京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2

《中国塑料》编辑部 ©2008-2024 版权所有

地址:北京市海淀区阜成路11号 邮编:100048

编辑部:010-68985541 联系信箱:cp@plaschina.com.cn

广告部/发行部:010-68985253 本系统由北京玛格泰克科技发展有限公司设计开发

中国塑料 ›› 2022, Vol. 36 ›› Issue (1): 32-41.DOI: 10.19491/j.issn.1001-9278.2022.01.005

王启扬1, 杨肖1, 陈吉奂2, 何悦星3, 杨冬梅1, 胡泊洋4, 郭红4( ), 李保安4

), 李保安4

收稿日期:2021-07-05

出版日期:2022-01-26

发布日期:2022-01-21

基金资助:

WANG Qiyang1, YANG Xiao1, CHEN Jihuan2, HE Yuexing3, YANG Dongmei1, HU Boyang4, GUO Hong4( ), LI Baoan4

), LI Baoan4

Received:2021-07-05

Online:2022-01-26

Published:2022-01-21

Contact:

GUO Hong

E-mail:guohong1218@163.com

摘要:

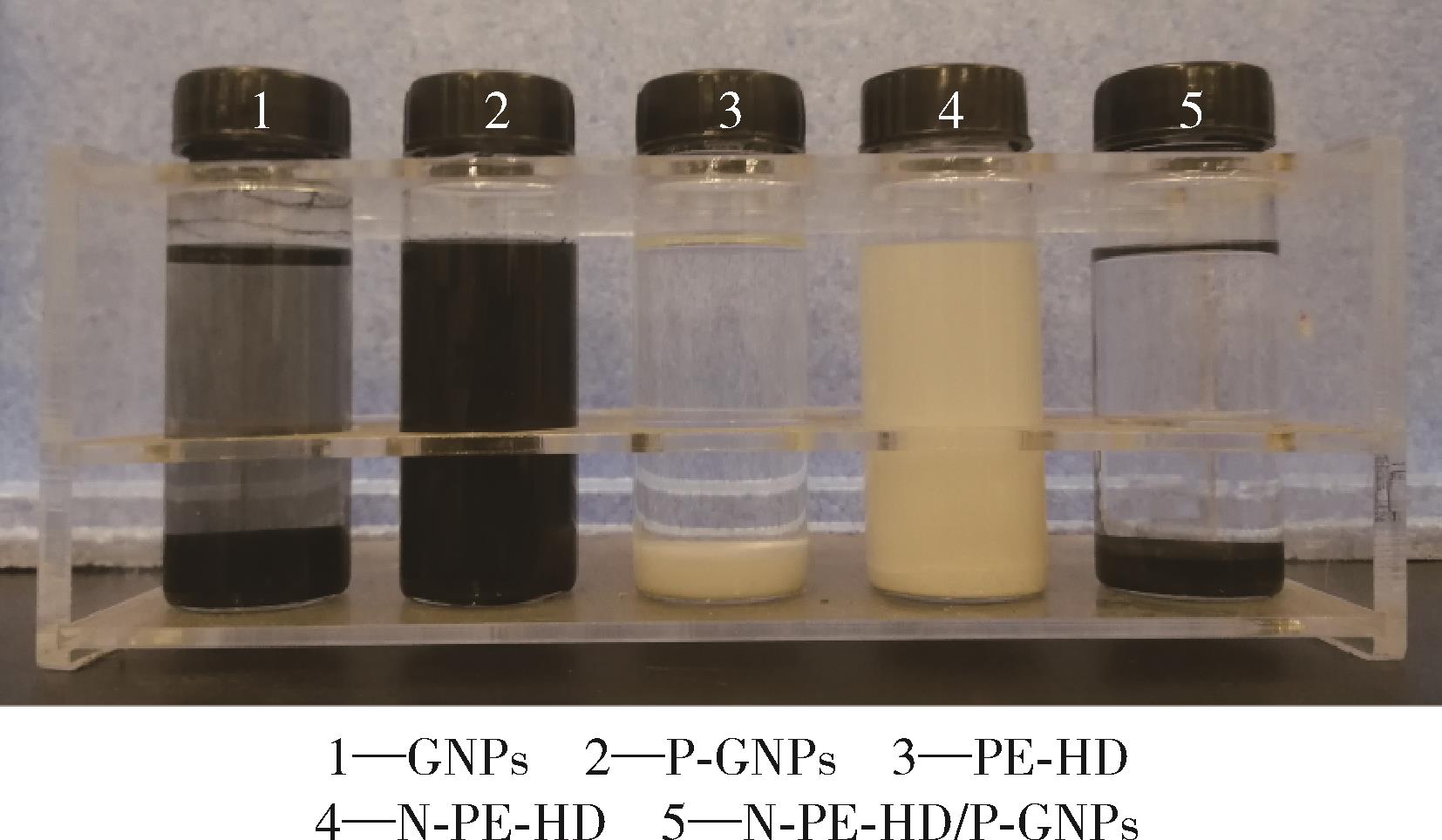

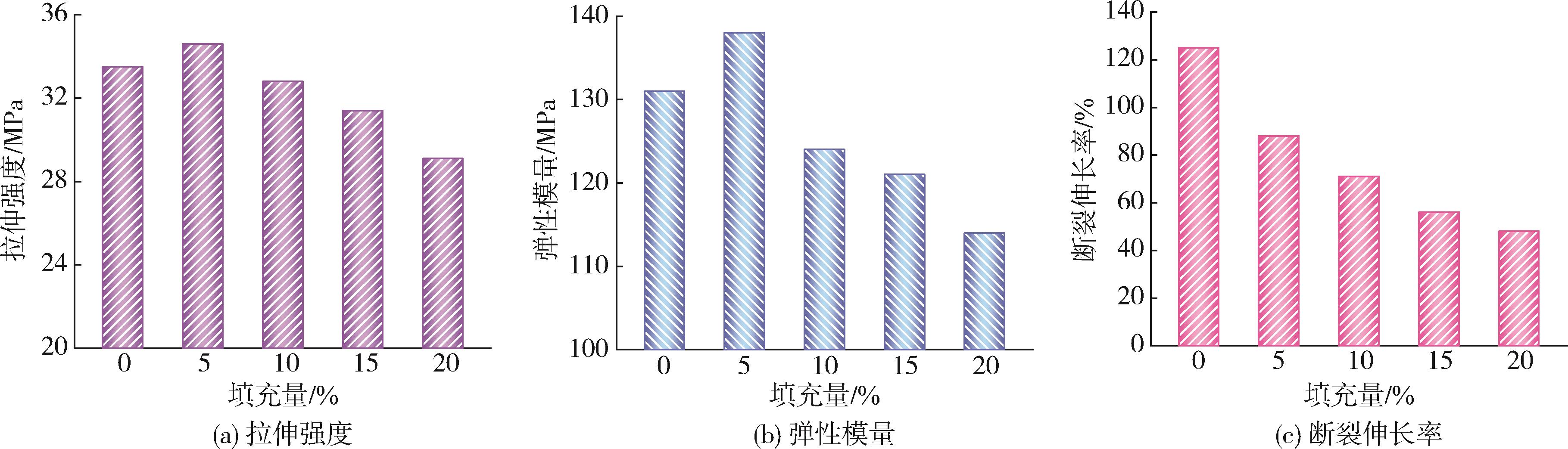

采用聚二烯丙基二甲基氯化铵改性石墨烯纳米片、聚苯乙烯磺酸钠改性聚乙烯颗粒,通过静电诱导自组装和热压成型工艺制备了具有蜂窝状石墨烯框架的聚乙烯复合材料(N?PE?HD/P?GNPs)。利用红外光谱仪、扫描电子显微镜、导热系数测试仪、电子拉力试验机对复合材料的改性状态、微观形貌、导热性能和力学性能等进行分析表征。结果表明,嵌入式连续石墨烯框架能够有效提升复合材料的导热性能,当P?GNPs含量为20 %(质量分数,下同)时,N?PE?HD/P?GNPs体系的热导率达到2.51 W/(m·K),相对于PE?HD/GNPs体系[1.71W/(m·K)]和纯PE?HD基体[0.44 W/(m·K)]分别提高1.47和5.70倍;同时复合材料可保持较好的力学性能和热稳定性,其拉伸强度、弹性模量、断裂伸长率分别为29.1 MPa、114 MPa、48 %,而熔点和热分解温度分别为135.2 ℃和458 ℃,比纯PE?HD提高了2 ℃和11 ℃。

中图分类号:

王启扬, 杨肖, 陈吉奂, 何悦星, 杨冬梅, 胡泊洋, 郭红, 李保安. 双隔离结构聚乙烯/石墨烯导热复合材料的研究[J]. 中国塑料, 2022, 36(1): 32-41.

WANG Qiyang, YANG Xiao, CHEN Jihuan, HE Yuexing, YANG Dongmei, HU Boyang, GUO Hong, LI Baoan. Study on double⁃segregated polyethylene/graphene composites with high thermal conductivity[J]. China Plastics, 2022, 36(1): 32-41.

| 填料 | 聚合物 | 填充量/% | 热导率/W·(m·K)-1 | 年份 | 参考文献 |

|---|---|---|---|---|---|

| 石墨烯 | 氰酸酯 | 20.0 | 0.339 | 2018 | [ |

| 还原氧化石墨烯 | 环氧树脂 | 3.0 | 0.670 | 2019 | [ |

| 改性石墨烯 | 聚偏氟乙烯 | 16.0 | 0.679 | 2019 | [ |

| 石墨烯 | PE?HD | 10.0 | 1.130 | 2019 | [ |

| 石墨烯/碳纳米管 | 氯乙烯/氟乙烯共聚物 | 0.3 | 1.300 | 2019 | [ |

| 碳纳米管/石墨烯 | 聚偏氟乙烯 | 10.0 | 1.460 | 2019 | [ |

| 定向石墨烯管 | 聚二甲基硅氧烷 | 4.5 | 1.700 | 2019 | [ |

| 石墨烯 | 环氧树脂 | 20.0 | 1.730 | 2019 | [ |

| 石墨烯凝胶 | 环氧树脂 | 1.11 | 2.690 | 2019 | [ |

| 石墨烯/氮化硼 | 环氧树脂 | 5.0 | 0.649 | 2020 | [ |

| 石墨烯/碳化硅 | 环氧树脂 | 3.5 | 0.708 | 2020 | [ |

| 石墨烯 | 聚二甲基硅氧烷/聚偏氟乙烯 | 15.0 | 2.180 | 2020 | [ |

| 石墨烯 | 酚酞聚芳醚酮环氧树脂 | 0.5 | 0.371 | 2021 | [ |

| 石墨烯/氮化硼 | 聚丙烯 | 39.0 | 1.320 | 2021 | [ |

| 改性石墨烯 | PE?HD | 20.0 | 2.510 | 2022 | 本文 |

| 填料 | 聚合物 | 填充量/% | 热导率/W·(m·K)-1 | 年份 | 参考文献 |

|---|---|---|---|---|---|

| 石墨烯 | 氰酸酯 | 20.0 | 0.339 | 2018 | [ |

| 还原氧化石墨烯 | 环氧树脂 | 3.0 | 0.670 | 2019 | [ |

| 改性石墨烯 | 聚偏氟乙烯 | 16.0 | 0.679 | 2019 | [ |

| 石墨烯 | PE?HD | 10.0 | 1.130 | 2019 | [ |

| 石墨烯/碳纳米管 | 氯乙烯/氟乙烯共聚物 | 0.3 | 1.300 | 2019 | [ |

| 碳纳米管/石墨烯 | 聚偏氟乙烯 | 10.0 | 1.460 | 2019 | [ |

| 定向石墨烯管 | 聚二甲基硅氧烷 | 4.5 | 1.700 | 2019 | [ |

| 石墨烯 | 环氧树脂 | 20.0 | 1.730 | 2019 | [ |

| 石墨烯凝胶 | 环氧树脂 | 1.11 | 2.690 | 2019 | [ |

| 石墨烯/氮化硼 | 环氧树脂 | 5.0 | 0.649 | 2020 | [ |

| 石墨烯/碳化硅 | 环氧树脂 | 3.5 | 0.708 | 2020 | [ |

| 石墨烯 | 聚二甲基硅氧烷/聚偏氟乙烯 | 15.0 | 2.180 | 2020 | [ |

| 石墨烯 | 酚酞聚芳醚酮环氧树脂 | 0.5 | 0.371 | 2021 | [ |

| 石墨烯/氮化硼 | 聚丙烯 | 39.0 | 1.320 | 2021 | [ |

| 改性石墨烯 | PE?HD | 20.0 | 2.510 | 2022 | 本文 |

| 1 | DU C Y, LI M, CAO M, et al. Mussel⁃inspired and magnetic co⁃functionalization of hexagonal boron nitride in poly(vinylidene fluoride) composites toward enhanced thermal and mechanical performance for heat exchangers[J]. ACS Applied Materials & Interfaces, 2018, 10(40):34 674⁃34 682. |

| 2 | KURUNERU S, VAFAI K, SAURET E, et al. Application of porous metal foam heat exchangers and the implications of particulate fouling for energy⁃intensive industries[J]. Chemical Engineering Science, 2020, 228:115968. |

| 3 | KARKRI, MUSTAPHA, LACHHEB, et al. Improvement of thermal conductivity of paraffin by adding expanded graphite[J]. Journal ofosite Materials, 2016, 50(19):2 589⁃2 601. |

| 4 | MIKULIONOK I O. Use of polymer materials in heat exchangers (review of patents)[J]. Chemical and Petroleum Engineering, 2019, 55(16):687⁃695. |

| 5 | CHEN H, GINZBURG V V, YANG J, et al. Thermal conductivity of polymer⁃based composites: fundamentals and applications[J]. Progress in Polymer Science, 2016,59:41⁃85. |

| 6 | CPFA B, LYY B, JIE Y B, et al. Recent advances in polymer⁃based thermal interface materials for thermal management: A mini⁃review[J]. Composites Communications, 2020, 22:100528. |

| 7 | ZHANG F, FENG Y Y, FENG W. Three⁃dimensional interconnected networks for thermally conductive polymer composites: design, preparation, properties, and mechanisms[J]. Materials Science and Engineering: R: Reports,2020, 142:100580. |

| 8 | FANG H, BAI S L, PING W C. Microstructure enginee⁃ring of graphene towards highly thermal conductive compo⁃sites[J]. Composites Part A: Applied ence and Manufacturing, 2018, 112:216⁃238. |

| 9 | IQBAL M Z, ABDALA A A, MITTAL V, et al. Processable conductive graphene/polyethylene nanocomposites: effects of graphene dispersion and polyethylene blending with oxidized polyethylene on rheology and microstructure[J]. Polymer, 2016, 98:143⁃155. |

| 10 | XUE P, ZHANG H B, LI X, et al. Thermally conductive and electrically insulating epoxy nanocomposites with silica⁃coated graphene[J]. Rsc Advances, 2014, 4(29):15 297⁃15 303. |

| 11 | KIM H S, JANG J, LEE H, et al. Thermal management in polymer composites: a review of physical and structural parameters[J]. Advanced Engineering Materials, 2018, 20(10):1800204. |

| 12 | NIETO A, DUA R, ZHANG C, et al. Three dimensio⁃nal graphene foam/polymer hybrid as a high strength biocompatible scaffold[J]. Advanced Functional Materials, 2015, 25(25):3 916⁃3 924. |

| 13 | JING Y, ZHANG E, LI X, et al. Cellulose/graphene aerogel supported phase change composites with high thermal conductivity and good shape stability for thermal energy storage[J]. Carbon, 2016, 98:50⁃57. |

| 14 | AN F, LI X, MIN P, et al. Vertically aligned high⁃quality graphene foams for anisotropically conductive polymer composites with ultrahigh through⁃plane thermal conductivities[J]. ACS Applied Materials & Interfaces, 2018,10:17 383⁃17 392. |

| 15 | CAO X, YIN Z, HUA Z. Three⁃dimensional graphene materials: preparation, structures and application in supercapacitors[J]. Energy and Environmental Science, 2014, 7(6):1 850⁃1 865. |

| 16 | ZHANG W, KONG Q.Q, TAO Z, et al. 3D thermally cross linked graphene aerogel enhanced silicone rubber elastomer as thermal interface material[J]. Advanced Materials Interfaces, 2019, 6(12):1900147. |

| 17 | CHEN Z, REN W, GAO L, et al. Three⁃dimensional flexible and conductive interconnected graphene networks grown by chemical vapour deposition[J]. Nature Materials, 2011, 10(6):424⁃428. |

| 18 | JUNG I, JANG H Y, PARK S. Direct growth of graphene nanomesh using a au nano⁃network as a metal catalyst via chemical vapor deposition[J]. Applied Physics Letters, 2013, 103(2):023105. |

| 19 | HUANG H, BI H, ZHOU M, et al. A three⁃dimensional elastic macroscopic graphene network for thermal management application[J]. Journal of Materials Chemistry. A, 2014, 43:18 215⁃18 218. |

| 20 | LIN Y, CHEN J, JIANG P, et al. Wood annual ring structured elastomer composites with high thermal conduction enhancement efficiency[J]. Chemical Engineering Journal, 2020, 389:123467. |

| 21 | QIN M, XU Y, CAO R, et al. Efficiently controlling the 3D thermal conductivity of a polymer nanocomposite via a hyperelastic double⁃continuous network of graphene and sponge[J]. Advanced functional materials, 2018, 28(45):1805053. |

| 22 | 于 慧, 高宝玉, 邵秀梅,等. 二甲基二烯丙基氯化铵聚合物的红外光谱研究[J]. 山东大学学报(理学版), 2001(3):330⁃335. |

| YU H, GAO B Y, SHAO X M, et al. Study on the dimethyldiallyammomium chloride by infrared spectrum[J]. Journal of Shandong University, 2001(3):330⁃335. | |

| 23 | 廖凯荣. 超高分子量聚乙烯的红外光谱的特性研究[J]. 高等学校化学学报, 1993(12):1 748⁃1 751. |

| LIAO K R. Studies on the infrared spectral behavior of ultra⁃high molecular weight polyethylene[J]. Chemical Journal of Chinese Universities, 1993(12):1 748⁃1 751. | |

| 24 | 杨南煌, 谢德明, 陈 英. 溶液聚合法制备交联聚苯乙烯磺酸钠[J]. 暨南大学学报(自然科学与医学版), 2006,27:724⁃728. |

| YANG N H, XIE D M, CHEN Y. Preparation and pro⁃perties of cross⁃linked sodium polystyrene sulfonate by solution polymerization[J]. Journal of Jinan University(Natural Science), 2006,27:724⁃728. | |

| 25 | 高 锋, 白 刚, 肖 伟,等. 石墨烯微片/氰酸酯多功能树脂基体研究[J]. 玻璃钢/复合材料, 2019(5):83⁃88. |

| GAO F, BAI G, XIAO W, et al. Study on multifunctional GNPs/cyanate ester resin matrix[J]. FRP/composite materials, 2019(5):83⁃88. | |

| 26 | OH H, KIM K, RYU S, et al. Enhancement of thermal conductivity of polymethyl methacrylate⁃coated graphene/epoxy composites using admicellar polymerization with different ionic surfactants[J]. Composites Part A: Applied Science and Manufacturing, 2019, 116:206⁃215. |

| 27 | LIN B, LI Z T, YANG Y, et al. Enhanced dielectric permittivity in surface⁃modified graphene/PVDF composites prepared by an electrospinning⁃hot pressing method[J]. Compos Sci Technol, 2019, 172:58⁃65. |

| 28 | 杨启容, 宫薛菲, 张正林,等. 石墨烯填充对不同聚合物导热性能和热稳定性的影响[J]. 功能材料, 2019, 50(7):7 001⁃7 007. |

| YANG Q R, GONG X F, ZHANG Z L, et al. Influence of graphene filling on thermal conductivity and thermal stability of different polymers[J]. Functional Materials, 2019, 50(7):7 001⁃7 007. | |

| 29 | HE G, LI X, DAI Y, et al. Constructing bioinspired hierarchical structure in polymer based energetic composites with superior thermal conductivity[J]. Composites Part B⁃Engineering, 2019, 162:678⁃684. |

| 30 | GUO H, LIU J, WANG Q, et al. High thermal conductive poly(vinylidene fluoride)⁃based composites with well⁃dispersed carbon nanotubes/graphene three⁃dimensional network structure via reduced interfacial thermal resistance[J]. Compos Sci Technol, 2019, 181:107713. |

| 31 | ZHANG Y F, REN Y J, GUO H C, et al. Enhanced thermal properties of PDMS composites containing vertically aligned graphene tubes[J]. Appl Therm Eng, 2019, 150:840⁃848. |

| 32 | ZHANG Y, PARK S J. Imidazolium⁃optimized conductive interfaces in multilayer graphene nanoplatelet/epoxy composites for thermal management applications and electroactive devices[J]. Polymer, 2019, 168:53⁃60. |

| 33 | LI Y, WEI W, WANG Y, et al. Construction of highly aligned graphene⁃based aerogels and their epoxy compo⁃sites towards high thermal conductivity[J]. J Mater Chem C, 2019, 7(38):11 783⁃11 789. |

| 34 | REN J, LI Q, YAN L, et al. Enhanced thermal conductivity of epoxy composites by introducing graphene@boron nitride nanosheets hybrid nanoparticles[J]. Materials & Design, 2020, 191:108663. |

| 35 | HE J, WANG H, QU Q, et al. Three⁃dimensional network constructed by vertically oriented multilayer graphene and SiC nanowires for improving thermal conductivity and operating safety of epoxy composites with ultralow loading[J]. Composites Part A: Applied Science and Manufacturing, 2020, 139:106062 |

| 36 | HAN B, SONG J, HU T, et al. High thermal conductivity in polydimethylsiloxane composite with vertically oriented graphene nanosheets by liquid⁃phase exfoliation[J]. Chem Phys Lett, 2020, 743:137156. |

| 37 | 欧阳泽宇, 王珂珂, 饶 琼, 等. 石墨烯纳米片/(酚酞聚芳醚酮⁃环氧树脂) 双逾渗导热复合材料的制备和性能 [J]. 复合材料学报, 2021, 38(3):722⁃731. |

| OUYANG Z Y, WANG K K, RAO Q, et al. Preparation and properties of thermally conductive grapheme nanoplates/(polyetherketone cardo⁃epoxy) composites with double percolation structures[J]. Acta Materiae Compositae Sinica, 2021, 38(3):722⁃731. | |

| 38 | XU Z, CHEN Y, CHEN X, et al. Enhanced thermal conductivity and electrically insulating of polymer compo⁃sites[J]. J Mater Sci, 2020, 56(6):4 225⁃4 238. |

| [1] | 于昌永, 辛忠. 基于六氢邻苯二甲酸盐的α/β复合成核剂对聚丙烯性能的影响[J]. 中国塑料, 2022, 36(7): 121-128. |

| [2] | 李果, 朱惠豪, 马玉录, 王玉, 吉华建, 谢林生. 导热型微孔透气薄膜的制备及性能研究[J]. 中国塑料, 2022, 36(7): 14-20. |

| [3] | 冯冰涛, 王晓珂, 张信, 孙国华, 汪殿龙, 侯连龙, 马劲松. 连续碳纤维增强热塑性复合材料制备与应用研究进展[J]. 中国塑料, 2022, 36(7): 165-173. |

| [4] | 谭立钦, 刘伟区, 梁利岩, 王硕, 冯志强, 林家明. 含巯基聚硅氧烷改性环氧树脂的制备及性能[J]. 中国塑料, 2022, 36(7): 21-29. |

| [5] | 宋银宝, 杨建军, 李传敏. PDMS/SiC功能梯度复合材料性能与制造精度研究[J]. 中国塑料, 2022, 36(7): 30-36. |

| [6] | 徐杰, 钟进福, 童晓茜, 李广富, 付栋梁, 李城城. 端羧基修饰单宁酸/没食子酸环氧树脂复合材料的制备与性能研究[J]. 中国塑料, 2022, 36(7): 44-50. |

| [7] | 周舒毅, 朱敏, 刘忆颖, 曹舒惠, 蔡启轩, 聂慧, 张玉霞, 周洪福. 高分子止血材料研究进展[J]. 中国塑料, 2022, 36(7): 74-84. |

| [8] | 李凯泽, 辛勇. 改性碳纳米管增强热塑性聚氨酯复合材料的性能研究[J]. 中国塑料, 2022, 36(6): 1-5. |

| [9] | 吴雄杰, 朱东波, 孙江波, 高龙美, 储雨, 程劲松, 谢爱迪. 聚乙烯/纳米硫酸钙粉体复合软包装应用性能研究[J]. 中国塑料, 2022, 36(6): 10-15. |

| [10] | 雷育杰, 陈明焕, 王洁瑶, 陈旺治, 李磊. 回收聚乙烯的交联发泡及其产品性能研究[J]. 中国塑料, 2022, 36(6): 124-129. |

| [11] | 刘伟, 吴显, 陈小澄, 成晓琼, 张纯. 羧基化填料对聚乙烯醇/纳米纤维素水凝胶力学、导电和传感性能的影响[J]. 中国塑料, 2022, 36(6): 16-23. |

| [12] | 杨小龙, 陈文静, 李永青, 闫晓堃, 王修磊, 谢鹏程, 马秀清. 导电型聚合物/石墨烯复合材料的研究进展[J]. 中国塑料, 2022, 36(6): 165-173. |

| [13] | 张文才, 郝晓刚, 李萍, 林浩, 裴强, 丰功吉, 付兆华, 于小芳. 聚乙烯接枝马来酸酐含量对废旧聚乙烯改性沥青性能的影响[J]. 中国塑料, 2022, 36(6): 24-31. |

| [14] | 王帅, 张玉迪, 杨富凯, 徐新宇. 聚酰亚胺/多壁碳纳米管泡沫材料的制备及性能研究[J]. 中国塑料, 2022, 36(6): 39-45. |

| [15] | 祝景云, 衣惠君, 鄢薇, 李大伟. 合成膜专用聚乙烯树脂原料的研发[J]. 中国塑料, 2022, 36(6): 77-80. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2