京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2

《中国塑料》编辑部 ©2008-2024 版权所有

地址:北京市海淀区阜成路11号 邮编:100048

编辑部:010-68985541 联系信箱:cp@plaschina.com.cn

广告部/发行部:010-68985253 本系统由北京玛格泰克科技发展有限公司设计开发

中国塑料 ›› 2024, Vol. 38 ›› Issue (12): 8-18.DOI: 10.19491/j.issn.1001-9278.2024.12.002

魏策1( ), 陈天宇1, 张秀涛1, 张翼遥1, 张思博1, 张骁雨1, 黄晶1,2(

), 陈天宇1, 张秀涛1, 张翼遥1, 张思博1, 张骁雨1, 黄晶1,2( ), 东为富1

), 东为富1

收稿日期:2024-07-01

出版日期:2024-12-26

发布日期:2024-12-25

通讯作者:

黄晶(1993-),女,副教授,从事可降解/回收高分子材料,jinghuang@jiangnan.edu.cn作者简介:魏策(2003-),男,在读本科生,从事可降解/回收高分子材料,1053210315@stu.jiangnan.edu.cn

基金资助:

WEI Ce1( ), CHEN Tianyu1, ZHANG Xiutao1, ZHANG Yiyao1, ZHANG Sibo1, ZHANG Xiaoyu1, HUANG Jing1,2(

), CHEN Tianyu1, ZHANG Xiutao1, ZHANG Yiyao1, ZHANG Sibo1, ZHANG Xiaoyu1, HUANG Jing1,2( ), DONG Weifu1

), DONG Weifu1

Received:2024-07-01

Online:2024-12-26

Published:2024-12-25

Contact:

HUANG Jing

E-mail:1053210315@stu.jiangnan.edu.cn;jinghuang@jiangnan.edu.cn

摘要:

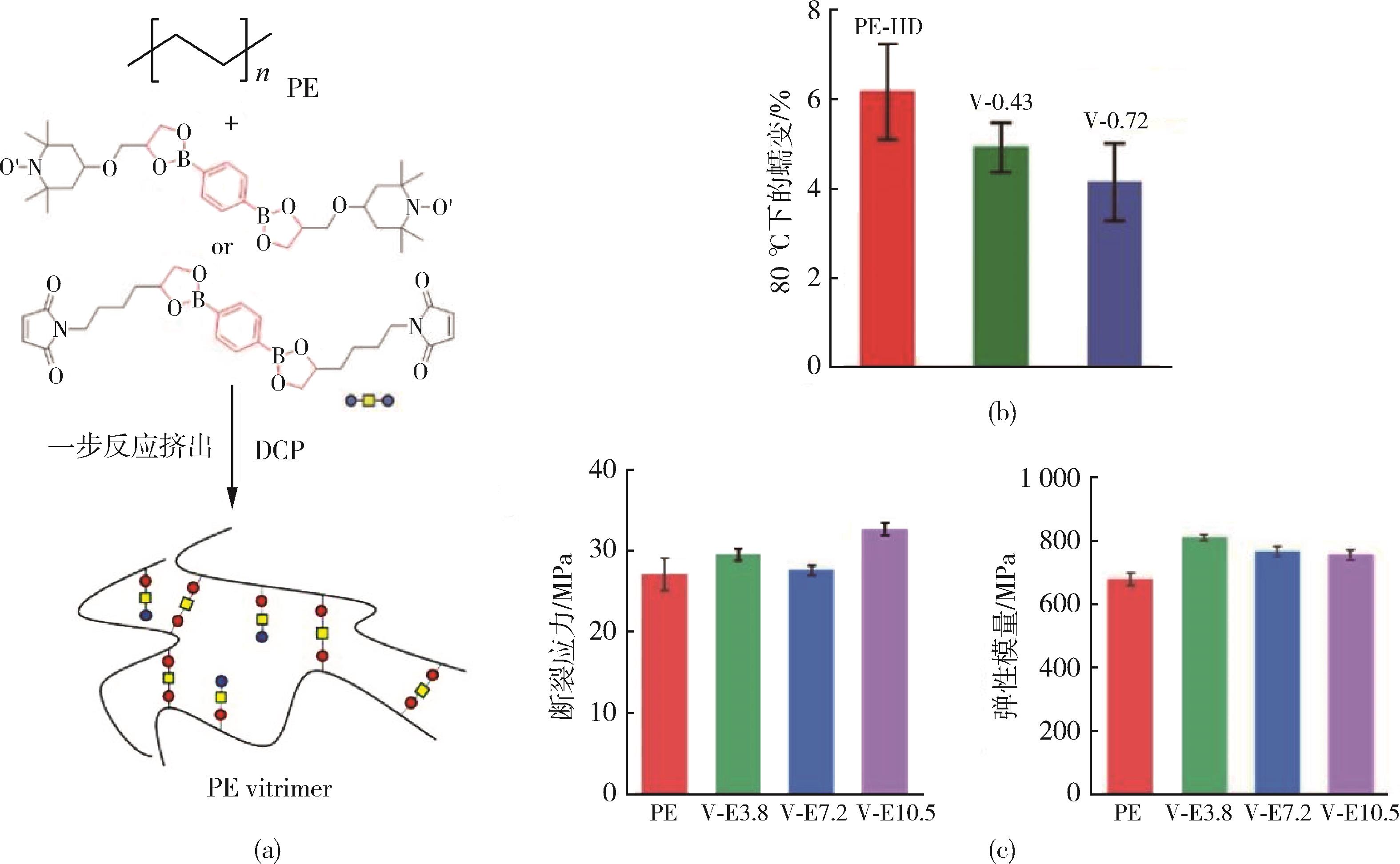

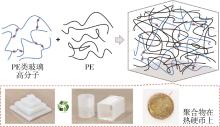

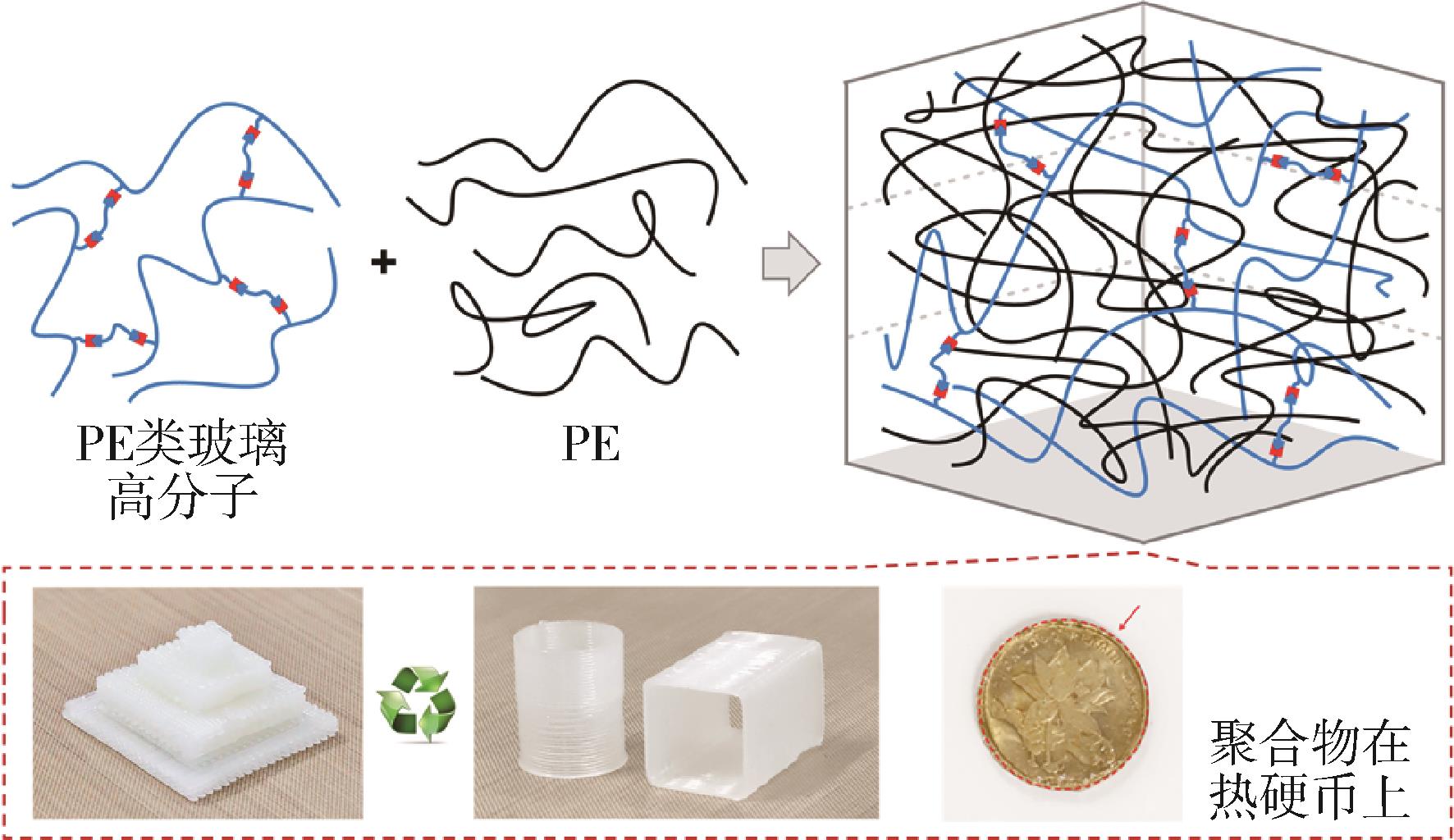

综述了动态共价交联网络在几种主要的热塑性塑料中的应用研究进展,包括聚烯烃、聚苯乙烯、聚甲基丙烯酸甲酯和聚酯。通过引入动态共价键,这些材料在保持原有特性的基础上,实现了熔体强度、力学性能、耐热性和耐溶剂等性能的提升。然而,尽管目前取得了诸多进展,动态共价交联技术在实际应用中仍面临一些挑战,如制备工艺复杂、成本较高以及长期稳定性和降解行为的研究不足。未来的研究应重点关注优化制备工艺、提升材料性能以及研究材料在各种环境条件下的长期稳定性,以推动动态共价交联技术在工业中的大规模应用。

中图分类号:

魏策, 陈天宇, 张秀涛, 张翼遥, 张思博, 张骁雨, 黄晶, 东为富. 动态共价交联网络在热塑性塑料中的应用:研究进展与未来展望[J]. 中国塑料, 2024, 38(12): 8-18.

WEI Ce, CHEN Tianyu, ZHANG Xiutao, ZHANG Yiyao, ZHANG Sibo, ZHANG Xiaoyu, HUANG Jing, DONG Weifu. Applications and future prospects dynamic covalent cross⁃linking networks in thermoplastic polymers, A review[J]. China Plastics, 2024, 38(12): 8-18.

| 样品编号 | Tg/℃ | Tc/℃ | ΔHc/J·g-1 | Tm/℃ | ΔHm/J·g-1 | σ/MPa | ε/% | E/MPa | Gf/% |

|---|---|---|---|---|---|---|---|---|---|

| PET | 80.5 | 205.6 | 38.6 | 252.2 | 39.5 | 56.0±0.8 | 618±47 | 891.00±38.62 | 0 |

| PET⁃0.1 | 81.5 | 197.4 | 38.1 | 251.3 | 38.9 | 54.3±1.4 | 753±96 | 809.52±81.09 | 0 |

| PET⁃0.3 | 81.8 | 183.7 | 36.0 | 249.4 | 37.2 | 56.3±1.0 | 703±65 | 868.31±51.08 | 0 |

| PET⁃0.5 | 82.1 | 184.9 | 31.8 | 248.8 | 33.2 | 62.3±1.1 | 338±40 | 1095.41±29.02 | 2.52 |

| PET⁃0.7 | 82.7 | 185.8 | 34.9 | 248.5 | 35.9 | 64.5±2.6 | 6±1 | 1240.94±110.42 | 66.18 |

| PET⁃1.0 | 83.0 | 185.2 | 36.0 | 248.0 | 37.5 | 63.4±2.5 | 6±1 | 1241.22±58.41 | 68.91 |

| PET⁃1.2 | 83.3 | 179.4 | 33.7 | 247.0 | 34.0 | 59.9±1.2 | 5±1 | 1262.24±135.88 | 76.29 |

| PET⁃1.5 | 84.4 | 178.4 | 32.2 | 245.1 | 33.0 | 50.9±2.3 | 4±1 | 1239.73±162.03 | 71.35 |

| PET⁃2.0 | 85.3 | 175.6 | 29.6 | 244.9 | 30.5 | 43.6±7.0 | 2±1 | 1273.22±396.00 | 69.54 |

| 样品编号 | Tg/℃ | Tc/℃ | ΔHc/J·g-1 | Tm/℃ | ΔHm/J·g-1 | σ/MPa | ε/% | E/MPa | Gf/% |

|---|---|---|---|---|---|---|---|---|---|

| PET | 80.5 | 205.6 | 38.6 | 252.2 | 39.5 | 56.0±0.8 | 618±47 | 891.00±38.62 | 0 |

| PET⁃0.1 | 81.5 | 197.4 | 38.1 | 251.3 | 38.9 | 54.3±1.4 | 753±96 | 809.52±81.09 | 0 |

| PET⁃0.3 | 81.8 | 183.7 | 36.0 | 249.4 | 37.2 | 56.3±1.0 | 703±65 | 868.31±51.08 | 0 |

| PET⁃0.5 | 82.1 | 184.9 | 31.8 | 248.8 | 33.2 | 62.3±1.1 | 338±40 | 1095.41±29.02 | 2.52 |

| PET⁃0.7 | 82.7 | 185.8 | 34.9 | 248.5 | 35.9 | 64.5±2.6 | 6±1 | 1240.94±110.42 | 66.18 |

| PET⁃1.0 | 83.0 | 185.2 | 36.0 | 248.0 | 37.5 | 63.4±2.5 | 6±1 | 1241.22±58.41 | 68.91 |

| PET⁃1.2 | 83.3 | 179.4 | 33.7 | 247.0 | 34.0 | 59.9±1.2 | 5±1 | 1262.24±135.88 | 76.29 |

| PET⁃1.5 | 84.4 | 178.4 | 32.2 | 245.1 | 33.0 | 50.9±2.3 | 4±1 | 1239.73±162.03 | 71.35 |

| PET⁃2.0 | 85.3 | 175.6 | 29.6 | 244.9 | 30.5 | 43.6±7.0 | 2±1 | 1273.22±396.00 | 69.54 |

| 1 | Zheng N, Xu Y, Zhao Q, et al. Dynamic covalent polymer networks: A molecular platform for designing functions beyond chemical recycling and self⁃healing[J]. Chemical Reviews, 2021, 121 (3): 1 716⁃1 745. |

| 2 | Guerre M, Taplan C, Winne J M, et al. Vitrimers: Directing chemical reactivity to control material properties[J]. Chemical Science, 2020, 11 (19): 4 855⁃4 870. |

| 3 | Kloxin C J, Scott T F, Adzima B J, et al. Covalent adaptable networks (CANs): A unique paradigm in crosslinked polymers[J]. Macromolecules, 2010, 43 (6): 2 643⁃2 653. |

| 4 | Denissen W, Winne J M, Du Prez F E. Vitrimers: Permanent organic networks with glass⁃like fluidity[J]. Chemical Science, 2016, 7 (1): 30⁃38. |

| 5 | Ji F, Zhou Y M, Yang Y M. Tailoring the structure and properties of epoxy⁃polyurea vitrimers via controllable network reconfiguration [J]. Journal of Materials Chemistry A, 2021, 9 (11): 7 172⁃7 179. |

| 6 | Fortman D J, Brutman J P, De Hoe G X, et al. Approaches to sustainable and continually recyclable cross⁃linked polymers[J]. ACS Sustainable Chemistry & Engineering, 2018, 6 (9): 11 145⁃11 159. |

| 7 | Montarnal D, Capelot M, Tournilhac F, et al. Silica⁃like malleable materials from permanent organic networks[J]. Science, 2011, 334 (6058): 965⁃968. |

| 8 | Zhang X. Reconfigurable, easy repairable and low⁃temperature resistant dynamic 3D polymer structures[J]. Acta Polymerica Sinica, 2016 (6): 685⁃687. |

| 9 | Zheng N, Xu Y, Zhao Q,et al. Dynamic covalent polymer networks: A molecular platform for designing functions beyond chemical recycling and self⁃healing[J]. Chemical Reviews, 2021, 121 (3): 1 716⁃1 745. |

| 10 | Zhang Z P, Rong M Z, Zhang M Q. Polymer engineering based on reversible covalent chemistry: A promising innovative pathway towards new materials and new functionalities[J]. Progress in Polymer Science, 2018, 80: 39⁃93. |

| 11 | Zheng J, Png Z M, Ng S H, et al. Vitrimers: Current research trends and their emerging applications[J]. Materials Today, 2021, 51: 586⁃625. |

| 12 | Zhu G Q, Zhang J S, Huang J, et al. High⁃performance 3D printing uv⁃curable resins derived from soybean oil and gallic acid[J]. Green Chemistry, 2021, 23 (16): 5 911⁃5 923. |

| 13 | Zhang Y J, Lin Z C, Li X P, et al. One⁃step and scalable synthesis of eaa⁃based reprocessable vitrimer with superior mechanical properties[J]. Journal of Polymers and the Environment, 2024, 32 (3): 1 080⁃1 089. |

| 14 | Kloxin C J, Bowman C N. Covalent adaptable networks: Smart, reconfigurable and responsive network systems[J]. Chemical Society Reviews, 2013, 42 (17): 7 161⁃7 173. |

| 15 | Elling B R, Dichtel W R. Reprocessable cross⁃linked polymer networks: Are associative exchange mechanisms desirable[J]. ACS Central Science, 2020, 6 (9): 1 488⁃1 496. |

| 16 | Chakma P, Morley C N, Sparks J L, et al. Exploring how vitrimer⁃like properties can be achieved from dissociative exchange in anilinium salts[J]. Macromolecules, 2020, 53 (4): 1 233⁃1 244. |

| 17 | Denissen W, Rivero G, Nicolaÿ R, et al. Vinylogous urethane vitrimers[J]. Advanced Functional Materials, 2015, 25 (16): 2 451⁃2 457. |

| 18 | 李涛. 聚乙烯化工材料的结构特点以及应用发展研究[J]. 建材与装饰, 2019 (14): 62⁃63. |

| LI T. Study on Structural Characteristics and Application Development of Polyethylene Chemical Materials [J]. Building Materials and Decoration, 2019 (14): 62⁃63. | |

| 19 | 秦丽婷. 聚乙烯的结构特点以及应用发展探析[J]. 化工设计通讯, 2022, 48 (10): 52⁃54. |

| QIN L T. Structural Characteristics and Application Development of Polyethylene [J]. Chemical Engineering Design Communications, 2022, 48 (10): 52⁃54. | |

| 20 | Kanerva M, Puolakka A, Takala T M, et al. Antibacterial polymer fibres by rosin compounding and melt⁃spinning[J]. Materials Today Communications, 2019, 20: 100 527⁃100 536. |

| 21 | Weingart N, Raps D, Lu M F, et al. Comparison of the foamability of linear and long⁃chain branched polypropylene⁃the legend of strain⁃hardening as a requirement for good foamability[J]. Polymers, 2020, 12 (3): 725⁃746. |

| 22 | Wang S, Ma S, Qiu J, et al. Upcycling of post⁃consumer polyolefin plastics to covalent adaptable networks via in situ continuous extrusion cross⁃linking[J]. Green Chemistry, 2021, 23 (8): 2 931⁃2 937. |

| 23 | Röttger M, Domenech T, van der Weegen R, et al. High⁃performance vitrimers from commodity thermoplastics through dioxaborolane metathesis[J]. Science, 2017, 356 (6333): 62⁃65. |

| 24 | Caffy F, Nicolaÿ R. Transformation of polyethylene into a vitrimer by nitroxide radical coupling of a bis⁃dioxaborolane[J]. Polymer Chemistry, 2019, 10 (23): 3 107⁃3 115. |

| 25 | Maaz M, Riba⁃Bremerch A, Guibert C, et al. Synthesis of polyethylene vitrimers in a single step: Consequences of graft structure, reactive extrusion conditions, and processing aids[J]. Macromolecules, 2021, 54 (5): 2 213⁃2 225. |

| 26 | Montoya⁃Ospina M C, Verhoogt H, Osswald T A. Processing and rheological behavior of cross⁃linked polyethylene containing disulfide bonds[J]. SPE Polymers, 2021, 3 (1): 25⁃40. |

| 27 | Zych A, Pinalli R, Soliman M, et al. Polyethylene vitrimers via silyl ether exchange reaction[J]. Polymer, 2020, 199: 122 567⁃122 573. |

| 28 | Wang S, Ma S Q, Qiu J F, et al. Upcycling of post⁃consumer polyolefin plastics to covalent adaptable networks via in sit continuous extrusion cross⁃linking[J]. Green Chemistry, 2021, 23 (8): 2 931⁃2 937. |

| 29 | Wang Z, Gu Y, Ma M, et al. Strengthening polyethylene thermoplastics through a dynamic covalent networking additive based on alkylboron chemistry[J]. Macromolecules, 2021, 54 (4): 1 760⁃1 766. |

| 30 | Saed M O, Lin X, Terentjev E M. Dynamic semicrystalline networks of polypropylene with thiol⁃anhydride exchangeable crosslinks[J]. ACS Applied Materials & Interfaces, 2021, 13(35): 42 044⁃42 051. |

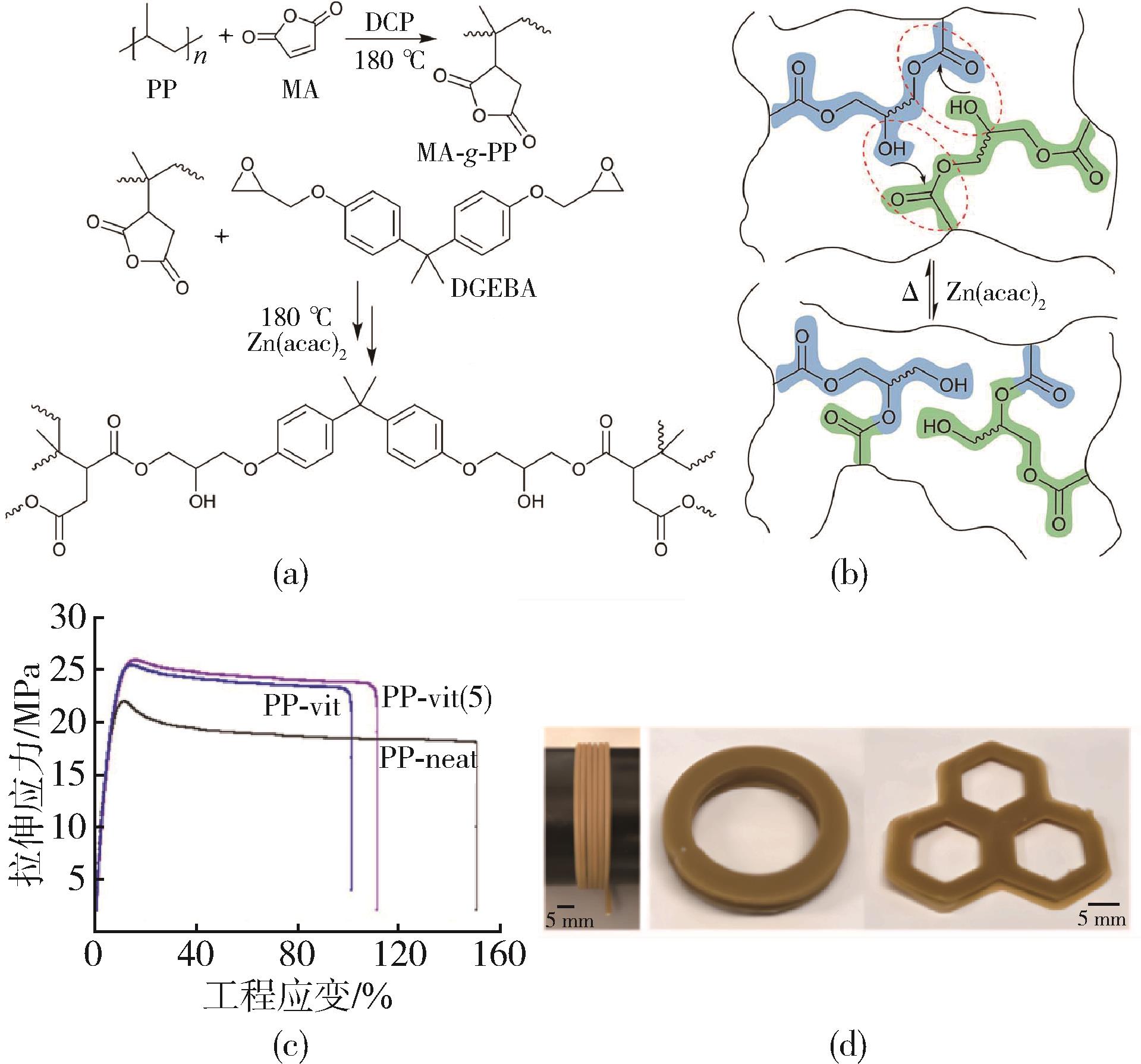

| 31 | Kar G P, Saed M O, Terentjev E M. Scalable upcycling of thermoplastic polyolefins into vitrimers through transesterification[J]. Journal of Materials Chemistry A, 2020, 8 (45): 24 137⁃24 147. |

| 32 | Kar G P, Lin X Y, Terentjev E M. Fused filament fabrication of a dynamically crosslinked network derived from commodity thermoplastics[J]. ACS Applied Polymer Materials, 2022, 4 (6): 4 364⁃4 372. |

| 33 | Gao Y C, Niu H. Polypropylene⁃based transesterification covalent adaptable networks with internal catalysis[J]. Polymer Chemistry, 2024, 15 (9): 884⁃895. |

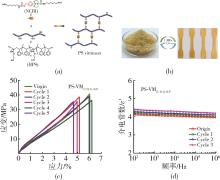

| 34 | Wang S, Wang B, Zhang X, et al. Fully recyclable and reprocessable polystyrene⁃based vitrimers with improved thermal stability and mechanical properties through nitrogen⁃coordinating cyclic boronic ester bonds[J]. Applied Surface Science, 2021, 570: 151 157⁃151 167. |

| 35 | Gad M M, Rahoma A, Al⁃Thobity A M, et al. Influence of incorporation of ZrO2 nanoparticles on the repair strength of polymethyl methacrylate denture bases[J]. International Journal of Nanomedicine, 2016, 11: 5 633⁃5 643. |

| 36 | Leao R D, Maior J R S, Lemos C A D, et al. Complications with PMMA compared with other materials used in cranioplasty: A systematic review and meta⁃analysis[J]. Brazilian Oral Research, 2018, 32 (e31): 1⁃12. |

| 37 | Leao R S, Moraes S L D, Gomes J M L, et al. Influence of addition of zirconia on pmma: A systematic review[J]. Journal of Materials Science and Engineering C, 2020, 106: 110 292⁃110 230. |

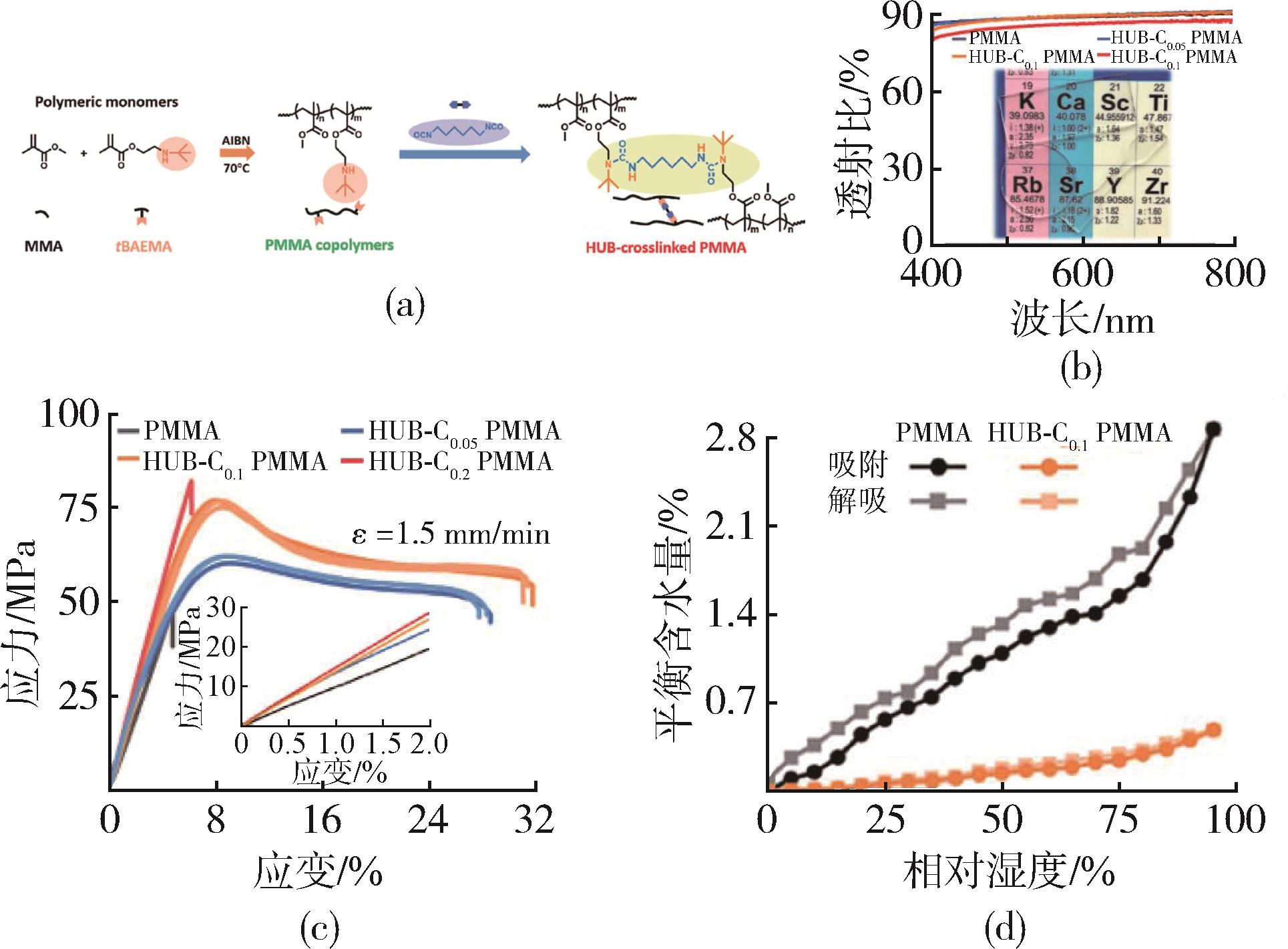

| 38 | Xie S, Wang D, Zhang S, et al. High performance poly(methyl methacrylate) via hindered urea bond crosslinking[J]. Journal of Materials Chemistry A, 2022, 10 (17): 9 457⁃9 467. |

| 39 | Lessard J J, Garcia L F, Easterling C P, et al. Catalyst⁃free vitrimers from vinyl polymers[J]. Macromolecules, 2019, 52 (5): 2 105⁃2 111. |

| 40 | Pan P, Liang Z, Zhu B, et al. Blending effects on polymorphic crystallization of poly(l⁃lactide)[J]. Macromolecules, 2009, 42: 3 374⁃3 380. |

| 41 | Rieckmann T, Völker S. Poly(ethylene terephthalate) polymerization⁃mechanism, catalysis, kinetics, mass transfer and reactor design[M]. John Wiley & Sons, Ltd, 2004: 29⁃115. |

| 42 | Zhang W, Zhang H D, Yang Y L, et al. Network homogeneity on linear and nonlinear viscoelasticity of polyethylene terephthalate vitrimers[J]. Polymer, 2024, 300: 127 015⁃127 025. |

| 43 | Qiu J F, Ma S Q, Wang S, et al. Upcycling of polyethylene terephthalate to continuously reprocessable vitrimers through reactive extrusion[J]. Macromolecules, 2021, 54(2): 703⁃712. |

| 44 | Wu S S, Li Y D, Hu Z, et al. Fast upcycling of poly(ethylene terephthalate) into catalyst⁃free vitrimers[J]. ACS Sustainable Chemistry & Engineering, 2023, 11(5): 1 974⁃1 984. |

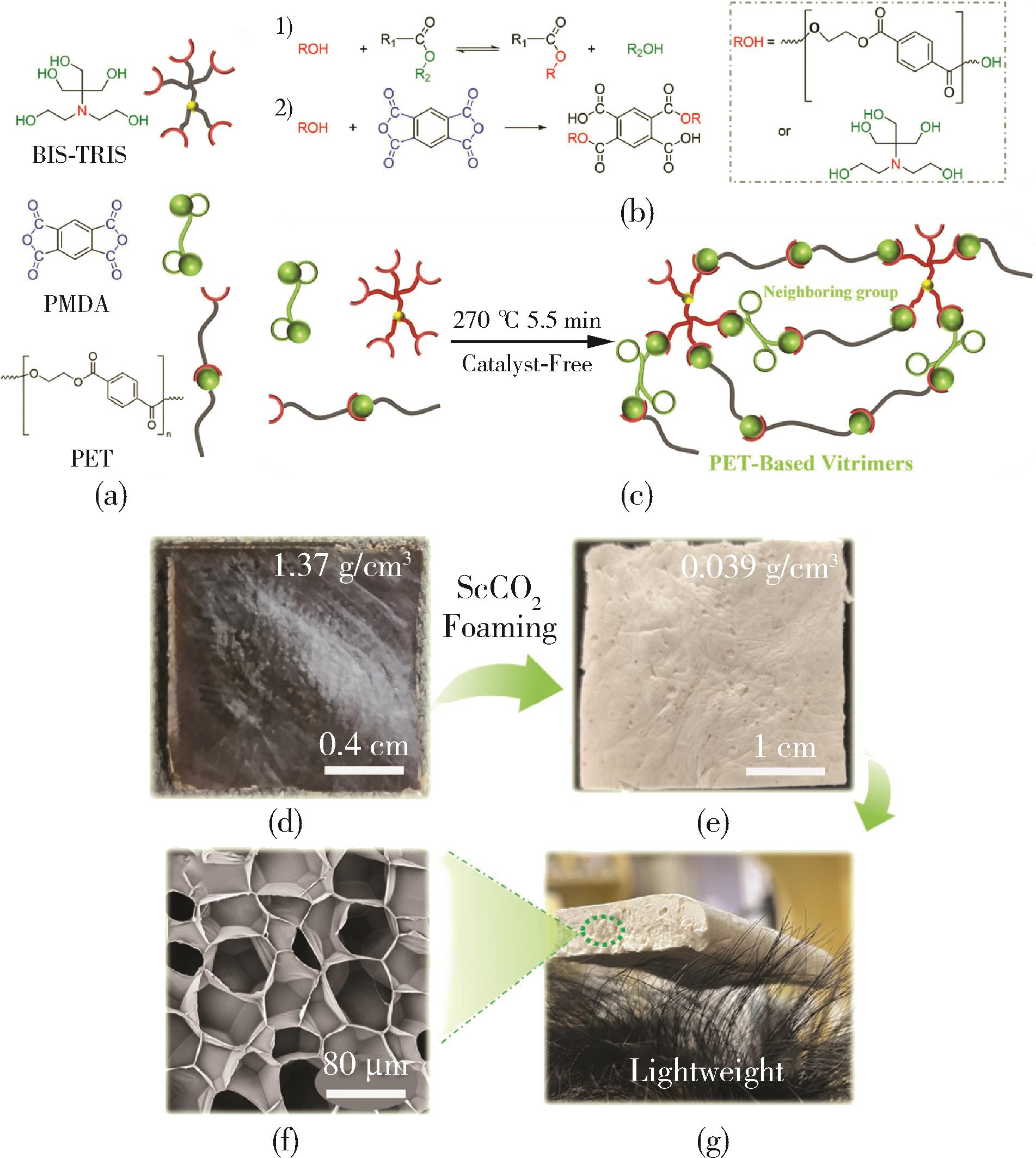

| 45 | Li P, Lan B, Zhang X, et al. Facile in situ construction of a covalent adaptable network polyester vitrimer with advanced performance in repairability, foamability and recyclability[J]. Green Chemistry, 2022, 24(14): 5 490⁃5 501. |

| 46 | Vyavahare S A, Kharat B M, More A P. Polybutylene terephthalate (PBT) blends and composites: A review[J]. Vietnam Journal of Chemistry, 2024, 1⁃11. |

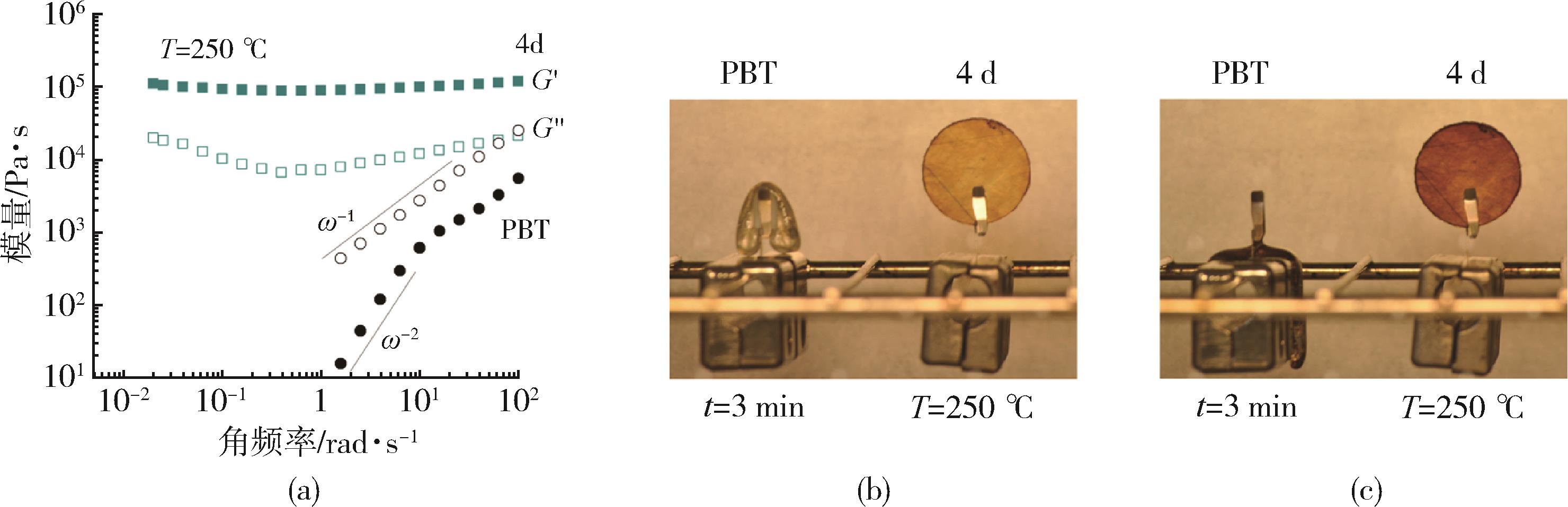

| 47 | Zhou Y, Goossens J G P, Sijbesma R P, et al. Poly(butylene terephthalate)/glycerol⁃based vitrimers via solid⁃state polymerization[J]. Macromolecules, 2017, 50 (17): 6 742⁃6 751. |

| 48 | Demongeot A, Groote R, Goossens H, et al. Cross⁃linking of poly(butylene terephthalate) by reactive extrusion using Zn(II) epoxy⁃vitrimer chemistry[J]. Macromolecules, 2017, 50 (16): 6 117⁃6 127. |

| 49 | Brutman J P, Delgado P A, Hillmyer M A. Polylactide vitrimers[J]. ACS Macro Letters, 2014, 3 (7): 607⁃610. |

| 50 | Borska K, Bednarek M, Pawlak A. Reprocessable polylactide⁃based networks containing urethane and disulfide linkages[J]. European Polymer Journal, 2021, 156: 110 636⁃110 645. |

| 51 | Liu Y B, Peng L M, Bao R Y, et al. Vitrimeric polylactide by two⁃step alcoholysis and transesterification during reactive processing for enhanced melt strength[J]. ACS Applied Materials & Interfaces, 2022, 14(40): 45 966⁃45 977. |

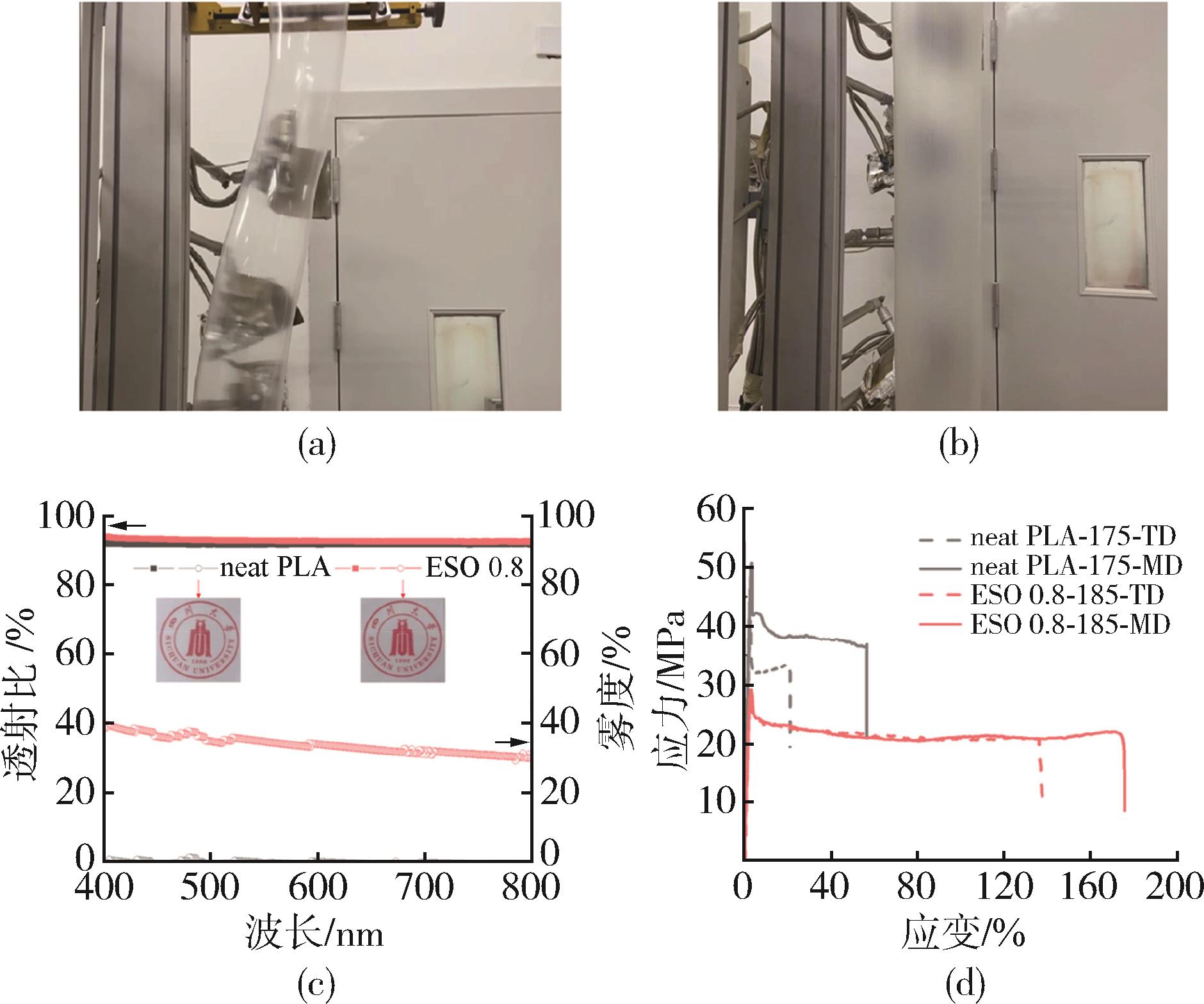

| 52 | Liu Y B, Xu Z, Zhang Z M, et al. Blowing tough polylactide film enabled by the in situ construction of covalent adaptive networks with epoxidized soybean oil as dynamic crosslinks[J]. Green Chemistry, 2023, 25(13): 5 182⁃5 194. |

| 53 | Zhou X W, Huang J, Zhang X H, et al. Design of tough, yet strong, heat⁃resistant pla/pbat blends with reconfigurable shape memory behavior by engineering exchangeable covalent crosslinks[J]. Chinese Journal of Polymer Science, 2023, 41(12): 1 868⁃1 878. |

| 54 | Xie J, Gu K, Zhao Y, et al. Enhancement of the mechanical properties of poly(lactic acid)/epoxidized soybean oil blends by the addition of 3⁃aminophenylboronic acid[J]. ACS Omega, 2022, 7( 21): 17 841⁃17 848. |

| 55 | Fourati Y, Tarrés Q, Mutjé P, Boufi S. PBAT/thermoplastic starch blends: Effect of compatibilizers on the rheological, mechanical and morphological properties[J]. Carbohydrate Polymers, 2018, 199: 51⁃57. |

| 56 | Gigante V, Canesi I, Cinelli P, et al. Rubber toughening of polylactic acid (PLA) with poly(butylene adipate⁃co⁃terephthalate) (PBAT): Mechanical properties, fracture mechanics and analysis of ductile⁃to⁃brittle behavior while varying temperature and test speed[J]. European Polymer Journal, 2019, 115: 125⁃137. |

| 57 | Mofokeng T G, Ojijo V, Ray S S. The influence of blend ratio on the morphology, mechanical, thermal, and rheological properties of PP/LDPE blends[J]. Macromolecular Materials and Engineering, 2016, 301(10): 1 191⁃1 201. |

| 58 | Oromiehie A R, Lari T T, Rabiee A. Physical and thermal mechanical properties of corn starch/ldpe composites[J]. Journal of Applied Polymer Science, 2013, 127(2): 1 128⁃1 134. |

| 59 | Zheng J, Lu J, Yang Z, et al. Fabrication of recyclable and biodegradable pbat vitrimer via construction of highly dynamic cross⁃linked network[J]. Polymer Degradation and Stability, 2024, 219: 110 602⁃110 614. |

| 60 | Fan Z Y, Shi Z, Ma L, et al. Dynamic cross⁃linked poly(butylene adipate⁃co⁃terephthalate) for high⁃performance green foam[J]. ACS Sustainable Chemistry & Engineering, 2023, 11(45): 16 354⁃16 364. |

| [1] | 曲道鹏, 张涛, 华晨曦, 宋欣雨, 程昌利, 刘禹, 王震宇. 高强电磁屏蔽环氧复合材料的3D打印工艺研究[J]. 中国塑料, 2024, 38(9): 24-29. |

| [2] | 何和智, 黄宗海, 赖文, 熊华威. PLA/PBAT/CB防静电包装材料的制备及其性能研究[J]. 中国塑料, 2024, 38(7): 1-8. |

| [3] | 胡永祥, 谢纪岭, 李伟铭, 张璐, 汤香港, 吕亿同, 申红望, 鞠冠男. 马来酸酐接枝改性GTR对聚乳酸性能的影响[J]. 中国塑料, 2024, 38(7): 20-24. |

| [4] | 王杰, 辛德华, 李晖, 蒋洪石, 周洪福, 赵建国. 纳米黏土与二氧化硅协同改性聚乳酸研究[J]. 中国塑料, 2024, 38(7): 43-48. |

| [5] | 徐琛, 骆博飞, 刘腾腾, 邢晶凯. 成核剂改性聚丙烯研究进展[J]. 中国塑料, 2024, 38(7): 79-85. |

| [6] | 刘莹, 孙昊, 杨勇, 姜开宇, 于同敏, 马赛, 祝铁丽. 超声振动对玻璃纤维增强聚酰胺6注塑制件力学性能的影响[J]. 中国塑料, 2024, 38(7): 9-14. |

| [7] | 杨莲, 蒋晶, 贾彩宜, 谢悦涵, 王小峰, 李倩. 聚酰胺6微纤增强聚丙烯复合材料制备及化学注塑发泡性能研究[J]. 中国塑料, 2024, 38(6): 12-18. |

| [8] | 周紫怡, 王洋样, 孙滔, 蒋伟, 董同力嘎, 云雪艳. 聚(己二酸/对苯二甲酸)⁃丁二醇酯基自发气调薄膜的性能研究及应用[J]. 中国塑料, 2024, 38(6): 31-38. |

| [9] | 董亚鹏, 赵恬娇, 王美珍, 崔文举, 林福华, 王波. 长链脂肪酸钠/芳基酰胺脂肪酸钠复配成核剂对聚丙烯性能影响研究[J]. 中国塑料, 2024, 38(6): 60-65. |

| [10] | 王涵, 梁金华, 高振国, 姜炜, 周昊. 微胶囊型自修复环氧树脂材料的力学性能及修复效率[J]. 中国塑料, 2024, 38(5): 40-46. |

| [11] | 张之琪, 王向东, 刘海明, 陈士宏. 聚酰胺弹性体对生物基聚酰胺56和聚酰胺66共混物的增韧改性及其发泡行为研究[J]. 中国塑料, 2024, 38(5): 55-60. |

| [12] | 孛海娃, 赵中国, 王筹萱, 薛嵘. 高导电、低逾渗PLA/CNTs导电复合材料的结构设计及性能研究[J]. 中国塑料, 2024, 38(4): 13-18. |

| [13] | 周子玉, 桑晓明, 耿旭, 肖晓红, 黄晓祥, 陈兴刚. 对位芳纶短切纤维对聚苯腈树脂力学性能的影响[J]. 中国塑料, 2024, 38(3): 13-17. |

| [14] | 陈炽盛, 杨帅, 张建军, 郭齐泰, 蔡瑗, 马素德. 提钛尾渣对聚丙烯材料力学性能的影响[J]. 中国塑料, 2024, 38(3): 26-30. |

| [15] | 国江, 许梦伊, 李辉, 黄想, 林浩, 姜胜宝, 陈尚, 陈程. 聚丙烯/氧化锆复合材料的制备及介电性能研究[J]. 中国塑料, 2024, 38(3): 44-48. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2