京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2

《中国塑料》编辑部 ©2008-2024 版权所有

地址:北京市海淀区阜成路11号 邮编:100048

编辑部:010-68985541 联系信箱:cp@plaschina.com.cn

广告部/发行部:010-68985253 本系统由北京玛格泰克科技发展有限公司设计开发

中国塑料 ›› 2024, Vol. 38 ›› Issue (10): 81-86.DOI: 10.19491/j.issn.1001-9278.2024.10.015

收稿日期:2023-11-02

出版日期:2024-10-26

发布日期:2024-10-21

通讯作者:

向光会(1986—),高级工程师,主要从事醋酸纤维素等高分子聚合物的研究和开发工作, dirray@126.com基金资助:

CHENG Ming, WANG Yongkang, HE Jie, WANG Ruyi, XIANG Guanghui( )

)

Received:2023-11-02

Online:2024-10-26

Published:2024-10-21

Contact:

XIANG Guanghui

E-mail:dirray@126.com

摘要:

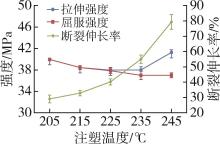

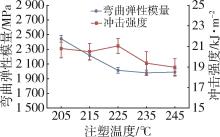

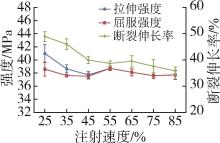

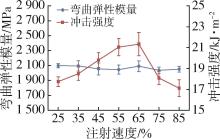

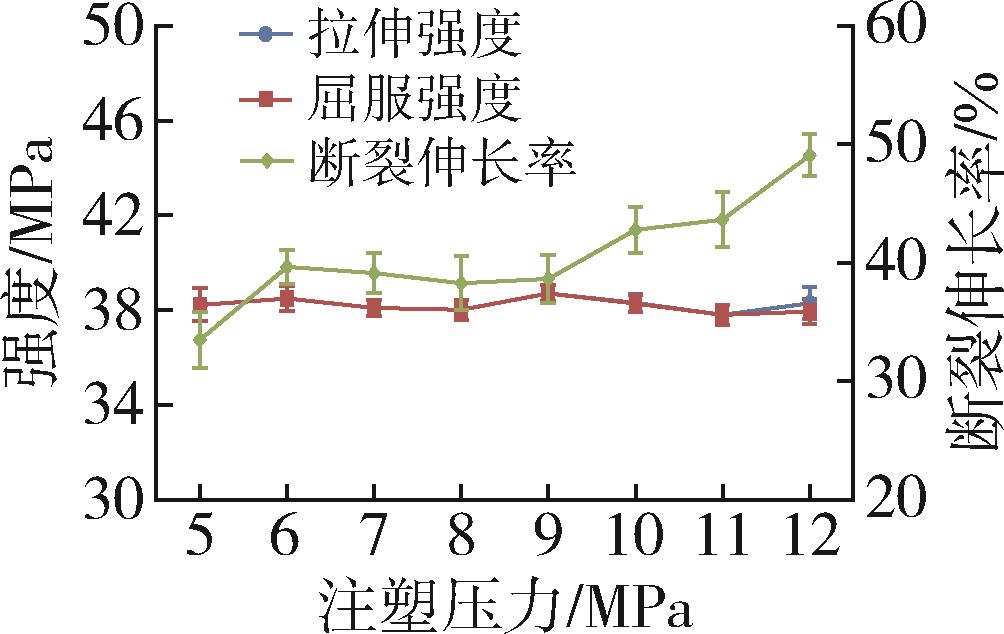

使用不同的工艺条件对二醋酸纤维素塑料(DACP)进行注射成型,将注塑温度、注射速度、压力等条件逐个改变,研究不同条件下DACP注塑制品力学性能的变化。结果表明,随着注塑条件的改变,材料的性能会出现一些规律性的变化,其中注塑温度对DACP韧性和断裂伸长率的影响较大,随着温度的提高韧性增强,断裂伸长率大幅增加,但在230 ℃以上材料出现黄变。过高或过低的注塑速度都会造成DACP的冲击性能下降,中速(55 %)的注射速度冲击强度最高。压力的变化对性能的影响不大,但过高的压力可能导致飞边的等缺陷的产生。工艺选择注塑温度为225 ℃,注射速度为55 %、压力为9 MPa时整体性能较好。因此选择合适的注塑工艺,对DACP制品的性能有所改善。

中图分类号:

成名, 王永康, 何杰, 王如意, 向光会. 浅析注塑工艺对二醋酸纤维素力学性能的影响[J]. 中国塑料, 2024, 38(10): 81-86.

CHENG Ming, WANG Yongkang, HE Jie, WANG Ruyi, XIANG Guanghui. Influence of injection molding process on mechanical properties of cellulose diacetate[J]. China Plastics, 2024, 38(10): 81-86.

| 试样部位名称和符号 | A1型(注塑) | B1型(注塑) |

|---|---|---|

| 总长度(l3)/mm | 170 | — |

| 宽度平行部分之间的距离(l2)/mm | 109.3±3.2 | — |

| 窄部平行部分长度(l1)/mm | 80±2 | 80±2 |

| 肩部半径(r)/mm | 24±1 | — |

| 端部宽度(b2 )/mm | 20±0.2 | — |

| 窄部平行部分宽度(b1 )/mm | 10.0±0.2 | 10.0±0.2 |

| 厚度(h)/mm | 4.0±0.2 | 4.0±0.2 |

| 试样部位名称和符号 | A1型(注塑) | B1型(注塑) |

|---|---|---|

| 总长度(l3)/mm | 170 | — |

| 宽度平行部分之间的距离(l2)/mm | 109.3±3.2 | — |

| 窄部平行部分长度(l1)/mm | 80±2 | 80±2 |

| 肩部半径(r)/mm | 24±1 | — |

| 端部宽度(b2 )/mm | 20±0.2 | — |

| 窄部平行部分宽度(b1 )/mm | 10.0±0.2 | 10.0±0.2 |

| 厚度(h)/mm | 4.0±0.2 | 4.0±0.2 |

| 1 | Roberson Calvin.Cellulose acetate: properties, uses and preparation[M]. New York : Nova Science Publishers: 1⁃ 12. |

| 2 | 蓝 炜. 塑料注塑工艺的影响因素[J]. 新型工业化,2021 11(9):18⁃19. |

| LAN W. Influencing factors of plastic injection molding process [J]. The Journal of New Industrialization, 2021,11(9): 18⁃19. | |

| 3 | 于桂平. 注塑工艺的影响因素及前沿技术研究[J]. 河南科技, 2018(10): 62⁃63. |

| YU G P. Research on the influencing factors and frontier technology of injection molding[J]. Henan Science and Technology, 2018(10): 62⁃63. | |

| 4 | 李庭军. 双色注塑的应用研究[J]. 日用电器, 2019(4): 60⁃62. |

| LI T J. Research on application of double color injection plastics[J]. Electrical Appliances, 2019(4): 60⁃62. | |

| 5 | 张明玉, 金家骏, 徐 骁, 等. 新能源汽车用热收缩套管材料研究现状分析[J]. 电工材料, 2019(6): 3⁃5. |

| ZHANG M Y, JIN J J, XU X, et al. Development present situation of heat⁃shrinkable material in new energy vehicle area[J]. Electrical Engineering Materials,2019(6): 3⁃5. | |

| 6 | 张迎辉, 樊玉卿, 赵 霞. PP塑料产品的注塑条件与制品性能的关系探讨[J]. 石化技术, 2017,24(5): 31. |

| ZHANG Y H, FAN Y Q, ZHAO X. Injection conditions and pro⁃perties of PP products[J]. Petrochemical Industry Technolog, 2017,24(5): 31. | |

| 7 | 王金科, 项长生. 析因设计在高分子材料注塑过程中的研究进展[J]. 现代塑料加工应用, 2022,34(3): 56⁃59. |

| WANG J K, XIANG C S. Reaearch progress of polymer by factorial design in injection molding[J]. Modern Plastics Processing and Applications, 2022,34(3): 56⁃59. | |

| 8 | 程芳伟, 姜其斌, 张志军, 等. 注塑工艺对PTW/PEEK制品力学性能的影响[J]. 塑料工业, 2014,42(10): 68⁃71. |

| CHENG F W, JIANG Q B, ZHANG Z J, et al. Effect of injection molding process on mechanical properties of PTW/PEEK products[J].China Plastics Industry, 2014,42(10): 68⁃71. | |

| 9 | 肖 亮, 戚天银, 柏莲桂, 等. 注塑工艺对哑光PC/ABS冲击性能的影响[J]. 工程塑料应用, 2018,46(5): 68⁃71. |

| XIAO L, QI T Y, BAI L G, et al. Influence of injection molding process on impact strength of matt PC/ABS[J]. Engineering Plastics Application, 2018,46(5): 68⁃71. | |

| 10 | 中蓝晨光成都检测技术有限公司, 国能榆林化工有限公司, 山东万达化工有限公司, 等. 塑料 拉伸性能的测定 第2部分:模塑和挤塑塑料的试验条件 [S]. 国家市场监督管理总局;国家标准化管理委员会, 2022. |

| 11 | 材料测试部中石化北化院国家化学建筑材料测试中心. 塑料 弯曲性能的测定 [S]. 中华人民共和国国家质量监督检验检疫总局;中国国家标准化管理委员会, 2008. |

| 12 | 国家合成树脂质量监督检验中心, 广州合成材料研究院有限公司. 塑料 悬臂梁冲击强度的测定 [S]. 中华人民共和国国家质量监督检验检疫总局;中国国家标准化管理委员会, 2008. |

| 13 | 何曼君. 高分子物理[M]. 上海:复旦大学出版社, 2007:196⁃205. |

| 14 | 黄 尧. CA材料的热稳定性研究[D]. 天津:天津科技大学, 2015. |

| 15 | 杨 齐. 醋酸纤维素的降解及其影响因素研究进展[J]. 塑料工业, 2020,48(8): 1⁃6. |

| YANG Q. Research progress of cellulose acetate degradation and its influencing factors[J].China Plastics Industry, 2020,48(8): 1⁃6. | |

| 16 | 马国成, 何 圳, 陈少军. 醋酸纤维素的降解性研究进展[J]. 中国塑料, 2022,36(9): 111⁃121. |

| MA G C, HE Z, CHEN S J. Research progress in degradability of cellulose acetate[J]. China Plastics, 2022,36(9): 111⁃121. | |

| 17 | 刘秀丽. 不同环境条件下可降解塑料的老化机制及力学性能模拟研究[D]. 重庆:重庆交通大学, 2022. |

| 18 | PHUONG V T, LAZZERI A. “Green” biocomposites based on cellulose diacetate and regenerated cellulose microfibers: effect of plasticizer content on morphology and mechanical properties[J]. Composites Part A: Applied Science and Manufacturing, 2012,43(12): 2 256⁃2 268. |

| 19 | GUO W, REESE C M, XIONG L, et al. Buckling instabilities in polymer brush surfaces via postpolymerization modification[J]. Macromolecules, 2017,50(21): 8 670⁃8 677. |

| 20 | FEINGOLD J M. Stress:diagnose it before it ruins your parts[J]. Plastics Technology, 2005(12): 51. |

| 21 | 李海青. 中空吹塑容器成型过程分析及数值模拟[D]. 西安:西安理工大学, 2009. |

| 22 | 刘朝福. 注塑成型实用手册[M]. 化学工业出版社, 2013: 288. |

| 23 | 张全平, 肖望东, 戴文利. 柠檬酸三正丁酯与三醋酸甘油酯增塑醋酸纤维素的研究[J]. 中国塑料, 2011,25(3): 43⁃48. |

| ZHANG Q P, XIANG W D, DAI W L. Study of cellulose acetate plasticized with tributyl citrateand glyceryl triacetate[J]. China Plastics, 2011,25(3): 43⁃48. |

| [1] | 曲道鹏, 张涛, 华晨曦, 宋欣雨, 程昌利, 刘禹, 王震宇. 高强电磁屏蔽环氧复合材料的3D打印工艺研究[J]. 中国塑料, 2024, 38(9): 24-29. |

| [2] | 梁济峰, 瞿金平. 体积脉动注塑rPE⁃HD/rPET混杂体系结构性能演变[J]. 中国塑料, 2024, 38(8): 1-7. |

| [3] | 何和智, 黄宗海, 赖文, 熊华威. PLA/PBAT/CB防静电包装材料的制备及其性能研究[J]. 中国塑料, 2024, 38(7): 1-8. |

| [4] | 胡永祥, 谢纪岭, 李伟铭, 张璐, 汤香港, 吕亿同, 申红望, 鞠冠男. 马来酸酐接枝改性GTR对聚乳酸性能的影响[J]. 中国塑料, 2024, 38(7): 20-24. |

| [5] | 王杰, 辛德华, 李晖, 蒋洪石, 周洪福, 赵建国. 纳米黏土与二氧化硅协同改性聚乳酸研究[J]. 中国塑料, 2024, 38(7): 43-48. |

| [6] | 徐琛, 骆博飞, 刘腾腾, 邢晶凯. 成核剂改性聚丙烯研究进展[J]. 中国塑料, 2024, 38(7): 79-85. |

| [7] | 刘莹, 孙昊, 杨勇, 姜开宇, 于同敏, 马赛, 祝铁丽. 超声振动对玻璃纤维增强聚酰胺6注塑制件力学性能的影响[J]. 中国塑料, 2024, 38(7): 9-14. |

| [8] | 叶卫文, 陈镇森, 姜炳春, 吴光明. 汽车热交换系统直管口双缩柯水室模具设计[J]. 中国塑料, 2024, 38(6): 117-124. |

| [9] | 杨莲, 蒋晶, 贾彩宜, 谢悦涵, 王小峰, 李倩. 聚酰胺6微纤增强聚丙烯复合材料制备及化学注塑发泡性能研究[J]. 中国塑料, 2024, 38(6): 12-18. |

| [10] | 曹帅, 姜涛, 刘雄, 王瑛, 李文戈, 吴新锋. MXene导热复合材料的制备研究进展[J]. 中国塑料, 2024, 38(6): 139-144. |

| [11] | 周紫怡, 王洋样, 孙滔, 蒋伟, 董同力嘎, 云雪艳. 聚(己二酸/对苯二甲酸)⁃丁二醇酯基自发气调薄膜的性能研究及应用[J]. 中国塑料, 2024, 38(6): 31-38. |

| [12] | 董亚鹏, 赵恬娇, 王美珍, 崔文举, 林福华, 王波. 长链脂肪酸钠/芳基酰胺脂肪酸钠复配成核剂对聚丙烯性能影响研究[J]. 中国塑料, 2024, 38(6): 60-65. |

| [13] | 王涵, 梁金华, 高振国, 姜炜, 周昊. 微胶囊型自修复环氧树脂材料的力学性能及修复效率[J]. 中国塑料, 2024, 38(5): 40-46. |

| [14] | 张之琪, 王向东, 刘海明, 陈士宏. 聚酰胺弹性体对生物基聚酰胺56和聚酰胺66共混物的增韧改性及其发泡行为研究[J]. 中国塑料, 2024, 38(5): 55-60. |

| [15] | 蒋方新, 李仙花, 田清涛, 王利民, 李佩勋, 杜江涛. 缓黏结预应力钢绞线用胶黏剂固化指标试验研究[J]. 中国塑料, 2024, 38(5): 94-99. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2