京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2

《中国塑料》编辑部 ©2008-2024 版权所有

地址:北京市海淀区阜成路11号 邮编:100048

编辑部:010-68985541 联系信箱:cp@plaschina.com.cn

广告部/发行部:010-68985253 本系统由北京玛格泰克科技发展有限公司设计开发

中国塑料 ›› 2022, Vol. 36 ›› Issue (11): 174-182.DOI: 10.19491/j.issn.1001-9278.2022.11.025

宋佳宁1,2, 杜斌1, 张振莉1, 高岗岗1, 荔栓红1, 祝文亲1, 曹文斌2, 陈商涛1( )

)

收稿日期:2022-08-09

出版日期:2022-11-26

发布日期:2022-11-25

通讯作者:

陈商涛(1978—),男,教授级高工,从事聚烯烃新产品开发,chenst7890@petrochina.com.cn

SONG Jianing1,2, DU Bin1, ZHANG Zhenli1, GAO Ganggang1, LI Shuanhong1, ZHU Wenqin1, CAO Wenbin2, CHEN Shangtao1( )

)

Received:2022-08-09

Online:2022-11-26

Published:2022-11-25

Contact:

CHEN Shangtao

E-mail:chenst7890@petrochina.com.cn

摘要:

阐述了直流电缆绝缘的基本要求,介绍了聚丙烯(PP)材料用于直流电缆绝缘时在力学性能、耐老化性能、绝缘性能及导热性能等方面存在的问题,综述了PP共聚改性、纳米粒子改性、共混改性和接枝改性的研究进展,并对PP基直流电缆绝缘材料在电力电缆领域未来的研究方向提出了展望。

中图分类号:

宋佳宁, 杜斌, 张振莉, 高岗岗, 荔栓红, 祝文亲, 曹文斌, 陈商涛. 聚丙烯基直流电缆绝缘材料的研究进展[J]. 中国塑料, 2022, 36(11): 174-182.

SONG Jianing, DU Bin, ZHANG Zhenli, GAO Ganggang, LI Shuanhong, ZHU Wenqin, CAO Wenbin, CHEN Shangtao. Research progress in polypropylene⁃based insulation materials for direct current power cables[J]. China Plastics, 2022, 36(11): 174-182.

| 性能 | PP | PE⁃XL |

|---|---|---|

| 熔点 | 较高 | 较低 |

| 生产工艺 | 简单高效 | 繁杂低效 |

| 是否交联 | 否 | 是 |

| 聚合物特性 | 热塑性 | 热固性 |

| 电缆长期工作温度/℃ | 90 | 70 |

| 力学性能 | 抗张强度高,热变形小 | 抗张强度较低,热变形大 |

| 电气性能 | 击穿场强高,体积电阻率高 | 击穿场强低,体积电阻率低 |

| 环保特性 | 可回收再利用 | 难回收再利用 |

| 性能 | PP | PE⁃XL |

|---|---|---|

| 熔点 | 较高 | 较低 |

| 生产工艺 | 简单高效 | 繁杂低效 |

| 是否交联 | 否 | 是 |

| 聚合物特性 | 热塑性 | 热固性 |

| 电缆长期工作温度/℃ | 90 | 70 |

| 力学性能 | 抗张强度高,热变形小 | 抗张强度较低,热变形大 |

| 电气性能 | 击穿场强高,体积电阻率高 | 击穿场强低,体积电阻率低 |

| 环保特性 | 可回收再利用 | 难回收再利用 |

| 1 | 王亚,吕泽鹏,吴锴,等. 高压直流XLPE电缆研究现状[J]. 绝缘材料,2014,47(1):4. |

| WANG Y, LV Z P, WU K,et al. Research status of HVDC XLPE cable[J]. Insulating Materials,2014,47(1):4. | |

| 2 | 杜伯学,李忠磊,杨卓然,等. 高压直流交联聚乙烯电缆应用与研究进展[J]. 高电压技术,2017,43(2):11. |

| DU B X, LI Z L, YANG Z R,et al. Application and research progress of HVDC XLPE cables[J]. High Voltage Engineering,2017,43(2):11. | |

| 3 | 邵森安,马勰,丰如男,等. 电力电缆国内外研究综述[J]. 电线电缆,2021,3:7. |

| SHAO S N, MA X, FENG R N,et al. Review of researches on power cables at home and abroad[J]. Wire & Cable, 2021,3:7. | |

| 4 | KurahashiK,MatsudaY,UedaA,et al. The application of novel polypropylene to the insulation of electric power cable [C]//Transmission and Distribution Conference and Exhibition:Asia Pacific. Yokohama: IEEE/PES,2002,2:1 278⁃1 283. |

| 5 | 东方网. 国内首根环保型PP绝缘电缆成功挂网试运行一周年[Z]. (2021⁃1⁃21)[2022⁃9⁃1]. http://ex.chinadaily.com.cn/exchange/partners/82/rss/channel/cn/columns/sz8srm /stories/WS600946c1a3101e7ce973c0e3.html. |

| 6 | 宁波东方集团. 国内首次10kV聚丙烯绝缘电缆高湿高盐雾环境挂网通电[Z]. (2022⁃1⁃5)[2022⁃9⁃1]. https://www.qrunning.com/news/view?id=1932. |

| 7 | 彭二磊,马壮,苏艳文,等. 新型环保聚丙烯绝缘中压电力电缆的研究[J]. 电线电缆, 2021,5:13⁃16. |

| PENG E L, MA Z, SU Y Y,et al. Research on new type environmental polypropylene insulated medium voltage power cable[J]. Wire & Cable, 2021,5:13⁃16. | |

| 8 | 朱乐为,杜伯学. 环境友好型直流电缆料聚丙烯绝缘的电树枝研究进展[J]. 电气工程学报,2018,13(11):21⁃29. |

| ZHU L W, DU B X. Research status on electrical tree of polymer insulation materials in HVDC cables [J]. Journal of Electrical Engineering,2018,13(11):21⁃29. | |

| 9 | 樊林禛,李琦,袁浩,等. 接枝对聚丙烯绝缘材料热氧老化的影响及机理[J]. 中国电机工程学报,2022,42(11):4 227⁃4 238. |

| FAN L Z, LI Q, YUAN H, et al. Influence and mechanism of grafting on thermal oxidative aging of polypropylene[J]. Proceedings of the CSEE,2022,42(11):4 227⁃4 238. | |

| 10 | 黄兴溢, 张军, 江平开. 热塑性电力电缆绝缘材料:历史与发展[J]. 高电压技术,2018,44(5):22. |

| HUANG X Y, ZHANG J, JIANG P K. Thermoplastic insulation materials for power cables: history and progress[J]. High Voltage Engineering,2018,44(5):22. | |

| 11 | 李盛涛,王诗航,李建英. 高压直流电缆料的研发进展与路径分析[J]. 高电压技术,2018,44(5):13. |

| LI S T, WANG S H, LI J Y. Research progress and path analysis of insulating materials used in HVDC cable[J]. High Voltage Engineering,2018,44(5):13. | |

| 12 | Kai W, Wang Y, Xia W,et al. Effect of space charge in the aging law of cross⁃linked polyethylene materials for high voltage DC cables[J]. IEEE Electrical Insulation Magazine,2017,33(4):53⁃59. |

| 13 | 吴锴,朱庆东,王浩森,等. 温度梯度下双层油纸绝缘系统的空间电荷分布特性[J]. 高电压技术,2012,38(9):7. |

| WU K, ZHU Q D, WANG H S,et al. Space charge distribution characteristic in double⁃layer oil impregnated papers under temperature gradient[J]. High Voltage Engineering,2012,38(9):7. | |

| 14 | Yao Zhou, Chao Yuan, Li Chuanyang, et al. Temperature dependent electrical properties of thermoplastic polypropylene nanocomposites for HVDC cable insulation[J]. IEEE Transactions on Dielectrics and Electrical Insulation,2019,26(5):1 596⁃1 604. |

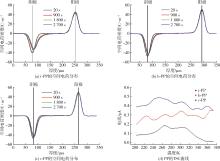

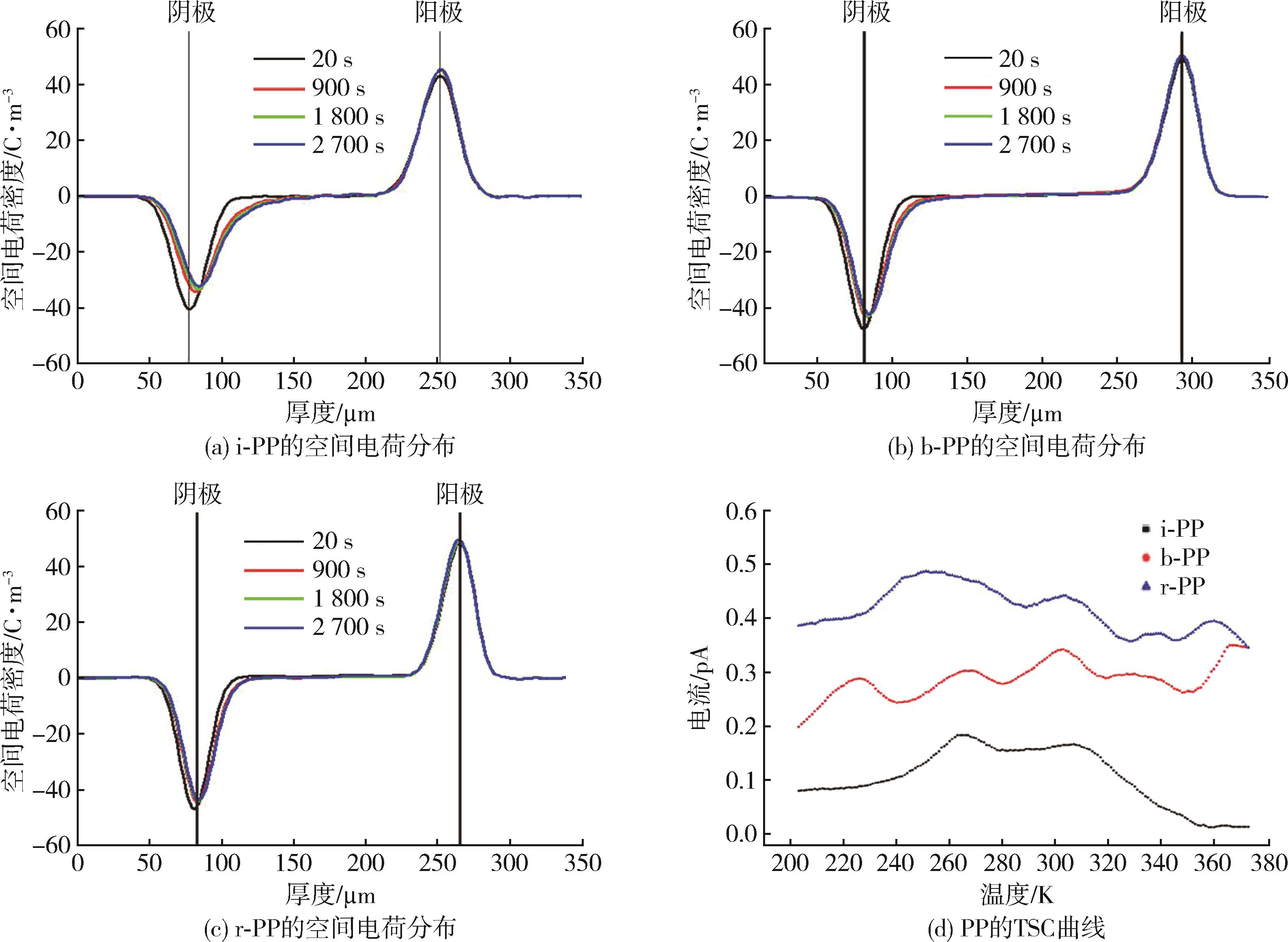

| 15 | Zha J W, Yan H D, Li W K,et al. Morphology and crystalline⁃phase⁃dependent electrical insulating properties in tailored polypropylene for HVDC cables[J]. Applied Physics Letters,2016,109(22):222902. |

| 16 | Meng P, Zhou Y, Yuan C,et al. Comparisons of different polypropylene copolymers as potential recyclable HVDC cable insulation materials[J]. IEEE Transactions on Dielectrics and Electrical Insulation,2019,26(3):674⁃680. |

| 17 | Huang X, Fan Y, Zhang J,et al. Polypropylene based thermoplastic polymers for potential recyclable HVDC cable insulation applications[J]. IEEE Transactions on Dielectrics and Electrical Insulation,2017,24(3):1 446⁃1 456. |

| 18 | 于凡,闫轰达,严智民,等. 共聚聚丙烯中乙烯含量对材料力学和介电性能的影响[J]. 石油化工,2022,51(5):541⁃547. |

| YU F, YAN H D, YAN Z M,et al. Effect of ethylene content on mechanical and dielectric properties of polypropylene copolymer[J]. Petrochemical Technology,2022,51(5):541⁃547. | |

| 19 | 马超,闵道敏,李盛涛,等. 聚丙烯/氧化铝纳米电介质的陷阱与直流击穿特性[J]. 物理学报,2017,66(6):281⁃289. |

| MA C, MIN D M, LI S T,et al.Trap distribution and direct current breakdown characteristics in polypropylene/Al2O3 nanodielectrics[J]. Acta Physica Sinica,2017,66(6):281⁃289. | |

| 20 | Yao Zhou, Chao Yuan, Qi Li,et al. Recyclable insulation material for HVDC cables in global energy interconnection[J]. Global Energy Interconnection,2018,1(4):520⁃526. |

| 21 | Hu S, Zhou Y, Yuan C,et al. Surface⁃modification effect of MgO nanoparticles on the electrical properties of polypropylene nanocomposite[J]. High Voltage,2020,5:249⁃255. |

| 22 | Gao Yahan, Huang Xingyi, Min Daomin,et al. Recyclable dielectric polymer nanocomposites with voltage stabilizer interface: toward new generation of high voltage direct current cable insulation[J]. ACS Sustainable Chemistry & Engineering, 2019, 7(1):513⁃525. |

| 23 | Zhou Y, Hu J, Dang B,et al. Effect of different nanoparticles on tuning electrical properties of polypropylene nanocomposites[J]. IEEE Transactions on Dielectrics and Electrical Insulation,2017,24(3):1 380⁃1 389. |

| 24 | Ebadi⁃Dehaghani H, Reiszadeh M, Chavoshi A,et al. The effect of zinc oxide and calcium carbonate nanoparticles on the thermal conductivity of polypropylene[J]. Journal of Macromolecular Science Part B⁃Physics,2014,53(1):93⁃107. |

| 25 | Cheewawuttipong W, Fuoka D, Tanoue S,et al. Thermal and mechanical properties of polypropylene/boron nitride composites[J]. Energy Procedia,2013,34:808⁃817. |

| 26 | Li Z, Fan M, Zhou S,et al. BNNS encapsulated TiO2 nanofillers endow polypropylene cable insulation with enhanced dielectric performance[J]. IEEE Transactions on Dielectrics and Electrical Insulation,2021,28(4):1 238⁃1 246. |

| 27 | Yang Jinhai, Yong Zhang, Zhang Yinxi. Brittle–ductile transition of PP/POE blends in both impact and high speed tensile tests[J]. Polymer,2003,44(17):5 047⁃5 052. |

| 28 | 栗松. 聚丙烯/弹性体复合材料的物理机械性能及交流介电特性[D]. 哈尔滨:哈尔滨理工大学,2018. |

| 29 | Zhang L, Wu W, Xu Y,et al. Effect of annealing rate on low⁃temperature impact strength and space charge characteristics of isotactic polypropylene[C]// 2021 IEEE Electrical Insulation Conference. Denver: IEEE,2021,482⁃485. |

| 30 | Hong Shin⁃Ki,Hwan Lee Seong, Jin Ah Han,et al. Polypropylene⁃based soft ternary blends for power cable insulation at low⁃to⁃high temperature[J]. Journal of Applied Polymer Science,2022,139(6):51619. |

| 31 | Ouyang Yingwei,Amir Masoud Pourrahim, Anja Lund,et al. High⁃temperature creep resistant ternary blends based on polyethylene and polypropylene for thermoplastic power cable insulation[J]. Journal of Applied Polymer Science,2021,59 (11):1 084⁃1 094. |

| 32 | Yu Seunggun,Hwan Lee Seong, Jin Ah Han,et al. Insulative ethylene⁃propylene copolymer⁃nanostructured polypropylene for high⁃voltage cable insulation applications[J],Polymer,2020, 202:122674. |

| 33 | 高铭泽. 聚丙烯基电缆绝缘材料改性方法与介电性能研究[D]. 哈尔滨:哈尔滨理工大学,2020. |

| 34 | Diao J, Huang X, Jia Q, et al. Thermoplastic isotactic polypropylene/ethylene⁃octene polyolefin copolymer nanocomposite for recyclable HVDC authorized licensed cable insulation[J]. IEEE Transactions on Dielectrics and Electrical Insulation,2017,24(3):1 416⁃1 429. |

| 35 | Yao Z, Dang B, Wang H,et al. Polypropylene⁃based ternary nanocomposites for recyclable high⁃voltage direct⁃current cable insulation[J]. Composites science & Technology,2018,165:168⁃174. |

| 36 | ZHA J W, WU Y H, WANG S J,et al. Improvement of space charge suppression of polypropylene for potential app⁃lication in HVDC cables[J]. IEEE Transactions on Dielectrics and Electrical Insulation,2016,23(4):2 337⁃2 343. |

| 37 | Yuan M, Zhang G, Li B,et al. Thermally stable low⁃loss polymer dielectrics enabled by attaching cross⁃linkable antioxidant to polypropylene[J]. ACS Applied Materials & Interfaces,2020,12(12):14 154⁃14 164. |

| [1] | 张林, 夏章川, 何亚东, 信春玲, 王瑞雪, 任峰. 等离子体射流载气流量大小对玻璃纤维改性效果影响的研究[J]. 中国塑料, 2022, 36(9): 7-15. |

| [2] | 张兵. 无规共聚聚丙烯管材氧化诱导时间测试探究[J]. 中国塑料, 2022, 36(8): 107-109. |

| [3] | 赵鸿敬, 朱江. 微纳层叠天然橡胶/聚丙烯两相挤出的数值模拟研究[J]. 中国塑料, 2022, 36(8): 110-114. |

| [4] | 刘义, 王叶, 孙伟, 曲国兴, 许霞, 杨少林, 袁宁. 红外光谱法测定聚丙烯中透明成核剂含量研究[J]. 中国塑料, 2022, 36(8): 115-118. |

| [5] | 张陶忠, 陈晓龙, 郝晓宇, 于福家. 滑石、CaCO3、BaSO4填充PP复合材料力学性能及界面相互作用对比[J]. 中国塑料, 2022, 36(8): 36-41. |

| [6] | 吴唯, 胡焕波, 沈辉, 赵天瑜. 4A沸石与钙镁铝水滑石对膨胀阻燃聚丙烯的双重协效阻燃作用与机理[J]. 中国塑料, 2022, 36(7): 1-7. |

| [7] | 于昌永, 辛忠. 基于六氢邻苯二甲酸盐的α/β复合成核剂对聚丙烯性能的影响[J]. 中国塑料, 2022, 36(7): 121-128. |

| [8] | 刘义, 孙伟, 曲国兴, 王叶, 袁宁, 杨少林, 许霞, 常小毅, 张宇飞. 薄壁注塑透明聚丙烯专用料的结构与性能分析[J]. 中国塑料, 2022, 36(7): 37-43. |

| [9] | 孙伟, 刘义, 廖云龙, 陈俊佳. 聚丙烯粉料乙烯含量测定影响因素研究[J]. 中国塑料, 2022, 36(6): 54-59. |

| [10] | 陈文静, 杨小龙, 韩顺涛, 韩颖, 马秀清. 聚丙烯腈材料改性方法及研究进展[J]. 中国塑料, 2022, 36(4): 158-165. |

| [11] | 王青松. 高强度低VOC玻璃纤维增强聚丙烯材料的开发[J]. 中国塑料, 2022, 36(4): 30-34. |

| [12] | 王富玉, 郭金强, 张玉霞. 聚合物原位成纤方法及其在PP共混体系中的应用[J]. 中国塑料, 2022, 36(3): 146-156. |

| [13] | 李瑞, 姜艳峰, 吴双, 安彦杰, 姜泽钰, 张明强. 升温淋洗分级研究聚丙烯流延膜专用料的微观结构及热学表征[J]. 中国塑料, 2022, 36(3): 53-57. |

| [14] | 曹志峰, 赵立品, 何汀, 马百钧. 五层共挤阻隔膜的制备与性能研究[J]. 中国塑料, 2022, 36(3): 64-68. |

| [15] | 翟玉娇, 信春玲, 何亚东, 闫宝瑞, 乔林军. 聚丙烯/超临界氮气微孔注塑充模过程工艺参数研究[J]. 中国塑料, 2022, 36(3): 69-74. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2