京ICP备13020181号-2

© 《China Plastics》

© 《China Plastics》

China Plastics ›› 2023, Vol. 37 ›› Issue (9): 57-63.DOI: 10.19491/j.issn.1001-9278.2023.09.009

• Processing and Application • Previous Articles Next Articles

Received:2023-04-10

Online:2023-09-26

Published:2023-09-18

CLC Number:

HUA Shaozhen, CAO Wei. Numerical algorithms for injection molding based on Giesekus viscoelastic model[J]. China Plastics, 2023, 37(9): 57-63.

Add to citation manager EndNote|Ris|BibTeX

URL: https://www.plaschina.com.cn/EN/10.19491/j.issn.1001-9278.2023.09.009

| 1 | Kennedy P, Zheng R. Flow analysis of injection molds (second edition) [M]. Hanser Publications,2013. |

| 2 | 曹 伟,任梦柯,刘春太,等.注射成型模拟理论与数值算法发展综述[J].中国科学:技术科学,2020,50(06):667⁃692. |

| CAO W, REN M K, LIU C T, et al. A review on the theories and numerical methods for injection molding simulations[J]. Scientia Sinica(Technologica), 2020,50(06):667⁃692. | |

| 3 | 丁 军,索双富,张 琦, 等.橡胶材料黏弹本构关系研究综述[J].合成橡胶工业,2022,45(06):523⁃529. |

| DING J, SUO S F, ZHANG Q, et al. Review of viscoelastic constitutive relation of rubber materials[J]. China Synthetic Rubber Industry, 2022,45(06):523⁃529. | |

| 4 | 陈腾飞,莫琪棉,张世勋,等.高弹态耐冲击聚苯乙烯本构模型分析[J].中国塑料,2022,36(04):89⁃94. |

| CHEN T F, MO Q M, ZHANG S X, et al. Analysis for constitutive models of high impact polystyrene in rubber⁃like state[J]. China Plastics, 2022,36(04):89⁃94. | |

| 5 | Baaijens F P, Douven L F. Calculation of flow⁃induced residual stresses in injection moulded products[J]. Applied Scientific Research,1993,48:141⁃157. |

| 6 | Kim K, Isayev A I, Kwon K, et al. Modeling and experimental study of birefringence in injection molding of semicrystalline polymers[J]. Polymer, 2005,46, 4 183⁃4 203. |

| 7 | Chang R Y, Chiou S Y. A unified K⁃BKZ model for residual stress analysis of injection molded three⁃dimensional thin shapes[J]. Polymer Engineering & Science,2010, 35:1 733⁃1 747. |

| 8 | 张世勋,曹 伟,叶曙兵, 等.高速微注射成型中熔体充填模式及裹气机理研究[J].中国塑料,2012,26(01):65⁃70. |

| ZHANG S X, CAO W, YE S B, et al. Study on melt filling mode and trapping air mechanism in high speed micro⁃injection molding[J]. China Plastics, ,2012,26(01):65⁃70. | |

| 9 | Cao W, Shen Y, Wang P, et al. Viscoelastic modeling and simulation for polymer melt flow in injection/compression molding[J]. Journal of Non⁃Newtonian Fluid Mecha⁃nics, 2019, 274: 104186. |

| 10 | Olley P. An approximation to the PTT viscoelastic model for gas assisted injection moulding simulation[J]. Journal of Non⁃Newtonian Fluid Mechanics, 2020, 278: 104246. |

| 11 | Baltussen MGHM, Hulsen MA, Peters GWM. Numerical simulation of the fountain flow instability in injection molding[J]. Journal of Non⁃Newtonian Fluid Mechanics,2010, 165:631⁃640. |

| 12 | 曹 伟,花少震,张世勋,等.基于ALE描述的压缩流动三维黏弹性数值模拟[J].应用力学学报,2016,33(03):447⁃453,547⁃548. |

| CAO W, HUA S Z, ZHANG S X, et al. 3D viscoelastic simulation for compressible flow based on ALE description[J]. Chinese Journal of Applied Mechanics, 2016,33(03):447⁃453,547⁃548. | |

| 13 | Zhang S, Hua S, Cao W, et al. 3D viscoelastic simulation of jetting in injection molding[J]. Polymer Engineering & Science, 2019, 59(s2): E397⁃E405. |

| 14 | 花少震. 注射成型喷射现象三维黏弹性数值模拟及机理研究[D].郑州:郑州大学,2017. |

| 15 | Liu Q S, Liu Y Q, Jiang C T, et al. Numerical simulation of viscoelastic flows during injection mold filling based on Rolie–Poly model[J]. Journal of Non⁃Newtonian Fluid Mechanics, 2019, 263: 140⁃153. |

| 16 | Baaijens F P T. Mixed finite element methods for viscoelastic flow analysis: a review[J]. Journal of Non⁃Newtonian Fluid Mechanics, 1998, 79(2): 361⁃385. |

| 17 | Marchal J M, Crochet M J. A new mixed finite element for calculating viscoelastic flow[J]. Journal of Non⁃Newtonian Fluid Mechanics, 1987, 26(1): 77⁃114. |

| 18 | Hughes T J, Brooks A. A theoretical framework for Petrov⁃Galerkin methods with discontinuous weighting functions: Application to the streamline⁃upwind procedure[J]. Finite Elements in Fluids, 1982, 4(2): 47⁃65. |

| 19 | Hughes T J, Brooks A. A theoretical framework for Petrov⁃Galerkin methods with discontinuous weighting functions: Application to the streamline⁃upwind procedure[J]. Finite Elements in Fluids, 1982, 4(2): 47⁃65. |

| 20 | Beris A, Armstrong R, Brown R. Finite element calculation of viscoelastic flow in a journal bearing: I. Small eccentricities[J]. Journal of Non⁃Newtonian Fluid Mecha⁃nics, 1984, 16(1/2): 141⁃172. |

| 21 | Beris A, Armstrong R, Brown R. Finite element calculation of viscoelastic flow in a journal bearing: Ⅱ. Moderate eccentricity[J]. Journal of Non⁃Newtonian Fluid Mecha⁃nics, 1986, 19(3): 323⁃347. |

| 22 | GueÂnette R, Fortin M. A new mixed finite element method for computing viscoelastic flows[J]. Journal of Non⁃Newtonian Fluid Mechanics,1995,60: 27⁃52. |

| 23 | Baaijens F P T, Selen S H A, Baaijens H P W, et al. Viscoelastic flow past a confined cylinder of a LDPE melt[J]. Journal of Non⁃Newtonian Fluid Mechanics, 1997,60:173⁃203. |

| 24 | Xu X, Tian L, Peng S, et al. Development of SPH for simulation of non⁃isothermal viscoelastic free surface flows with application to injection molding[J]. Applied Mathematical Modelling, 2022, 104: 782⁃805. |

| 25 | Kuron M, Stewart C, de Graaf J, et al. An extensible lattice Boltzmann method for viscoelastic flows: complex and moving boundaries in Oldroyd⁃B fluids[J]. The European Physical Journal E, 2021, 44: 1⁃14. |

| 26 | Esteghamatian A, Zaki T A. Dilute suspension of neutrally buoyant particles in viscoelastic turbulent channel flow[J]. Journal of Fluid Mechanics, 2019, 875: 286⁃320. |

| 27 | Favero J L, Secchi A R, Cardozo N, et al. Viscoelastic flow analysis using the software OpenFOAM and differential constitutive equations[J]. Journal of Non⁃Newtonian Fluid Mechanics. 165 (2010) 1 625⁃1 636. |

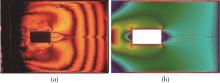

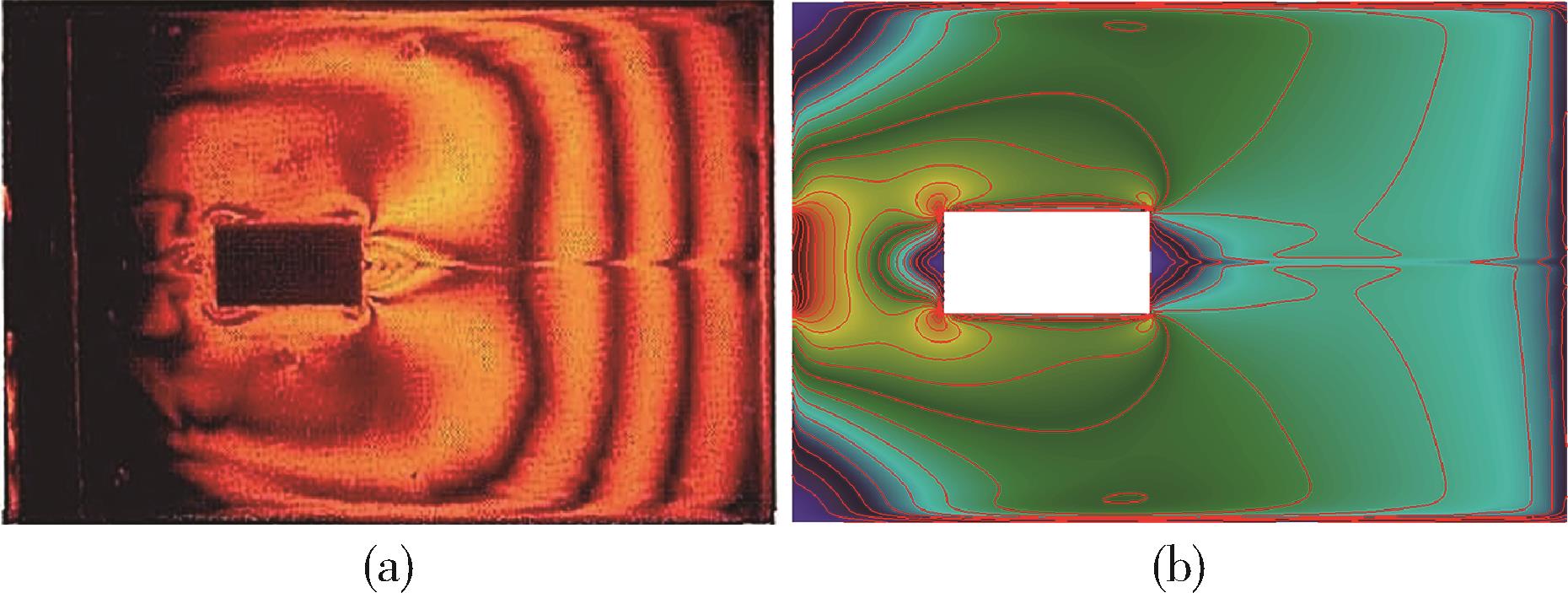

| 28 | 花少震,孟凡净.注射成型喷射现象的实验及数值研究[J].西安交通大学学报,2019,53(09):88⁃95. |

| HUA S Z, MENG F J. Experimental and numerical research on jetting phenomenon during injection molding[J]. Journal of Xi'an Jiaotong University, 2019,53(09):88⁃95. | |

| 29 | 韩 健,申长雨,刘春太,等.注射成型熔接线区域流动诱导双折射行为[J].化工学报,2008(05):1 305⁃1 309. |

| HAN J, SHEN C Y, LIU C T, et al. Flow induced birefringence of weldline region in polystyrene injection mol⁃ding[J]. Journal of Chemical Industry & Engineering,2008, 59:1 305⁃1 309. |

| [1] | HU Xuechuan, FANG Jiahao, LI Youbing, ZHOU Jianjun, LI Li, ZHANG Jixiang, DENG Yajun, LIU Yuan. Injection defect analysis and molding optimization of high⁃gloss grille for an automobile [J]. China Plastics, 2022, 36(9): 70-73. |

| [2] | XU Yuxuan, DANG Kaifang, FU Nanhong, JIAO Xiaolong, XIE Pengcheng, YANG Weimin. Research progress in adaptive optimization technology for injection molding process [J]. China Plastics, 2022, 36(9): 180-186. |

| [3] | WANG Xiaodong, WANG Quan, CHEN Tuo, ZHENG Yue. Optimization of multi⁃objective parameters for double color injection⁃molding based on grey relational analysis and entropy weight method [J]. China Plastics, 2022, 36(7): 115-120. |

| [4] | LIU Yi, SUN Wei, QU Guoxing, WANG Ye, YUAN Ning, YANG Shaolin, XU Xia, CHANG Xiaoyi, ZHANG Yufei. Structure and performance analysis of transparent polypropylene special material for thin⁃wall injection molding [J]. China Plastics, 2022, 36(7): 37-43. |

| [5] | DENG Shixin, WANG Jian, YANG Weimin. Simulation and analysis of fluid high⁃pressure and high⁃speed collision in mixing head cavity of enhanced reaction injection molding machine [J]. China Plastics, 2022, 36(6): 130-136. |

| [6] | SUN Wenbo, XIN Chunling, HE Yadong, ZHAI Yujiao, YAN Baorui. Influence of micro⁃foaming injection molding process on cell structure of glass⁃fiber⁃reinforced PBT products [J]. China Plastics, 2022, 36(5): 1-7. |

| [7] | ZHAI Yujiao, XIN Chunling, HE Yadong, YAN Baorui, QIAO Linjun. Study on process parameters for filling process of polypropylene microcellular injection molding under supercritical N2 [J]. China Plastics, 2022, 36(3): 69-74. |

| [8] | LIU Ganhua, TANG Naifu, MA Ruiwu. Multi⁃objective optimization for MIM process parameters of equal⁃distance spiral bevel gear [J]. China Plastics, 2022, 36(3): 96-103. |

| [9] | ZHANG Xiang, YAN Zhenhao, KONG Xiaoya, ZHU Jianxiao, GUAN Guotao, ZHAO Na, LI Qian. Study on structural optimization of disc screw in micro injection machine [J]. China Plastics, 2022, 36(2): 147-156. |

| [10] | ZHAI Yujiao, XIN Chunling, HE Yadong, YAN Baorui, QIAO Linjun. Study on surface quality optimization of microfoaming injection⁃molded products [J]. China Plastics, 2022, 36(2): 19-26. |

| [11] | HUANG Wei, LIU Hesheng, HUANG Xingyuan, ZHANG Wei, KUANG Tangqing, CHEN Zhongshi. Study on high⁃pressure water penetration behavior of square cross⁃sectional pipes based on short⁃glass⁃fiber⁃reinforced polypropylene [J]. China Plastics, 2022, 36(2): 82-88. |

| [12] | REN Lihui, LI Fuzhu, WANG Yun, DAI Yachun, YANG Hui, XU Zhenying. Multi⁃objective optimization of injection molding quality based on TOPSIS⁃grey relational analysis [J]. China Plastics, 2022, 36(2): 96-102. |

| [13] | ZHENG Fangli, FU Nanhong, JIAO Xiaolong, YANG Weimin, XIE Pengcheng. Research progress in applications and optimization of artificial intelligence technology in injection molding parameters setting [J]. China Plastics, 2022, 36(1): 84-91. |

| [14] | QIAO Linjun, XIN Chunling, HE Yadong, ZHAI Yujiao, YAN Baorui. Visualization Study on Gas Injection Process of A New Type of Micro⁃foaming Gas Injector [J]. China Plastics, 2021, 35(9): 128-135. |

| [15] | ZHA Yan, ZHENG Fangli, XIAO Jian, YANG Weimin, XIE Pengcheng. Research on the Application of Co⁃simulation in the Reduced Design of Automotive Injection Parts [J]. China Plastics, 2021, 35(8): 112-116. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||