京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2

《中国塑料》编辑部 ©2008-2024 版权所有

地址:北京市海淀区阜成路11号 邮编:100048

编辑部:010-68985541 联系信箱:cp@plaschina.com.cn

广告部/发行部:010-68985253 本系统由北京玛格泰克科技发展有限公司设计开发

中国塑料 ›› 2023, Vol. 37 ›› Issue (11): 74-80.DOI: 10.19491/j.issn.1001-9278.2023.11.008

收稿日期:2023-05-26

出版日期:2023-11-26

发布日期:2023-11-22

通讯作者:

杨建军(1977—),男,教授,从事3D打印、微纳增材制造、柔性电子方面研究,yjjdem@163.com基金资助:

WANG Luowei, YANG Jianjun( ), ZHU Jialei

), ZHU Jialei

Received:2023-05-26

Online:2023-11-26

Published:2023-11-22

Contact:

YANG Jianjun

E-mail:yjjdem@163.com

摘要:

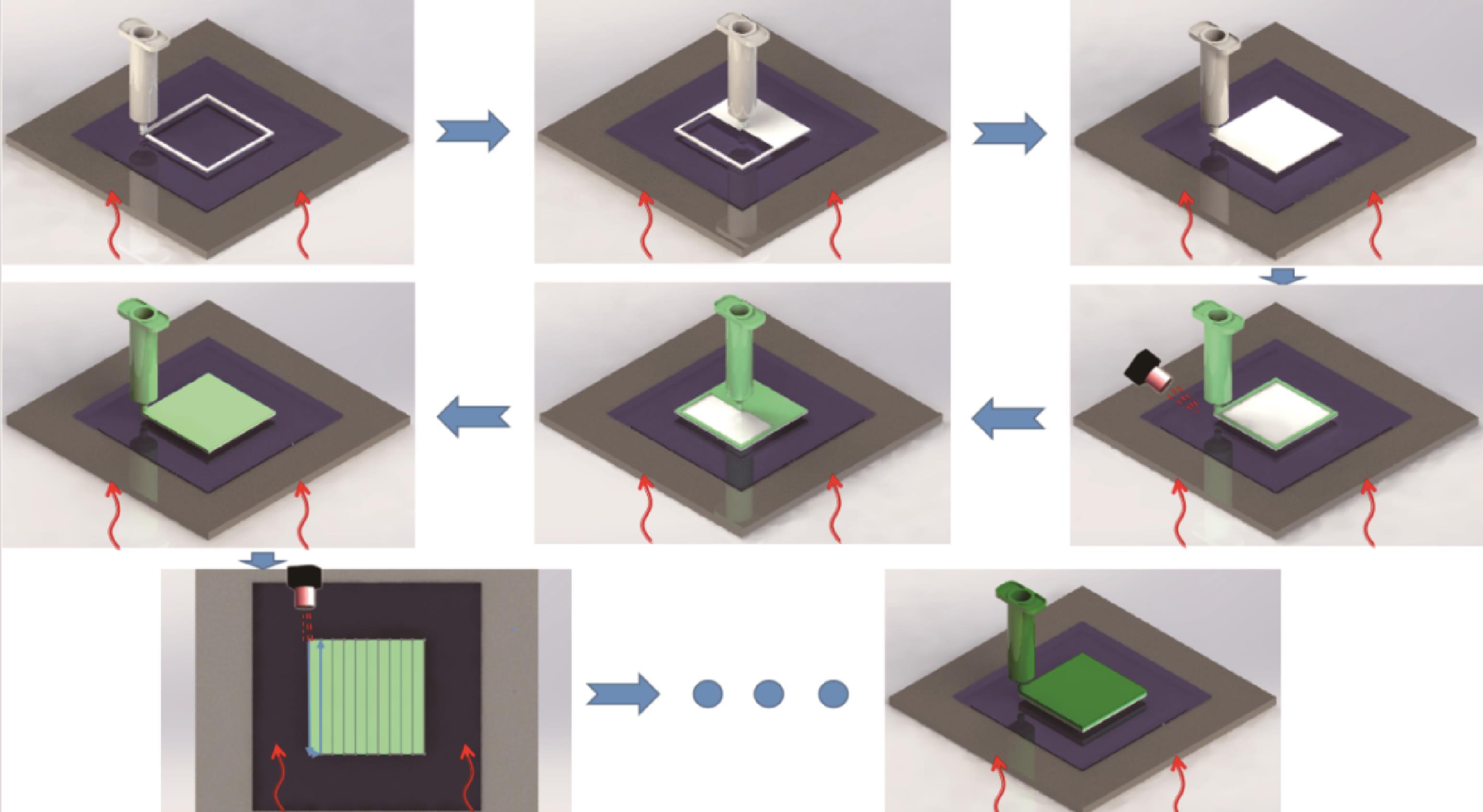

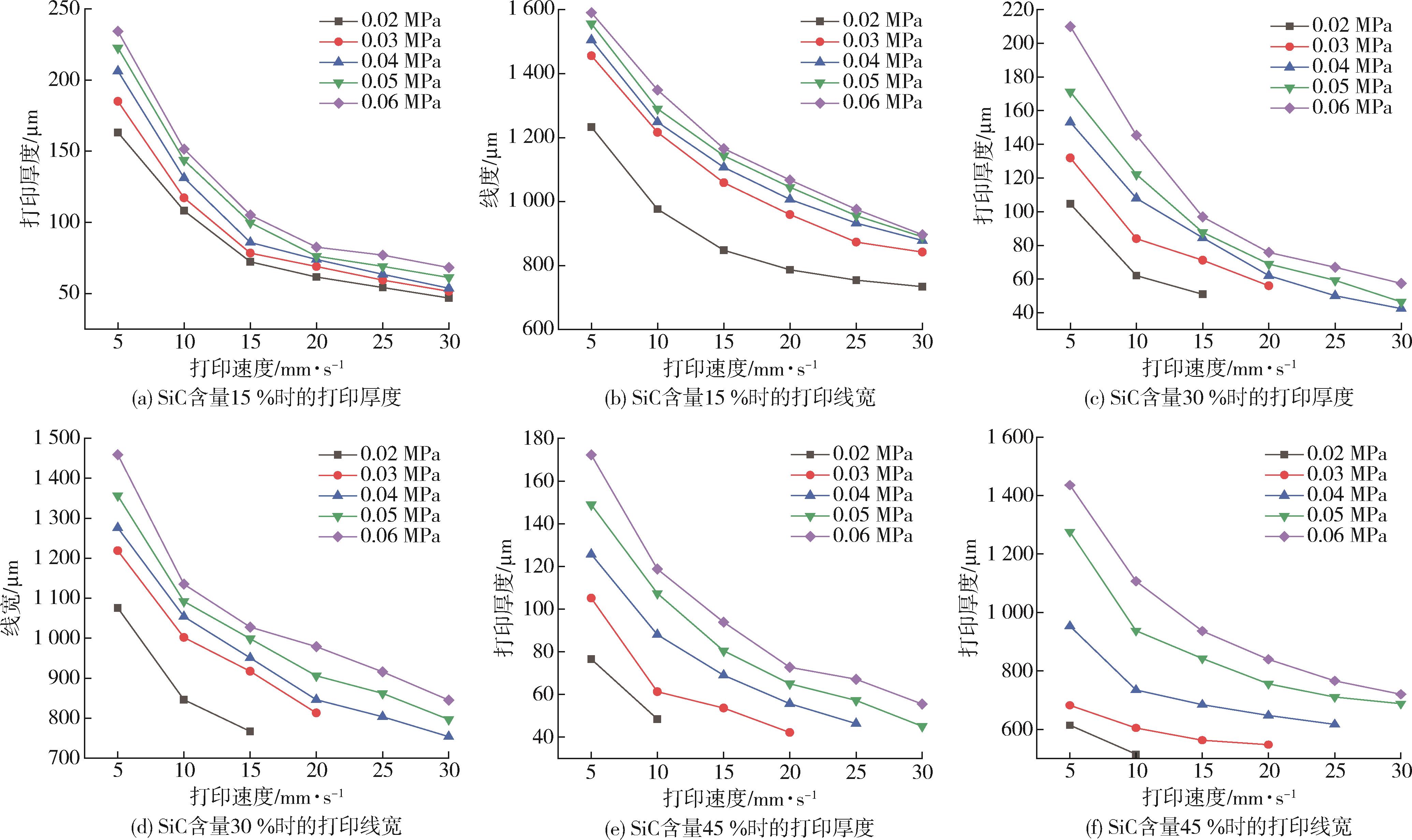

聚二甲基硅氧烷(PDMS)基材料未固化状态下具有摊铺(流动浸润)特性,传统底部加热的固化方式无法满足及时固化的需求。针对此问题,以PDMS和碳化硅(SiC)粉末混合功能梯度材料为例,采用顶部与底板双重加热方式,提出了一种边框区与填充区两步3D打印的精密成形方法,探究了打印速度、气压、激光功率密度等工艺参数对不同SiC含量PDMS/SiC复合材料制造精度的影响规律。最终选取激光功率密度101.85 W/cm2时进行功能梯度样件打印。结果表明,采用分步打印方式制备的样件整体形貌优异,样件侧面倾角40°增大到80°,极大地提高了打印形状尺寸精度。

中图分类号:

王洛唯, 杨建军, 朱嘉乐. 基于顶部加热与分步制造的PDMS/SiC功能梯度材料3D打印成形规律研究[J]. 中国塑料, 2023, 37(11): 74-80.

WANG Luowei, YANG Jianjun, ZHU Jialei. 3D printing formation law of PDMS/SiC functionally graded materials based on top heating and step⁃by⁃step forming[J]. China Plastics, 2023, 37(11): 74-80.

| 打印层 | 区域 | SiC 含量/% | 激光功率密度/W·cm-2 | 打印速度/mm·s-1 | 气压/MPa |

|---|---|---|---|---|---|

| 基底层 | 边框区 | 0 | — | 20 | 0.05 |

| 填充区 | |||||

| 第一层 | 边框区 | 15 | 101.85 | 5 | 0.04 |

| 填充区 | — | 10 | 0.04 | ||

| 第二层 | 边框区 | 30 | 101.85 | 8 | 0.06 |

| 填充区 | — | 12 | 0.05 | ||

| 第三层 | 边框区 | 45 | 101.85 | 5 | 0.06 |

| 填充区 | — | 10 | 0.06 |

| 打印层 | 区域 | SiC 含量/% | 激光功率密度/W·cm-2 | 打印速度/mm·s-1 | 气压/MPa |

|---|---|---|---|---|---|

| 基底层 | 边框区 | 0 | — | 20 | 0.05 |

| 填充区 | |||||

| 第一层 | 边框区 | 15 | 101.85 | 5 | 0.04 |

| 填充区 | — | 10 | 0.04 | ||

| 第二层 | 边框区 | 30 | 101.85 | 8 | 0.06 |

| 填充区 | — | 12 | 0.05 | ||

| 第三层 | 边框区 | 45 | 101.85 | 5 | 0.06 |

| 填充区 | — | 10 | 0.06 |

| 1 | Mahamood R M, Akinlabi E T, MWahamood R M, et al. Types of functionally graded materials and their areas of application[M]. Berlin, German:Springer International Publishing, 2017: 9⁃21. |

| 2 | Mondal K, Nuñez L, Downey C M, et al. Recent advances in the thermal barrier coatings for extreme environments[J]. Materials Science for Energy Technologies, 2021, 4: 208⁃210. |

| 3 | Mallick A, Setti S G, Sahu R K. Centrifugally cast functionally graded materials: fabrication and challenges for probable automotive cylinder liner application[J]. Ceramics International, 2022, 49(6): 8 649⁃8 682. |

| 4 | Johari N, Rafati F, Zohari F, et al. Porous functionally graded scaffolds of poly(ε⁃caprolactone)/ZnO nanocomposite for skin tissue engineering: morphological, mechanical and biological evaluation[J]. Materials Chemistry and Physics, 2022, 280: 125786. |

| 5 | Zhang G, Li P, Wang X, et al. Flexible battery‐free wireless sensor array based on functional gradient‐structured wood for pressure and temperature monitoring[J]. Advanced Functional Materials, 2023, 33(2): 2208900. |

| 6 | Lim H, Kim H S, Qazi R, et al. Advanced soft materials, sensor integrations, and applications of wearableflexible hybrid electronics in healthcare, energy, and environment[J]. Advanced Materials, 2020, 32: 1901924. |

| 7 | Bartlett N W, Tolley M T, Overvelde J T, et al. A 3D⁃printed, functionally graded soft robotpowered by combustion[J]. Science, 2015, 349(6 244): 161⁃165. |

| 8 | 夏晓光, 段国林. 功能梯度材料增材制造技术的研究进展及展望[J]. 材料导报, 2022, 36(10): 134⁃140. |

| XIA X G, DUAN G L. Advances and prospects of additive manufacturing technology of functionally graded material[J]. Materials Reports, 2022, 36(10): 134⁃140. | |

| 9 | Saadi M, Maguire A, Pottackal N T, et al. Direct ink writing: a 3D printing technology for diverse materials[J]. Advanced Materials, 2022, 34(28): 2108855. |

| 10 | 齐田宇, 杨建军, 赵佳伟, 等. 基于多材料 3D 打印和约束牺牲层连续功能梯度材料⁃结构一体化制造与性能[J]. 复合材料学报, 2021, 39(3): 1 055⁃1 067. |

| QI T Y, YANG J J, ZHAO J E, et al. Integrated manufacturing and performance study of continuous functionally graded materials⁃structures based on multi⁃material 3D printing and constraint sacrifice layer[J]. Acta Materiae Compositae Sinica, 2022, 39(3): 1 055⁃1 067. | |

| 11 | Ji Z, Jiang D, Zhang X, et al. Facile photo and thermal two⁃stage curing for high⁃performance 3D printing of poly (dimethylsiloxane)[J]. Macromolecular Rapid Communications, 2020, 41(10): 2000064. |

| 12 | Aabith S, Caulfield R, Akhlaghi O, et al. 3D direct⁃write printing of water soluble micromoulds for high⁃resolution rapid prototyping[J]. Additive Manufacturing, 2022, 58: 103019. |

| 13 | Khan Y, Thielens A, Muin S, et al. A new frontier of printed electronics: flexible hybrid electronics[J]. Advanced Materials, 2020, 32(15): 1905279. |

| 14 | 杨晓冬, 邵建新, 廖生鸿 等. 刀口法测量高斯光束光斑半径研究[J].激光与红外,2009,39(8):829⁃832. |

| YANG X D, SHAO J X, LIAO S H, et al. Investigation on measuring beam width of the Gaussian beam by knife⁃edge method[J]. Laser & Infrared, 2009, 39(8): 829⁃832. | |

| 15 | Yang J C, Mun J, Kwon S Y, et al. Electronic skin: recent progress and future prospects forskin⁃attachable devices for health monitoring, robotics, and prosthetics[J]. Advanced Materials, 2019, 31(48): 1904765. |

| [1] | 周纪委, 王明伟, 吴迪, 张文超, 林连明, 于峻伟. 汽车尾门左右窗框饰板气辅注塑模具设计[J]. 中国塑料, 2023, 37(11): 141-148. |

| [2] | 张一明, 黄志刚, 徐珍, 程媛媛. 螺杆构型对啮合异向双螺杆流场影响的仿真分析[J]. 中国塑料, 2023, 37(10): 131-138. |

| [3] | 赵利平, 张维合, 彭新华. 汽车座椅侧护板注塑模具创新设计[J]. 中国塑料, 2023, 37(10): 139-143. |

| [4] | 叶卫文, 陈镇森, 姜炳春, 吴光明. 汽车热交换系统斜向管口气室模具设计[J]. 中国塑料, 2023, 37(9): 102-108. |

| [5] | 花少震, 曹伟. 基于Giesekus黏弹性本构的注射成型数值算法研究[J]. 中国塑料, 2023, 37(9): 57-63. |

| [6] | 周磊, 张礼华, 陈景铭, 毛旭, 陈曙光, 邱建成. 可降解塑料片材机头流道的流场分析及设计优化[J]. 中国塑料, 2023, 37(9): 90-95. |

| [7] | 秦森, 何和智, 张涛, 黄照夏, 瞿金平. 塑料体积脉动注射成型技术研究[J]. 中国塑料, 2023, 37(9): 96-101. |

| [8] | 叶卫文, 张小娟, 赵利平, 侯贤州. 汽车弯管接头注塑模具设计[J]. 中国塑料, 2023, 37(8): 107-112. |

| [9] | 丁海, 马秉馨, 花少震, 曹伟. 中心静脉导管挤出成型的Polyflow优化与模具设计[J]. 中国塑料, 2023, 37(8): 113-117. |

| [10] | 邓小珍, 刘彪, 肖兵, 江诗雨, 陈天荣. 聚合物双层微管单双侧气体辅助微挤出成型差异性研究[J]. 中国塑料, 2023, 37(8): 55-60. |

| [11] | 王颢霖, 王廷玺. 基于离散单元法一字排列三螺杆挤出机固体输送段输送机理分析[J]. 中国塑料, 2023, 37(8): 61-68. |

| [12] | 高海亮, 胡程, 周宇强, 刘欣, 程建明, 宋桂珍. 3D打印零件的尺寸精度及控制[J]. 中国塑料, 2023, 37(8): 79-85. |

| [13] | 张维合, 温煌英, 冯婧. 智能定位器面盖双色注塑模设计[J]. 中国塑料, 2023, 37(2): 101-105. |

| [14] | 王德建, 俞鹏飞, 丁玉梅, 杨卫民. 层叠流道中天然高分子挤压流动过程的数值模拟[J]. 中国塑料, 2023, 37(1): 60-65. |

| [15] | 薛鹏, 张宇, 周国发. 微细万向球形机械运动副模内微装配成型控形模拟研究[J]. 中国塑料, 2023, 37(1): 66-73. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2