京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2

《中国塑料》编辑部 ©2008-2024 版权所有

地址:北京市海淀区阜成路11号 邮编:100048

编辑部:010-68985541 联系信箱:cp@plaschina.com.cn

广告部/发行部:010-68985253 本系统由北京玛格泰克科技发展有限公司设计开发

中国塑料 ›› 2025, Vol. 39 ›› Issue (4): 118-125.DOI: 10.19491/j.issn.1001-9278.2025.04.020

• 综述 • 上一篇

收稿日期:2024-06-20

出版日期:2025-04-26

发布日期:2025-04-23

作者简介:栗小茜(1996- )女,从事材料科学与工程以及汽车智能制造方面研究,lxq07252022@126.com

基金资助:

LI Xiaoqian1( ), CHEN Hao1, GE Zhenghao2, SONG Haojie3, GAO Yanjun1

), CHEN Hao1, GE Zhenghao2, SONG Haojie3, GAO Yanjun1

Received:2024-06-20

Online:2025-04-26

Published:2025-04-23

摘要:

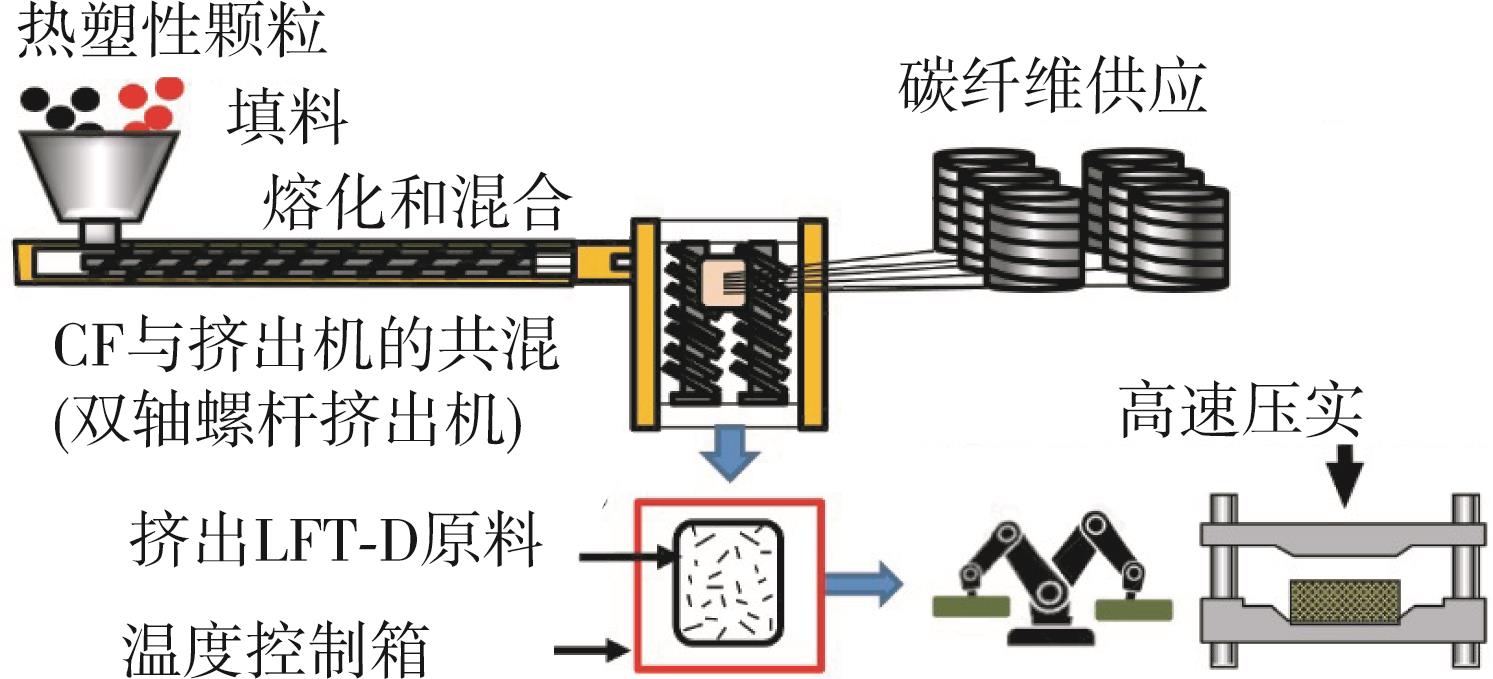

对不同种类的车用碳纤维复合材料(CFRPs)的成型工艺进行了分析概述,详细对比了CFRPs性能提升的各类方案,并结合工业应用案例对现有成型工艺和设计方案进行讨论分析,探讨了车用CFRPs绿色化技术的发展前景,以及汽车产业车辆轻量化材料研究所面临的机遇与挑战。

中图分类号:

栗小茜, 陈浩, 葛正浩, 宋浩杰, 高彦军. 车用碳纤维复合材料结构优化与性能研究进展[J]. 中国塑料, 2025, 39(4): 118-125.

LI Xiaoqian, CHEN Hao, GE Zhenghao, SONG Haojie, GAO Yanjun. Research progress in structural optimization and performance investigation of carbon⁃fiber⁃reinforced composite materials for automobiles[J]. China Plastics, 2025, 39(4): 118-125.

| 前驱体 | 聚合物基体 | 拉伸强度/GPa | 断裂伸长率/% |

|---|---|---|---|

| PAN[ | PA | 7.3 | 7.7 |

| CPVC[ | - | 1.83 | 6.7 |

| 木质素[ | PA | 4.3 | 3.0±0.1 |

| 前驱体 | 聚合物基体 | 拉伸强度/GPa | 断裂伸长率/% |

|---|---|---|---|

| PAN[ | PA | 7.3 | 7.7 |

| CPVC[ | - | 1.83 | 6.7 |

| 木质素[ | PA | 4.3 | 3.0±0.1 |

| 改性方案 | 聚合物 基体 | 界面性能 | 提升率/ % |

|---|---|---|---|

| 等离子[ | 环氧树脂 | (46 | 18 |

| 高能辐照(γ射线)[ | - | 78.6 MPa | 120.9 |

| 磁控溅射(C/Ta)[ | 环氧树脂 | 60 MPa | 63.53 |

| 施胶(乙烯基聚硅氧烷)[ | 橡胶 | 66.6 N | 221 |

| 施胶(改性硅烷偶联剂)[ | PA6 | 52.53 MPa | 23.83 |

| 电化学(C25H33BrFeN)[ | 环氧树脂 | 30.82 MPa | 59.3 |

| 电化学(C6H4BF4N3O2)[ | PP | (232.03 | 36.1 |

| 酸处理(硫酸)[ | 环氧树脂 | 63.1 MPa | 80.8 |

| 酸处理(硝酸)[ | PA6 | 184.4 MPa(150 ℃) | - |

| 改性方案 | 聚合物 基体 | 界面性能 | 提升率/ % |

|---|---|---|---|

| 等离子[ | 环氧树脂 | (46 | 18 |

| 高能辐照(γ射线)[ | - | 78.6 MPa | 120.9 |

| 磁控溅射(C/Ta)[ | 环氧树脂 | 60 MPa | 63.53 |

| 施胶(乙烯基聚硅氧烷)[ | 橡胶 | 66.6 N | 221 |

| 施胶(改性硅烷偶联剂)[ | PA6 | 52.53 MPa | 23.83 |

| 电化学(C25H33BrFeN)[ | 环氧树脂 | 30.82 MPa | 59.3 |

| 电化学(C6H4BF4N3O2)[ | PP | (232.03 | 36.1 |

| 酸处理(硫酸)[ | 环氧树脂 | 63.1 MPa | 80.8 |

| 酸处理(硝酸)[ | PA6 | 184.4 MPa(150 ℃) | - |

| 填料 | 聚合物基体 | 界面性能 | 提升率/% | |

|---|---|---|---|---|

| 聚合物 | 苯氧热塑性塑料[ | 环氧树脂 | 69 MPa | 38 |

| 核壳橡胶 [ | 环氧树脂 | 77 MPa | 54 | |

| 聚醚砜[ | 环氧树脂 | 88 MPa | 18 | |

| 金属氧化物 | Fe2O3[ | 环氧树脂 | 64.01 MPa | 15 |

| Al2O3[ | 环氧树脂 | 270.70 MPa | 19.7 | |

| SiO2[ | 环氧树脂 | 81.8 MPa | 72.9 | |

无机 材料 | 羟基磷灰石(HAp)[ | 聚芳基醚酮 | 67.2 MPa | 40.9 |

| 六方氮化硼(h⁃BN)[ | 聚醚醚酮(PEEK) | 176.05 MPa | 97.54 | |

| MXene[ | 环氧树脂 | 57.43 MPa | 49.9 | |

| 填料 | 聚合物基体 | 界面性能 | 提升率/% | |

|---|---|---|---|---|

| 聚合物 | 苯氧热塑性塑料[ | 环氧树脂 | 69 MPa | 38 |

| 核壳橡胶 [ | 环氧树脂 | 77 MPa | 54 | |

| 聚醚砜[ | 环氧树脂 | 88 MPa | 18 | |

| 金属氧化物 | Fe2O3[ | 环氧树脂 | 64.01 MPa | 15 |

| Al2O3[ | 环氧树脂 | 270.70 MPa | 19.7 | |

| SiO2[ | 环氧树脂 | 81.8 MPa | 72.9 | |

无机 材料 | 羟基磷灰石(HAp)[ | 聚芳基醚酮 | 67.2 MPa | 40.9 |

| 六方氮化硼(h⁃BN)[ | 聚醚醚酮(PEEK) | 176.05 MPa | 97.54 | |

| MXene[ | 环氧树脂 | 57.43 MPa | 49.9 | |

| 1 | 高丰岭,王雪颖,战 楠,等.碳纤维复合材料车用结构设计与仿真研究综述 [J]. 汽车科技,2020(2):74⁃80. |

| GAO F L, WANG X Y, ZHAN N, et al. A research review on design and simulation for vehicle structure made of carbon fiber reinforced polymers [J]. Auto Sci⁃Tech,2020(2):74⁃80. | |

| 2 | 李永刚.碳纤维复合材料汽车保险杠的研究 [D]. 沈阳:沈阳理工大学,2015. |

| 3 | 吴方贺.碳纤维复合材料发动机罩结构设计与优化[D].长春:吉林大学, 2017. |

| 4 | Botkin M E. Modelling and optimal design of a carbon fibre reinforced composite automotive roof [J]. Engineering with Computers,2000,16(1):16⁃23. |

| 5 | 荆云娟,崔 博,马 军,等.碳纤维复合材料产业链发展现状[J].合成纤维,2023,52(10):37⁃42. |

| 6 | 康元春,郑 冲.车用电池箱体碳纤维材料铺层研究[J].机械设计,2020,37(12):102⁃106. |

| KANG Y C, ZHENG C. Carbon⁃fiber layer design for vehicle battery box [J]. Journal of Mechanical Design,2020,37(12):102⁃106. | |

| 7 | 魏雅君. 树脂传递模塑成型工艺中预成型体渗透率预测及充模仿真[D].哈尔滨:哈尔滨工业大学,2015. |

| 8 | 高 猛,程从前,孟宪明,等.基于PAM⁃RTM的复合材料电池箱上盖板CRTM工艺填充仿真[J].工程塑料应用,2022,50(11):55⁃60. |

| GAO M, CHENG C Q, MENG X M, et al. Filling simulation of CRTM process for upper cover plate of composite battery box based on PAM⁃RTM [J]. Engineering Plastics Application,2022,50(11):55⁃60. | |

| 9 | Chinkanjanarot Sorayot, Matthew S, et al. Multiscale thermal modeling of cured cycloaliphatic epoxy/carbon fiber composites [J]. Journal of Applied Polymer Science,2018,135(25):63⁃71. |

| 10 | 臧 杰,周金宇.基于自适应遗传算法的碳纤维复合材料汽车防撞梁优化设计研究[J].机械设计,2019,36(4):87⁃91. |

| ZANJ J, ZHOU J Y. Optimization design of CFRP automobile collision⁃resistant beam based on adaptive genetic algorithm [J]. Journal of Machine Desgin,2019,36(4):87⁃91. | |

| 11 | Muhammad Salman Sarfraz, Hong Hyunsoo, Su Kim Seong. Recent developments in the manufacturing technologies of composite components and their cost⁃effectiveness in the automotive industry: a review study [J]. Composite Structures,2021,266: 113864. |

| 12 | Djebara Y, Imad A, Saouab A, et al. A numerical modelling for resin transfer molding (RTM) process and effective thermal conductivity prediction of a particle–filled composite carbon–epoxy [J]. Journal of Composite Materials,2020,55(1):1⁃13. |

| 13 | Seuffert Julian, Rosenberg Philipp, karger Luise, et al. Experimental and numerical investigations of pressure⁃controlled resin transfer molding (PC⁃RTM) [J]. Advanced Manufacturing: Polymer Composites Science,2020,6(3):154⁃163. |

| 14 | Zanchini Michele, Longhi Daniel, Mantovani Sara, et al. Fatigue and failure analysis of aluminium and composite automotive wheel rims: experimental and numerical investigation [J]. Engineering Failure Analysis,2023,146:107064. |

| 15 | Park Seung bhin, Lee Dong woo, Song Jung il. Fabrication and evaluation of mechanical properties of carbon/epoxy square tube using pressure bag molding and compared with autoclave method [J]. International Journal of Precision Engineering and Manufacturing,2018,19(3):441⁃446. |

| 16 | Gue Wan Hwang, Kim Jae Won, Cho Jae Ung. A Study on the fracture behavior of CFRP specimen with bonding interface under mode 1 fatigue load according to laminate angle [J]. International Journal of Precision Engineering and Manufacturing,2018,19(12):1 829⁃1 836. |

| 17 | Lee Jung⁃Min, Lee Chan⁃Joo, Kim Byung⁃Min, et al. Design of prepreg compression molding for manufacturing of CFRTP B⁃pillar reinforcement with equivalent mechanical properties to existing steel part [J]. International Journal of Precision Engineering and Manufacturing,2020,21(3):545⁃556. |

| 18 | Kim Jae⁃Hong, Jung Yong⁃Hun, Lambiase Francesco, et al. Novel approach toward the forming process of CFRP reinforcement with a hot stamped part by prepreg compression molding [J]. Materials,2022,15(14):4 743⁃4 743. |

| 19 | Garschke C, Weimer C, Parlevliet P P, et al. Out⁃of⁃autoclave cure cycle study of a resin film infusion process using in situ process monitoring [J]. Composites Part A,2012,43(6):935⁃944. |

| 20 | Lee Jeong⁃Min, Kim Byung⁃Min, Ko Dae⁃Cheol. Development of vacuum⁃assisted prepreg compression molding for production of automotive roof panels [J]. Composite Structures,2019,213:144⁃152. |

| 21 | 高 翔,马鸣图,李 波,等.汽车用LFT前端框架的开发和应用[J].化工新型材料,2020,48(10):263⁃267. |

| GAO X, MA M T, LI B, et al. Development and application of LFT front⁃end module for automobile [J]. New chemical materials,2020,48(10):263⁃267. | |

| 22 | Ishikawa Takashi, Amaoka Kazuaki, Masubuchi Yuichi, et al. Overview of automotive structural composites technology developments in Japan [J]. Composites Science and Technology,2018,155:221⁃246. |

| 23 | Lee Heesook, Cho Donghwan. Effects of A, B, and S components on fiber length distribution, mechanical, and impact properties of carbon fiber/ABS composites produced by different processing methods [J]. Journal of Applied Polymer Science,2021,138(28):1⁃13. |

| 24 | Kuhn Christoph, Koerner Enrico, Taeger Olaf. A simulative overview on fiber predictions models for discontinuous long fiber composites [J]. Polymer Composites,2020,41(1):73⁃81. |

| 25 | Susanne Katrin Kugler, Kech Armin, Cruz Camilo, et al. Fiber orientation predictions—a review of existing models [J]. Journal of Composites Science,2020,4(69):1⁃21. |

| 26 | Romanenko V. Duhovic M. Schommer D,et al. Advanced process simulation of compression molded carbon fiber sheet molding compound (C⁃SMC) parts in automotive series applications [J]. Composites Part A,2022,157:106924. |

| 27 | Stelzer Philipp S, Umut Cakmak, Lisa Eisner, et al. Experimental feasibility and environmental impacts of compression molded discontinuous carbon fiber composites with opportunities for circular economy [J]. Composites Part B,2022,234:109638. |

| 28 | 赵英男.轨道交通车辆用碳纤维复合材料的性能研究[J].中国新技术新产品,2024(2):57⁃59. |

| ZHAO Y N. Research on the performance of carbon fiber composite materials for rail transit vehicles [J]. China Academic Journal Electronic, 2024(2):57⁃59. | |

| 29 | 秦铭泽,张伟涛,姬晓晨,等.复合材料在我国航空航天与轨道交通领域中的应用研究[J].热加工工艺,2024,53(6):6⁃9. |

| QIN M Z, ZHANG W T, JI X C, et al. Application research of composite materials in aerospace and rail transit in China [J]. Hot Working Technology,2024,53(6):6⁃9. | |

| 30 | Baker Darren A, Gallego Nidia C, Baker Frederick S. On the characterization and spinning of an organic⁃purified lignin toward the manufacture of low⁃cost carbon fiber [J]. Journal of Applied Polymer Science,2012,124(1):227⁃234. |

| 31 | Hiremath Nitilaksha, Young Stephen, Ghossein Hicham, et al. Low cost textile⁃grade carbon⁃fiber epoxy composites for automotive and wind energy applications[J]. Composites Part B,2020,198:108156. |

| 32 | Le N D, Varley R J, Hummel M, et al. A review of future directions in the development of sustainable carbon fiber from bio⁃based precursors[J]. Materials Today Sustainability,2022,20:100251. |

| 33 | Mondal Kunal, Maitra Tanmoy, Alok Kumar Srivastava, et al. 110th anniversary: particle size effect on enhanced graphitization and electrical conductivity of suspended gold/carbon composite nanofibers [J]. Industrial & Engineering Chemistry Research,2020,59(5):1 944⁃1 952. |

| 34 | Li Denghua, Lu Chunxiang, Gangping Wuet al. Structural heterogeneity and its influence on the tensile fracture of PAN⁃based carbon fibers[J]. RSC Advances,2014,4(105):60 648⁃60 651. |

| 35 | Ashley Morris E., Weisenberger Matthew C, Abdallah Mohamed G, et al. High performance carbon fibers from very high molecular weight polyacrylonitrile precursors[J]. Carbon,2016,101:245⁃252. |

| 36 | Merah Nesar. Natural weathering effects on some properties of CPVC pipe material [J]. Journal of Materials Processing Tech,2007,191:198⁃201. |

| 37 | Kim Jiyeon, Lee Jaewoong, Chaehyun Jo, et al. Development of low cost carbon fibers based on chlorinated polyvinyl chloride (CPVC) for automotive applications[J]. Materials Design,2021,204:109682. |

| 38 | Mainka Hendrik, Täger Olaf, Körner Enrico, et al. Lignin⁃an alternative precursor for sustainable and cost⁃effective automotive carbon fiber[J]. Journal of Materials Research and Technology,2015,4(3):283⁃296. |

| 39 | Anne Beaucamp, Muhammad Muddasar, Mario Culebras, et al. Sustainable lignin⁃based carbon fibre reinforced polyamide compo⁃sites: production, characterisation and life cycle analysis [J]. Composites Communications,2024,45:101782. |

| 40 | Chinkanjanarot Sorayot, Radue Matthew S, Gowtham S, et al. Multiscale thermal modeling of cured cycloaliphatic epoxy/carbon fiber composites [J]. Journal of Applied Polymer Science,2018,135(25):46371. |

| 41 | Sarath Kumar P, Karingamanna Jayanarayanan, Meera Balachandran. High⁃performance thermoplastic polyaryletherketone/carbon fiber composites: comparison of plasma, carbon nanotubes/graphene nano⁃anchoring, surface oxidation techniques for enhanced interface adhesion and properties[J]. Composites Part B,2023,253:110560. |

| 42 | Feng Zhao, Huang Yudong. Uniform modification of carbon fibers in high density fabric by γ⁃ray irradiation grafting[J]. Materials Letters,2011,65:3351⁃3353. |

| 43 | Yang Li, Jiang Shu, Chen Yuan, et al. Effect of carbon/tantalum hybrid film on the properties of carbon fiber and its composites based on magnetron sputtering[J]. Composites Science and Technology,2023,243:110224. |

| 44 | Dong Ruihao, Xie Haonan, Cao Weiyu. Surface modification of carbon fiber by vinyl functionalized silane to enhance the interfacial adhesion with rubber via co⁃vulcanization[J]. Surfaces and Interfaces,2023,43:103591. |

| 45 | Sun Na, Zhu Bo, Cai Xun, et al. 3⁃isocyanatopropyltriethoxysilane block⁃graft engineering tailoring carbon fiber surface to manipulate interface properties of carbon fiber/polyamide 6 composites[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects,2024,682:132920. |

| 46 | ZHANG Xiao⁃fang, YAO Ting⁃ting, LIU Yu⁃ting, et al. Reversible surface modification of pan⁃based carbon fibers by a ferrocene⁃based surfactant [J]. Carbon,2024,216:118554. |

| 47 | Newman Ben, Randall James D, Varley Russell J,et al. Bioinspired hard–soft interface management for superior performance in carbon fibre composites [J]. Fibers and Polymers,2023,24(9):3 279⁃3 288. |

| 48 | Jing Xiao, Tian Siyuan, Hang Zhou, et al. Construction of polar functional groups on the surface of a high⁃modulus carbon fiber and its effect on the interfacial properties of composites [J]. ACS omega,2023,8(32):29 262⁃29 269. |

| 49 | Wei Chen, Hu Zhonglue, Li Xiping, et al. Additive manufacturing of high‐strength polyamide 6 composites reinforced with continuous carbon fiber prepreg [J]. Polymer Composites,2024,45(1):668⁃679. |

| 50 | Dabees Sameh, Borkar Ameya, Newman Ben, et al. Improving carbon fibre reinforced polyphenylene sulfide using amine and phenolic interphase modifications[J]. Composites Part A,2024,179:108045. |

| 51 | He Di, Kim Hyung Chul, Silvano Sommacal, et al. Improving mechanical and life cycle environmental performances of recycled CFRP automotive component by fibre architecture preservation [J]. Composites Part A: Applied Science and Manufacturing,2023;175:107749. |

| 52 | Quan Guipeng, Wu Yunhuan, Li Weiwen, et al. Growth of ZnO nanorods/flowers on the carbon fiber surfaces using sodium alginate as medium to enhance the mechanical properties of composites[J]. International Journal of Biological Macromolecules,2024,260:129457. |

| 53 | Li Yinhui, Sun Jiaojiao, Li Pengwei, et al. High⁃performance piezoelectric nanogenerators based on hierarchical ZnO@CF/PVDF composite film for self⁃powered meteorological sensor[J]. Journal of Materials Chemistry A,2023,11(25):13 708⁃13 719. |

| 54 | Gupta M K, Hindersinn R R. Shelf life of phenolic resole resins [J]. Polymer Engineering and Science,1987,27(13):976⁃978. |

| 55 | Jin Woo Yi, Yu Jin Lee, Sang Bok Lee, et al. Effect of dimethylpolysiloxane liquid on the cryogenic tensile strength and thermal contraction behavior of epoxy resins [J]. Cryogenics,2014,61:63⁃69. |

| 56 | Hirata Tatsuya, Peng Li, Fan Lei, et al. Epoxy nanocomposites with reduced coefficient of thermal expansion [J]. Journal of Applied Polymer Science,2019,136(26):47703. |

| 57 | Yin Lu, Yu Xinye, Lu Han, et al. Recent progress of high⁃performance thermosets based on norbornene functional benzoxazine resins [J]. Polymers,2021,13(9):1 417. |

| 58 | Jubsilp Chanchira, Jantaramaha Jakkrit, Mora Phattarin, et al. Tribological performance and thermal stability of nanorubber⁃modified polybenzoxazine composites for non⁃asbestos friction materials [J]. Polymers,2021,13(15):2 435. |

| 59 | Carlevaris Davide, Fambri Luca, Menapace Cinzia, et al. Assessment of benzoxazine resins as brake pad friction material binder: tribological properties and PM emission [J]. Tribology International,2024,194:109531. |

| 60 | Yi Xu, Sun Xinyue, Zhu Keqi, et al. Mechanical property improvement of recyclable carbon fiber reinforced rigid⁃flexible polybenzoxazine/silica based polyhexahydrotriazine IPN [J]. European Polymer Journal,2023,201:112524. |

| 61 | Liu Xiaohong, Zhang Ending, Liu Jiaming, et al. Self⁃healing, reprocessable, degradable, thermadapt shape memory multifunctional polymers based on dynamic imine bonds and their application in nondestructively recyclable carbon fiber composites[J]. Chemical Engineering Journal,2023,454:139992. |

| 62 | Van Velthem Pascal, Gabriel Sarah, Pardoen Thomas, et al. Synergy between phenoxy and CSR tougheners on the fracture toughness of highly cross⁃linked epoxy⁃based composites [J]. Polymers,2021,13(15):2 477. |

| 63 | Jung Hyun⁃Seok, Park Yonmin, Nah Chang⁃Woon, et al. Evaluation of the mechanical properties of polyether sulfone⁃toughened epoxy resin for carbon fiber composites [J]. Fibers and Polymers,2021,22(1):184⁃195. |

| 64 | Cheng Chunxia, Zhang Mengjie, Wang Siyu, et al. Improving interfacial properties and thermal conductivity of carbon fiber/epoxy composites via the solvent⁃free GO@Fe3O4 nanofluid modified water⁃based sizing agent [J]. Composites Science and Technology,2021,209:108788. |

| 65 | Noor Hassan Ali, Suha K. Shihab & Muzher T. Mohamed,et al. Influence of ceramic particles additives on the mechanical properties and machinability of carbon fiber/polymer composites [J]. Silicon,2023,15(13):5 485⁃5 502. |

| 66 | 袁玉环,左进霞,彭 聪,等.聚氨酯/纳米SiO2改性碳纤维增强环氧树脂复合材料界面性能[J].复合材料学报,2023,40(11):6 073⁃6 086. |

| YUAN Y H, ZUO J X, PENG C, et al. Interfacial properties of polyurethane/nano⁃SiO2 modified carbon fiber epoxy resin composites [J]. Acta Materiae Compositae Sinica,2023,40(11):6 073⁃6 086. | |

| 67 | Liu Chengde, Mei Pengxin, Cheng Xitong, et al. Enhancing interfacial adhesion of carbon fiber/poly(phthalazinone ether ketone) composites by the hybrid sizing agent of hydroxyapatite⁃reinforced PAEK⁃COOH [J]. Polymer Composites,2024,45(3):2 589⁃2 601. |

| 68 | Fei Yang, Li Jun, Han Sensen, et al. Wear resistant PEEK composites with great mechanical properties and high thermal conductivity synergized with carbon fibers and h⁃BN nanosheets [J]. Polymers for Advanced Technologies,2023,34(7):2 224⁃2 234. |

| 69 | Hang Wu, Qiu Shuilai, Zhou Yifan, et al. A novel carbon fiber/MXene coalition prepared by a bidirectional diazotization strategy: properties and applications [J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects,2022,642:128649. |

| 70 | Chen Jinchuan, Yang Dezhen, Yuan Baogang, et al. Polydopamine particle in⁃situ assisted carbon fiber/CNTs brush with dynamic imine bonds for enhancing the interface properties of its polyamide 6 composites [J]. Composites Communications,2023,40:101625. |

| 71 | Cheng Xianhe, Han Qigang, Yue Boying, et al. Self⁃assembled nano⁃polymers modified water⁃based sizing agent for enhancing the dual interfacial properties of carbon fibre/epoxy resin composites [J]. Composites Part B,2023,262:110828. |

| 72 | 肖景月.基于软硬结构的短纤维改性及其复合材料界面性能研究[D].合肥:中国科学技术大学,2023. |

| [1] | 栗小茜 陈浩 葛正浩 宋浩杰 高彦军. 车用碳纤维复合材料结构优化与性能研究进展[J]. , 2025, 39(5): 118-125. |

| [2] | 张文超, 吴迪, 张晗, 妙磊, 崔恩铭, 王明伟, 叶星辉, 于峻伟. 汽车前A柱上饰板低压注塑包覆成型工艺分析与模具设计[J]. 中国塑料, 2025, 39(4): 104-110. |

| [3] | 叶卫文, 陈镇森, 姜炳春, 吴光明. 汽车热交换系统直管口双缩柯水室模具设计[J]. 中国塑料, 2024, 38(6): 117-124. |

| [4] | 曹帅, 姜涛, 刘雄, 王瑛, 李文戈, 吴新锋. MXene导热复合材料的制备研究进展[J]. 中国塑料, 2024, 38(6): 139-144. |

| [5] | 李轩, 何瑜, 明白, 张晓燕, 刘福华, 来升. 聚酰亚胺树脂基复合摩擦材料成型技术研究进展[J]. 中国塑料, 2024, 38(4): 116-123. |

| [6] | 李双燕, 卢新宇, 苏琼, 赵梦驰, 阿丽旦·如扎洪, 王玉璞, 赵利斌. 环境友好生物质材料改性及发泡方法的研究进展[J]. 中国塑料, 2024, 38(12): 163-171. |

| [7] | 成名, 王永康, 何杰, 王如意, 向光会. 浅析注塑工艺对二醋酸纤维素力学性能的影响[J]. 中国塑料, 2024, 38(10): 81-86. |

| [8] | 叶卫文, 陈镇森, 姜炳春, 冯婧. 汽车座椅头枕塑胶模具结构设计[J]. 中国塑料, 2024, 38(10): 97-102. |

| [9] | 叶卫文, 陈镇森, 姜炳春, 吴光明. 汽车热交换系统斜向管口气室模具设计[J]. 中国塑料, 2023, 37(9): 102-108. |

| [10] | 钟罗浩, 匡唐清, 赖家美, 柳和生, 赖德炜. 成型工艺对短玻璃纤维增强聚丙烯注塑管件的壁厚分布及玻璃纤维取向的影响[J]. 中国塑料, 2021, 35(5): 11-16. |

| [11] | 郭金强, 王富玉, 张玉霞. 高阻隔高分子材料研究进展[J]. 中国塑料, 2021, 35(5): 146-155. |

| [12] | 马秀清, 孙凯欣, 李瑞, 张亚军, 范一强. PMMA微流控芯片最佳注射成型工艺的实验研究[J]. 中国塑料, 2021, 35(4): 47-52. |

| [13] | 张莉彦, 高丽洁, 马昊鹏, 马具彪, 杨卫民, 焦志伟, 于源. 非溶剂致相分离3D打印聚合物的成型工艺研究[J]. 中国塑料, 2021, 35(11): 71-76. |

| [14] | 汪传生 张伟 江瑞 马亚标 边慧光 晁宇琦. 基于螺杆挤出式工业陶瓷3D打印技术的最佳成型工艺研究[J]. 中国塑料, 2019, 33(11): 64-70. |

| [15] | 王大鹏, 刘美苓, 姜焕英, 孙岩, 王庆昭. 油气产业用增强热塑性复合管研究进展[J]. 中国塑料, 2017, 31(07): 16-22 . |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2