京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2

《中国塑料》编辑部 ©2008-2024 版权所有

地址:北京市海淀区阜成路11号 邮编:100048

编辑部:010-68985541 联系信箱:cp@plaschina.com.cn

广告部/发行部:010-68985253 本系统由北京玛格泰克科技发展有限公司设计开发

中国塑料 ›› 2025, Vol. 39 ›› Issue (12): 64-71.DOI: 10.19491/j.issn.1001-9278.2025.12.011

郭恒瑞, 王飞( ), 白彦军, 毕经新, 程千帅, 杨文钊, 王文卓

), 白彦军, 毕经新, 程千帅, 杨文钊, 王文卓

收稿日期:2024-12-19

出版日期:2025-12-26

发布日期:2025-12-22

通讯作者:

王飞(1985—),男,副教授,从事3D打印、微纳增材制造、柔性电子方面研究,wangfei@qut.edu.cn基金资助:

GUO Hengrui, WANG Fei( ), BAI Yanjun, BI Jingxin, CHENG Qianshuai, YANG Wenzhao, WANG Wenzhuo

), BAI Yanjun, BI Jingxin, CHENG Qianshuai, YANG Wenzhao, WANG Wenzhuo

Received:2024-12-19

Online:2025-12-26

Published:2025-12-22

Contact:

WANG Fei

E-mail:wangfei@qut.edu.cn

摘要:

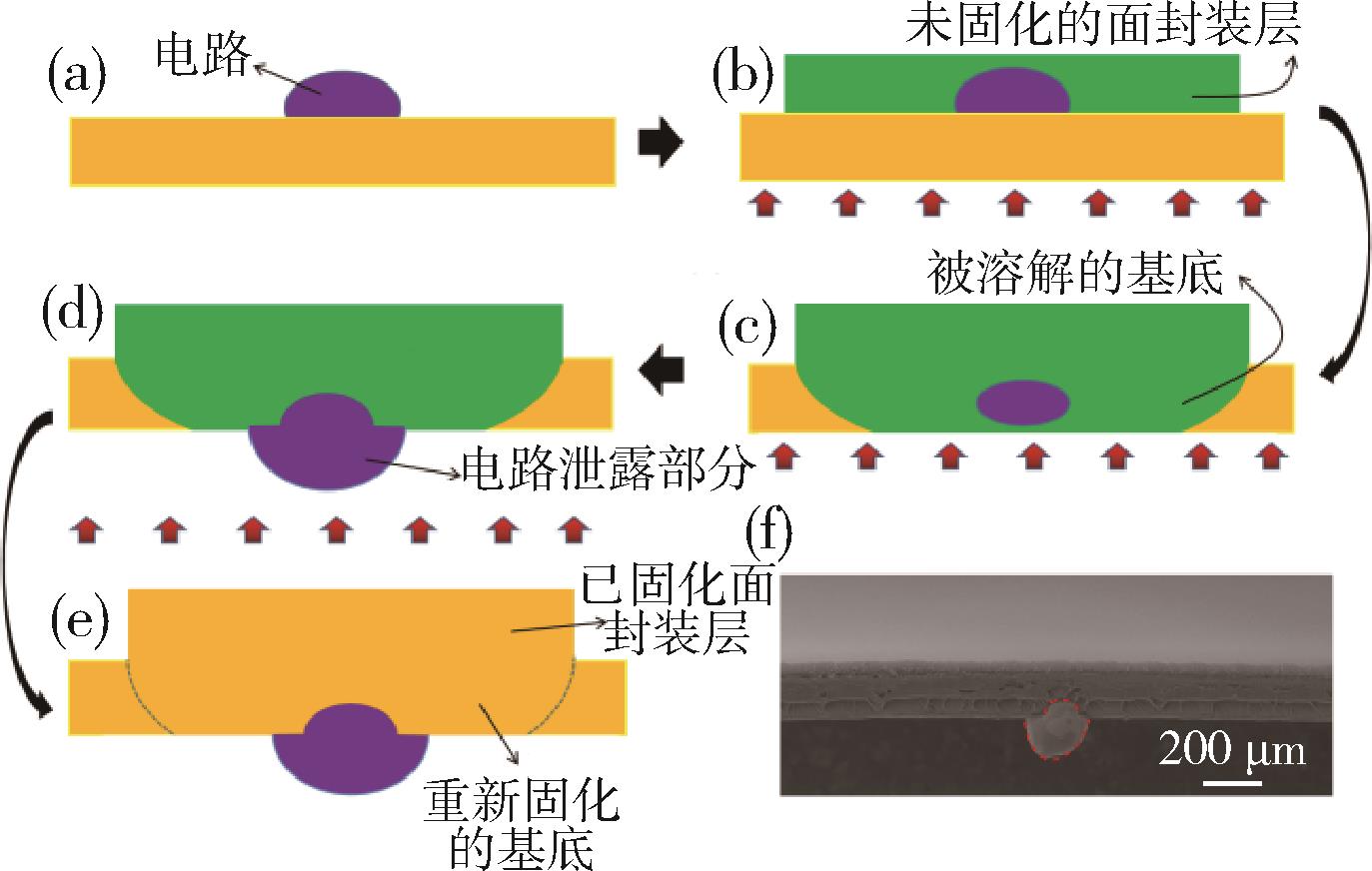

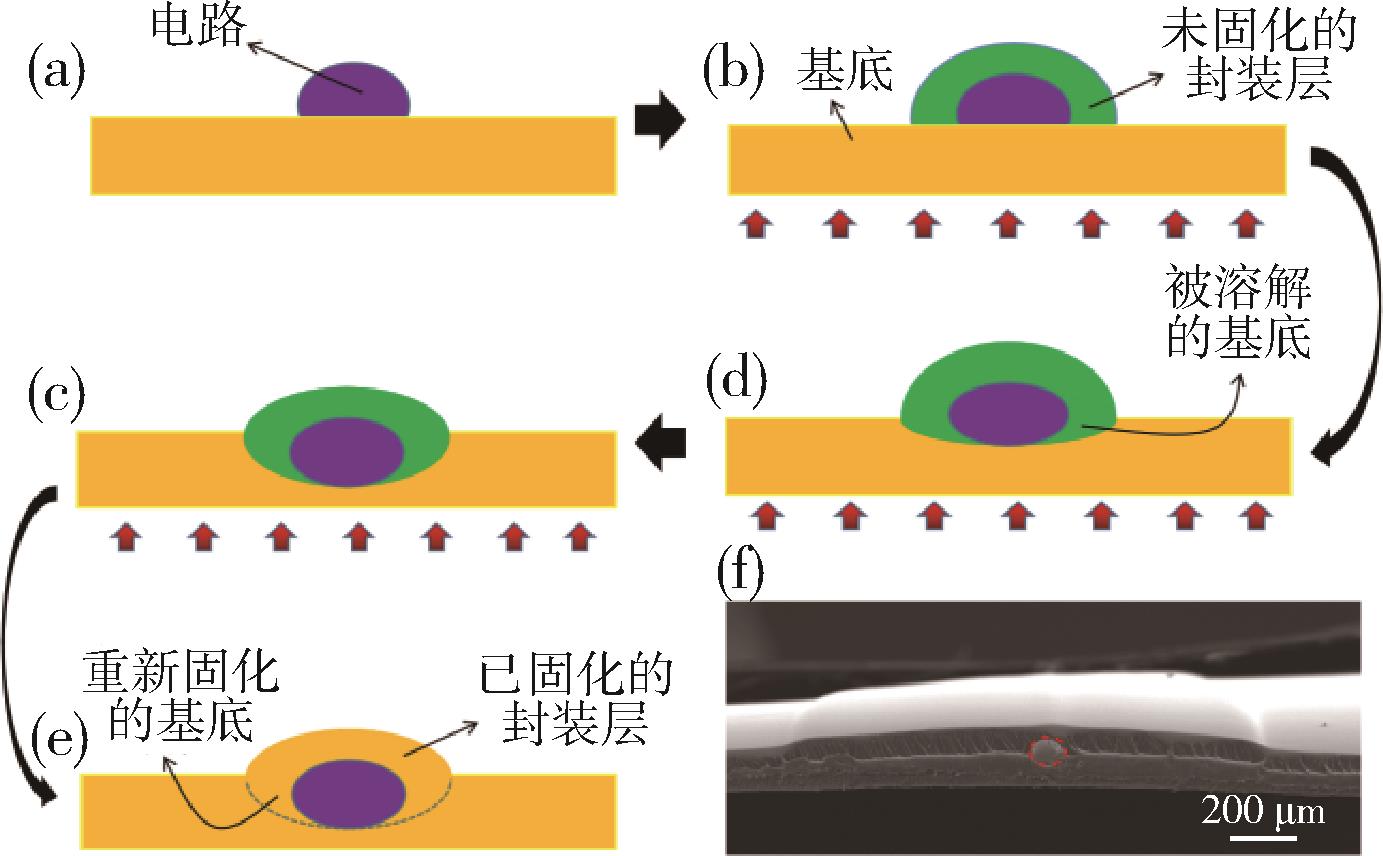

创新性地提出基于聚酰亚胺(PI)基材的液态金属柔性电路线封装3D打印技术研究。通过调节固态基底亚胺化程度和液态封装层线宽,调控基底的溶解进而控制电路的沉降。同时研究了不同工艺参数对PI基底层厚度及表面粗糙度、电路和封装层线宽的影响规律,利用提出的方法制备了柔性电路样品,并对其进行了弯曲和扭转性能测试。结果表明,电路沉降率最低可以降至8 %;在不同弯曲直径(3.5~2 cm)下分别循环弯曲100次,电阻变化率均保持在0.54 %以下;同样,在90 °~360 °扭转范围内分别循环扭转100次,电阻变化率也均低于0.45 %;基于提出的方法制备了PI基的柔性LED电路板,在不同角度的弯曲扭转形变环境中,该器件展现出了良好的柔韧性和电路连接的稳定性。

中图分类号:

郭恒瑞, 王飞, 白彦军, 毕经新, 程千帅, 杨文钊, 王文卓. 基于PI基材的液态金属柔性电路线封装3D打印技术研究[J]. 中国塑料, 2025, 39(12): 64-71.

GUO Hengrui, WANG Fei, BAI Yanjun, BI Jingxin, CHENG Qianshuai, YANG Wenzhao, WANG Wenzhuo. Study on 3D printing of flexible liquid metal circuits with encapsulation on a polyimide substrate[J]. China Plastics, 2025, 39(12): 64-71.

| [1] | 黄晨凯,车 波,刘 磊,等.柔性可持续穿戴的肺音信号监测听诊贴研究[J].传感器与微系统,2024,43(5):27⁃30.DOI:10.13873/J.1000-9787(2024)05-0027-04 . |

| [2] | 赵 帅,朱 荣.基于热感应的多维传感机理及柔性电子皮肤研究[J].机械工程学报,2022,58(3):44. |

| [3] | Xin Y, Lan J, Xu J, et al. Vapor⁃mediated stretchable and reversible conductors from microporous liquid metal polymers[J]. ACS Applied Materials & Interfaces, 2021, 13(16): 19 351⁃19 359. |

| [4] | Albeltagi A, Tolvanen J, Bhalerao S R, et al. Soft and Stretchable Humidity‐Insensitive Thermoresistive Temperature Sensor with A Tensile Strain Modulated Sensitivity[J]. Macromolecular Materials and Engineering, 2024, 309(4): 2300379. |

| [5] | 王曦宇,李 科,王源升,等.聚合物/镓基液态金属复合材料的研究及应用进展[J].高分子材料科学与工程,2021,37(1):327⁃334.DOI:10.16865/j.cnki.1000-7555.2021.0025 . |

| [6] | 陈杨钟,王 晗,鲁圣国.基于微结构表面超疏水性的液态金属图案化方法[J].电子元件与材料,2021,40(01):1⁃5+10.DOI:10.14106/j.cnki.1001-2028.2021.1645 . |

| [7] | Duan L, Zhou T, Zhang Y, et al. Surface optics and color effects of liquid metal materials[J]. Advanced Materials, 2023, 35(26): 2210515. |

| [8] | Hoang T T, Sy L, Bussu M, et al. A wearable soft fabric sleeve for upper limb augmentation[J]. Sensors, 2021, 21(22): 7 638. |

| [9] | 田浩为,邱 晔,徐校杰,等.基于液态金属的柔性可重构频率选择表面[J].微纳电子技术,2024,61(11):50⁃58.DOI:10.13250/j.cnki.wndz.24110301 . |

| [10] | Zhang S, Yue Y, Xu Y, et al. Liquid‐Metal/Nd2Fe14B/Ecoflex Composite Soft Robots and Their Electric Signal Transmission using Non‐Contact Tentacles[J]. Advanced Materials Technologies, 2023, 8(19): 2300827. |

| [11] | Wang J, Zhu B, Hui C Y, et al. Delayed fracture caused by time⁃dependent damage in PDMS[J]. Journal of the Mechanics and Physics of Solids, 2023, 181: 105459. |

| [12] | Ahmad D, Ajaj R M. A multiaxial fracture of ecoflex skin with different shore hardness for morphing wing application[J]. Polymers, 2023, 15(6): 1 526. |

| [13] | Tony A, Badea I, Yang C, et al. A preliminary experimental study of polydimethylsiloxane (PDMS)⁃to⁃PDMS bonding using oxygen plasma treatment incorporating isopropyl alcohol[J]. Polymers, 2023, 15(4): 1006. |

| [14] | Bakr M, Su Y, Rezaei A, et al. Over⁃molding of flexible polyimide⁃based electronic circuits[J]. Flexible and Printed Electronics, 2021, 6(2): 025007. |

| [15] | Jiang P, Jia H, Xu J, et al. Preparation of high⁃strength polyimide membranes capped by ionic liquids[J]. High Performance Polymers, 2021, 33(5): 568⁃575. |

| [16] | Zha J W, Liu X J, Tian Y, et al. High⁃temperature polyimide dielectric materials for energy storage[M]//Polyimide for Electronic and Electrical Engineering Applications. London, UK: IntechOpen, 2020. |

| [17] | 孟祥胜,柯红军,阎敬灵,等.热固性聚酰亚胺树脂研究进展[J].高分子通报,2023,36(08):1027⁃1041.DOI:10.14028/j.cnki.1003-3726.2023.08.010 . |

| [18] | Chen H, Zhang E, Dai X, et al. Influence of solvent solubility parameter on the power law exponents and critical concentrations of one soluble polyimide in solution[J]. Journal of Polymer Research, 2019, 26: 1⁃11. |

| [19] | Li H, Kong X, Wang S, et al. Sustainable dielectric films with ultralow permittivity from soluble fluorinated polyimide[J]. Molecules, 2023, 28(7): 3 095. |

| [20] | Lee J, Kim S S, Kang D, et al. Physicochemical characterization of polyimide (PI)/p⁃aramid: New functional and safe materials with improved heat resistance by a simple coating of polyimide on the surface of p⁃aramid[J]. Progress in Organic Coatings, 2019, 127: 117⁃123. |

| [21] | Xiong X, Li W, Ren R, et al. Isothermal curing analysis and properties of ultra heat‐resistant polyimide composites by DMA method[J]. Journal of Applied Polymer Science, 2023, 140(29): e54056. |

| [1] | 冯超, 汪顺国, 朱坚. 3D打印技术在模具智能化制造中应用的研究进展[J]. 中国塑料, 2025, 39(11): 137-141. |

| [2] | 解明东, 秦柳, 司道星, 刘家鑫, 杨卫民. 真空辅助发泡制备硬质低密度开孔聚酰亚胺泡沫的结构与性能[J]. 中国塑料, 2025, 39(11): 7-12. |

| [3] | 曲道鹏, 张涛, 华晨曦, 宋欣雨, 程昌利, 刘禹, 王震宇. 高强电磁屏蔽环氧复合材料的3D打印工艺研究[J]. 中国塑料, 2024, 38(9): 24-29. |

| [4] | 于佳滨, 王非, 石文天, 蒋雅婷. 模具的智能化制造研究进展[J]. 中国塑料, 2024, 38(7): 100-105. |

| [5] | 任小龙, 李艺, 苏丹妮. 高透明性聚酰亚胺薄膜专利技术研究与工业化进展[J]. 中国塑料, 2024, 38(7): 120-137. |

| [6] | 李轩, 何瑜, 明白, 张晓燕, 刘福华, 来升. 聚酰亚胺树脂基复合摩擦材料成型技术研究进展[J]. 中国塑料, 2024, 38(4): 116-123. |

| [7] | 胡家嫒, 张怡晴, 许佳贺, 李巧丽, 冯茜茜, 徐轩, 李新傲, 倪天恒, 侯连龙, 马海坤, 孙国华. 聚酰亚胺/羟乙基纤维素复合纤维膜的制备及其电池性能研究[J]. 中国塑料, 2024, 38(11): 47-52. |

| [8] | 赵云浦, 万周原野, 齐云赓, 李海明. 木质纤维素及其衍生物在墨水直写式3D打印中的应用进展[J]. 中国塑料, 2024, 38(10): 114-121. |

| [9] | 相利学, 唐波, 周刚, 代旭明, 王二轲, 姜涛, 吴新锋. 3D打印技术在高导热复合材料中的应用研究[J]. 中国塑料, 2023, 37(9): 125-132. |

| [10] | 王容容, 江涛, 孙少阳, 周洲, 汪翔, 申莹, 邢剑. 聚酰亚胺/多壁碳纳米管杂化纳米纤维的制备与性能研究[J]. 中国塑料, 2023, 37(12): 23-28. |

| [11] | 汪杰, 张伟蒙, 胡晶. 聚乳酸⁃羟基乙酸共聚物涂层对聚乳酸3D打印支架的性能影响[J]. 中国塑料, 2023, 37(1): 1-7. |

| [12] | 董玥, 董霄, 朱德兆, 杨延翔, 罗琛, 李阳, 李锦山. 聚酰亚胺发展概况与应用展望[J]. 中国塑料, 2022, 36(9): 85-95. |

| [13] | 杨超永, 郭金强, 王富玉, 张玉霞. 高性能塑料薄膜制备方法及改性研究进展[J]. 中国塑料, 2022, 36(9): 167-179. |

| [14] | 王帅, 张玉迪, 杨富凯, 徐新宇. 聚酰亚胺/多壁碳纳米管泡沫材料的制备及性能研究[J]. 中国塑料, 2022, 36(6): 39-45. |

| [15] | 卢春燕, 王刚, 刘帅, 朱天容, 刘芸, 汪海平, 胡思前. 高温缩聚法制备高透明性聚酰亚胺薄膜[J]. 中国塑料, 2022, 36(3): 48-52. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2