京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2

《中国塑料》编辑部 ©2008-2024 版权所有

地址:北京市海淀区阜成路11号 邮编:100048

编辑部:010-68985541 联系信箱:cp@plaschina.com.cn

广告部/发行部:010-68985253 本系统由北京玛格泰克科技发展有限公司设计开发

中国塑料 ›› 2025, Vol. 39 ›› Issue (5): 63-69.DOI: 10.19491/j.issn.1001-9278.2025.05.010

汤文亮1,2,3( ), 燕集中4, 沈利民1,2,3(

), 燕集中4, 沈利民1,2,3( ), 杨洪1,2,3, 吴胜平4, 王国新4

), 杨洪1,2,3, 吴胜平4, 王国新4

收稿日期:2024-07-07

出版日期:2025-05-26

发布日期:2025-05-22

通讯作者:

沈利民(1984—),男,副教授,从事极端环境下材料损伤与断裂研究,shenlm@cumt.edu.cn作者简介:汤文亮(1998—),男,在读硕士研究生,从事极端环境下材料损伤与断裂研究,TS22040210P31@cumt.edu.cn

基金资助:

TANG Wenliang1,2,3( ), YAN Jizhong4, SHEN Limin1,2,3(

), YAN Jizhong4, SHEN Limin1,2,3( ), YANG Hong1,2,3, WU Shengping4, WANG GuoXing4

), YANG Hong1,2,3, WU Shengping4, WANG GuoXing4

Received:2024-07-07

Online:2025-05-26

Published:2025-05-22

Contact:

SHEN Limin

E-mail:TS22040210P31@cumt.edu.cn;shenlm@cumt.edu.cn

摘要:

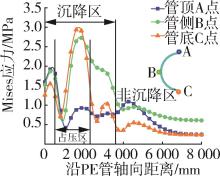

基于ABAQUS软件,开展了近线占压、地面沉降、管道内压、管道埋深及环境温度协同作用的聚乙烯(PE)管道损伤数值模拟工作,通过设计正交试验,研究不同因素对管道损伤的影响贡献度。结果表明:在多因素协同作用下,管道受到轴向拉伸和径向弯曲,在占压区边缘出现最大Mises应力及最大管道横截面变化率。通过正交试验分析,发现在近线占压及管道周边土壤沉降同时发生时,地面占压为PE管道损伤的主控因素,地面沉降则对管道损伤影响有限。

中图分类号:

汤文亮, 燕集中, 沈利民, 杨洪, 吴胜平, 王国新. 多因素协同作用的PE管道损伤数值模拟研究[J]. 中国塑料, 2025, 39(5): 63-69.

TANG Wenliang, YAN Jizhong, SHEN Limin, YANG Hong, WU Shengping, WANG GuoXing. Numerical simulation of PE pipeline damages with synergistic effect of multiple factors[J]. China Plastics, 2025, 39(5): 63-69.

| 温度/℃ | 材料 | 泊松比 | 管材密度/kg·m-3 | 初始弹性模量(E0)/MPa | 屈服应力(ReL)/MPa |

|---|---|---|---|---|---|

| -15 | PE100 | 0.45 | 951 | 595.82 | 23.08 |

| 15 | 363.67 | 14.79 | |||

| 30 | 284.12 | 11.80 |

| 温度/℃ | 材料 | 泊松比 | 管材密度/kg·m-3 | 初始弹性模量(E0)/MPa | 屈服应力(ReL)/MPa |

|---|---|---|---|---|---|

| -15 | PE100 | 0.45 | 951 | 595.82 | 23.08 |

| 15 | 363.67 | 14.79 | |||

| 30 | 284.12 | 11.80 |

| 因素 | 地面占压(FZ)/MPa | 地面沉降(Hc)/mm | 管道内压(P)/MPa | 环境温度(T)/℃ | 管道埋深(H)/mm |

|---|---|---|---|---|---|

| 水平1 | 0 | 0 | 0.2 | -15 | 600 |

| 水平2 | 0.5 | 1 500 | 0.4 | 15 | 800 |

| 水平3 | 1.0 | 3 000 | 0.6 | 30 | 1 000 |

| 因素 | 地面占压(FZ)/MPa | 地面沉降(Hc)/mm | 管道内压(P)/MPa | 环境温度(T)/℃ | 管道埋深(H)/mm |

|---|---|---|---|---|---|

| 水平1 | 0 | 0 | 0.2 | -15 | 600 |

| 水平2 | 0.5 | 1 500 | 0.4 | 15 | 800 |

| 水平3 | 1.0 | 3 000 | 0.6 | 30 | 1 000 |

| 编号 | FZ | Hc | (Fz×Hc)1(Fz×Hc)2 | P | (Fz×P)1(Fz×P)2(Hc×P)1 | T | H | (Hc×P)2 | |||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| 2 | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| 3 | 1 | 1 | 1 | 1 | 3 | 3 | 3 | 3 | 3 | 3 | 3 |

| 4 | 1 | 2 | 2 | 2 | 1 | 1 | 1 | 2 | 2 | 2 | 3 |

| 5 | 1 | 2 | 2 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 1 |

| 6 | 1 | 2 | 2 | 2 | 3 | 3 | 3 | 1 | 1 | 1 | 2 |

| 7 | 1 | 3 | 3 | 3 | 1 | 1 | 1 | 3 | 3 | 3 | 2 |

| 8 | 1 | 3 | 3 | 3 | 2 | 2 | 2 | 1 | 1 | 1 | 3 |

| 9 | 1 | 3 | 3 | 3 | 3 | 3 | 3 | 2 | 2 | 2 | 1 |

| 10 | 2 | 1 | 2 | 3 | 1 | 2 | 3 | 1 | 2 | 3 | 1 |

| 11 | 2 | 1 | 2 | 3 | 2 | 3 | 1 | 2 | 3 | 1 | 2 |

| 12 | 2 | 1 | 2 | 3 | 3 | 1 | 2 | 3 | 1 | 2 | 3 |

| 13 | 2 | 2 | 3 | 1 | 1 | 2 | 3 | 2 | 3 | 1 | 3 |

| 14 | 2 | 2 | 3 | 1 | 2 | 3 | 1 | 3 | 1 | 2 | 1 |

| 15 | 2 | 2 | 3 | 1 | 3 | 1 | 2 | 1 | 2 | 3 | 2 |

| 16 | 2 | 3 | 1 | 2 | 1 | 2 | 3 | 3 | 1 | 2 | 2 |

| 17 | 2 | 3 | 1 | 2 | 2 | 3 | 1 | 1 | 2 | 3 | 3 |

| 18 | 2 | 3 | 1 | 2 | 3 | 1 | 2 | 2 | 3 | 1 | 1 |

| 19 | 3 | 1 | 3 | 2 | 1 | 3 | 2 | 1 | 3 | 2 | 1 |

| 20 | 3 | 1 | 3 | 2 | 2 | 1 | 3 | 2 | 1 | 3 | 2 |

| 21 | 3 | 1 | 3 | 2 | 3 | 2 | 1 | 3 | 2 | 1 | 3 |

| 22 | 3 | 2 | 1 | 3 | 1 | 3 | 2 | 2 | 1 | 3 | 3 |

| 23 | 3 | 2 | 1 | 3 | 2 | 1 | 3 | 3 | 2 | 1 | 1 |

| 24 | 3 | 2 | 1 | 3 | 3 | 2 | 1 | 1 | 3 | 2 | 2 |

| 25 | 3 | 3 | 2 | 1 | 1 | 3 | 2 | 3 | 2 | 1 | 2 |

| 26 | 3 | 3 | 2 | 1 | 2 | 1 | 3 | 1 | 3 | 2 | 3 |

| 27 | 3 | 3 | 2 | 1 | 3 | 2 | 1 | 2 | 1 | 3 | 1 |

| 编号 | FZ | Hc | (Fz×Hc)1(Fz×Hc)2 | P | (Fz×P)1(Fz×P)2(Hc×P)1 | T | H | (Hc×P)2 | |||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| 2 | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| 3 | 1 | 1 | 1 | 1 | 3 | 3 | 3 | 3 | 3 | 3 | 3 |

| 4 | 1 | 2 | 2 | 2 | 1 | 1 | 1 | 2 | 2 | 2 | 3 |

| 5 | 1 | 2 | 2 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 1 |

| 6 | 1 | 2 | 2 | 2 | 3 | 3 | 3 | 1 | 1 | 1 | 2 |

| 7 | 1 | 3 | 3 | 3 | 1 | 1 | 1 | 3 | 3 | 3 | 2 |

| 8 | 1 | 3 | 3 | 3 | 2 | 2 | 2 | 1 | 1 | 1 | 3 |

| 9 | 1 | 3 | 3 | 3 | 3 | 3 | 3 | 2 | 2 | 2 | 1 |

| 10 | 2 | 1 | 2 | 3 | 1 | 2 | 3 | 1 | 2 | 3 | 1 |

| 11 | 2 | 1 | 2 | 3 | 2 | 3 | 1 | 2 | 3 | 1 | 2 |

| 12 | 2 | 1 | 2 | 3 | 3 | 1 | 2 | 3 | 1 | 2 | 3 |

| 13 | 2 | 2 | 3 | 1 | 1 | 2 | 3 | 2 | 3 | 1 | 3 |

| 14 | 2 | 2 | 3 | 1 | 2 | 3 | 1 | 3 | 1 | 2 | 1 |

| 15 | 2 | 2 | 3 | 1 | 3 | 1 | 2 | 1 | 2 | 3 | 2 |

| 16 | 2 | 3 | 1 | 2 | 1 | 2 | 3 | 3 | 1 | 2 | 2 |

| 17 | 2 | 3 | 1 | 2 | 2 | 3 | 1 | 1 | 2 | 3 | 3 |

| 18 | 2 | 3 | 1 | 2 | 3 | 1 | 2 | 2 | 3 | 1 | 1 |

| 19 | 3 | 1 | 3 | 2 | 1 | 3 | 2 | 1 | 3 | 2 | 1 |

| 20 | 3 | 1 | 3 | 2 | 2 | 1 | 3 | 2 | 1 | 3 | 2 |

| 21 | 3 | 1 | 3 | 2 | 3 | 2 | 1 | 3 | 2 | 1 | 3 |

| 22 | 3 | 2 | 1 | 3 | 1 | 3 | 2 | 2 | 1 | 3 | 3 |

| 23 | 3 | 2 | 1 | 3 | 2 | 1 | 3 | 3 | 2 | 1 | 1 |

| 24 | 3 | 2 | 1 | 3 | 3 | 2 | 1 | 1 | 3 | 2 | 2 |

| 25 | 3 | 3 | 2 | 1 | 1 | 3 | 2 | 3 | 2 | 1 | 2 |

| 26 | 3 | 3 | 2 | 1 | 2 | 1 | 3 | 1 | 3 | 2 | 3 |

| 27 | 3 | 3 | 2 | 1 | 3 | 2 | 1 | 2 | 1 | 3 | 1 |

| 编号 | Fz | Hc | (Fz×Hc)1(Fz×Hc)2 | P | (Fz×P)1(Fz×P)2(Hc×P)1 | T | H | (Hc×P)2 | 最大 应力 | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0.621 |

| 2 | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 1.546 |

| 3 | 1 | 1 | 1 | 1 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 2.517 |

| 4 | 1 | 2 | 2 | 2 | 1 | 1 | 1 | 2 | 2 | 2 | 3 | 0.647 |

| 5 | 1 | 2 | 2 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 1 | 1.639 |

| 6 | 1 | 2 | 2 | 2 | 3 | 3 | 3 | 1 | 1 | 1 | 2 | 2.659 |

| 7 | 1 | 3 | 3 | 3 | 1 | 1 | 1 | 3 | 3 | 3 | 2 | 0.675 |

| 8 | 1 | 3 | 3 | 3 | 2 | 2 | 2 | 1 | 1 | 1 | 3 | 1.635 |

| 9 | 1 | 3 | 3 | 3 | 3 | 3 | 3 | 2 | 2 | 2 | 1 | 2.530 |

| 10 | 2 | 1 | 2 | 3 | 1 | 2 | 3 | 1 | 2 | 3 | 1 | 1.541 |

| 11 | 2 | 1 | 2 | 3 | 2 | 3 | 1 | 2 | 3 | 1 | 2 | 1.571 |

| 12 | 2 | 1 | 2 | 3 | 3 | 1 | 2 | 3 | 1 | 2 | 3 | 2.855 |

| 13 | 2 | 2 | 3 | 1 | 1 | 2 | 3 | 2 | 3 | 1 | 3 | 1.124 |

| 14 | 2 | 2 | 3 | 1 | 2 | 3 | 1 | 3 | 1 | 2 | 1 | 2.345 |

| 15 | 2 | 2 | 3 | 1 | 3 | 1 | 2 | 1 | 2 | 3 | 2 | 3.216 |

| 16 | 2 | 3 | 1 | 2 | 1 | 2 | 3 | 3 | 1 | 2 | 2 | 2.155 |

| 17 | 2 | 3 | 1 | 2 | 2 | 3 | 1 | 1 | 2 | 3 | 3 | 3.033 |

| 18 | 2 | 3 | 1 | 2 | 3 | 1 | 2 | 2 | 3 | 1 | 1 | 3.291 |

| 19 | 3 | 1 | 3 | 2 | 1 | 3 | 2 | 1 | 3 | 2 | 1 | 3.024 |

| 20 | 3 | 1 | 3 | 2 | 2 | 1 | 3 | 2 | 1 | 3 | 2 | 6.050 |

| 21 | 3 | 1 | 3 | 2 | 3 | 2 | 1 | 3 | 2 | 1 | 3 | 3.501 |

| 22 | 3 | 2 | 1 | 3 | 1 | 3 | 2 | 2 | 1 | 3 | 3 | 5.457 |

| 23 | 3 | 2 | 1 | 3 | 2 | 1 | 3 | 3 | 2 | 1 | 1 | 3.128 |

| 24 | 3 | 2 | 1 | 3 | 3 | 2 | 1 | 1 | 3 | 2 | 2 | 4.191 |

| 25 | 3 | 3 | 2 | 1 | 1 | 3 | 2 | 3 | 2 | 1 | 2 | 2.938 |

| 26 | 3 | 3 | 2 | 1 | 2 | 1 | 3 | 1 | 3 | 2 | 3 | 4.346 |

| 27 | 3 | 3 | 2 | 1 | 3 | 2 | 1 | 2 | 1 | 3 | 1 | 7.846 |

| 编号 | Fz | Hc | (Fz×Hc)1(Fz×Hc)2 | P | (Fz×P)1(Fz×P)2(Hc×P)1 | T | H | (Hc×P)2 | 最大 应力 | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0.621 |

| 2 | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 1.546 |

| 3 | 1 | 1 | 1 | 1 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 2.517 |

| 4 | 1 | 2 | 2 | 2 | 1 | 1 | 1 | 2 | 2 | 2 | 3 | 0.647 |

| 5 | 1 | 2 | 2 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 1 | 1.639 |

| 6 | 1 | 2 | 2 | 2 | 3 | 3 | 3 | 1 | 1 | 1 | 2 | 2.659 |

| 7 | 1 | 3 | 3 | 3 | 1 | 1 | 1 | 3 | 3 | 3 | 2 | 0.675 |

| 8 | 1 | 3 | 3 | 3 | 2 | 2 | 2 | 1 | 1 | 1 | 3 | 1.635 |

| 9 | 1 | 3 | 3 | 3 | 3 | 3 | 3 | 2 | 2 | 2 | 1 | 2.530 |

| 10 | 2 | 1 | 2 | 3 | 1 | 2 | 3 | 1 | 2 | 3 | 1 | 1.541 |

| 11 | 2 | 1 | 2 | 3 | 2 | 3 | 1 | 2 | 3 | 1 | 2 | 1.571 |

| 12 | 2 | 1 | 2 | 3 | 3 | 1 | 2 | 3 | 1 | 2 | 3 | 2.855 |

| 13 | 2 | 2 | 3 | 1 | 1 | 2 | 3 | 2 | 3 | 1 | 3 | 1.124 |

| 14 | 2 | 2 | 3 | 1 | 2 | 3 | 1 | 3 | 1 | 2 | 1 | 2.345 |

| 15 | 2 | 2 | 3 | 1 | 3 | 1 | 2 | 1 | 2 | 3 | 2 | 3.216 |

| 16 | 2 | 3 | 1 | 2 | 1 | 2 | 3 | 3 | 1 | 2 | 2 | 2.155 |

| 17 | 2 | 3 | 1 | 2 | 2 | 3 | 1 | 1 | 2 | 3 | 3 | 3.033 |

| 18 | 2 | 3 | 1 | 2 | 3 | 1 | 2 | 2 | 3 | 1 | 1 | 3.291 |

| 19 | 3 | 1 | 3 | 2 | 1 | 3 | 2 | 1 | 3 | 2 | 1 | 3.024 |

| 20 | 3 | 1 | 3 | 2 | 2 | 1 | 3 | 2 | 1 | 3 | 2 | 6.050 |

| 21 | 3 | 1 | 3 | 2 | 3 | 2 | 1 | 3 | 2 | 1 | 3 | 3.501 |

| 22 | 3 | 2 | 1 | 3 | 1 | 3 | 2 | 2 | 1 | 3 | 3 | 5.457 |

| 23 | 3 | 2 | 1 | 3 | 2 | 1 | 3 | 3 | 2 | 1 | 1 | 3.128 |

| 24 | 3 | 2 | 1 | 3 | 3 | 2 | 1 | 1 | 3 | 2 | 2 | 4.191 |

| 25 | 3 | 3 | 2 | 1 | 1 | 3 | 2 | 3 | 2 | 1 | 2 | 2.938 |

| 26 | 3 | 3 | 2 | 1 | 2 | 1 | 3 | 1 | 3 | 2 | 3 | 4.346 |

| 27 | 3 | 3 | 2 | 1 | 3 | 2 | 1 | 2 | 1 | 3 | 1 | 7.846 |

| 方差来源 | 差异(S) | 因素自由度(f) | 方差(MS) | F |

|---|---|---|---|---|

| 40.571 6 | 2 | 20.285 8 | 284.710 5 | |

| 1.667 5 | 2 | 0.833 8 | 11.701 7 | |

| 11.559 4 | 2 | 5.779 7 | 81.117 6 | |

| 6.541 9 | 2 | 3.271 0 | 45.907 9 | |

| 7.848 9 | 2 | 3.924 4 | 55.079 4 | |

| 0.806 | 4 | 0.201 5 | 2.828 2 | |

| 0.247 4 | 4 | 0.061 9 | 0.868 2 | |

| 4.097 1 | 4 | 1.024 3 | 14.375 7 | |

| 误差(e) | 0.076 | 4 | 0.071 3 | — |

| 总和 | 73.418 | 26 | — | — |

| 方差来源 | 差异(S) | 因素自由度(f) | 方差(MS) | F |

|---|---|---|---|---|

| 40.571 6 | 2 | 20.285 8 | 284.710 5 | |

| 1.667 5 | 2 | 0.833 8 | 11.701 7 | |

| 11.559 4 | 2 | 5.779 7 | 81.117 6 | |

| 6.541 9 | 2 | 3.271 0 | 45.907 9 | |

| 7.848 9 | 2 | 3.924 4 | 55.079 4 | |

| 0.806 | 4 | 0.201 5 | 2.828 2 | |

| 0.247 4 | 4 | 0.061 9 | 0.868 2 | |

| 4.097 1 | 4 | 1.024 3 | 14.375 7 | |

| 误差(e) | 0.076 | 4 | 0.071 3 | — |

| 总和 | 73.418 | 26 | — | — |

| 1 | 贺子东,梁耀方 .聚乙烯燃气管道的应用及发展[J].化工管理,2022,04:107⁃109. |

| HE Z, LIANG Y. Application and development of polyethylene gas pipeline[J]. Chemical Management, 2022,04:107⁃109. | |

| 2 | 彭星煜,陈桂芳,陈磊,等 .建筑物占压作用下输气管道的安全可靠性评估[J].油气储运, 2022,41(05):549⁃556. |

| PENG X, CHEN G, CHEN L, et al. Safety and reliability assessment of gas transmission pipeline under building occupying pressure[J]. Hydrocarbon Storage and Transportation, 2022,41(05):549⁃556. | |

| 3 | 李杰 .PE管道在施工过程中地面沉降影响因素的研究[D].南昌:南昌大学,2019. |

| 4 | Tafreshi S N M, Khalaj O. Laboratory tests of small⁃diameter HDPE pipes buried in reinforced sand under repeated⁃load[J]. Geotextiles and Geomembranes, 2008,26(2):145⁃163. |

| 5 | 孙文君,肖成志,王嘉勇,等 .循环荷载作用下埋地管道力学与变形性能研究[J].公路工程,2018,43(05):61⁃68. |

| SUN W, XIAO C, WANG J, et al. Study on mechanical and deformation properties of buried pipeline under cyclic load [J]. Highway Engineering, 2018,43(05):61⁃68. | |

| 6 | Franco Y B, Silva J L D, Valentin C A. A new small⁃scale test apparatus for modeling buried pipes under axial or lateral soil loading[J]. Geotechnical Testing Journal, 2020,43(1):52⁃69. |

| 7 | 王博 .典型复杂载荷下埋地含缺陷PE管道强度的数值模拟研究[D].广州:华南理工大学,2018. |

| 8 | Luo X, Lu S, Shi J, et al. Numerical simulation of strength failure of buried polyethylene pipe under foundation settlement[J]. Engineering Failure Analysis, 2015,48:144⁃152. |

| 9 | 周敏.地层沉陷过程中埋地高密度聚乙烯(HDPE)管道力学行为研究[J].岩石力学与工程学报,2017, 36(S2):4 177⁃4 187. |

| ZHOU M. Study on mechanical behavior of buried high density polyethylene (HDPE) pipeline during formation subsidence[J]. Chinese Journal of Rock Mechanics and Engineering, 2017, 36(S2):4 177⁃4 187. | |

| 10 | 罗利,马燕,张永军,等 .地基沉降作用下埋地聚乙烯管强度失效的数值模拟[J].建筑材料学报,2020,23(02):473⁃478. |

| LUO L, MA Y, ZHANG Y, et al. Numerical simulation of strength failure of buried polyethylene pipe under foundation settlement[J]. Journal of Building Materials, 2019, 23(02):473⁃478. | |

| 11 | 帅健,王晓霖,左尚志 .地质灾害作用下管道的破坏行为与防护对策[J].焊管,2008,05:9⁃15. |

| SHUAI J, WANG X, ZUO S. Failure behavior of pipeline under geological hazards and protective measures[J]. Welded Pipe, 2008, 05:9⁃15. | |

| 12 | 马涛,廖公云,黄晓明 .Abaqus有限元软件在道路工程中的应用[M].南京:东南大学出版社,2008:138⁃139. |

| 13 | 刘鹏,李玉星,张宇,等 .典型地质灾害下埋地管道的应力计算[J].油气储运,2021,40(02):157⁃165. |

| LIU P, LI Y, ZHANG Y, et al. Stress calculation of buried pipeline under typical geological hazards[J]. Oil and Gas Storage and Transportation, 2021, 40(02):157⁃165. | |

| 14 | 杨洪 .环境⁃载荷协同作用的埋地PE燃气管道损伤数值模拟[D].徐州:中国矿业大学,2023. |

| 15 | 刘炯天,樊民强 .试验研究方法[M].徐州:中国矿业大学出版社,2016:495⁃496. |

| [1] | 陈正男, 陈斌艺, 黄岸. 基于Moldex3D的插座外壳的注塑优化[J]. 中国塑料, 2025, 39(5): 64-70. |

| [2] | 汤文亮 燕集中 沈利民 杨洪 吴胜平 王国新. 多因素协同作用的PE管道损伤数值模拟研究[J]. , 2025, 39(5): 63-69. |

| [3] | 王禹, 张亚军, 郑永彪, 高聪. 聚合物气辅挤出技术研究进展及应用[J]. 中国塑料, 2025, 39(3): 114-117. |

| [4] | 黄可, 邹华杰, 钱子龙, 李兵兵. 轿车用皮纹后饰条注塑参数优化及试验验证[J]. 中国塑料, 2025, 39(3): 77-80. |

| [5] | 王禹 张亚军 郑永彪 高聪. 聚合物气辅挤出技术研究进展及应用[J]. , 2025, 39(3): 114-117. |

| [6] | 翟孟雷, 陈文广, 黄明, 雷金宇, 张娜, 刘春太, 高国利. 大丝束碳纤维束内横向动态渗透率计算方法及数值验证[J]. 中国塑料, 2024, 38(9): 54-59. |

| [7] | 任清海, 孙祖东, 耿铁. 气辅成型工艺参数正交精准设计优化[J]. 中国塑料, 2024, 38(7): 62-67. |

| [8] | 林高明, 张国辉, 宗胡曾, 王重阳, 贺有凤, 王苏炜. 聚合物基高黏浆料立式螺旋挤注装填装备关键元件结构的仿真优化[J]. 中国塑料, 2024, 38(5): 107-112. |

| [9] | 陈浩, 杨卫民, 寻尚伦, 张海涛, 焦志伟. 双螺杆挤出机塑化系统电磁加热过程的数值模拟与实验研究及应用[J]. 中国塑料, 2024, 38(3): 101-108. |

| [10] | 李宁利, 王瑞, 常紫攀, 栗培龙. 沥青路面水性聚氨酯丙烯酸热反射涂料制备[J]. 中国塑料, 2024, 38(1): 21-27. |

| [11] | 周磊, 张礼华, 陈景铭, 毛旭, 陈曙光, 邱建成. 可降解塑料片材机头流道的流场分析及设计优化[J]. 中国塑料, 2023, 37(9): 90-95. |

| [12] | 丁海, 马秉馨, 花少震, 曹伟. 中心静脉导管挤出成型的Polyflow优化与模具设计[J]. 中国塑料, 2023, 37(8): 113-117. |

| [13] | 李红伟, 章勇锋, 齐武军, 阮刚勇, 阮沥波, 方宇超. 聚乙烯管道及其增强复合管道在实际工程应用中的问题[J]. 中国塑料, 2023, 37(8): 69-78. |

| [14] | 马秀清, 劳志超, 李明谦, 韩顺涛, 胡楠. 螺杆构型对PLA/PTW共混物性能影响的研究[J]. 中国塑料, 2023, 37(11): 127-134. |

| [15] | 武立文, 乔亮, 范峻铭, 闻炯明, 李兆璞, 张毅. 聚乙烯管道寿命预测研究进展[J]. 中国塑料, 2023, 37(11): 149-162. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2