京ICP备13020181号-2

© 《China Plastics》

© 《China Plastics》

China Plastics ›› 2025, Vol. 39 ›› Issue (2): 106-111.DOI: 10.19491/j.issn.1001-9278.2025.02.020

• Review • Previous Articles

WANG Yixiao1, FANG Yuxuan1, HOU Jiale1, LIU Guoling2, HAO Xufeng3, WU Xinfeng1( )

)

Received:2024-04-29

Online:2025-02-26

Published:2025-02-27

CLC Number:

WANG Yixiao, FANG Yuxuan, HOU Jiale, LIU Guoling, HAO Xufeng, WU Xinfeng. Research progress in highly thermally conductive boron nitride polymer⁃based phase change material[J]. China Plastics, 2025, 39(2): 106-111.

| 方法 | 材料 | 热导率/W·(m·K) -1 | 潜热/J·g-1 | 参考文献 |

|---|---|---|---|---|

| 共混法 | 六方氮化硼、棕榈酸、烯烃嵌段共聚物 | 0.299(10 % h⁃BN) | — | [ |

| 共混法 | 六方氮化硼、正十八烷、硬脂酸 | 0.322(10 % h⁃BN) | 202.1 | [ |

| 共混法 | 六方氮化硼、肉豆蔻酸 | 0.238(2 % h⁃BN) | 201.4 | [ |

| 共混法 | 六方氮化硼、月桂酸 | 0.261(2 % h⁃BN) | 184.4 | [ |

| 共混法 | 六方氮化硼、聚乙二醇 | 0.191(2 % h⁃BN) | 160.0 | [ |

| 共混法 | 六方氮化硼、聚丙烯酸十四酯 | 0.62(20 %h⁃BN) | — | [ |

| 共混法 | 六方氮化硼、聚乙二醇、石墨烯纳米板 | 3.63(15 %h⁃BN) | 119.3 | [ |

| 共混法 | 六方氮化硼、肉豆酱酸、氧化镁 | 0.52±0.02(14 %h⁃BN) | 140.4 | [ |

| 方法 | 材料 | 热导率/W·(m·K) -1 | 潜热/J·g-1 | 参考文献 |

|---|---|---|---|---|

| 共混法 | 六方氮化硼、棕榈酸、烯烃嵌段共聚物 | 0.299(10 % h⁃BN) | — | [ |

| 共混法 | 六方氮化硼、正十八烷、硬脂酸 | 0.322(10 % h⁃BN) | 202.1 | [ |

| 共混法 | 六方氮化硼、肉豆蔻酸 | 0.238(2 % h⁃BN) | 201.4 | [ |

| 共混法 | 六方氮化硼、月桂酸 | 0.261(2 % h⁃BN) | 184.4 | [ |

| 共混法 | 六方氮化硼、聚乙二醇 | 0.191(2 % h⁃BN) | 160.0 | [ |

| 共混法 | 六方氮化硼、聚丙烯酸十四酯 | 0.62(20 %h⁃BN) | — | [ |

| 共混法 | 六方氮化硼、聚乙二醇、石墨烯纳米板 | 3.63(15 %h⁃BN) | 119.3 | [ |

| 共混法 | 六方氮化硼、肉豆酱酸、氧化镁 | 0.52±0.02(14 %h⁃BN) | 140.4 | [ |

| 方法 | 材料 | 热导率/ W·(m·K) -1 | 潜热/ J·g-1 | 参考 文献 |

|---|---|---|---|---|

| 自组装法 | 六方氮化硼、 多壁碳纳米管 | 1.21(10 % h⁃BN) | 109.1 | [ |

| 自组装法 | 六方氮化硼、 石墨烯 | 1.44(25 %h⁃BN) | 208.3 | [ |

| 自组装法 | 六方氮化硼、 碳化硅纳米线 | 4.22(3.17 %h⁃BN) | — | [ |

| 自组装法 | 六方氮化硼、石蜡、 聚二甲基硅氧烷 | 1.44(28.6 %h⁃BN) | — | [ |

| 方法 | 材料 | 热导率/ W·(m·K) -1 | 潜热/ J·g-1 | 参考 文献 |

|---|---|---|---|---|

| 自组装法 | 六方氮化硼、 多壁碳纳米管 | 1.21(10 % h⁃BN) | 109.1 | [ |

| 自组装法 | 六方氮化硼、 石墨烯 | 1.44(25 %h⁃BN) | 208.3 | [ |

| 自组装法 | 六方氮化硼、 碳化硅纳米线 | 4.22(3.17 %h⁃BN) | — | [ |

| 自组装法 | 六方氮化硼、石蜡、 聚二甲基硅氧烷 | 1.44(28.6 %h⁃BN) | — | [ |

| 方法 | 材料 | 热导率/ W·(m·K) -1 | 潜热/ J·g-1 | 参考 文献 |

|---|---|---|---|---|

| 冰模板法 | 六方氮化硼、 石墨烯 | 0.85(10 % h⁃BN) | 165.4 | [ |

| 冰模板法 | 六方氮化硼、 聚氨酯、石蜡 | 0.96(3.5 % h⁃BN) | 140.4 | [ |

| 冰模板法 | 六方氮化硼、 氧化石墨烯纳米片 | 1.12(90 % h⁃BN) | 187.2 | [ |

| 冰模板法 | 六方氮化硼、 壳聚糖、石蜡 | 1.14(41 % h⁃BN) | 118.4 | [ |

| 冰模板法 | 六方氮化硼、聚乙二醇、氧化石墨烯 | 1.06(14.4 % h⁃BN) | — | [ |

| 方法 | 材料 | 热导率/ W·(m·K) -1 | 潜热/ J·g-1 | 参考 文献 |

|---|---|---|---|---|

| 冰模板法 | 六方氮化硼、 石墨烯 | 0.85(10 % h⁃BN) | 165.4 | [ |

| 冰模板法 | 六方氮化硼、 聚氨酯、石蜡 | 0.96(3.5 % h⁃BN) | 140.4 | [ |

| 冰模板法 | 六方氮化硼、 氧化石墨烯纳米片 | 1.12(90 % h⁃BN) | 187.2 | [ |

| 冰模板法 | 六方氮化硼、 壳聚糖、石蜡 | 1.14(41 % h⁃BN) | 118.4 | [ |

| 冰模板法 | 六方氮化硼、聚乙二醇、氧化石墨烯 | 1.06(14.4 % h⁃BN) | — | [ |

| 方法 | 材料 | 热导率/ W·(m·K) -1 | 潜热/J·g-1 | 参考文献 |

|---|---|---|---|---|

| 纺丝法 | 六方氮化硼、纤维素纳米纤维、壳聚糖 | 4.005(10 % h⁃BN) | 103 | [ |

| 纺丝法 | 六方氮化硼、聚酰亚胺、 聚多巴胺 | 1.26(10 % h⁃BN) | — | [ |

| 方法 | 材料 | 热导率/ W·(m·K) -1 | 潜热/J·g-1 | 参考文献 |

|---|---|---|---|---|

| 纺丝法 | 六方氮化硼、纤维素纳米纤维、壳聚糖 | 4.005(10 % h⁃BN) | 103 | [ |

| 纺丝法 | 六方氮化硼、聚酰亚胺、 聚多巴胺 | 1.26(10 % h⁃BN) | — | [ |

| 1 | Jiang T, Xu K, Wang Y,et al.In situ construction of high⁃thermal⁃conductivity and negative⁃permittivity epoxy/carbon fiber@carbon composites with a 3D network by high⁃temperature chemical vapor deposition[J].ACS Appl Mater Interfaces,2023,15(46):54 027⁃54 038. |

| 2 | Jiang Tao, Wang Ying, Xu Kang, et al. Highly thermally conductive and negative permittivity epoxy composites by constructing the carbon fiber/carbon networks [J]. Composites Communications, 2023: 39101560. |

| 3 | Guo Sihua, Chen Shujin, Amos Nkansah, et al. Toward ultrahigh thermal conductivity graphene films [J]. 2D Materials, 2022, 10(1):014002. |

| 4 | Shi Shanshan, Jiang Tao, Wang Ying, et al. Review on the construction of thermal conductive organic phase change materials by three⁃dimensional network method [J]. Journal of Materials Science, 2023, 58(34):13 580⁃13 604. |

| 5 | Cao Xing, Zhang Ruiqi, Zhang Ning, et al. Flexible composite phase change material with improved hydrophobicity and thermal conductivity characters for thermal management [J]. Journal of Energy Storage, 2023, 72:108641. |

| 6 | Su Di, Jia Yuting, Guruprasad Alva, et al. Preparation and thermal properties of N⁃octadecane/stearic acid eutectic mixtures with hexagonal boron nitride as phase change materials for thermal energy storage [J]. Energy and Buildings, 2016, 131:35⁃41. |

| 7 | Mohammed Ouikhalfan, Ahmet Sarı, Gökhan Hekimoğlu, et al. Thermal energy storage properties, thermal conductivity, chemical/and thermal reliability of three different organic phase change materials doped with hexagonal boron nitride [J]. Surfaces and Interfaces, 2022, 32:102176. |

| 8 | Li Shuqin, Wang Haixia, Mao Huiqin, et al. Enhanced thermal management performance of comb⁃like polymer/boron nitride composite phase change materials for the thermoregulated fabric application [J]. Journal of Energy Storage, 2021, 40:102826. |

| 9 | Xue Sen, Lei Chuxin, Liu Dingyao, et al. Thermo⁃conductive phase change materials with binary fillers of core⁃shell⁃like distribution [J]. Composites Part A: Applied Science and Manufacturing, 2021, 144:106326. |

| 10 | Zhang Huan, Wang Wenze, Fu Tingwei, et al. Fabrication and thermal properties of novel myristic acid/MgO/BN composite phase change materials for thermal energy storage [J]. Journal of Materials Research, 2023, 38(12):3 151⁃3 159. |

| 11 | Yang Yukai, Xia Yongpeng, Chen Fazhan, et al. Hexagonal boron nitride⁃induced lamellar⁃structured flexible phase change film for temperature⁃controlled information storage and wearable thermal regulation [J]. Journal of Energy Storage, 2023, 72:108443. |

| 12 | Xia Y, Li Q, Ji R, et al.Multielement synergetic effect of boron nitride and multiwalled carbon nanotubes for the fabrication of novel shape⁃stabilized phase⁃change composites with enhanced thermal conductivity[J].ACS Appl Mater Interfaces,2020,12(37):41 398⁃41 409. |

| 13 | Hui S, Ji R, Zhang H, et al. N⁃octadecane encapsulated by assembled BN/GO aerogels for highly improved thermal conductivity and energy storage capacity [J]. Nanomaterials (Basel), 2023, 13(16):2317. |

| 14 | Xiao Chao, Guo Yujie, Tang Yunlu, et al. Epoxy composite with significantly improved thermal conductivity by constructing a vertically aligned three⁃dimensional network of silicon carbide nanowires/ boron nitride nanosheets [J]. Composites Part B: Engineering, 2020, 187:107855. |

| 15 | Du Qingyuan, Li Chenglin, Sun Jingyao, et al. Efficient preparation of polydimethylsiloxane⁃based phase change composites by forced network assembly with outstanding thermal management capability [J]. Journal of Polymer Research, 2023, 30(4) :158. |

| 16 | Wang Zhuoya, Zhang Kaihang, Zhang Bing, et al. Ultrafast battery heat dissipation enabled by highly ordered and interconnected hexagonal boron nitride thermal conductive composites [J]. Green Energy & Environment, 2022, 7(6): 1 401⁃1 410. |

| 17 | Qian Zhenchao, Shen Heng, Fang Xin, et al. Phase change materials of paraffin in h⁃BN porous scaffolds with enhanced thermal conductivity and form stability [J]. Energy and Buildings, 2018, 158:1 184⁃1 188. |

| 18 | Ren Shibing, Yan Jiamin, Li Min, et al. High thermal conductive shape⁃stabilized phase change materials based on water⁃borne polyurethane/boron nitride aerogel [J]. Ceramics International, 2023, 49(6): 8 945⁃8 951. |

| 19 | Xu L, Ding Y, Wang L. Self⁃assembled boron nitride nanosheet⁃based aerogels as support frameworks for efficient thermal energy storage phase change materials [J]. RSC Adv, 2023, 13(48): 34 291⁃34 298. |

| 20 | Du Guohao, Lai Xin, Hu Jianfeng, et al. Construction of high thermal conductive boron Nitrid@Chitosan aerogel/ paraffin composite phase change material [J]. Solar Energy Materials and Solar Cells, 2022, 240:111532. |

| 21 | Yang Guoqing, Zhao Lunyu, Shen Chuanfei, et al. Boron nitride microsheets bridged with reduced graphene oxide as scaffolds for multifunctional shape stabilized phase change materials [J]. Solar Energy Materials and Solar Cells, 2020, 209:110441. |

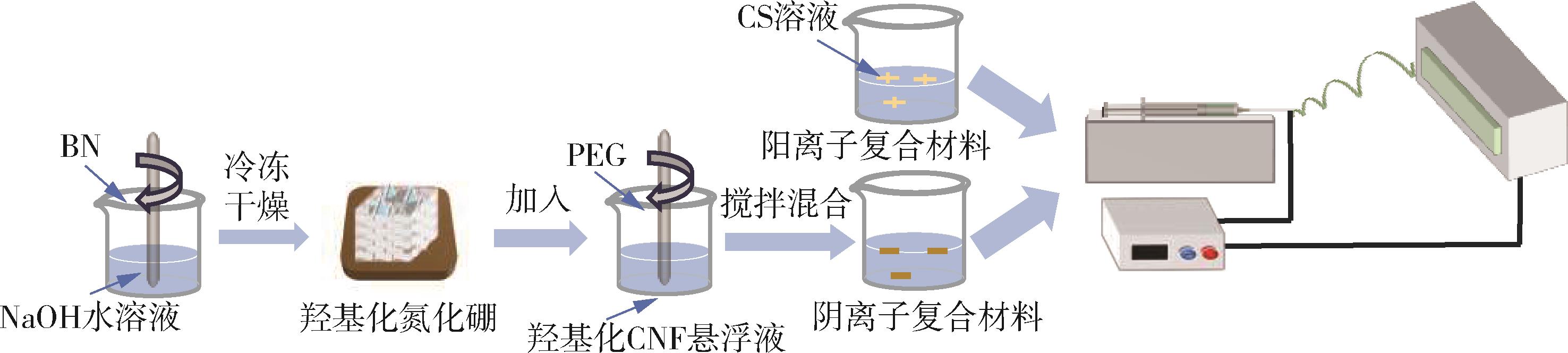

| 22 | Fang H, Lin J, Zhang L, et al. Fibrous form⁃stable phase change materials with high thermal conductivity fabricated by interfacial polyelectrolyte complex spinning [J]. Carbohydr Polym, 2020, 249: 116836. |

| 23 | Xie Fan, Dai Qiyang, Zhuo Longhai, et al. Boron nitride nanosheets modified with polydopamine and polyimide nanofibers as flexible thermal management materials [J]. ACS Applied Nano Materials, 2024, 7(1): 1 089⁃1 098. |

| 24 | Cao Hong, Li Yuan, Xu Weidi, et al. Leakage⁃proof flexible phase change gels with salient thermal conductivity for efficient thermal management [J]. ACS Applied Materials & Interfaces, 2022, 10:3444. |

| [1] | ZENG Yu, TANG Lu. Effects of boron nitride on dielectric and mechanical properties of onion⁃like carbons/silicone rubber composites [J]. China Plastics, 2025, 39(1): 25-30. |

| [2] | TAN Jiao, WANG Junzhu, LI Shuai, LIU Xinye. Preparation and performance evaluation of phase⁃change microcapsules and performance analysis of phase change asphalt [J]. China Plastics, 2024, 38(9): 1-7. |

| [3] | TANG Bo, XIANG Lixue, DAI Xumin, WANG Erke, JIANG Tao, WANG Ying, WU Xinfeng. Research progress in diamond thermally conductive composite material [J]. China Plastics, 2024, 38(8): 125-131. |

| [4] | CAO Shuai, JIANG Tao, LIU Xiong, WANG Ying, LI Wenge, WU Xinfeng. Research progress in preparation of thermal conductive composites with MXene [J]. China Plastics, 2024, 38(6): 139-144. |

| [5] | GAO Wei, XIONG Changyi, HAN Fei, KONG Nizao, YAN Yuanwei. Study on modification and design of thermal conductive and microwave absorbing dual⁃functional powders [J]. China Plastics, 2024, 38(6): 19-24. |

| [6] | ZHANG Jun, XI Wang, QIAN Lijun, ZHOU Fengshuai, QIU Yong, WANG Jingyu, ZHANG Zhipeng. Preparation and characterizations of flame⁃retardant and heat⁃conductive polycarbonate⁃based composites with boron nitride and phosphaphenanthrene [J]. China Plastics, 2024, 38(3): 31-37. |

| [7] | ZHENG Chenxiao, LIU Jiaqi, CUI Yangang, LIU Zeqin, TIAN Shen, CAO Yibao. Research status and prospect of phase⁃change thermal storage floor in construction field [J]. China Plastics, 2024, 38(10): 70-74. |

| [8] | XIANG Lixue, TANG Bo, ZHOU Gang, DAI Xumin, WANG Erke, JIANG Tao, WU Xinfeng. A review of application research on 3D printing technology in high thermal conductivity engineering plastics [J]. China Plastics, 2023, 37(9): 125-132. |

| [9] | . Study on synergistic reinforcement of intrinsically conductive epoxy resin matrix composites with short?cut/continuous carbon fibers [J]. , 2023, 37(4): 1-10. |

| [10] | ZHANG Qiang, ZHANG Jian, LIN Lin, LIU Jing, WANG Tianhe. Research progress in heat transfer enhancement measures for wall materials of microencapsulated phase change materials [J]. China Plastics, 2022, 36(7): 187-196. |

| [11] | YANG Xiaolong, CHEN Wenjing, LI Yongqing, YAN Xiaokun, WANG Xiulei, XIE Pengcheng, MA Xiuqing. Research progress in polymer/graphene conductive composites [J]. China Plastics, 2022, 36(6): 165-173. |

| [12] | ZHANG Yunfeng, ZHONG Wei, ZHANG Lu, LAN Zhixing, DONG Zhibo. Preparation and performance of liquid paraffin/polysulfone resin/nano⁃SiO2 composite phase change materials [J]. China Plastics, 2022, 36(6): 32-38. |

| [13] | LIU Wen, SHI Wenzhao, LIU Jinshu, LU Shaofeng, ZHOU Hongjuan. Research progress in electro⁃active shape memory composite materials [J]. China Plastics, 2022, 36(4): 175-189. |

| [14] | HE Mingfeng, WANG Ke, WANG Qiyang, YANG Xiao, GUO Hong, HU Boyang, LI Baoan. Study on polyvinylidene fluoride/matrix⁃like groups⁃modified graphene composites with high thermal conductivity [J]. China Plastics, 2022, 36(2): 41-48. |

| [15] | WANG Qiyang, YANG Xiao, CHEN Jihuan, HE Yuexing, YANG Dongmei, HU Boyang, GUO Hong, LI Baoan. Study on double⁃segregated polyethylene/graphene composites with high thermal conductivity [J]. China Plastics, 2022, 36(1): 32-41. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||