京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2

《中国塑料》编辑部 ©2008-2024 版权所有

地址:北京市海淀区阜成路11号 邮编:100048

编辑部:010-68985541 联系信箱:cp@plaschina.com.cn

广告部/发行部:010-68985253 本系统由北京玛格泰克科技发展有限公司设计开发

中国塑料 ›› 2024, Vol. 38 ›› Issue (10): 103-113.DOI: 10.19491/j.issn.1001-9278.2024.10.019

肖扬, 岳楠, 郭学钟, 陆波( ), 冯跃战, 黄明, 刘春太

), 冯跃战, 黄明, 刘春太

收稿日期:2024-07-31

出版日期:2024-10-26

发布日期:2024-10-21

通讯作者:

陆波(1988—),男,副教授,主要从事高分子复合材料及成型加工方面的研究,bolu@zzu.edu.cn基金资助:

XIAO Yang, YUE Nan, GUO Xuezhong, LU Bo( ), FENG Yuezhan, HUANG Ming, LIU Chuntai

), FENG Yuezhan, HUANG Ming, LIU Chuntai

Received:2024-07-31

Online:2024-10-26

Published:2024-10-21

Contact:

LU Bo

E-mail:bolu@zzu.edu.cn

摘要:

综述了近年来类玻璃高分子(vitrimer)基碳纤维复合材料的研究现状,重点介绍了基于不同种类动态共价键的类玻璃高分子体系及其在复合材料中的应用,涵盖了催化方式、回收能力、生物基原料引入、多功能性和界面增强等方面。总结了类玻璃高分子基碳纤维复合材料的主要成型方式,并对每种方式的成型特点进行了详细阐述。最后,指出当前类玻璃高分子基碳纤维复合材料存在的问题和不足,并对其未来的发展方向进行了展望。

中图分类号:

肖扬, 岳楠, 郭学钟, 陆波, 冯跃战, 黄明, 刘春太. 类玻璃高分子基碳纤维复合材料及其成型方法研究进展[J]. 中国塑料, 2024, 38(10): 103-113.

XIAO Yang, YUE Nan, GUO Xuezhong, LU Bo, FENG Yuezhan, HUANG Ming, LIU Chuntai. Research progress in vitrimer⁃based carbon⁃fiber⁃reinforced composites and their molding methods[J]. China Plastics, 2024, 38(10): 103-113.

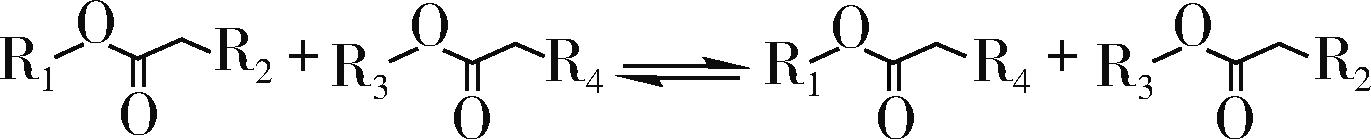

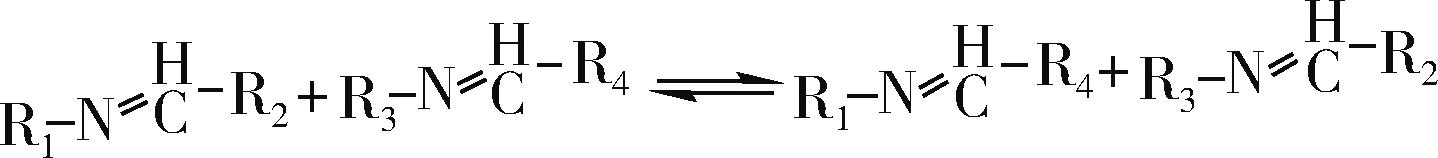

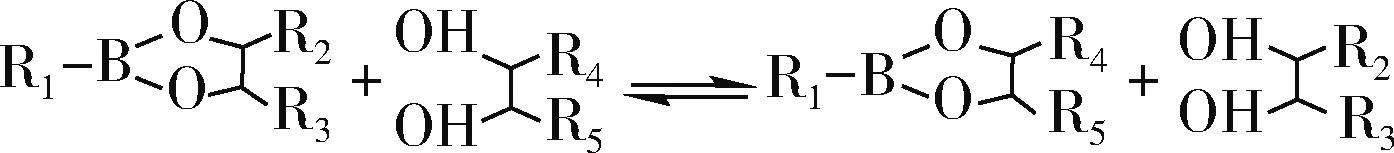

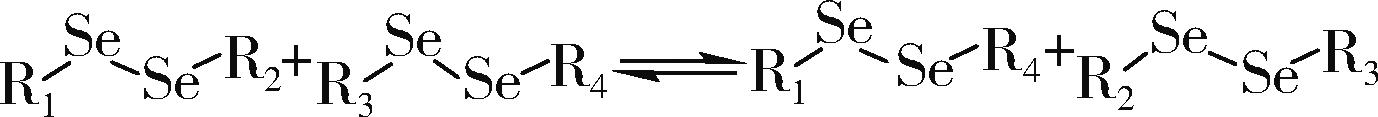

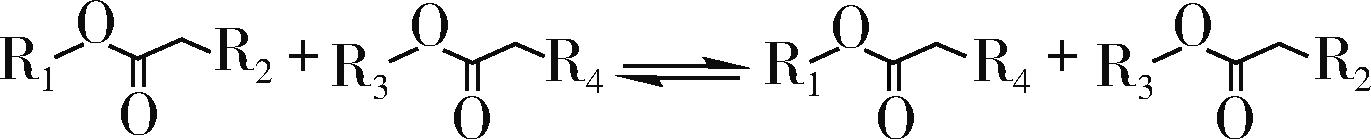

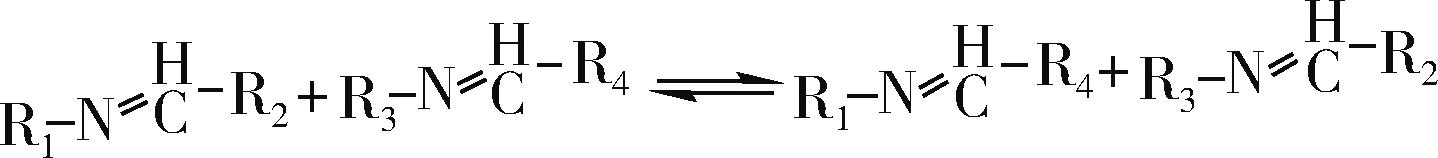

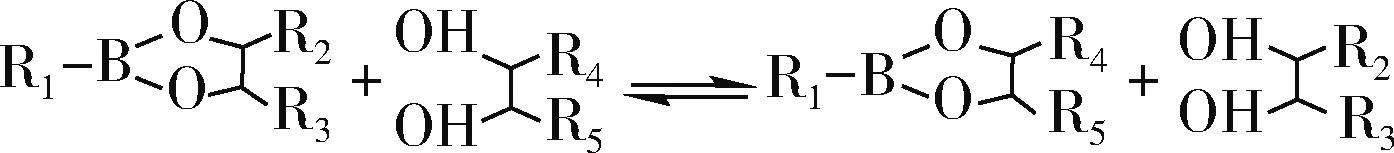

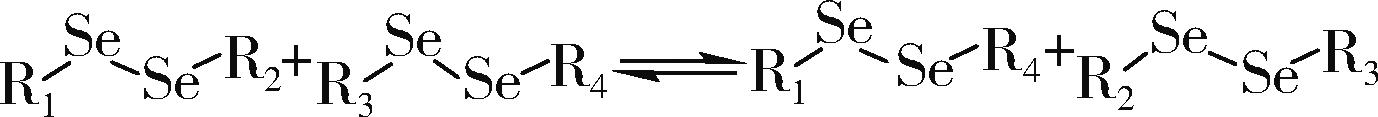

反应 名称 | 反应方程式 | 参考 文献 |

|---|---|---|

| 酯交换 |  | [ |

| 二硫⁃硫醇交换 |  | [ |

二硫键 交换 |  | [ |

亚胺键 交换 |  | [ |

硼酯键 交换 |  | [ |

二硒键 交换 |  | [ |

反应 名称 | 反应方程式 | 参考 文献 |

|---|---|---|

| 酯交换 |  | [ |

| 二硫⁃硫醇交换 |  | [ |

二硫键 交换 |  | [ |

亚胺键 交换 |  | [ |

硼酯键 交换 |  | [ |

二硒键 交换 |  | [ |

| 动态键类型 | 类玻璃高分子基体 | 拉伸强度/MPa | 层间剪切强度/MPa | 回收方法 | 回收时间/温度 | 文献编号 |

|---|---|---|---|---|---|---|

| 酯键 | 双酚A二缩水甘油醚 | 90 | - | 乙二醇 | 4 h/180 ℃ | [ |

| 衣康酸基环氧树脂 | 423 | 45 | 氢氧化钠 | 5 h/25 ℃ | [ | |

| 桐油基三甘油酯 | 541 | - | 乙醇胺 | 1 h/90 ℃ | [ | |

| 双酚A二缩水甘油醚 | 495 | - | 乙醇胺 | 1 h/100 ℃ | [ | |

| 环氧氯丙烷 | 120 | - | 乙醇 | 1 h/25 ℃ | [ | |

| 甘油三缩水甘油醚 | 585 | 43 | 乙二醇 | 12 h/180 ℃ | [ | |

| 二硫键 | 双(4⁃缩水甘油氧基苯基)二硫化物 | 334 | - | 二硫苏糖醇 | 1 h/90 ℃ | [ |

| 愈创木酚环氧树脂 | - | - | 巯基乙醇 | 25 ℃ | [ | |

| 双酚A二缩水甘油醚 | 401 | - | 巯基乙醇 | 24 h/100 ℃ | [ | |

| 亚胺键 | 香草醛 | 763 | - | 盐酸 | 15 h/25 ℃ | [ |

| 香草醛 | 505 | - | 盐酸 | 24 h/60 ℃ | [ | |

| 超支化聚酰亚胺 | 681 | 32 | 磷酸 | 8 h/90 ℃ | [ | |

| 环氧大豆油 | 145 | - | 盐酸 | 24 h/25 ℃ | [ | |

| 硼酯键 | 硼酸三聚体 | 569 | - | 乙醇 | 4 h/95 ℃ | [ |

| 硼化三嵌段共聚物 | 730 | - | 频哪醇 | 12 h/65 ℃ | [ | |

| 环氧亚麻籽油 | 220 | - | 乙醇 | 3 h/75 ℃ | [ | |

| 二硒键 | 双酚A二缩水甘油醚 | 650 | - | 二硒化物 | 12 h/40 ℃ | [ |

| 六氢三嗪键 | 端超支化环氧 | 365 | 76 | 磷酸 | 24 h/25 ℃ | [ |

| 动态键类型 | 类玻璃高分子基体 | 拉伸强度/MPa | 层间剪切强度/MPa | 回收方法 | 回收时间/温度 | 文献编号 |

|---|---|---|---|---|---|---|

| 酯键 | 双酚A二缩水甘油醚 | 90 | - | 乙二醇 | 4 h/180 ℃ | [ |

| 衣康酸基环氧树脂 | 423 | 45 | 氢氧化钠 | 5 h/25 ℃ | [ | |

| 桐油基三甘油酯 | 541 | - | 乙醇胺 | 1 h/90 ℃ | [ | |

| 双酚A二缩水甘油醚 | 495 | - | 乙醇胺 | 1 h/100 ℃ | [ | |

| 环氧氯丙烷 | 120 | - | 乙醇 | 1 h/25 ℃ | [ | |

| 甘油三缩水甘油醚 | 585 | 43 | 乙二醇 | 12 h/180 ℃ | [ | |

| 二硫键 | 双(4⁃缩水甘油氧基苯基)二硫化物 | 334 | - | 二硫苏糖醇 | 1 h/90 ℃ | [ |

| 愈创木酚环氧树脂 | - | - | 巯基乙醇 | 25 ℃ | [ | |

| 双酚A二缩水甘油醚 | 401 | - | 巯基乙醇 | 24 h/100 ℃ | [ | |

| 亚胺键 | 香草醛 | 763 | - | 盐酸 | 15 h/25 ℃ | [ |

| 香草醛 | 505 | - | 盐酸 | 24 h/60 ℃ | [ | |

| 超支化聚酰亚胺 | 681 | 32 | 磷酸 | 8 h/90 ℃ | [ | |

| 环氧大豆油 | 145 | - | 盐酸 | 24 h/25 ℃ | [ | |

| 硼酯键 | 硼酸三聚体 | 569 | - | 乙醇 | 4 h/95 ℃ | [ |

| 硼化三嵌段共聚物 | 730 | - | 频哪醇 | 12 h/65 ℃ | [ | |

| 环氧亚麻籽油 | 220 | - | 乙醇 | 3 h/75 ℃ | [ | |

| 二硒键 | 双酚A二缩水甘油醚 | 650 | - | 二硒化物 | 12 h/40 ℃ | [ |

| 六氢三嗪键 | 端超支化环氧 | 365 | 76 | 磷酸 | 24 h/25 ℃ | [ |

| 1 | Shi X H, Xu Y J, Long J W, et al. Layer⁃by⁃layer assembled flame⁃retardant architecture toward high⁃performance carbon fiber composite [J]. Chemical Engineering Journal, 2018, 353: 550⁃558. |

| 2 | Zhuang X, Ma J, Liu F, et al. Characterization of hydrothermal aging induced voids in carbon fiber reinforced epoxy resin composites using micro⁃computed tomography [J]. Polymer Degradation and Stability, 2022, 206: 110198. |

| 3 | Pansare A V, Khairkar S R, Shedge A. A., et al. In situ nanoparticle embedding for authentication of epoxy composites [J]. Advanced Materials, 2018, 30(33): 1801523. |

| 4 | Forintos N, Czigany T. Multifunctional application of carbon fiber reinforced polymer composites: electrical properties of the reinforcing carbon fibers⁃a short review [J]. Composites Part B⁃Engineering, 2019, 162: 331⁃343. |

| 5 | Yu K, Shi Q, Dunn M L, et al. Carbon fiber reinforced thermoset composite with near 100 % recyclability [J]. Advanced Functional Materials, 2016, 26(33): 6 098⁃6 106. |

| 6 | Zou W, Dong J, Luo Y, et al. Dynamic covalent polymer networks: from old chemistry to modern day innovations [J]. Advanced Materials, 2017, 29(14): 1606100. |

| 7 | Denissen W, Winne J, Du Prez F. Vitrimers: permanent organic networks with glass⁃like fluidity, Chem [J]. Sci, 2016, 7(1): 30⁃38. |

| 8 | Vidal J, Hornero C, Garcia R, et al. Use of covalent dynamic networks as binders on epoxy‐based carbon fiber composites: effect on properties, processing, and recyclability [J]. Polymer Composites, 2023, 44(11): 7 444⁃7 456. |

| 9 | Feng X, Li G. Room⁃temperature self⁃healable and mechanically robust thermoset polymers for healing delamination and recycling carbon fibers [J]. ACS Applied Materials & Interfaces, 2021, 13(44): 53 099⁃53 110. |

| 10 | Taynton P, Ni H, Zhu C, et al. Repairable woven carbon fiber composites with full recyclability enabled by malleable polyimine networks [J]. Advanced Materials, 2016, 28(15): 2 904⁃2 909. |

| 11 | Zhou Z, Kim S, Bowland C C, et al. Unraveling a path for multi⁃cycle recycling of tailored fiber⁃reinforced vitrimer composites [J]. Cell Reports Physical Science, 2022, 3(9): 101036. |

| 12 | Ma X, Xu H, Xu Z, et al. Closed⁃loop recycling of both resin and fiber from high⁃performance thermoset epoxy/carbon fiber composites [J]. ACS Macro Letters, 2021, 10(9): 1 113⁃1 118. |

| 13 | 张 希. 可多次塑型、易修复及耐低温的三维动态高分子结构 [J]. 高分子学报, 2016 (6): 685⁃687. |

| ZHANG X. Reconfigurable,easy repairable and low⁃temperature resistant dynamic 3D polymer structures [J]. Acta Polymerica Sinica, 2016 (6): 685⁃687. | |

| 14 | Montarnal D, Capelot M, Tournilhac F, et al. Silica⁃like malleable materials from permanent organic networks [J]. Science, 2011, 334(6058): 965⁃968. |

| 15 | 阮芳涛, 施 建, 徐珍珍, 等. 碳纤维增强树脂基复合材料的回收及其再利用研究进展 [J]. 纺织学报, 2019, 40(6): 153⁃158. |

| RUAN F T, SHI J, XU J J, et al. Research progress in recycling and reuse of carbon fiber reinforced resin composites [J]. Journal of Textile Research, 2019, 40(6): 153⁃158. | |

| 16 | Li W, Xiao L, Huang J, et al. Bio⁃based epoxy vitrimer for recyclable and carbon fiber reinforced materials: synthesis and structure⁃property relationship [J]. Composites Science and Technology, 2022, 227: 109575. |

| 17 | Liu Y, Wang B, Ma S, et al. Catalyst⁃free malleable, degradable, bio⁃based epoxy thermosets and its application in recyclable carbon fiber composites [J]. Composites Part B: Engineering, 2021, 211: 108654. |

| 18 | Xu Y Z, Dai S L, Zhang H B, et al. Reprocessable, self⁃adhesive, and recyclable carbon fiber⁃reinforced composites using a catalyst⁃free self⁃healing bio⁃based vitrimer matrix [J]. Acs Sustainable Chemistry & Engineering, 2021, 9(48): 16 281⁃16 290. |

| 19 | Li W, Chang Q, Xiao L, et al. Readily recyclable, auto⁃catalyzed tung oil⁃derived vitrimers and carbon fiber⁃reinforced composites [J]. Acs Applied Polymer Materials, 2023, 5(6): 4 498⁃4 508. |

| 20 | Yu L, Zhu C, Sun X, et al. Rapid fabrication of malleable fiber reinforced composites with vitrimer powder [J]. Acs Applied Polymer Materials, 2019, 1(9): 2 535⁃2 542. |

| 21 | Zhang W, Wu J, Gao L, et al. Recyclable, reprocessable, self⁃adhered and repairable carbon fiber reinforced polymers using full biobased matrices from camphoric acid and epoxidized soybean oil [J]. Green Chemistry, 2021, 23(7): 2 763⁃2 772. |

| 22 | Xu Y, Zhang H, Dai S, et al. Hyperbranched polyester catalyzed self⁃healing bio⁃based vitrimer for closed⁃loop recyclable carbon fiber⁃reinforced polymers [J]. Composites Science and Technology, 2022, 228: 109676. |

| 23 | Chen J H, Liu B W, Lu J H, et al. Catalyst⁃free dynamic transesterification towards a high⁃performance and fire⁃safe epoxy vitrimer and its carbon fiber composite [J]. Green Chemistry, 2022, 24(18): 6 980⁃6 988. |

| 24 | Liu T, Hao C, Shao L, et al. Carbon fiber reinforced epoxy vitrimer: robust mechanical performance and facile hydrothermal decomposition in pure water [J]. Macromolecular Rapid Communications, 2021, 42(3): 2000458. |

| 25 | Chen M, Luo W, Lin S, et al. Recyclable, reprocessable, self⁃healing elastomer⁃like epoxy vitrimer with low dielectric permittivity and its closed⁃loop recyclable carbon fiber reinforced composite [J]. Composites Part B: Engineering, 2023, 257: 110666. |

| 26 | Si H, Zhou L, Wu Y, et al. Rapidly reprocessable, degradable epoxy vitrimer and recyclable carbon fiber reinforced thermoset composites relied on high contents of exchangeable aromatic disulfide crosslinks [J]. Composites Part B: Engineering, 2020, 199: 108278. |

| 27 | Ruiz de Luzuriaga A, Martin R, Markaide N, et al. Epoxy resin with exchangeable disulfide crosslinks to obtain reprocessable, repairable and recyclable fiber⁃reinforced thermoset composites[J]. Materials Horizons, 2020, 7(9): 2 460⁃2 461. |

| 28 | Martinez⁃Diaz D, Cortés A, Jiménez⁃Suárez A, et al. Hardener isomerism and content of dynamic disulfide bond effect on chemical recycling of epoxy networks [J]. Acs Applied Polymer Materials, 2022, 4(7): 5 068⁃5 076. |

| 29 | Tang S, Lin H, Dong K, et al. Closed⁃loop recycling and degradation of guaiacol⁃based epoxy resin and its carbon fiber reinforced composites with SS exchangeable bonds [J]. Polymer Degradation and Stability, 2023, 210: 110298. |

| 30 | Liu Y Y, Liu G L, Li Y D, et al. Biobased high⁃performance epoxy vitrimer with UV shielding for recyclable carbon fiber reinforced composites [J]. Acs Sustainable Chemistry & Engineering, 2021, 9(12): 4 638⁃4 647. |

| 31 | Nabipour H, Wang X, Kandola B, et al. A bio⁃based intrinsically flame⁃retardant epoxy vitrimer from furan derivatives and its application in recyclable carbon fiber composites [J]. Polymer Degradation and Stability, 2023, 207: 110206. |

| 32 | Wang S, Ma S, Li Q, et al. Facile in situ preparation of high⁃performance epoxy vitrimer from renewable resources and its application in nondestructive recyclable carbon fiber composite [J]. Green Chemistry, 2019, 21(6): 1 484⁃1 497. |

| 33 | Wang Y, Xu A, Zhang L, et al. Recyclable carbon fiber reinforced vanillin‐based polyimine vitrimers: degradation and mechanical properties study [J]. Macromolecular Materials and Engineering, 2022, 307(7): 2100893. |

| 34 | Memon H, Wei Y, Zhang L, et al. An imine⁃containing epoxy vitrimer with versatile recyclability and its application in fully recyclable carbon fiber reinforced composites [J]. Composites Science and Technology, 2020, 199: 108314. |

| 35 | Liu Y Y, He J, Li Y D, et al. Biobased epoxy vitrimer from epoxidized soybean oil for reprocessable and recyclable carbon fiber reinforced composite [J]. Composites Communications, 2020, 22: 100445. |

| 36 | Chen B, Lai G, Liu Z, et al. Silicon⁃bridged epoxy vitrimers with antibacterial and UV⁃blocking properties [J]. Acs Applied Polymer Materials, 2023, 5(8): 6 421⁃6 428. |

| 37 | Hong J, Hong Y, Jeong J, et al. Robust biobased vitrimers and its application to closed⁃loop recyclable carbon fiber⁃reinforced composites [J]. Acs Sustainable Chemistry & Engineering, 2023, 11(38): 14 112⁃14 123. |

| 38 | Rahman M A, Karunarathna M S, Bowland C C, et al. Tough and recyclable carbon⁃fiber composites with exceptional interfacial adhesion via a tailored vitrimer⁃fiber interface [J]. Cell Reports Physical Science, 2023, 4(12): 101695. |

| 39 | Sangaletti D, Ceseracciu L, Marini L, et al. Biobased boronic ester vitrimer resin from epoxidized linseed oil for recyclable carbon fiber composites [J]. Resources, Conservation and Recycling, 2023, 198: 107205. |

| 40 | An X, Ding Y, Xu Y, et al. Epoxy resin with exchangeable diselenide crosslinks to obtain reprocessable, repairable and recyclable fiber⁃reinforced thermoset composites [J]. Reactive and Functional Polymers, 2022, 172: 105189. |

| 41 | Otera J. Transesterification [J]. Chemical Reviews, 1993, 93(4): 1 449⁃1 470. |

| 42 | Han J, Liu T, Hao C, et al. A catalyst⁃free epoxy vitrimer system based on multifunctional hyperbranched polymer [J]. Macromolecules, 2018, 51(17): 6 789⁃6 799. |

| 43 | Humphrey R, Hawkins J. Reduction of aromatic disulfides with triphenylphosphine [J]. Analytical Chemistry, 1964, 36(9): 1 812⁃1 814. |

| 44 | Singh R, Kats L. Catalysis of reduction of disulfide by selenol [J]. Analytical biochemistry, 1995, 232(1): 86⁃91. |

| 45 | Bach R D, Dmitrenko O, Thorpe C. Mechanism of thiolate⁃ disulfide interchange reactions in biochemistry [J]. The Journal of Organic Chemistry, 2008, 73(1): 12⁃21. |

| 46 | Mai V D, Shin S R, Lee D S, et al. Thermal healing, reshaping and ecofriendly recycling of epoxy resin crosslinked with schiff base of vanillin and hexane-1,6⁃diamine [J]. Polymers, 2019, 11(2): 293. |

| 47 | 王艳萍, 刘晓琴, 井新利, 等. 环氧树脂类玻璃高分子研究进展 [J]. 化学通报, 2021, 84(4): 313⁃321. |

| WANG Y P, LIU X Q, JING X L, et al. Research progress in epoxy vitrimer [J]. Chemistry, 2021, 84(4): 313⁃321. | |

| 48 | Wanasinghe S V, Dodo O J, Konkolewicz D. Dynamic bonds: adaptable timescales for responsive materials [J]. Angewandte Chemie International Edition, 2022, 61(50): e202206938. |

| 49 | Li M, Yu H, Liu X, et al. Dual rapid self⁃healing and easily recyclable carbon fiber reinforced vitrimer composites [J]. Chemical Engineering Journal, 2024, 480: 148147. |

| 50 | Xia J, Li T, Lu C, et al. Selenium⁃containing polymers: perspectives toward diverse applications in both adaptive and biomedical materials [J]. Macromolecules, 2018, 51(19): 7 435⁃7 455. |

| 51 | Xu H, Hu J, Liu X, et al. Interface strengthening and high⁃value recycling of epoxy resin/carbon fiber fabric composites [J]. Chemical Engineering Journal, 2023, 465: 142998. |

| 52 | Chabert E, Vial J, Cauchois J P, et al. Multiple welding of long fiber epoxy vitrimer composites [J]. Soft Matter, 2016, 12(21): 4 838⁃4 845. |

| 53 | 吴伟萍, 王威力. 树脂基复合材料RTM工艺的研究进展 [J]. 纤维复合材料, 2022, 39(2): 91⁃94. |

| WU W P, WANG W L. Research progress of RTM for resin matrix composites [J]. Fiber Composites, 2022, 39(2): 91⁃94. | |

| 54 | 汪 东, 李丽英, 柯红军, 等. 高性能可回收环氧树脂及其复合材料的制备与性能研究 [J]. 高分子学报, 2020, 51(3): 303⁃310. |

| WANG D, LI L Y, KE H J, et al. Preparation and properties of recyclable high⁃performance epoxy resins and composites [J]. Acta Polymerica Sinica, 2020, 51(3): 303⁃310. | |

| 55 | 滕凌虹, 曹伟伟, 朱 波, 等. 纤维增强热塑性树脂预浸料的制备工艺及研究进展 [J]. 材料工程, 2021, 49(2): 42⁃53. |

| TENG L H, CAO W W, ZHU B, et al. Research progress in the preparation of fiber reinforced thermoplastic resin prepreg [J]. Journal of Materials Engineering, 2021, 49(2): 42⁃53. | |

| 56 | Denissen W, De Baere I, Van Paepegem W, et al. Vinylogous urea vitrimers and their application in fiber reinforced composites [J]. Macromolecules, 2018, 51(5): 2 054⁃2 064. |

| 57 | Wang S, Xing X, Zhang X, et al. Room⁃temperature fully recyclable carbon fibre reinforced phenolic composites through dynamic covalent boronic ester bonds [J]. Journal of Materials Chemistry A, 2018, 6(23): 10 868⁃10 878. |

| 58 | 刘 嘉, 周 蕾, 罗文东, 等. 复合材料成型技术研究现状 [J]. 橡塑技术与装备, 2022, 48(8): 27⁃31. |

| LIU J, ZHOU L, LUO W D, et al. Research status of composite material forming technology [J]. China Rubber/Plastics Technology and Equipment, 2022, 48(8): 27⁃31. | |

| 59 | Hernández S, Sket F, González C, et al. Optimization of curing cycle in carbon fiber⁃reinforced laminates: void distribution and mechanical properties [J]. Composites Science and Technology, 2013, 85: 73⁃82. |

| 60 | Kandemir A, Longana M L, Hamerton I, et al. Developing aligned discontinuous flax fibre composites: Sustainable matrix selection and repair performance of vitrimers [J]. Composites Part B⁃Engineering, 2022, 243: 110139. |

| 61 | Zureick A, Scott D. Short⁃term behavior and design of fiber⁃reinforced polymeric slender members under axial compression [J]. Journal of Composites for Construction, 1997, 1(4): 140⁃149. |

| 62 | Tena I, Sarrionandia M, Torre J, et al. The effect of process parameters on ultraviolet cured out of die bent pultrusion process [J]. Composites Part B: Engineering, 2016, 89: 9⁃17. |

| 63 | Aranberri I, Landa M, Elorza E, et al. Thermoformable and recyclable CFRP pultruded profile manufactured from an epoxy vitrimer [J]. Polymer Testing, 2021, 93: 106931. |

| 64 | 宋晨曦, 林海涛, 赖恩平, 等. 碳纤维增强热塑性复合材料成型工艺的研究进展 [J]. 纺织科学与工程学报, 2023, 40(4): 86⁃93. |

| SONG C X, LIN H T, LAI E P, et al. Research progress of the forming process of carbon fiber reinforced thermoplastic composites [J]. Journal of Textile Science and Engineering, 2023, 40(4): 86⁃93. | |

| 65 | Jiang Z, Diggle B, Tan M L, et al. Extrusion 3D printing of polymeric materials with advanced properties [J]. Advanced Science, 2020, 7(17): 2001379. |

| 66 | Shi Q, Yu K, Kuang X, et al. Recyclable 3D printing of vitrimer epoxy [J]. Materials Horizons, 2017, 4(4): 598⁃607. |

| [1] | 曲道鹏, 张涛, 华晨曦, 宋欣雨, 程昌利, 刘禹, 王震宇. 高强电磁屏蔽环氧复合材料的3D打印工艺研究[J]. 中国塑料, 2024, 38(9): 24-29. |

| [2] | 翟孟雷, 陈文广, 黄明, 雷金宇, 张娜, 刘春太, 高国利. 大丝束碳纤维束内横向动态渗透率计算方法及数值验证[J]. 中国塑料, 2024, 38(9): 54-59. |

| [3] | 孙鹤, 何欣, 骆彤雨, 吉欣, 廖琪玲, 张玉霞, 周洪福. ABS/CNTs/Fe3O4复合材料及其双峰泡沫的电磁屏蔽性能研究[J]. 中国塑料, 2024, 38(8): 46-52. |

| [4] | 戈家荣, 关国英, 姚子佳, 童方强, 王博群. 大型无人机复合材料舵面整体制造技术[J]. 中国塑料, 2024, 38(8): 76-80. |

| [5] | 张馨鹏, 徐军, 杜夕彦, 郭宝华. 纳米蒙脱土复合改性酯化淀粉及其性能研究[J]. 中国塑料, 2024, 38(8): 8-12. |

| [6] | 何和智, 黄宗海, 赖文, 熊华威. PLA/PBAT/CB防静电包装材料的制备及其性能研究[J]. 中国塑料, 2024, 38(7): 1-8. |

| [7] | 魏佳, 刘凯, 彭丽娟, 田阳阳, 赵琳, 李艳红, 杨佩佩, 李松伟, 陆波. 壳聚糖/聚苯胺⁃氧化石墨烯尼古丁分子印迹复合材料的制备与吸附性能研究[J]. 中国塑料, 2024, 38(7): 32-36. |

| [8] | 曹帅, 姜涛, 刘雄, 王瑛, 李文戈, 吴新锋. MXene导热复合材料的制备研究进展[J]. 中国塑料, 2024, 38(6): 139-144. |

| [9] | 刘帅, 赵子豪, 俞盈, 杨嘉欣, 张扬. 核壳型碳纤维毡@聚苯胺复合材料的制备及其介电性能[J]. 中国塑料, 2024, 38(6): 25-30. |

| [10] | 王涵, 梁金华, 高振国, 姜炜, 周昊. 微胶囊型自修复环氧树脂材料的力学性能及修复效率[J]. 中国塑料, 2024, 38(5): 40-46. |

| [11] | 赵小红, 卢杏. 淀粉的改性及其对淀粉/PBAT/碳酸钙复合材料结构和性能的影响[J]. 中国塑料, 2024, 38(4): 40-46. |

| [12] | 姜曙, 王阳, 翟孟雷, 李庆涛, 黄明, 刘春太. 连续碳纤增强B柱加强板结构设计与铺覆仿真[J]. 中国塑料, 2024, 38(4): 73-78. |

| [13] | 崔晓凤, 方梅, 杜松林, 张娜, 黄明, 高国利, 许经纬. 电泳烘烤对EP/CF及EP/CF/GF复合材料力学性能的影响[J]. 中国塑料, 2024, 38(3): 1-6. |

| [14] | 国江, 许梦伊, 李辉, 黄想, 林浩, 姜胜宝, 陈尚, 陈程. 聚丙烯/氧化锆复合材料的制备及介电性能研究[J]. 中国塑料, 2024, 38(3): 44-48. |

| [15] | 赵川涛, 贾志欣, 刘立君, 李继强, 张臣臣, 荣迪, 高利珍, 姚吉尔. 环氧树脂/碳纤维复合材料模压制品翘曲变形的影响因素分析[J]. 中国塑料, 2024, 38(3): 59-66. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2