京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2

《中国塑料》编辑部 ©2008-2024 版权所有

地址:北京市海淀区阜成路11号 邮编:100048

编辑部:010-68985541 联系信箱:cp@plaschina.com.cn

广告部/发行部:010-68985253 本系统由北京玛格泰克科技发展有限公司设计开发

中国塑料 ›› 2024, Vol. 38 ›› Issue (6): 1-11.DOI: 10.19491/j.issn.1001-9278.2024.06.001

• 材料与性能 • 下一篇

收稿日期:2023-08-09

出版日期:2024-06-26

发布日期:2024-06-20

通讯作者:

王洪学(1962-),男,研究员,从事新型高分子材料技术开发研究,JamesWang.sshy@sinopec.com

LUO Jiawei, ZHOU Bing, WANG James H( ), JIA Qin

), JIA Qin

Received:2023-08-09

Online:2024-06-26

Published:2024-06-20

Contact:

WANG James H

E-mail:JamesWang.sshy@sinopec.com

摘要:

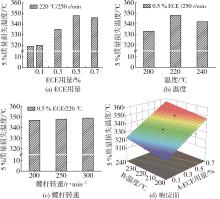

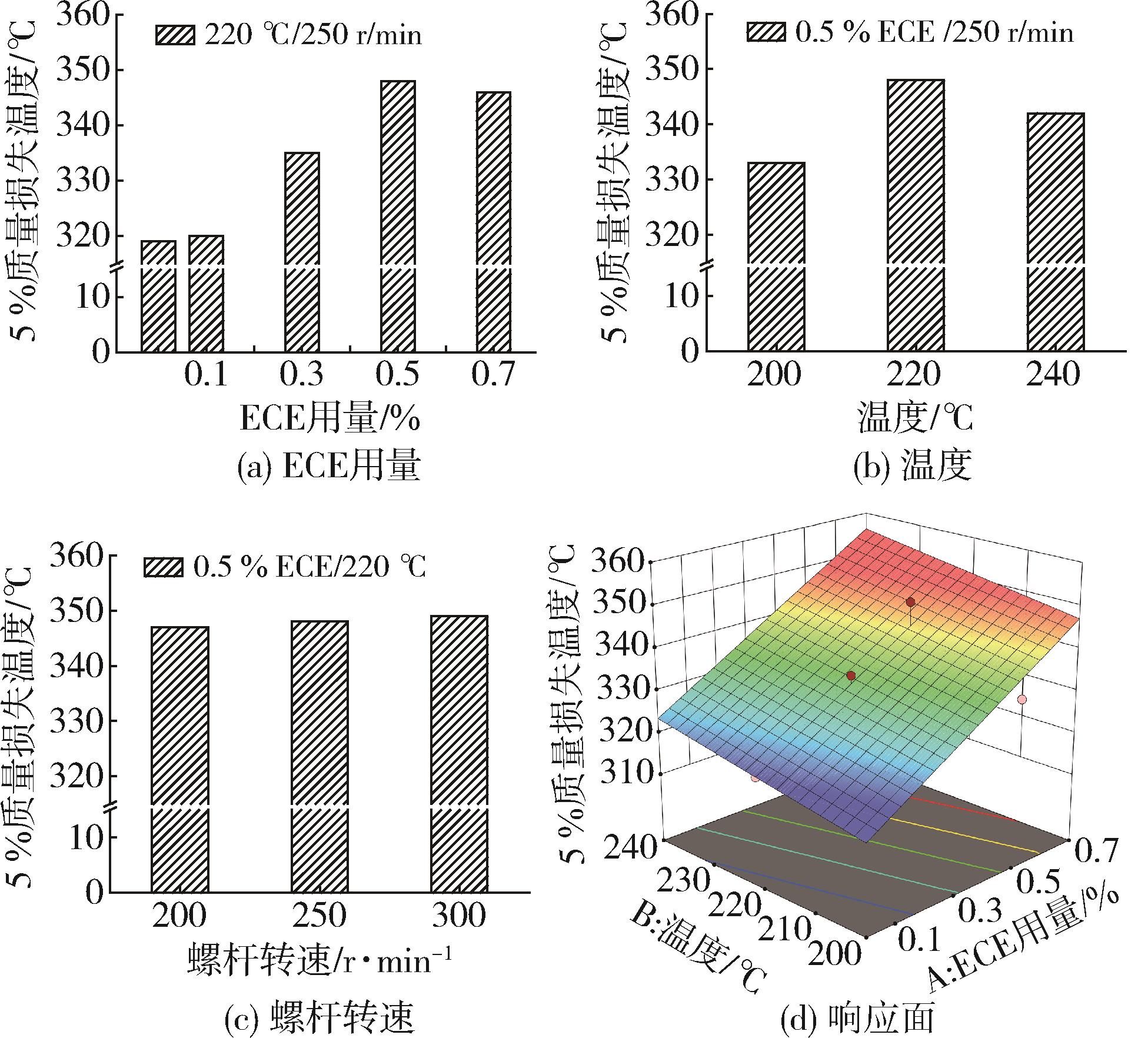

将一种多环氧官能团聚合物作为聚丁二酸丁二酯⁃共⁃对苯二甲酸丁二酯(PBST)的扩链剂,研究熔体反应挤出过程中的扩链条件对PBST/滑石粉共混物性能的影响。将扩链剂用量、反应温度和螺杆转速作为本研究的主要研究因素,通过方差分析寻找主要影响因素及各因素间交互作用。结果表明,扩链剂用量的影响最为显著,其次是温度,螺杆转速的影响不显著;随着扩链剂用量的增加,熔融温度和结晶温度降低,分子量、熔体黏度和热稳定性增加;同时,随着扩链剂用量的增加,改性PBST强度提高但韧性降低;响应面分析表明扩链剂用量、反应温度和螺杆转速分别为0.66 %、200 ℃和300 r/min时扩链条件最优。

中图分类号:

骆佳伟, 周炳, 王洪学, 贾钦. 扩链条件对聚丁二酸丁二酯⁃共⁃对苯二甲酸丁二酯/滑石粉共混物性能的影响[J]. 中国塑料, 2024, 38(6): 1-11.

LUO Jiawei, ZHOU Bing, WANG James H, JIA Qin. Effects of chain⁃extension condition on properties of poly(butylene succinate⁃co⁃terephthalate)/talc blends[J]. China Plastics, 2024, 38(6): 1-11.

| 样品编号 | PBST/份 | 滑石粉母料/份 | ECE/% | 白油/% | 温度*/℃ | 螺杆转速/r•min-1 |

|---|---|---|---|---|---|---|

| PBST⁃0 | 75 | 25 | 0 | 0 | 220 | 250 |

| PBST⁃1/220/250 | 75 | 25 | 0.1 | 0.8 | 220 | 250 |

| PBST⁃3/220/250 | 75 | 25 | 0.3 | 0.8 | 220 | 250 |

| PBST⁃5/220/250 | 75 | 25 | 0.5 | 0.8 | 220 | 250 |

| PBST⁃7/220/250 | 75 | 25 | 0.7 | 0.8 | 220 | 250 |

| PBST⁃5/200/250 | 75 | 25 | 0.5 | 0.8 | 200 | 250 |

| PBST⁃5/240/250 | 75 | 25 | 0.5 | 0.8 | 240 | 250 |

| PBST⁃5/220/200 | 75 | 25 | 0.5 | 0.8 | 220 | 200 |

| PBST⁃5/220/300 | 75 | 25 | 0.5 | 0.8 | 220 | 300 |

| 样品编号 | PBST/份 | 滑石粉母料/份 | ECE/% | 白油/% | 温度*/℃ | 螺杆转速/r•min-1 |

|---|---|---|---|---|---|---|

| PBST⁃0 | 75 | 25 | 0 | 0 | 220 | 250 |

| PBST⁃1/220/250 | 75 | 25 | 0.1 | 0.8 | 220 | 250 |

| PBST⁃3/220/250 | 75 | 25 | 0.3 | 0.8 | 220 | 250 |

| PBST⁃5/220/250 | 75 | 25 | 0.5 | 0.8 | 220 | 250 |

| PBST⁃7/220/250 | 75 | 25 | 0.7 | 0.8 | 220 | 250 |

| PBST⁃5/200/250 | 75 | 25 | 0.5 | 0.8 | 200 | 250 |

| PBST⁃5/240/250 | 75 | 25 | 0.5 | 0.8 | 240 | 250 |

| PBST⁃5/220/200 | 75 | 25 | 0.5 | 0.8 | 220 | 200 |

| PBST⁃5/220/300 | 75 | 25 | 0.5 | 0.8 | 220 | 300 |

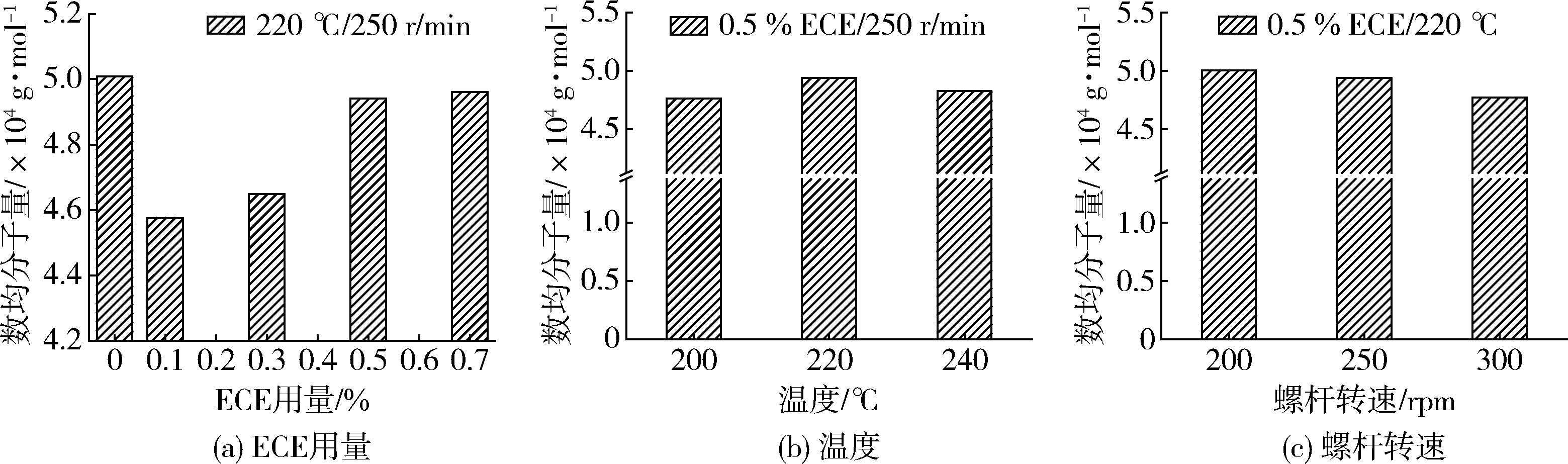

| 样品 | ECE用量/% | 温度/℃ | 螺杆转速/r•min-1 | PDI | ||

|---|---|---|---|---|---|---|

| PBST⁃0 | 0 | 220 | 250 | 50 084 | 73 874 | 1.47 |

| PBST⁃1/220/250 | 0.1 | 220 | 250 | 45 751 | 67 990 | 1.49 |

| PBST⁃3/220/250 | 0.3 | 220 | 250 | 46 489 | 68 390 | 1.47 |

| PBST⁃5/220/250 | 0.5 | 220 | 250 | 49 402 | 75 053 | 1.52 |

| PBST⁃7/220/250 | 0.7 | 220 | 250 | 49 607 | 74 822 | 1.51 |

| PBST⁃5/200/250 | 0.5 | 200 | 250 | 47 637 | 71 717 | 1.51 |

| PBST⁃5/240/250 | 0.5 | 240 | 250 | 48 271 | 72 157 | 1.49 |

| PBST⁃5/220/200 | 0.5 | 220 | 200 | 50 048 | 74 519 | 1.49 |

| PBST⁃5/220/300 | 0.5 | 220 | 300 | 47 727 | 71 167 | 1.49 |

| 样品 | ECE用量/% | 温度/℃ | 螺杆转速/r•min-1 | PDI | ||

|---|---|---|---|---|---|---|

| PBST⁃0 | 0 | 220 | 250 | 50 084 | 73 874 | 1.47 |

| PBST⁃1/220/250 | 0.1 | 220 | 250 | 45 751 | 67 990 | 1.49 |

| PBST⁃3/220/250 | 0.3 | 220 | 250 | 46 489 | 68 390 | 1.47 |

| PBST⁃5/220/250 | 0.5 | 220 | 250 | 49 402 | 75 053 | 1.52 |

| PBST⁃7/220/250 | 0.7 | 220 | 250 | 49 607 | 74 822 | 1.51 |

| PBST⁃5/200/250 | 0.5 | 200 | 250 | 47 637 | 71 717 | 1.51 |

| PBST⁃5/240/250 | 0.5 | 240 | 250 | 48 271 | 72 157 | 1.49 |

| PBST⁃5/220/200 | 0.5 | 220 | 200 | 50 048 | 74 519 | 1.49 |

| PBST⁃5/220/300 | 0.5 | 220 | 300 | 47 727 | 71 167 | 1.49 |

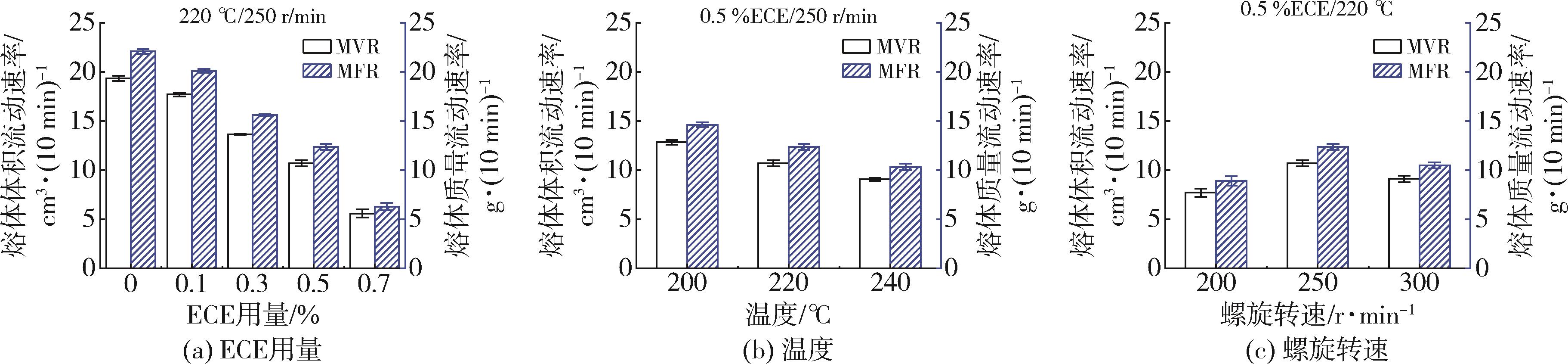

| 样品 | ECE用量/% | 温度/℃ | 螺杆转速/r•min-1 | 熔体体积流动速率 (MVR)/cm3·(10 min)-1 | 熔体质量流动速率 (MFR)/g·(10 min)-1 |

|---|---|---|---|---|---|

| 纯PBST | - | - | - | 21.05±0.19 | 23.24±0.18 |

| PBST⁃0 | 0 | 220 | 250 | 19.33±0.25 | 22.07±0.25 |

| PBST⁃1/220/250 | 0.1 | 220 | 250 | 17.70±0.20 | 20.09±0.20 |

| PBST⁃3/220/250 | 0.3 | 220 | 250 | 13.62±0.04 | 15.62±0.09 |

| PBST⁃5/220/250 | 0.5 | 220 | 250 | 10.69±0.31 | 12.36±0.33 |

| PBST⁃7/220/250 | 0.7 | 220 | 250 | 5.59±0.40 | 6.28±0.39 |

| PBST⁃5/200/250 | 0.5 | 200 | 250 | 12.82±0.25 | 14.61±0.24 |

| PBST⁃5/240/250 | 0.5 | 240 | 250 | 9.06±0.16 | 10.32±0.32 |

| PBST⁃5/220/200 | 0.5 | 220 | 200 | 7.70±0.42 | 8.90±0.49 |

| PBST⁃5/220/300 | 0.5 | 220 | 300 | 9.11±0.34 | 10.47±0.30 |

| 样品 | ECE用量/% | 温度/℃ | 螺杆转速/r•min-1 | 熔体体积流动速率 (MVR)/cm3·(10 min)-1 | 熔体质量流动速率 (MFR)/g·(10 min)-1 |

|---|---|---|---|---|---|

| 纯PBST | - | - | - | 21.05±0.19 | 23.24±0.18 |

| PBST⁃0 | 0 | 220 | 250 | 19.33±0.25 | 22.07±0.25 |

| PBST⁃1/220/250 | 0.1 | 220 | 250 | 17.70±0.20 | 20.09±0.20 |

| PBST⁃3/220/250 | 0.3 | 220 | 250 | 13.62±0.04 | 15.62±0.09 |

| PBST⁃5/220/250 | 0.5 | 220 | 250 | 10.69±0.31 | 12.36±0.33 |

| PBST⁃7/220/250 | 0.7 | 220 | 250 | 5.59±0.40 | 6.28±0.39 |

| PBST⁃5/200/250 | 0.5 | 200 | 250 | 12.82±0.25 | 14.61±0.24 |

| PBST⁃5/240/250 | 0.5 | 240 | 250 | 9.06±0.16 | 10.32±0.32 |

| PBST⁃5/220/200 | 0.5 | 220 | 200 | 7.70±0.42 | 8.90±0.49 |

| PBST⁃5/220/300 | 0.5 | 220 | 300 | 9.11±0.34 | 10.47±0.30 |

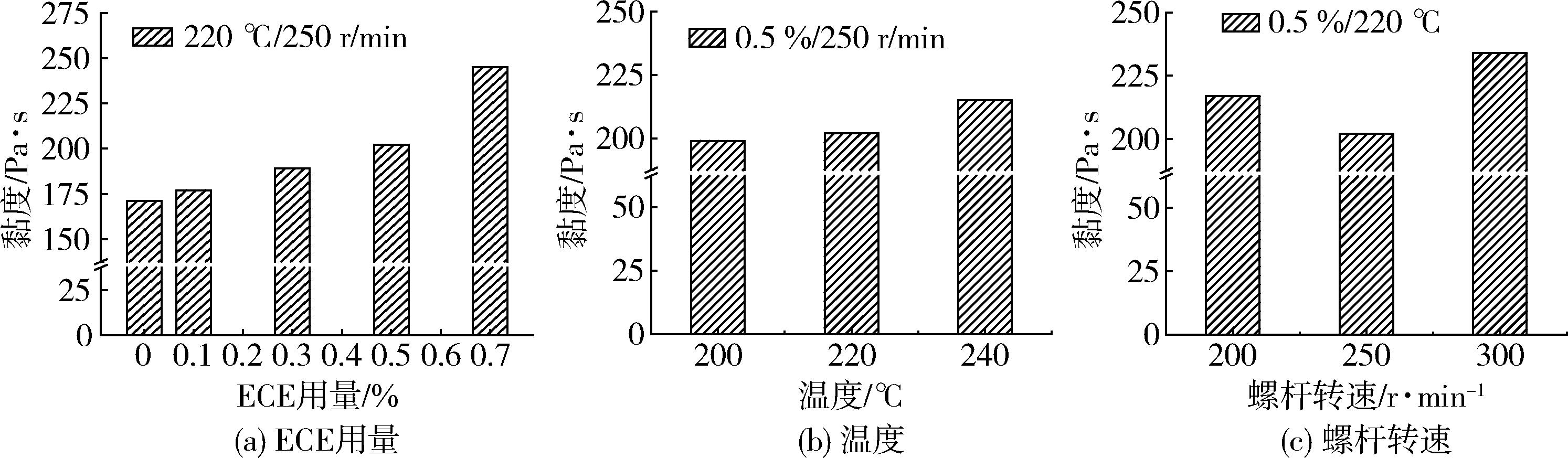

| 样品 | ECE用量/% | 温度/℃ | 螺杆转速/r•min-1 | 180 ℃下熔体黏度/Pa·s | |

|---|---|---|---|---|---|

| 100 s-1 | 1 000 s-1 | ||||

| PBST⁃0 | 0 | 220 | 250 | 394 | 171 |

| PBST⁃1/220/250 | 0.1 | 220 | 250 | 399 | 177 |

| PBST⁃3/220/250 | 0.3 | 220 | 250 | 461 | 189 |

| PBST⁃5/220/250 | 0.5 | 220 | 250 | 551 | 202 |

| PBST⁃7/220/250 | 0.7 | 220 | 250 | 683 | 245 |

| PBST⁃5/200/250 | 0.5 | 200 | 250 | 518 | 199 |

| PBST⁃5/240/250 | 0.5 | 240 | 250 | 546 | 215 |

| PBST⁃5/220/200 | 0.5 | 220 | 200 | 586 | 217 |

| PBST⁃5/220/300 | 0.5 | 220 | 300 | 610 | 234 |

| 样品 | ECE用量/% | 温度/℃ | 螺杆转速/r•min-1 | 180 ℃下熔体黏度/Pa·s | |

|---|---|---|---|---|---|

| 100 s-1 | 1 000 s-1 | ||||

| PBST⁃0 | 0 | 220 | 250 | 394 | 171 |

| PBST⁃1/220/250 | 0.1 | 220 | 250 | 399 | 177 |

| PBST⁃3/220/250 | 0.3 | 220 | 250 | 461 | 189 |

| PBST⁃5/220/250 | 0.5 | 220 | 250 | 551 | 202 |

| PBST⁃7/220/250 | 0.7 | 220 | 250 | 683 | 245 |

| PBST⁃5/200/250 | 0.5 | 200 | 250 | 518 | 199 |

| PBST⁃5/240/250 | 0.5 | 240 | 250 | 546 | 215 |

| PBST⁃5/220/200 | 0.5 | 220 | 200 | 586 | 217 |

| PBST⁃5/220/300 | 0.5 | 220 | 300 | 610 | 234 |

| 来源 | 平方和(SST) | df | 均方(MSE) | F值 | p值 | |

|---|---|---|---|---|---|---|

| 模型 | 159.73 | 3 | 53.24 | 35.77 | 0.000 8 | 显著 |

| A(ECE用量) | 151.67 | 1 | 151.67 | 101.9 | 0.000 2 | |

| B(温度) | 7.07 | 1 | 7.07 | 4.75 | 0.081 2 | |

| C(螺杆转速) | 0.994 1 | 1 | 0.994 1 | 0.667 9 | 0.451 0 | |

| 残差 | 7.44 | 5 | 1.49 | - | - | |

| 总相关系数 | 167.18 | 8 | - | - | - |

| 来源 | 平方和(SST) | df | 均方(MSE) | F值 | p值 | |

|---|---|---|---|---|---|---|

| 模型 | 159.73 | 3 | 53.24 | 35.77 | 0.000 8 | 显著 |

| A(ECE用量) | 151.67 | 1 | 151.67 | 101.9 | 0.000 2 | |

| B(温度) | 7.07 | 1 | 7.07 | 4.75 | 0.081 2 | |

| C(螺杆转速) | 0.994 1 | 1 | 0.994 1 | 0.667 9 | 0.451 0 | |

| 残差 | 7.44 | 5 | 1.49 | - | - | |

| 总相关系数 | 167.18 | 8 | - | - | - |

| 样品 | Tga /℃ | Tm b /℃ | ΔHm c /J·g-1 | Tc d/℃ | ΔHc e/J·g-1 | Xc f /% |

|---|---|---|---|---|---|---|

| PBST⁃0 | -20.4 | 115.2 | 8.4 | 72.8 | 11.5 | 6.08 |

| PBST⁃1/220/250 | -20.6 | 114.4 | 10.0 | 72.6 | 13.7 | 7.23 |

| PBST⁃3/220/250 | -20.3 | 113.6 | 10.8 | 70.5 | 13.4 | 7.81 |

| PBST⁃5/220/250 | -19.3 | 112.6 | 12.9 | 66.6 | 13.5 | 9.33 |

| PBST⁃7/220/250 | -19.9 | 110.0 | 13.2 | 63.9 | 13.4 | 9.55 |

| PBST⁃5/200/250 | -20.3 | 112.5 | 11.8 | 68.8 | 13.3 | 8.54 |

| PBST⁃5/240/250 | -20.2 | 112.0 | 10.8 | 67.3 | 13.1 | 7.81 |

| PBST⁃5/220/200 | -19.2 | 112.1 | 12.9 | 66.5 | 16.7 | 9.33 |

| PBST⁃5/220/300 | -20.2 | 113.1 | 11.3 | 69.3 | 12.4 | 8.18 |

| ECE | 51.2 | 67.2 | 9.77 | - | - | - |

| 样品 | Tga /℃ | Tm b /℃ | ΔHm c /J·g-1 | Tc d/℃ | ΔHc e/J·g-1 | Xc f /% |

|---|---|---|---|---|---|---|

| PBST⁃0 | -20.4 | 115.2 | 8.4 | 72.8 | 11.5 | 6.08 |

| PBST⁃1/220/250 | -20.6 | 114.4 | 10.0 | 72.6 | 13.7 | 7.23 |

| PBST⁃3/220/250 | -20.3 | 113.6 | 10.8 | 70.5 | 13.4 | 7.81 |

| PBST⁃5/220/250 | -19.3 | 112.6 | 12.9 | 66.6 | 13.5 | 9.33 |

| PBST⁃7/220/250 | -19.9 | 110.0 | 13.2 | 63.9 | 13.4 | 9.55 |

| PBST⁃5/200/250 | -20.3 | 112.5 | 11.8 | 68.8 | 13.3 | 8.54 |

| PBST⁃5/240/250 | -20.2 | 112.0 | 10.8 | 67.3 | 13.1 | 7.81 |

| PBST⁃5/220/200 | -19.2 | 112.1 | 12.9 | 66.5 | 16.7 | 9.33 |

| PBST⁃5/220/300 | -20.2 | 113.1 | 11.3 | 69.3 | 12.4 | 8.18 |

| ECE | 51.2 | 67.2 | 9.77 | - | - | - |

| 1 | Sudesh K, Iwata T. Sustainability of Biobased and Biodegradable Plastics[J]. CLEAN⁃Soil, Air, Water, 2010, 36(5/6): 433⁃442. |

| 2 | Alvarez⁃Chavez C R, Edwards S, Moure⁃Eraso R, et al. Sustainability of bio⁃based plastics: general comparative analysis and recommendations for improvement[J]. Journal of Cleaner Production, 2012, 23(1): 47⁃56. |

| 3 | Müller R J, Kleeberg I, Deckwer W D. Biodegradation of polyesters containing aromatic constituents[J]. Journal of Biotechnology, 2001, 86(2): 87⁃95. |

| 4 | Witt U, Müller R J, Augusta J, et al. Synthesis, properties and biodegradability of polyesters based on 1,3⁃propanediol[J]. Macromolecular Chemistry and Physics, 1994, 195(2): 793⁃802. |

| 5 | Witt U, Müller R J, Deckwer W D. Evaluation of the biodegradability of copolyesters containing aromatic compounds by investigations of model oligomers[J]. Journal of Environmental Polymer Degradation, 1996, 4(1):9⁃20. |

| 6 | Müller R J, Witt U, Rantze E, et al. Architecture of biodegradable copolyesters containing aromatic constituents[J]. Polymer Degradation & Stability, 1998, 59(1): 203⁃208. |

| 7 | Witt U, Yamamoto M, Seeliger U, et al. Biodegradable Polymeric Materials—Not the Origin but the Chemical Structure Determines Biodegradability[J]. Angewandte Chemie International Edition, 1999, 38(10): 1 438⁃1 442. |

| 8 | Witt U, Einig T, Yamamoto M, et al. Biodegradation of aliphatic⁃aromatic copolyesters: evaluation of the final biodegradability and ecotoxicological impact of degradation intermediates.[J]. Chemosphere, 2001, 44(2): 289⁃299. |

| 9 | Honda N, Taniguchi I, Miyamoto M, et al. Reaction Mechanism of Enzymatic Degradation of Poly(butylene succinate⁃co⁃terephthalate) (PBST) with a Lipase Originated from Pseudomonas cepacia[J]. Macromolecular Bioscience, 2003, 3(3/4): 189⁃197. |

| 10 | Lee S H, Lim S W, Lee K H. Properties of potentially biodegradable copolyesters of (succinic acid-1,4⁃butanediol)/(dimethyl terephthalate-1,4⁃butanediol) [J]. Polymer International, 1999, 48(9): 861⁃867. |

| 11 | 祝桂香,叶文亮.生物可降解共聚酯PBST的合成,结构性能及应用研究进展[J].化工与医药工程, 2022, 43(5):1⁃6. |

| ZHU G X, YE W L. Research progress in synthesis,structure,properties and application of biodegradable copolyester PBST[J]. Chemical and Pharmaceutical Engineering, 2022, 43(5):1⁃6. | |

| 12 | Shaik A A, Richter M, Kricheldorf H R, et al. New polymer syntheses. CIX. Biodegradable, alternating copolyesters of terephthalic acid, aliphatic dicarboxylic acids, and alkane diols[J]. Journal of Polymer Science Part A: Polymer Chemistry, 2001, 39(19): 3 371⁃3 382. |

| 13 | 舒梦莹,翁云宣,张彩丽.多元环氧扩链剂(ADR)对PBAT的扩链改性及其耐老化性能的影响[J].中国塑料, 2020, 34(3):33⁃39. |

| SHU M Y, WENG Y X, ZHANG C L. Influence of multi⁃component epoxy chain⁃extension agent on aging resistance of chain⁃extension modified PBAT[J]. China Plastics, 2020, 34(3):33⁃39. | |

| 14 | Li H, Huneault M A. Effect of chain extension on the properties of PLA/TPS blends[J]. Journal of Applied Polymer Science, 2011, 122(1): 134⁃141. |

| 15 | Eslami H, Kamal M R. Effect of a chain extender on the rheological and mechanical properties of biodegradable poly(lactic acid)/poly[(butylene succinate)⁃co⁃adipate] blends[J]. Journal of Applied Polymer Science, 2013, 129(5): 2 418⁃2 428. |

| 16 | Baimark Y, Cheerarot O. Effect of Chain Extension on Thermal Stability Behaviors of Polylactide Bioplastics[J]. Oriental Journal of Chemistry, 2015, 31(2): 635⁃641. |

| 17 | Baimark Y, Srihanam P. Influence of chain extender on thermal properties and melt flow index of stereocomplex PLA[J]. Polymer Testing, 2015, 45: 52⁃57. |

| 18 | 王勋林,张敬勋,赵保才,等.PPC/PBAT薄膜制品性能研究[J].塑料科技, 2015, 43(5): 70⁃72. |

| WANG X L, ZHANG J X, ZHAO B C, et al. Research on PPC/PBAT film products[J]. Plastics Science and Technology, 2015, 43(5): 70⁃72. | |

| 19 | Freitas A L P, Filho L R T, Calvao P S, et al. Effect of montmorillonite and chain extender on rheological, morphological and biodegradation behavior of PLA/PBAT blends[J]. Polymer Testing, 2017, 62: 189⁃195. |

| 20 | 宋敬思,王贤增,周洪福,等.PBAT的扩链反应及其微孔发泡行为研究[J].中国塑料, 2018, 32(11):42⁃48. |

| SONG J S, WANG Z X, ZHOU H F, et al. Study on chain extension and microcellular foaming behaviors of poly(butyleneadipate⁃co⁃terephthlate)[J]. China Plastics, 2018, 32(11):42⁃48. | |

| 21 | Souza A G, Nunes E C D, Rosa D S. Understanding the effect of chain extender on poly(butylene adipate⁃co⁃terephthalate) structure[J]. Iranian Polymer Journal, 2019, 28(12): 1 035⁃1 044. |

| 22 | Nunes E C, Souza A G, Rosa D S. Use of a chain extender as a dispersing agent of the CaCO3 into PBAT matrix[J]. Journal of Composite Materials, 2019, 54(10): 1 373⁃1 382. |

| 23 | 王 杰,吴卫东,周洪福.EMA对PBAT的扩链改性及其微孔发泡行为[J].工程塑料应用, 2020, 48(3):28⁃33. |

| WANG J, WU W D, ZHOU H F. Chain extension of poly (butylene adipate⁃co⁃terephthalate) by ethylene⁃glycidyl methacrylate copolymer and its microcellular foaming behaviors[J]. Engineering Plastics Application, 2020, 48(3):28⁃33. | |

| 24 | Zhang T, Han W Y, Zhang C L, et al. Effect of chain extender and light stabilizer on the weathering resistance of PBAT/PLA blend films prepared by extrusion blowing[J]. Polymer Degradation and Stability, 2021, 183: 109455. |

| 25 | 赵海鹏,胡顺朋,夏学莲,等.扩链剂增容PBAT/PLA共混体系结构及性能[J].工程塑料应用, 2021, 49(10):131⁃137. |

| ZHAO H P, HU S P, XIA X L, et al. Structures and properties of PBAT/PLA composites with chain extender[J]. Engineering Plastics Application, 2021, 49(10):131⁃137. | |

| 26 | 宋 浩,白 楠,宋立新,等.扩链剂对PBAT/TPS共混体系性能的影响[J].塑料科技, 2022, 50(5):23⁃28. |

| Song H, Bai N, Song L X, et al. Effect of chain extender on properties of PBAT/TPS blends[J]. Plastics Science and Technology, 2022, 50(5):23⁃28. | |

| 27 | Jia S L, Wang X Y, Zhang Y,et al.Superior Toughened Biodegradable Poly(L⁃lactic acid)⁃based Blends with Enhanced Melt Strength and Excellent Low⁃temperature Toughness via In situ Reaction Compatibilization[J]. Chinese Journal of Polymer Science, 2023, 41(3): 373⁃385. |

| 28 | Grcev S, Schoenmakers P, Iedema P. Determination of molecular weight and size distribution and branching characteristics of PVAc by means of size exclusion chromatography/multi⁃angle laser light scattering (SEC/MALLS)[J]. Polymer, 2004, 45(1):39⁃48. |

| 29 | 郭宝华, 丁慧鸽, 徐晓琳,等. 生物可降解共聚物聚丁二酸/对苯二甲酸丁二醇酯(PBST)的序列结构及结晶性研究[J]. 高等学校化学学报, 2003, 24(12): 2 312⁃2 316. |

| GUO B H, DING H G, XU X L, et al. Studies on the sequence structure and crystallinity of poly(butylene succinate) copolymers with terephthalic acid [J]. Chemical Journal of Chinese Universities, 2003, 24(12): 2 312⁃2 316. | |

| 30 | Hwang I T, Jung C H, Kuk I S, et al. Electron beam⁃induced crosslinking of poly(butylene adipate⁃co⁃terephthalate)[J].Nuclear Instruments & Methods in Physics Research, 2010, 268(21): 3 386⁃3 389. |

| [1] | 沈丹彤, 薛雨亭, 李荣杰, 徐芳, 翁云宣. 聚乳酸基水性聚氨酯的制备及其在合成革中的应用研究[J]. 中国塑料, 2024, 38(4): 19-25. |

| [2] | 孙乙博, 刘亚宁, 芦浩凡, 陈士宏, 王向东, 武丽丽. PA66扩链改性及其超临界CO2微孔发泡行为研究[J]. 中国塑料, 2023, 37(12): 41-46. |

| [3] | 蔡小芳, 袁航, 刁晓倩, 李字义, 封棣. 食品接触聚乳酸杯盖中的滑石粉迁移分析[J]. 中国塑料, 2021, 35(7): 91-96. |

| [4] | 王从龙, 韩硕, 张一辉, 陈士宏, 王向东. 聚醚砜超临界CO2发泡行为研究[J]. 中国塑料, 2021, 35(6): 13-19. |

| [5] | 应杰, 邱琪浩, 章兴, 顾亥楠, 罗锐. 滑石粉对阻燃聚碳酸酯性能的影响[J]. 中国塑料, 2021, 35(5): 107-112. |

| [6] | 祖钰, 任亚男, 胡晶. 聚乳酸/聚(3⁃羟基丁酸⁃co⁃3⁃羟基戊酸酯)共混材料3D打印线材改性研究[J]. 中国塑料, 2020, 34(7): 36-43. |

| [7] | 丁剑峰, 王伟, 刘耀, 夏浙安, 李欣欣. 无机成核剂改性聚酰胺6/碳纤维复合材料的结构与性能[J]. 中国塑料, 2020, 34(12): 8-16. |

| [8] | 韩硕, 王向东, 陈士宏, 姜璨, 王亚桥. 环氧扩链剂增容PET/PA6共混物对结晶与流变性能的影响[J]. 中国塑料, 2019, 33(10): 23-27. |

| [9] | 马秋, 宋伟华, 梁娜, 李术, 顾鹏云, 李淑慧. 适用于汽车尾门板的热塑性材料力学行为研究[J]. 中国塑料, 2017, 31(08): 84-87 . |

| [10] | 段景宽, 姚利辉, 程波, 王晓雄, 余志强. 一种新型多功能助剂在聚丙烯/滑石粉复合材料中的应用[J]. 中国塑料, 2017, 31(07): 114-120 . |

| [11] | 林鸿裕, 夏新曙, 杨松伟, 黄宝铨, 陈庆华, 肖荔人. ADR4370F对聚乳酸流变行为和力学性能的影响[J]. 中国塑料, 2017, 31(06): 54-58 . |

| [12] | 曾以仁, 章家立. 扩链增黏回收PET的特性黏度和结晶行为研究[J]. 中国塑料, 2017, 31(02): 17-26 . |

| [13] | 宋建强, 彭鹤松, 王光硕, 王玉梅. 不同无机粉体在PE木塑复合材料中的应用研究[J]. 中国塑料, 2017, 31(01): 70-74 . |

| [14] | 段雨婷, 许国志. PLA/PHBV共混改性研究[J]. 中国塑料, 2017, 31(01): 29-35 . |

| [15] | 周峰, 吕奇, 张月航, 洪艳, 严海彪. 扩链剂联用对PETG扩链反应与流变性能的影响[J]. 中国塑料, 2016, 30(03): 94-98 . |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2