京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2

《中国塑料》编辑部 ©2008-2024 版权所有

地址:北京市海淀区阜成路11号 邮编:100048

编辑部:010-68985541 联系信箱:cp@plaschina.com.cn

广告部/发行部:010-68985253 本系统由北京玛格泰克科技发展有限公司设计开发

中国塑料 ›› 2024, Vol. 38 ›› Issue (1): 92-99.DOI: 10.19491/j.issn.1001-9278.2024.01.013

收稿日期:2023-07-12

出版日期:2024-01-26

发布日期:2024-01-22

通讯作者:

张茜(1991—),女,讲师,从事环境友好高分子材料的聚集态结构与降解性能的研究,zhangxi2021@btbu.edu.cn基金资助:

CHEN Zeyu, FU Ye, ZHANG Xi( ), WENG Yunxuan(

), WENG Yunxuan( )

)

Received:2023-07-12

Online:2024-01-26

Published:2024-01-22

Contact:

ZHANG Xi, WENG Yunxuan

E-mail:zhangxi2021@btbu.edu.cn;wyxuan@th.btbu.edu.cn

摘要:

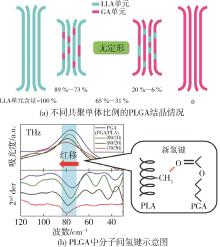

从合成方法、聚集态结构、降解性能等方面对聚乳酸⁃羟基乙酸共聚物(PLGA)的研究进展进行了综述,并总结了合成方法和聚集态结构对PLGA降解性能的影响规律,同时简述了PLGA在药物控释、医用手术缝合线、骨组织工程支架等领域的应用情况。

中图分类号:

陈泽宇, 付烨, 张茜, 翁云宣. PLGA的降解行为及应用研究进展[J]. 中国塑料, 2024, 38(1): 92-99.

CHEN Zeyu, FU Ye, ZHANG Xi, WENG Yunxuan. Research progress in degradation behavior and applications of PLGA[J]. China Plastics, 2024, 38(1): 92-99.

| 样品名称 | 结晶度/% | 降解周期/周 |

|---|---|---|

| 聚(L⁃丙交酯) | 37 | 12~18 |

| 聚(D,L丙交酯) | - | 11~15 |

| 聚(D,L⁃丙交酯⁃co⁃乙交酯)85/15 | - | 5~6 |

| 聚(D,L⁃丙交酯⁃co⁃乙交酯)75/25 | - | 4~5 |

| 聚(D,L⁃丙交酯⁃co⁃乙交酯)50/50 | - | 1~2 |

| 样品名称 | 结晶度/% | 降解周期/周 |

|---|---|---|

| 聚(L⁃丙交酯) | 37 | 12~18 |

| 聚(D,L丙交酯) | - | 11~15 |

| 聚(D,L⁃丙交酯⁃co⁃乙交酯)85/15 | - | 5~6 |

| 聚(D,L⁃丙交酯⁃co⁃乙交酯)75/25 | - | 4~5 |

| 聚(D,L⁃丙交酯⁃co⁃乙交酯)50/50 | - | 1~2 |

| 1 | 陈学思. 可降解医用高分子材料 [M]. 科学出版社, 2020:1⁃2. |

| 2 | Rosli N A, Karamanlioglu M, Kargarzadeh H, et al. Comprehensive exploration of natural degradation of poly(lactic acid) blends in various degradation media: a review [J]. International Journal of Biological Macromolecules, 2021, 187: 732⁃741. |

| 3 | Zhang X, Yang B, Fan B, et al. Enhanced nonisothermal crystallization and heat resistance of poly(l⁃lactic acid) by d⁃sorbitol as a homogeneous nucleating agent [J]. ACS Macro Letters, 2021, 10(1): 154⁃160. |

| 4 | Low Y J, Andriyana A, Ang B C, et al. Bioresorbable and degradable behaviors of PGA: Current state and future prospects [J]. Polymer Engineering & Science, 2020, 60(11): 2 657⁃2 675. |

| 5 | Samantaray P K, Little A, Haddleton D M, et al. Poly(glycolic acid) (PGA): a versatile building block expanding high performance and sustainable bioplastic applications [J]. Green Chemistry, 2020, 22(13): 4 055⁃4 081. |

| 6 | El⁃Hammadi M M, Arias J L. Recent advances in the surface functionalization of PLGA⁃based nanomedicines [J]. Nanomaterials, 2022, 12(3): 354. |

| 7 | Sun J, Walker J, Beck⁃Broichsitter M, et al. Characterization of commercial PLGAs by NMR spectroscopy [J]. Drug Delivery and Translational Research, 2021, 12(3): 720⁃729. |

| 8 | Rocha C V, Gonçalves V, da Silva M C, et al. PLGA⁃Based composites for various biomedical applications [J]. International Journal of Molecular Sciences, 2022, 23(4): 2 034. |

| 9 | Kapoor D N, Bhatia A, Kaur R, et al. PLGA: a unique polymer for drug delivery [J]. Therapeutic Delivery, 2015, 6(1): 41⁃58. |

| 10 | Rocha C V, Goncalves V, da Silva M C, et al. PLGA⁃based composites for various biomedical applications [J]. International Journal of Molecular Sciences, 2022, 23(4): 2 034. |

| 11 | 孙 斌. 生物可降解材料⁃聚乳酸及其共聚物的制备与性质研究 [D].济南:山东师范大学, 2015. |

| 12 | 顾伟楠, 田 阳, 赵子明, 等. 聚丙交酯⁃乙交酯的合成及表征的研究进展 [J]. 中国医药工业杂志, 2022, 53(6): 819⁃832. |

| GU W N, TIAN Y, ZHAO Z M,et al. Research progress of synthesis and characterization of poly(lactide⁃co⁃glycolide) [J]. Chinese Journal of Pharmaceuticals, 2022, 53(6): 819⁃832. | |

| 13 | Shen Y, Li D, Kou X H, et al. Ultrafast ring⁃opening copolymerization of lactide with glycolide toward random poly(lactic⁃co⁃glycolic acid) copolymers by an organophosphazene base and urea binary catalysts [J]. Polymer Chemistry, 2022, 13(13): 1 861⁃1 868. |

| 14 | Washington M A, Balmert S C, Fedorchak M V, et al. Monomer sequence in PLGA microparticles: Effects on acidic microclimates and in vivo inflammatory response [J]. Acta Biomaterialia, 2018, 65: 259⁃271. |

| 15 | Giram P S, Garnaik B. Evaluation of biocompatibility of synthesized low molecular weight PLGA copolymers using zinc L⁃proline through green route for biomedical application [J]. Polymers for Advanced Technologies, 2021, 32(11): 4 502⁃4 515. |

| 16 | 张伊洁, 郭宁子, 刘万卉, 等. 缓控释注射剂中丙交酯乙交酯共聚物(PLGA)分析方法的研究进展 [J]. 中国医药工业杂志, 2019, 50(10): 1 180⁃1 187. |

| ZHANG Y J, GUO N Z, LIU W H,et al. Research in analytical methods of poly(lactide⁃co⁃glycolide)(PLGA) in sustained⁃and controlled⁃release injections [J].Chinese Journal of Pharmaceuticals, 2019, 50(10): 1 180⁃1 187. | |

| 17 | 王佳欣, 肖二飞, 张 龙, 等. 聚乳酸羟基乙酸的研究进展 [J]. 合成纤维, 2023, 52(5): 1⁃5. |

| WANG J X, XIAO E F, ZHANG L,et al. Research progress of poly(lactic acid⁃co⁃glycolic acid) [J] Synthetic fibers in China, 2023, 52 (5): 1⁃5. | |

| 18 | Wang Z Y, Zhao Y M, Wang F, et al. Syntheses of poly(lactic acid⁃co⁃glycolic acid) serial biodegradable polymer materials via direct melt polycondensation and their characterization [J]. Journal of Applied Polymer Science, 2006, 99(1): 244⁃252. |

| 19 | Steinborn⁃Rogulska I, Rokicki G. Solid⁃state polycondensation (SSP) as a method to obtain high molecular weight polymers. Part II. Synthesis of polylactide and polyglycolide via SSP [J]. Polimery, 2013, 58(2): 85⁃92. |

| 20 | 吕 莉, 丁晓慧, 林国良. 聚乳酸乙醇酸的固相聚合研究 [J]. 厦门大学学报, 2013, 52(5): 655⁃659. |

| LV L, DING X H, LIN G L. Study on the synthesis of copoly(lactic acid⁃co⁃glycolic acid)by solid⁃state polymerization [J] Journal of Xiamen University, 2013, 52 (5): 655⁃659. | |

| 21 | 王 宁, 尹会会. 乳酸⁃乙醇酸共聚物的制备方法综述 [J]. 毛纺科技, 2018, 46(9): 84⁃90. |

| WANG N, YIN H H. Review on the preparation method of lactic acid⁃glycolic acid copolymer [J] Wool Textile Technology, 2018, 46 (9): 84⁃90. | |

| 22 | Choi S Y, Park S J, Kim W J, et al. One⁃step fermentative production of poly(lactate⁃co⁃glycolate) from carbohydrates in escherichia coli [J]. Wool Textile Journal, 2016, 34(4): 435⁃440. |

| 23 | Li J, Rothstein S N, Little S R, et al. The effect of monomer order on the hydrolysis of biodegradable poly(lactic⁃co⁃glycolic acid) repeating sequence copolymers [J]. Journal of the American Chemical Society, 2012, 134(39): 16 352⁃16 359. |

| 24 | Dai J, Liang M, Zhang Z, et al. Synthesis and crystallization behavior of poly (lactide⁃co⁃glycolide) [J]. Polymer, 2021, 235: 124302. |

| 25 | 熊左春, 陈栋梁, 李 庆, 等. 不同旋光度PLGA的制备及其结晶性能研究 [J]. 合成化学, 2009, 17(3): 292⁃295. |

| XIONG Z C, CHEN D L, LI Q,et al. Preparaion of PLGA with different optical rotation and their crystallization behavior [J] Chinese Journal of Synthetic Chemistry, 2009, 17 (3): 292⁃295. | |

| 26 | Tsuji H, Kikkawa K, Arakawa Y. Cocrystallization of monomer units of biobased and biodegradable poly(l⁃lactic acid⁃co⁃glycolic acid) random copolymers [J]. Polymer Journal, 2018, 50(11): 1 079⁃1 088. |

| 27 | Nishimae A, Sato H. Study of co⁃crystallization and intermolecular hydrogen bondings of poly(glycolide⁃co⁃l⁃lactide) copolymers by terahertz and low⁃frequency raman spectroscopy [J]. Macromolecules, 2021, 54(13): 6 440⁃6 448. |

| 28 | Wang Z G, Hsiao B S, Zong X H, et al. Morphological development in absorbable poly(glycolide), poly(glycolide⁃co⁃lactide) and poly(glycolide⁃co⁃caprolactone) copolymers during isothermal crystallization [J]. Polymer, 2000, 41(2): 621⁃628. |

| 29 | Fu B X, Hsiao B S, Chen G, et al. Structure and property studies of bioabsorbable poly(glycolide⁃co⁃lactide) fiber during processing and in vitro degradation [J]. Polymer, 2002, 43(20): 5 527⁃5 534. |

| 30 | Tsuji H. Quiescent crystallization of poly (lactic acid) and its copolymers⁃based materials[J]. Thermal properties of bio⁃based polymers, 2019,283: 37⁃86. |

| 31 | Zheng Y, Pan P. Crystallization of biodegradable and biobased polyesters: polymorphism, cocrystallization, and structure⁃property relationship [J]. Progress in Polymer Science, 2020, 109: 101291. |

| 32 | Zheng Y, Yu C, Bao Y, et al. Temperature⁃dependent crystal structure and structural evolution of poly(glycolide⁃co⁃lactide) induced by comonomeric defect inclusion/exclusion [J]. Polymer, 2021, 227: 123867. |

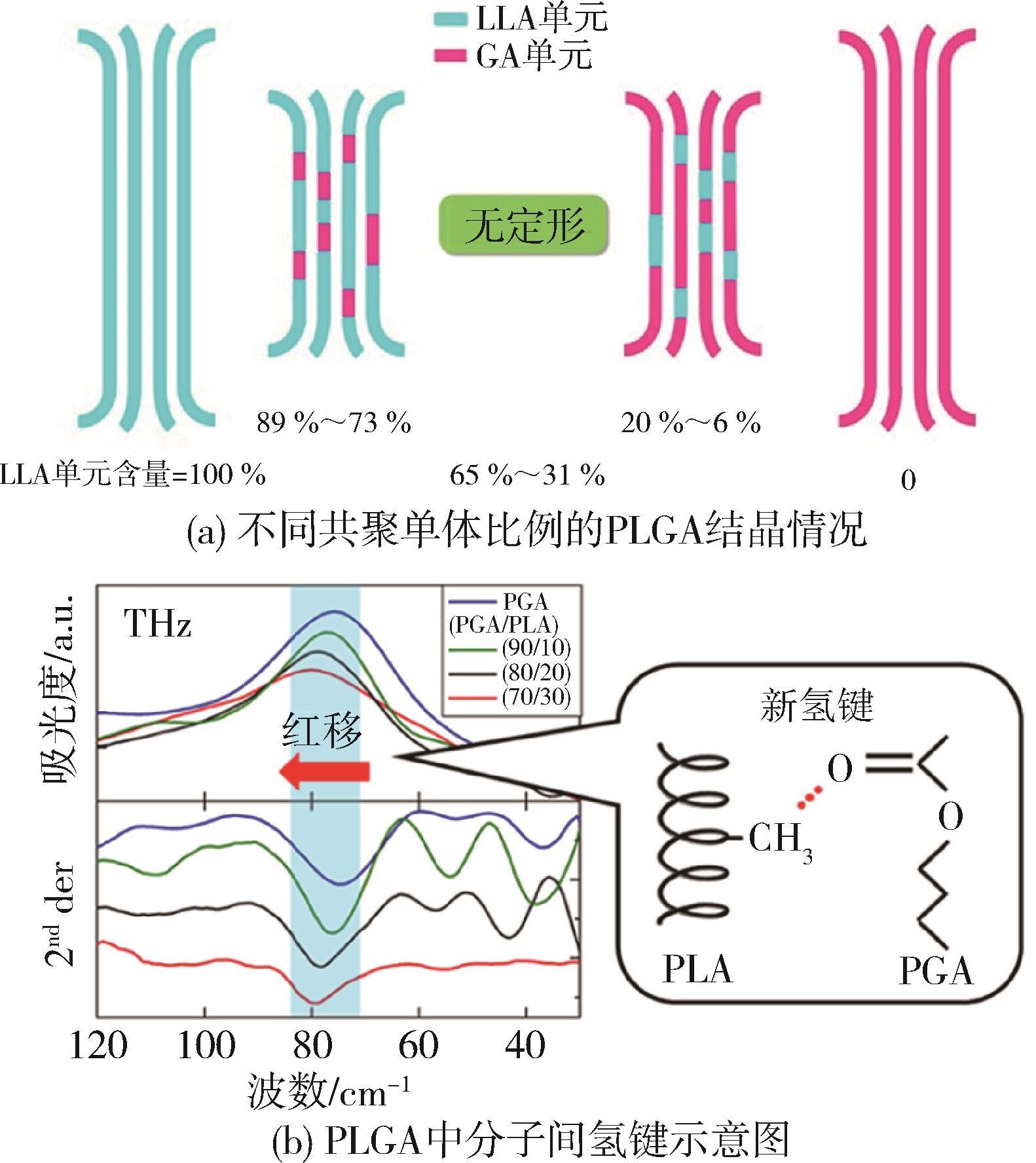

| 33 | Dong Z, Miao Y, Cui H, et al. Structural evolution of polyglycolide and poly(glycolide⁃co⁃lactide) fibers during the heat⁃setting process [J]. Biomacromolecules, 2021, 22(8): 3 342⁃3 356. |

| 34 | Miao Y, Cui H, Dong Z, et al. Structural evolution of polyglycolide and poly(glycolide⁃co⁃lactide) fibers during in vitro degradation with different heat⁃setting temperatures [J]. ACS Omega, 2021, 6(43): 29 254⁃29 266. |

| 35 | dos Santos F A, Valle Iulianelli G C, Bruno Tavares M I. Deve⁃lopment and properties evaluation of bio⁃based PLA/PLGA blend films reinforced with microcrystalline cellulose and organophilic silica [J]. Polymer Engineering & Science, 2017, 57(4): 464⁃472. |

| 36 | Dai J, Liang M, Zhang Z, et al. Synthesis and crystallization behavior of poly (lactide⁃co⁃glycolide) [J]. Polymer, 2021, 235: 124302. |

| 37 | Tsuji H, Yamasaki M, Arakawa Y. Stereocomplex formation between enantiomeric alternating lactic acid⁃based copolymers as a versatile method for the preparation of high performance biobased biodegradable materials [J]. ACS Applied Polymer Materials, 2019, 1(6): 1 476⁃1 484. |

| 38 | Washington M A, Swiner D J, Bell K R, et al. The impact of monomer sequence and stereochemistry on the swelling and erosion of biodegradable poly(lactic⁃co⁃glycolic acid) matrices [J]. Biomaterials, 2017, 117: 66⁃76. |

| 39 | Narancic T, Cerrone F, Beagan N, et al. Recent advances in bioplastics: application and biodegradation [J]. Polymers, 2020, 12(4): 920. |

| 40 | Thomas C M, Lutz J F. Precision synthesis of biodegradable polymers [J]. Angew Chem Int Ed Engl, 2011, 50(40): 9 244⁃9 246. |

| 41 | Gentile P, Chiono V, Carmagnola I, et al. An overview of poly(lactic⁃co⁃glycolic) acid (PLGA)⁃based biomaterials for bone tissue engineering [J]. International Journal of Molecular Sciences, 2014, 15(3): 3 640⁃3 659. |

| 42 | Fredericks R J, Melveger A J, Dolegiewitz L J. Morphological and structural changes in a copolymer of glycolide and lactide occurring as a result of hydrolysis [J]. Journal of Polymer Science: Polymer Physics Edition, 1984, 22(1): 57⁃66. |

| 43 | Kumskova N, Ermolenko Y, Osipova N, et al. How subtle differences in polymer molecular weight affect doxorubicin⁃loaded PLGA nanoparticles degradation and drug release [J]. Journal of Microencapsulation, 2020, 37(3): 283⁃295. |

| 44 | Lee P W, Pokorski J K. Poly(lactic⁃co⁃glycolic acid) devices: production and applications for sustained protein delivery [J]. 2018, 10(5): e1516. |

| 45 | Machatschek R, Lendlein A. Fundamental insights in PLGA degradation from thin film studies [J]. Journal of Controlled Release, 2020, 319: 276⁃284. |

| 46 | Lu Y, Cheng D F, Niu B H, et al. Properties of poly (lactic⁃co⁃glycolic acid) and progress of poly (lactic⁃co⁃glycolic acid)⁃based biodegradable materials in biomedical research [J]. Pharmaceuticals, 2023, 16(3): 454. |

| 47 | Dong Z M, Miao Y S, Cui H S, et al. Structural evolution of polyglycolide and poly(glycolide⁃co⁃lactide) fibers during the heat⁃setting process [J]. Biomacromolecules, 2021, 22(8): 3 342⁃3 356. |

| 48 | Li P, Feng X L, Jia X L, et al. Influences of tensile load on in vitro degradation of an electrospun poly(L⁃lactide⁃co⁃glycolide) scaffold [J]. Acta Biomaterialia, 2010, 6(8): 2 991⁃2 996. |

| 49 | Chu Z W, Zheng Q, Guo M, et al. The effect of fluid shear stress on the in vitro degradation of poly(lactide⁃co⁃glycolide) acid membranes [J]. Journal of Biomedical Materials Research Part A, 2016, 104(9): 2 315⁃2 324. |

| 50 | Markocic E, Botic T, Kavcic S, et al. In vitro degradation of poly(D,L⁃lactide⁃co⁃glycolide) foams processed with supercritical fluids [J]. Industrial & Engineering Chemistry Research, 2015, 54(7): 2 114⁃2 119. |

| 51 | Yoshioka T, Kawazoe N, Tateishi T, et al. Effects of structural change induced by physical aging on the biodegradation behavior of PLGA films at physiological temperature [J]. Macromolecular Materials and Engineering, 2011, 296(11): 1 028⁃1 034. |

| 52 | Cai Q, Shi G X, Bei J Z, et al. Enzymatic degradation behavior and mechanism of poly(lactide⁃co⁃glycolide) foams by trypsin [J]. Biomaterials, 2003, 24(4): 629⁃638. |

| 53 | Dodda J M, Remiš T, Rotimi S, et al. Progress in the drug encapsulation of poly(lactic⁃co⁃glycolic acid) and folate⁃decorated poly(ethylene glycol)⁃poly(lactic⁃co⁃glycolic acid) conjugates for selective cancer treatment [J]. Journal of Materials Chemistry B, 2022, 10(22): 4 127⁃4 141. |

| 54 | Lee P C, Zan B S, Chen L T, et al. Multifunctional PLGA⁃based nanoparticles as a controlled release drug delivery system for antioxidant and anticoagulant therapy [J]. International Journal of Nanomedicine, 2019, 14: 1 533⁃1 549. |

| 55 | Panda A, Sharma P K, McCann T, et al. Fabrication and development of controlled release PLGA microneedles for macromolecular delivery using FITC⁃dextran as model molecule [J]. Journal of Drug Delivery Science and Technology, 2022, 68: 102712. |

| 56 | Mir M, Ahmed N, Rehman A U. Recent applications of PLGA based nanostructures in drug delivery [J]. Colloids and Surfaces B: Biointerfaces, 2017, 159: 217⁃231. |

| 57 | Mundargi R C, Babu V R, Rangaswamy V, et al. Nano/micro technologies for delivering macromolecular therapeutics using poly(d,l⁃lactide⁃co⁃glycolide) and its derivatives [J]. Journal of Controlled Release, 2008, 125(3): 193⁃209. |

| 58 | Wang Y C, Li P W, Kong L X. Chitosan⁃modified PLGA nanoparticles with versatile surface for improved drug delivery [J]. Aaps Pharmscitech, 2013, 14(2): 585⁃592. |

| 59 | Huh B K, Kim B H, Kim S⁃N, et al. Surgical suture braided with a diclofenac⁃loaded strand of poly(lactic⁃co⁃glycolic acid) for local, sustained pain mitigation [J]. Materials Science and Engineering C⁃Materials for Biological Applications, 2017, 79: 209⁃215. |

| 60 | Lee H S, Park S H, Lee J H, et al. Antimicrobial and biodegradable PLGA medical sutures with natural grapefruit seed extracts [J]. Materials Letters, 2013, 95: 40⁃43. |

| 61 | Bae S, DiBalsi M J, Meilinger N, et al. Heparin⁃eluting electrospun nanofiber yarns for antithrombotic vascular sutures [J]. Acs Applied Materials & Interfaces, 2018, 10(10): 8 426⁃8 435. |

| 62 | Lee D H, Kwon T Y, Kim K H, et al. Anti⁃inflammatory drug releasing absorbable surgical sutures using poly(lactic⁃co⁃glycolic acid) particle carriers [J]. Polymer Bulletin, 2014, 71(8): 1 933⁃1 946. |

| 63 | Zhao D, Zhu T, Li J, et al. Poly(lactic⁃co⁃glycolic acid)⁃based composite bone⁃substitute materials [J]. Bioactive Materials, 2021, 6(2): 346⁃360. |

| 64 | Zheng S, Guan Y, Yu H, et al. Poly⁃L⁃lysine⁃coated PLGA/poly(amino acid)⁃modified hydroxyapatite porous scaffolds as efficient tissue engineering scaffolds for cell adhesion, proliferation, and differentiation [J]. New Journal of Chemistry, 2019, 43(25): 9 989⁃10 002. |

| 65 | Nie H, Wang C H. Fabrication and characterization of PLGA/HAp scaffolds for delivery of BMP-2 plasmid composite DNA [J]. Journal of Controlled Release, 2007, 120(1/2): 111⁃121. |

| 66 | Dai W, Kawazoe N, Lin X, et al. The influence of structural design of PLGA/collagen hybrid scaffolds in cartilage tissue engineering [J]. Biomaterials, 2010, 31(8): 2 141⁃2 152. |

| 67 | Bazgir M, Zhang W, Zhang X M, et al. Degradation and characterisation of electrospun polycaprolactone (PCL) and poly(lactic⁃co⁃glycolic acid) (PLGA) scaffolds for vascular tissue engineering [J]. Materials, 2021, 14(17): 4 773. |

| 68 | Wang J, Cui X, Zhou Y, et al. Core⁃shell PLGA/collagen nanofibers loaded with recombinant FN/CDHs as bone tissue engineering scaffolds [J]. Connective Tissue Research, 2014, 55(4): 292⁃298. |

| [1] | 汪杰, 张伟蒙, 胡晶. 聚乳酸⁃羟基乙酸共聚物涂层对聚乳酸3D打印支架的性能影响[J]. 中国塑料, 2023, 37(1): 1-7. |

| [2] | 甄建, 高志武. 高耐压等级PP⁃RCT管材料的结构与性能[J]. 中国塑料, 2022, 36(12): 57-64. |

| [3] | 姜洪丽 董建. IFR/SiO2和IFR/MgSiO3协效阻燃TPU材料的性能比较[J]. 中国塑料, 2019, 33(7): 38-43. |

| [4] | 姜洪丽. 三嗪膨胀阻燃剂/硅酸镁协效阻燃TPU的制备及性能研究[J]. 中国塑料, 2018, 32(07): 122-125. |

| [5] | 容腾, 叶元坚, 蔡锦安, 陈志, 袁嘉伟, 潘永红. 增塑剂BBP和DBS在不同温度下的热降解行为研究[J]. 中国塑料, 2017, 31(01): 93-97 . |

| [6] | 姜洪丽, 施成涛, 王光照. 聚磷酸铵对聚乳酸/麦秸秆复合材料阻燃和力学性能的影响[J]. 中国塑料, 2016, 30(07): 30-33 . |

| [7] | 冯才敏, 黄健光, 梁敏仪, 刘洪波. 化合物对乙丙弹性体/IFR体系阻燃性能和热降解行为的影响[J]. 中国塑料, 2015, 29(03): 70-74 . |

| [8] | 陈佳 刘继延 刘学清. 二烷基次膦酸盐类阻燃剂的结构设计与合成方法研究进展[J]. 中国塑料, 2012, 26(02): 83-87 . |

| [9] | 蒋爱云 赵磊 李新法 陈金周 牛明军. SA型透明聚酰胺的聚集态结构和热性能研究[J]. 中国塑料, 2012, 26(02): 20-22 . |

| [10] | 杨智韬, 高军, 瞿金平. 振动力场对注射制品取向结构影响研究[J]. 中国塑料, 2009, 23(01): 77-81 . |

| [11] | 石玉元, 李桂娟, 于祥, 孙中心, 王坤燕. 微波辐照对PET/PEN共混物非等温热降解行为的影响[J]. 中国塑料, 2007, 21(7): 39-43. |

| [12] | 黄年华, 熊奇, 李治华, 张强, 唐盛斌. 碳酸钙对乙烯一丙烯酸丁酯共聚物阻燃与力学性能及热降解行为影响研究[J]. 中国塑料, 2007, 21(2): 77-81. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2