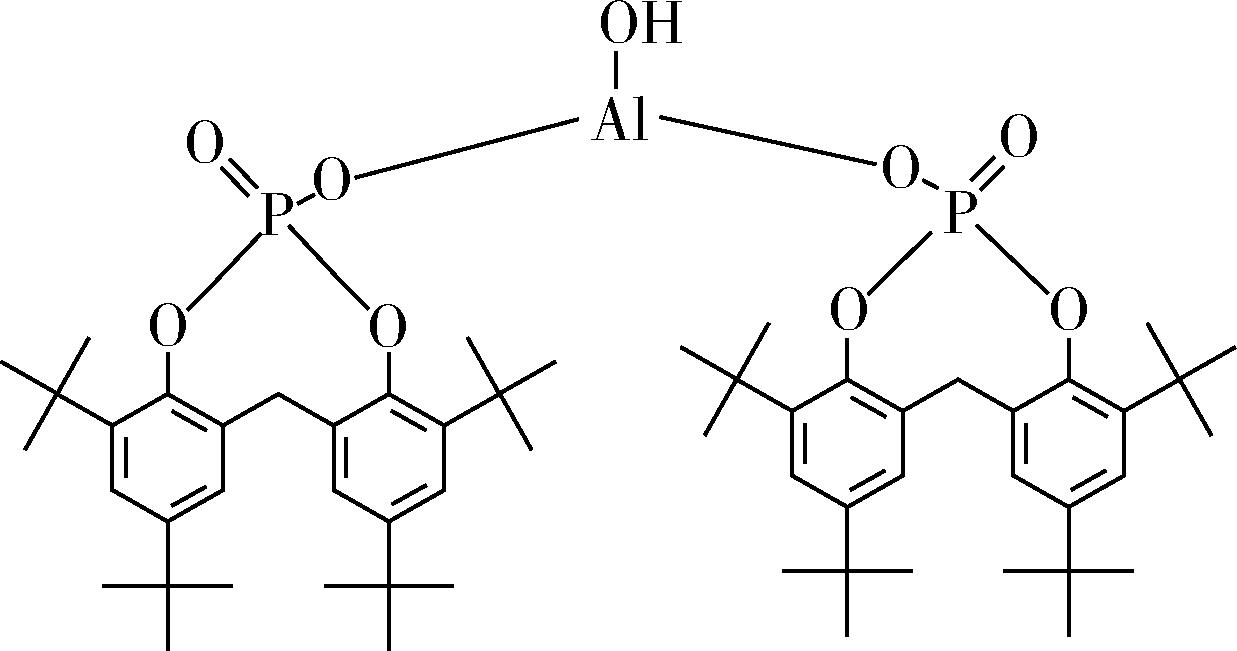

| 有机磷酸盐成核剂 |  | [ |

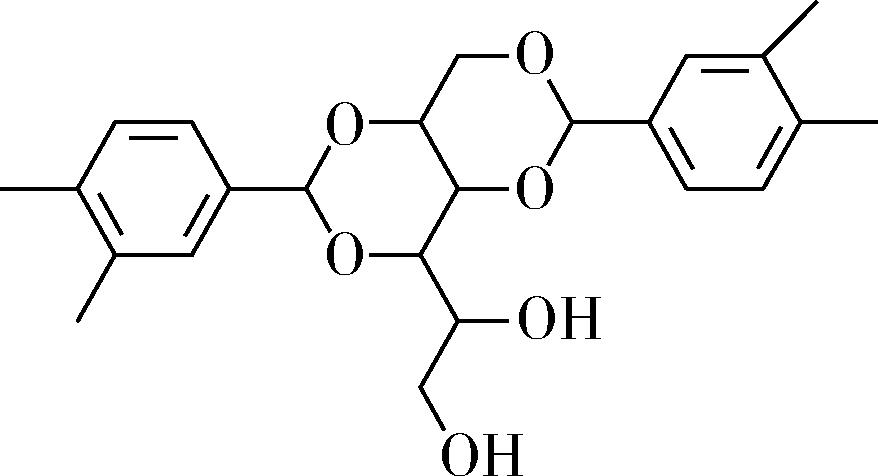

| 山梨醇成核剂 |  | [ |

| 稀土成核剂 | La+3Ca2+P m X n Q x | [ |

| 酰胺基成核剂 |  | [ |

| 1 | Song G H, Tan D Q. Atomic layer deposition for polypropylene film engineering⁃a review[J]. Macromolecular Materials and Engineering, 2020, 305(6).202000127 |

| 2 | Himma N F, Anisah S, Prasetya N, et al. Advances in preparation, modification, and application of polypropylene membrane[J]. Journal of Polymer Engineering, 2016, 36(4): 329⁃362. |

| 3 | Xu J T, Guan F X, Yasin T, et al. Isothermal crystallization of metallocene⁃based polypropylenes with different isotacticity and regioregularity[J]. Journal of Applied Polymer Science, 2003, 90(12): 3 215⁃3 221. |

| 4 | Ma G Q, Liu Y P, Wei S X, et al. Surface modification of polypropylene by ethylene plasma and its induced beta⁃form in polypropylene[J]. Chinese Journal of Polymer Science, 2015, 33(5): 669⁃673. |

| 5 | Broda J, Baczek M, Fabia J, et al. Nucleating agents based on graphene and graphene oxide for crystallization of the beta⁃form of isotactic polypropylene[J]. Journal of Materials Science, 2020, 55(4): 1 436⁃1 450. |

| 6 | Iwasaki S, Yamazaki A, Hatakeyama K, et al. Preparation of microporous film composed of polypropylene containing beta⁃form nucleating agent[J]. Nihon Reoroji Gakkaishi, 2022, 50(2): 171⁃179. |

| 7 | Liu Z Z, Zheng G Q, Shi H H, et al. Simultaneous enhancement of toughness and strength of stretched iPP film via tiny amount of beta⁃nucleating agent under "Shear⁃free" melt⁃extrusion[J]. Chinese Journal of Polymer Science, 2021, 39(11): 1 481⁃1 488. |

| 8 | Libster D, Aserin A, Garti N. Advanced nucleating agents for polypropylene[J]. Polymers for Advanced Technologies, 2007, 18(9): 685⁃695. |

| 9 | 全燕南. 全同立构聚丙烯诱导结晶行为研究[D]. 北京:北京化工大学, 2013. |

| 10 | 任玉方. α成核剂和工艺条件对聚丙烯注塑件结晶与力学性能的影响[D].郑州:郑州大学, 2014. |

| 11 | 吕 品, 王长松. 不同成核剂对聚丙烯力学性能的影响[J]. 辽宁化工, 2018, 47(9): 858⁃861. |

| LV P, WANG C S. Effect of different nucleating agents on the mechanical properties of polypropylene[J]. Liaoning Chemical Industry, 2018, 47(9): 858⁃861. | |

| 12 | 刘可华. 聚丙烯β晶成核剂庚二酸锌的制备及其成核效应[D]. 上海:华东理工大学, 2018. |

| 13 | 任 娜. 基于NA⁃11的复配成核剂对聚丙烯性能的影响[D]. 天津:河北工业大学, 2016. |

| 14 | 丁 律. 液晶高分子诱导等规聚丙烯的结晶熔融行为及力学性能研究[D]. 常州:常州大学, 2018. |

| 15 | 周真真, 李慧慧, 闫寿科. 同聚丙烯α晶向β晶生长转变研究[C]. 2015年全国高分子学术论文报告会, 2015: 120. |

| 16 | 石尧麒. 基于α/β复合成核剂成核聚丙烯结晶过程调控及成核机理的研究[D]. 上海:华东理工大学, 2012. |

| 17 | 胡成浪, 张才亮, 盛仲夷. 成核剂改性共聚聚丙烯的研究进展[J]. 塑料助剂, 2020(2): 1⁃6. |

| HU C L, ZHANG C L, SHENG Z Y,et al. Research progress of nucleating agent modified copolymer polypropylene[J]. Plastic Additives, 2020(2): 1⁃6. | |

| 18 | Nagarajan K, Levon K, Myerson A S. Nucleating agents in polypropylene[J]. Journal of Thermal Analysis and Calorimetry, 2000, 59(1⁃2): 497⁃508. |

| 19 | 周群华, 杨立群, 时惠敏, 等. 聚丙烯β晶成核剂及其对iPP结晶行为的影响[J]. 高分子通报, 2021(8): 9⁃18. |

| ZHOU Q H, YANG L Q, SHI H M,et al. Polypropylene β crystalline nucleating agent and its effect on the crystallization behavior of ipp[J].Polymer Bulletin, 2021(8): 9⁃18. | |

| 20 | 郭俊强, 李 倩, 罗 志, 等. 聚丙烯β成核剂的研究进展[J]. 高分子通报, 2022(7): 11⁃21. |

| GUO J Q, LI Q, LUO Z,et al. Research progress on polypropy⁃lene β nucleating agent[J].Polymer Bulletin, 2022(7): 11⁃21. | |

| 21 | Zhang P Y, Liu X X, Li Y Q. Influence of beta⁃nucleating agent on the mechanics and crystallization characteristics of polypropylene[J]. Materials Science and Engineering a⁃Structural Materials Pro⁃perties Microstructure and Processing, 2006, 434(1⁃2): 310⁃313. |

| 22 | Horvath F, Bihari L, Menyhard A. Effect of N,N'⁃Dicyclohexyl terephthalic dihydrazide on the crystallization and properties of isotactic polypropylene[J]. Periodica Polytechnica⁃Chemical Engineering, 2022, 66(2): 182⁃191. |

| 23 | Xin Z, Zhang X, Xin S, et al. Cage⁃type polyhedral oligomeric siloxane nucleating agent useful for modified polypropylene, prepared from cage silsesquioxane and metal oxide or hydroxide: CN112159594⁃A[P].2021⁃01⁃01. |

| 24 | Broda J, Fabia J, Baczek M, et al. Supramolecular structure of polypropylene fibers extruded with addition of functionalized reduced graphene oxide[J]. Polymers, 2020, 12(4):910. |

| 25 | Xiang J, Li Y, Zhong J R, et al. Influence of chemical structures of bisamide nucleating agents on the crystallization behavior and properties of isotactic polypropylene[J]. Journal of Thermal Analysis and Calorimetry, 2023, 148(6): 2 417⁃2 428. |

| 26 | 何 满. 稀土成核剂与氧化石墨烯的协同效应对等规聚丙烯结晶行为的影响[D].郑州:郑州大学, 2021. |

| 27 | Manias E, Touny A, Wu L, et al. Polypropylene/montmorillonite nanocomposites. review of the synthetic routes and materials properties[J]. Chemistry of Materials, 2001, 13(10): 3 516⁃3 523. |

| 28 | Mo Z, Zhao W. Polypropylene composite additive used for modifying copolymerized polypropylene, comprises nucleating agent comprising 2,2'⁃methylene-bis(4,6⁃di⁃tert⁃butylphenyl)sodium phosphate or hydroxyaluminum tert-butylbenzoate, and nucleating agent carrier comprising nano hydrotalcite: CN115710381⁃A[P].2023⁃02⁃24. |

| 29 | Luo Z, Li Q, Wang L, et al. Nano-composite nucleating agent useful in polypropylene, and in preparing modified polypropylene, comprises nano⁃zinc oxide, and cyclohexane⁃1,2⁃dicarboxylate compound: CN113773550⁃A; CN113773550⁃B[P].2021⁃12⁃10. |

| 30 | Shen L, Chen Z B, Kou J X. High⁃quality modification of general polypropylene by the synergistic effect of zinc adipate, hydrotalcite, and polypropylene (SP179)[J]. Journal of Applied Polymer Science, 2023, 140(14):53 704. |

| 31 | Qin W, Xin Z, Pan C M, et al. In situ formation of zinc phthalate as a highly dispersed beta⁃nucleating agent for mechanically strengthened isotactic polypropylene[J]. Chemical Engineering Journal, 2019, 358: 1 243⁃1 252. |

| 32 | Feng L, Gu X, Zhang C, et al. Polypropylene toughening macromolecular beta nucleating agent useful for preparing polypropylene products, prepared by e.g. melt⁃extruding polypropylene, initiator and hydroxy⁃containing aromatic monomer: CN113461862⁃A; CN113461862⁃B[P].2022⁃06⁃10. |

| 33 | Wu Y, Lai F, Li J, et al. Beta crystal form compound nucleating agent used in polypropylene, comprises aryl amide nucleating agent and imidazolyl bis (trifluoromethanesulfonyl) imide salt ion liquid: CN114085425⁃A; CN114085425⁃B[P].2023⁃03⁃28. |

| 34 | Balkaev D, Neklyudov V, Starshinova V, et al. Novel nucleating agents for polypropylene and modifier of its physical⁃mechanical properties[J]. Materials Today Communications, 2021, 26:101783. |

| 35 | Gajzlerova L, Navratilova J, Ryzi A, et al. Joint effects of long⁃chain branching and specific nucleation on morphology and thermal properties of polypropylene blends[J]. Express Polymer Letters, 2020, 14(10): 952⁃961. |

| 36 | 李庆华, 常海波, 李润明, 等. 高分子物理实验课程改革研究进展[J]. 广州化工, 2018, 46(21): 139⁃141. |

| LI Q H, CHANG H B, LI R M,et al. Research progress on polymer physics laboratory curriculum reform[J].Guangzhou Chemical, 2018, 46(21): 139⁃141. | |

| 37 | 程亨伦. β成核剂与纳米二氧化硅协同增韧改性聚丙烯的制备及性能[D]. 杭州:浙江大学, 2021. |

| 38 | Paulik C, Tranninger C, Wang J B, et al. Catalyst type effects on structure/property relations of polypropylene random copolymers[J]. Macromolecular Chemistry and Physics, 2021, 222(23): 2100302. |

| 39 | Ramazanov M A, Shirinova H A, Nuriyeva S G, et al. Structure and optic properties of the nanocomposites based on polypropylene and amorphous silica nanoparticles[J]. Journal of Thermoplastic Composite Materials, 2023, 36(4): 1 762⁃1 774. |

| 40 | Ren Z. New polypropylene nucleating agent useful in melt extrusion of polypropylene resin, and prepared by e.g. neutralizing acrylic acid and sodium hydroxide solution, dropping glycidyl methacrylate and phthalic anhydride and reacting: CN112812218⁃A; CN112812218⁃B[P].2021⁃05⁃18. |

| 41 | Yi Z, Yi H. Nucleating agent master batch used for preparing polypropylene with high transparency, comprises polypropylene resin, organic enoate, and diol dienoic acid diester: CN114195941⁃A[P].2022⁃03⁃18. |

| 42 | Xiao M, Zhang M D, Liu H L, et al. Dielectric property and breakdown strength performance of long⁃chain branched polypropylene for metallized film capacitors[J]. Materials, 2022, 15(9): 3 071. |

| 43 | He X Z, Seri P, Rytoluoto I, et al. Dielectric performance of silica⁃filled nanocomposites based on miscible (PP/PP⁃HI) and immiscible (PP/EOC) polymer blends[J]. Ieee Access, 2021, 9: 15 847⁃15 859. |

| [1] | SONG Wenlan, SONG Wenxing, LI Bing, LIU Qian, OUYANG Yuge, TIAN Huafeng, GUO Gaiping. Research progress in BOPP films of capacitors for enhancing dielectric and electric energy storage [J]. China Plastics, 2024, 38(7): 138-143. |

| [2] | HU Yongxiang, XIE Jiling, LI Weiming, ZHANG Lu, TANG Xianggang, LYU Yitong, SHEN Hongwang, JU Guannan. Effect of maleic anhydride graft⁃modified ground tire rubber on properties of poly(lactic acid) [J]. China Plastics, 2024, 38(7): 20-24. |

| [3] | LIU Chaofan, LIAO Shenglong, ZHONG Shuying, LIN Ying. Synthesis and properties of responsive hyaluronic acid micelles [J]. China Plastics, 2024, 38(7): 25-31. |

| [4] | WANG Jie, XIN Dehua, LI Hui, JIANG Hongshi, ZHOU Hongfu, ZHAO Jianguo. Effect of hybrid reinforcement of nanoclay and silica on properties of poly(lactic acid) [J]. China Plastics, 2024, 38(7): 43-48. |

| [5] | SUN Fangfang, SONG Yunyun. Synthesis of N⁃phenylmaleimide copolymer and its heat⁃resistant modification effect on PVC resin [J]. China Plastics, 2024, 38(7): 49-54. |

| [6] | SHEN Qiangfeng, LYU Mingfu, XU Yaohui. Study on autoclave foaming properties of metallocene polypropylene [J]. China Plastics, 2024, 38(7): 55-61. |

| [7] | WANG Shen, LIU Xuanbo, ZHANG Yanfang, JIA Xuefei, ZHU Guixiang, ZHANG Longgui. Research progress in biodegradable nonwoven materials [J]. China Plastics, 2024, 38(7): 86-92. |

| [8] | LIU Ying, SUN Hao, YANG Yong, JIANG Kaiyu, YU Tongmin, MA Sai, ZHU Tieli. Effect of ultrasonic vibration on mechanical properties of injection⁃molded parts of glass⁃fiber⁃reinforced polyamide 6 [J]. China Plastics, 2024, 38(7): 9-14. |

| [9] | NIU He, LYU Mingfu, ZHANG Zongyin, XU Yaohui, XU Wei, ZHANG Shijun, GUO Peng. Application progress in additives in polyglycolic acid processing [J]. China Plastics, 2024, 38(6): 105-110. |

| [10] | YANG Lian, JIANG Jing, JIA Caiyi, XIE Yuehan, WANG Xiaofeng, LI Qian. Preparation of polyamide 6 microfiber reinforced polypropylene composite and its property of chemical foam injection molding [J]. China Plastics, 2024, 38(6): 12-18. |

| [11] | LIU Shuai, ZHAO Zihao, YU Ying, YANG Jiaxin, ZHANG Yang. Preparation and dielectric properties of core⁃shell structural carbon⁃fiber felt@polyaniline composite [J]. China Plastics, 2024, 38(6): 25-30. |

| [12] | ZHOU Ziyi, WANG Yangyang, SUN Tao, JIANG Wei, DONG Tungalag, YUN Xunyan. Properties and applications of poly(butylene adipate⁃co⁃terephthalate)⁃based self⁃regulating gas film [J]. China Plastics, 2024, 38(6): 31-38. |

| [13] | HE Songdi, LI Guanyu, CHEN Jiamin, WANG Chenyi, XU Jianping. Preparation and applications of OBC/WPS⁃reinforced master batch for EPDM [J]. China Plastics, 2024, 38(6): 39-43. |

| [14] | SU Yuhang, ZHOU Yuhong, LIN Yuanzhi, MAO Jianquan, WANG Yongxiang, LIU Xiang, YU Li, KE Junmu. Effect of elastomer on the properties of glue⁃free PP/EVA composite films [J]. China Plastics, 2024, 38(6): 44-50. |

| [15] | DONG Yapeng, ZHAO Tianjiao, WANG Meizhen, CUI Wenju, LIN Fuhua, WANG Bo. Effect of long chain fatty acid sodium/sodium arylamide fatty acid compounding nucleating agent on properties of polypropylene [J]. China Plastics, 2024, 38(6): 60-65. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||