京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2

《中国塑料》编辑部 ©2008-2024 版权所有

地址:北京市海淀区阜成路11号 邮编:100048

编辑部:010-68985541 联系信箱:cp@plaschina.com.cn

广告部/发行部:010-68985253 本系统由北京玛格泰克科技发展有限公司设计开发

中国塑料 ›› 2022, Vol. 36 ›› Issue (10): 46-53.DOI: 10.19491/j.issn.1001-9278.2022.10.007

翟前超1, 刘光远1, 王丰武2, 汪义辉2, 张忠洁3( ), 郑德宝2, 陈祥迎1(

), 郑德宝2, 陈祥迎1( )

)

收稿日期:2022-06-27

出版日期:2022-10-26

发布日期:2022-10-27

通讯作者:

张忠洁(1981-),女,副教授,研究方向为聚烯烃改性与粘接树脂,zhangzj16@ahut.edu.cn作者简介:第一联系人:地址:北京市海淀区阜成路11号《中国塑料》杂志社广告部

ZHAI Qianchao1, LIU Guangyuan1, WANG Fengwu2, WANG Yihui2, ZHANG Zhongjie3( ), ZHENG Debao2, CHEN Xiangying1(

), ZHENG Debao2, CHEN Xiangying1( )

)

Received:2022-06-27

Online:2022-10-26

Published:2022-10-27

Contact:

ZHANG Zhongjie, CHEN Xiangying

E-mail:zhangzj16@ahut.edu.cn;chenxy@hfut.edu.cn

摘要:

首先以二甲苯(PX)为溶剂,聚乙烯蜡(PEW)为接枝主链,过氧化苯甲酰(BPO)为引发剂,将马来酸酐(MAH)接枝到PEW上,制备PEW⁃g⁃MAH接枝料;其次,以丙酮为沉淀剂,使其析出沉淀;最后,对上述混液进行抽滤、干燥、研磨、筛分,得到PEW⁃g⁃MAH微粉。利用傅里叶变换红外光谱仪(FTIR)和激光衍射粒度分析仪(LDPA)对产物结构进行表征,通过附着力测试仪对产物进行附着力性能测定。通过考察单因素与设计正交试验,探究反应最佳的工艺条件。结果表明,当PEW的含量为10 g,此时MAH的最佳含量为0.6 g,最佳反应温度为110 °C,引发剂的最佳含量为0.2 g,最佳反应时间为4 h。该条件下,MAH的接枝效率最高,为58.57 %,接枝率为3.51 %,平均粒径为15.54 µm,附着力为0级。因此,该PEW⁃g⁃MAH微粉在粉末涂料中具有较好的应用潜力。

中图分类号:

翟前超, 刘光远, 王丰武, 汪义辉, 张忠洁, 郑德宝, 陈祥迎. 马来酸酐接枝聚乙烯蜡微粉的制备工艺及其在粉末涂料中的应用研究[J]. 中国塑料, 2022, 36(10): 46-53.

ZHAI Qianchao, LIU Guangyuan, WANG Fengwu, WANG Yihui, ZHANG Zhongjie, ZHENG Debao, CHEN Xiangying. Preparation process of PEW⁃g⁃MAH micropowders and their application in powder coatings[J]. China Plastics, 2022, 36(10): 46-53.

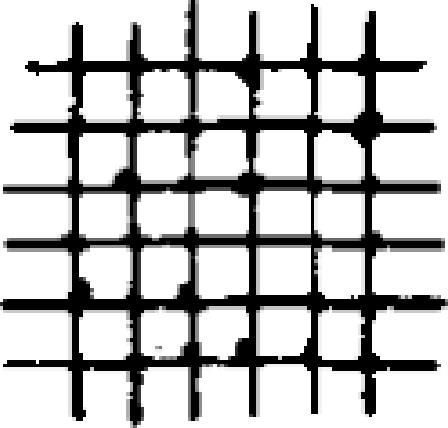

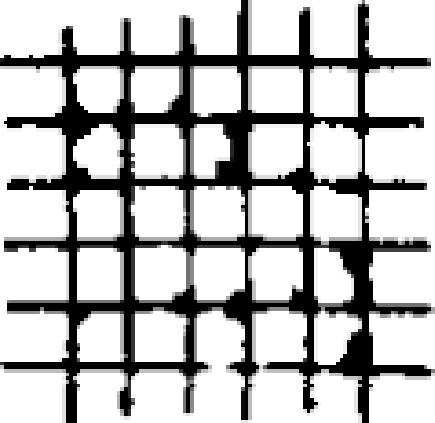

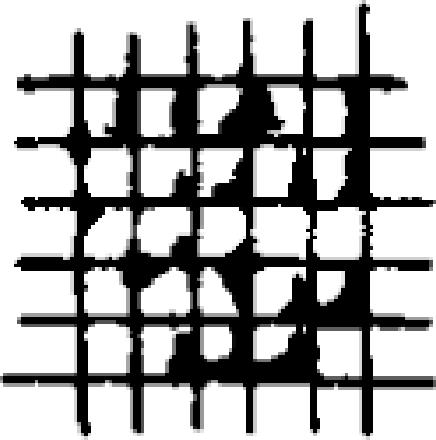

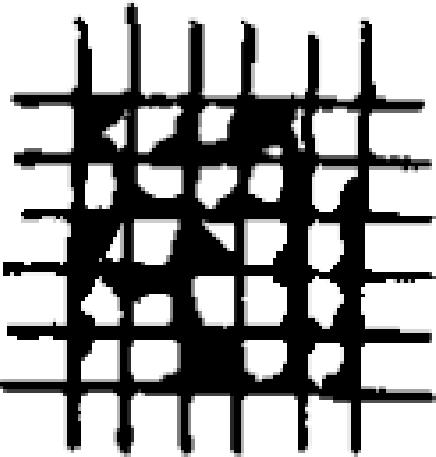

| 分级 | 说明 | 切割区表面外观 |

|---|---|---|

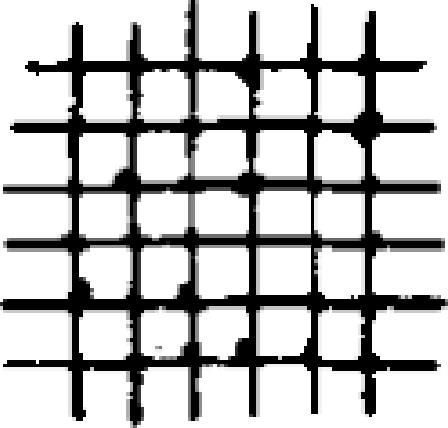

| 0 | 切割边缘完全平滑,无一处脱落。 | — |

| 1 | 在切口交叉处有少许图层脱落,但交叉切割面积受影响不能明显大于5 %。 |  |

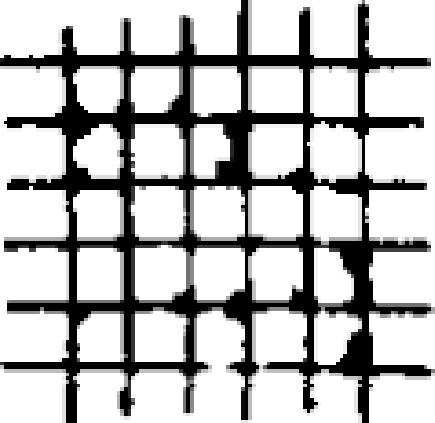

| 2 | 在切口交叉处和/或沿切口边缘有涂层脱落,受影响的交叉切割面积明显大于5 %,但不能明显大于15 %。 |  |

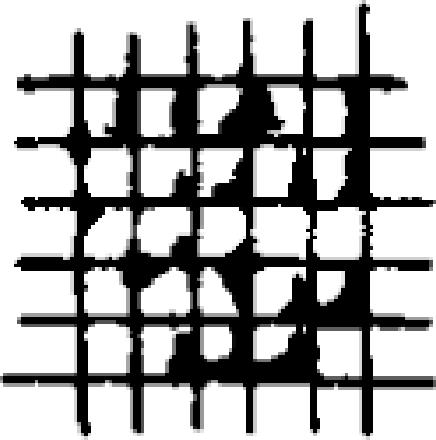

| 3 | 涂层沿切割边缘部分或全部以大碎片脱落,或在格子不同部位上部分或全部剥落,受影响的交叉切割面积明显大于 15 %,但不能明显大于 35 %。 |  |

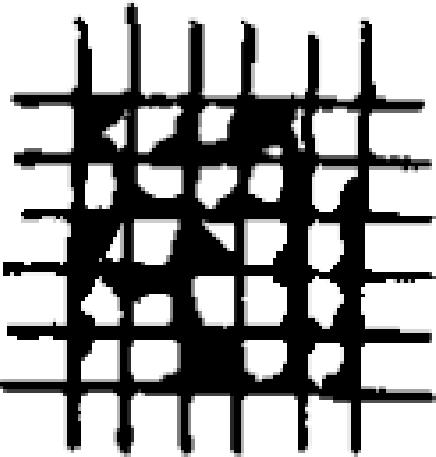

| 4 | 涂层沿切割边缘大碎片剥落,或一些方格部分或全部出现脱落。受影响交叉面积明显大于35 %,但不能明显大于65 %。 |  |

| 5 | 剥落程度超过4级。 | — |

| 分级 | 说明 | 切割区表面外观 |

|---|---|---|

| 0 | 切割边缘完全平滑,无一处脱落。 | — |

| 1 | 在切口交叉处有少许图层脱落,但交叉切割面积受影响不能明显大于5 %。 |  |

| 2 | 在切口交叉处和/或沿切口边缘有涂层脱落,受影响的交叉切割面积明显大于5 %,但不能明显大于15 %。 |  |

| 3 | 涂层沿切割边缘部分或全部以大碎片脱落,或在格子不同部位上部分或全部剥落,受影响的交叉切割面积明显大于 15 %,但不能明显大于 35 %。 |  |

| 4 | 涂层沿切割边缘大碎片剥落,或一些方格部分或全部出现脱落。受影响交叉面积明显大于35 %,但不能明显大于65 %。 |  |

| 5 | 剥落程度超过4级。 | — |

| 编号 | MAH含量(A)/g | 反应温度(B)/°C | 引发剂含量(C)/g | 反应时间(D)/h | MAH接枝效率/% |

|---|---|---|---|---|---|

| 1 | 1(0.4 g) | 1(100 ℃) | 1(0.10 g) | 1(4 h) | 40.11 |

| 2 | 1 | 2(110 ℃) | 2(0.15 g) | 2(5 h) | 53.02 |

| 3 | 1 | 3(120 ℃) | 3(0.20 g) | 3(6 h) | 45.58 |

| 4 | 2(0.6 g) | 1 | 2 | 3 | 42.15 |

| 5 | 2 | 2 | 3 | 1 | 58.57 |

| 6 | 2 | 3 | 1 | 2 | 47.03 |

| 7 | 3(0.8 g) | 1 | 3 | 2 | 38.11 |

| 8 | 3 | 2 | 1 | 3 | 45.03 |

| 9 | 3 | 3 | 2 | 1 | 40.32 |

| K1 | 138.71 | 120.37 | 132.17 | 139.00 | |

| K2 | 147.75 | 156.62 | 135.49 | 138.16 | |

| K3 | 123.46 | 132.93 | 142.26 | 132.76 | |

| k1 | 46.24 | 40.12 | 44.06 | 46.33 | |

| k2 | 49.25 | 52.21 | 45.16 | 46.05 | |

| k3 | 41.15 | 44.31 | 47.42 | 44.25 | |

| 极差R | 8.10 | 12.09 | 3.36 | 2.08 | |

| 因素主次 | B>A>C>D | ||||

| 优化方案 | B2A2C3D1 | ||||

| 编号 | MAH含量(A)/g | 反应温度(B)/°C | 引发剂含量(C)/g | 反应时间(D)/h | MAH接枝效率/% |

|---|---|---|---|---|---|

| 1 | 1(0.4 g) | 1(100 ℃) | 1(0.10 g) | 1(4 h) | 40.11 |

| 2 | 1 | 2(110 ℃) | 2(0.15 g) | 2(5 h) | 53.02 |

| 3 | 1 | 3(120 ℃) | 3(0.20 g) | 3(6 h) | 45.58 |

| 4 | 2(0.6 g) | 1 | 2 | 3 | 42.15 |

| 5 | 2 | 2 | 3 | 1 | 58.57 |

| 6 | 2 | 3 | 1 | 2 | 47.03 |

| 7 | 3(0.8 g) | 1 | 3 | 2 | 38.11 |

| 8 | 3 | 2 | 1 | 3 | 45.03 |

| 9 | 3 | 3 | 2 | 1 | 40.32 |

| K1 | 138.71 | 120.37 | 132.17 | 139.00 | |

| K2 | 147.75 | 156.62 | 135.49 | 138.16 | |

| K3 | 123.46 | 132.93 | 142.26 | 132.76 | |

| k1 | 46.24 | 40.12 | 44.06 | 46.33 | |

| k2 | 49.25 | 52.21 | 45.16 | 46.05 | |

| k3 | 41.15 | 44.31 | 47.42 | 44.25 | |

| 极差R | 8.10 | 12.09 | 3.36 | 2.08 | |

| 因素主次 | B>A>C>D | ||||

| 优化方案 | B2A2C3D1 | ||||

| 1 | 王文学. 粉末涂料中氧化聚乙烯蜡的应用性能研究[D]. 青岛:青岛科技大学, 2020. |

| 2 | 李 鑫. 副产物聚乙烯蜡的精制方法及其应用进展[J]. 石油化工, 2021, 50(8):841⁃847. |

| LI X. Refining method and application progress of by⁃product polyethylene wax[J]. Petrochemical, 2021, 50(8):841⁃847. | |

| 3 | Duarte L T, Silva E M P E, Branco J R T, et al. Production and characterization of thermally sprayed polyethylene terephthalate coatings[J]. Surface and Coatings Technology, 2004, 182(2):261⁃267. |

| 4 | 唐舫成, 汪加胜, 刘宝玉. 聚乙烯蜡的功能化研究进展[J]. 广东化工, 2013, 40(2):57⁃58. |

| TANG F C, WANG J S, LIU B Y. Rewiew of the functionalized polyethylene waxes[J]. Guangdong Chemical Industry, 2013, 40(2):57⁃58. | |

| 5 | Li W F, Yao Z H, Yao R X, et al. Polyethylene grafted polyether pentaerythritol mono⁃maleate to improve wettability of liquid on polyethylene films[J]. Polymer⁃Plastics Technology and Engineering, 2013, 52(6):603⁃606. |

| 6 | 李 颜, 杨国明, 李 燕. 马来酸酐接枝聚乙烯蜡的研制[J]. 精细石油化工, 2000, 6:18⁃20. |

| LI Y, YANG G M, LI Y. The study and preparation of maleicanhydrie grafted polyethylene wax[J]. Fine Petrochemicals, 2000, 6:18⁃20. | |

| 7 | 王 燕, 马沛岚. 聚乙烯蜡氧化及接枝改性研究[J]. 应用化工, 2009, 38(10):1 445⁃1 448. |

| WANG Y, MA P L. The study of polyethylene wax oxidation and graft modification[J]. Applied chemicals, 2009, 38(10):1 445⁃1 448. | |

| 8 | 涂琴丽, 周建萍, 许文英. 马来酸酐乳液固相接枝发泡聚丙烯泡沫的研究[J]. 塑料工业, 2013, 41(2):47⁃50. |

| TU Q L, ZHOU J P, XU W Y. Grafting of maleic anhydride onto EPP via solid⁃phase reaction[J]. Plastics Industry, 2013, 41(2):47⁃50. | |

| 9 | 朱德钦, 王剑峰, 张丽珍, 等. 溶液法聚乙烯蜡接枝马来酸酐的表征[J]. 化学工程与装备, 2007, 5:12⁃15. |

| ZHU D Q, WANG J F, ZHANG L Z. Characterization of polyethylene wax grafted with maleic anhydride by solution method[J]. Chemical Engineering and Equipment, 2007, 5:12⁃15. | |

| 10 | 中国国家标准化管理委员会. [S]. 上海: 中国标准出版社, 2016. |

| 11 | 金 谷, 江万权. 定量分析化学实验[M]. 合肥: 中国科学技术大学出版社, 2005:72⁃78. |

| 12 | 肖祥雄, 张兴华. 返滴法测定PP⁃g⁃MAH的接枝率[J]. 材料科学化工之友, 2007, 13(9):44⁃45. |

| XIAO X X, ZHANG X H. The grafting rate of PP⁃g⁃MAH was determined by the backdrop method[J]. Friends of Materials Science and Chemicals, 2007, 13(9):44⁃45. | |

| 13 | Murillo E A, Lopez B L. Study of the impact resistance of physically and dynamically vulcanized mixtures of PP/EPDM[J]. Macromolecular Symposia, 2006, 242(1):131⁃139. |

| 14 | Bettini S H P, Agnelli J A M. Grafting of maleic anhydride onto polypropylene by reactive processing. Ⅱ. effect of rotor speed and reacion time[J]. Journal of Applied Polymer Science, 1999,74(2):256⁃263. |

| 15 | 刘光远, 王丰武, 汪义辉, 等. 马来酸二丁酯接枝高密度聚乙烯及其在粘接树脂中的应用[J]. 高分子材料科学与工程, 2021, 37(12):17⁃23. |

| LIU G Y, WANG F W, WANG Y H, et al. Grafting high density polyethylene with Dibutyl maleate and its application in adhensive resin[J]. Polymer Materials Science and Engineering, 2021, 37(12):17⁃23. | |

| 16 | 王宗田. 附着力测定方法及其影响因素[J].现代涂料与涂装, 2020,13(8):22⁃24. |

| WANG Z T. Determination method and influence factors of adhesion[J]. Modern Coatings and Coatings, 2020,13(8):22⁃24. | |

| 17 | 郑德宝, 刘光远, 王丰武, 等. 马来酸酐接枝线型低密度聚乙烯及其在铝塑板中的应用[J]. 安徽化工, 2022, 48(1):71⁃75. |

| ZHENG D B, LIU G Y, WANG F W, et al. Study on continuous synthesis process of pentachloropyridine[J]. Anhui Chemical Industry, 2022, 48(1):71⁃75. | |

| 18 | Liu M Z, Liu Z M, Ding S L, et al. Graft copolymerization of oleic acid onto low⁃density polyethylene in the molten state[J]. Journal of Applied Polymer Science, 2003, 90(12):3 299⁃3 304. |

| 19 | 禄秋艺. 聚乙烯熔融接枝马来酸酐的制备与应用[D].贵阳:贵州大学, 2015. |

| 20 | Huang L, Zhou X, Wei C, et al. Maleic anhydride⁃grafted linear low⁃density polyethylene with low gel content[J]. Polymer Engineering and Science, 2009, 49(4):673⁃679. |

| 21 | 吴相国. 聚乙烯蜡接枝改性及其应用[D]. 青岛:青岛科技大学, 2021. |

| 22 | 王 影. 聚烯烃接枝马来酸酐结构与性能的研究[D]. 沈阳:沈阳化工大学, 2020. |

| 23 | 皮 沁, 王雁飞. 粉末涂料附着力性能探讨[J]. 涂层与防护, 2021, 42(9):12⁃18. |

| PI Q, WANG Y F. Discussion on adhesion of powder coatings[J]. Coating and protection, 2021, 42(9):12⁃18. |

| [1] | 刘光远, 翟前超, 王丰武, 汪义辉, 郑德宝, 陈祥迎, 张忠洁. 基于二元接枝单体制备PE⁃HD相容剂、粘接树脂及其性能研究[J]. 中国塑料, 2022, 36(4): 35-42. |

| [2] | 郑德宝, 翟前超, 刘光远, 王丰武, 汪义辉, 张忠洁, 陈祥迎. POE⁃g⁃MAH相容剂的制备及其在粘接树脂领域的应用研究[J]. 中国塑料, 2021, 35(12): 51-57. |

| [3] | 梁帅, 满子博, 张志彬, 杨凤敏, 曹春雷. CPE溶胀条件对ACS树脂结构与性能的影响[J]. 中国塑料, 2019, 33(9): 8-12. |

| [4] | 夏艳平, 陈慧蓉, 陶圣熹, 曹峥, 陶国良. 双单体接枝PP-g-(NVP-co-PEGMA)改性剂的制备及其表征[J]. 中国塑料, 2017, 31(06): 100-104 . |

| [5] | 徐先锋, 曾玲升, 刘烁, 包永忠, 张嘉敏. PA6/GF/SP三元复合材料的制备及其力学性能研究[J]. 中国塑料, 2015, 29(04): 19-23 . |

| [6] | 姜彦, 李彬, 张洪文, 王克敏. 环糊精对聚合物乳胶粒子性能影响的研究[J]. 中国塑料, 2014, 28(10): 40-44 . |

| [7] | 李敬媛 李又兵 史文 潘燕 王恒兵. 聚丙烯/玻璃纤维复合材料增强与增韧改性研究[J]. 中国塑料, 2013, 27(12): 47-51 . |

| [8] | 郝壮 宁荣昌 明璐 杨卫朋. 环氧树脂/微粉化双氰胺复合材料制备与性能研究究[J]. 中国塑料, 2013, 27(02): 30-33 . |

| [9] | 吴长城, 刘喜, . EPT接枝共聚物的制备及其对PA6/EPT共混体系的增容作用 [J]. 中国塑料, 2013, 27(01): 42-47. |

| [10] | 王雅珍 贾伟男 李永 岳成娥 马迪. 超临界CO2辅助聚丙烯固相接枝丙烯腈的制备[J]. 中国塑料, 2012, 26(11): 32-34 . |

| [11] | 祝宝东 王鉴 李红伶 董维超 董群. 苯乙烯/二乙烯苯协助马来酸酐熔融接枝聚丙烯研究[J]. 中国塑料, 2012, 26(06): 50-56 . |

| [12] | 朱清梅 李淑华 赵研峰 付博. PP/CaCO3/PP-g- AA 复合材料形态与性能研究[J]. 中国塑料, 2012, 26(02): 46-49 . |

| [13] | 杨明山 刘阳 李林楷 李冬雪. 硅微粉粒径及其匹配对IC封装用环氧模塑料流动性的影响[J]. 中国塑料, 2010, 24(03): 92-95 . |

| [14] | 甘馨, 宁涛, 乔辉, 吴立峰. 配色过程中影响塑料制品颜色品质的主要因素[J]. 中国塑料, 2008, 22(06): 49-53 . |

| [15] | 操彬, 马秀清, 方辉, 周新慧. 不同螺杆构型下充满度与接枝反应接枝率关系的研究[J]. 中国塑料, 2007, 21(7): 77-82. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2