京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2

《中国塑料》编辑部 ©2008-2024 版权所有

地址:北京市海淀区阜成路11号 邮编:100048

编辑部:010-68985541 联系信箱:cp@plaschina.com.cn

广告部/发行部:010-68985253 本系统由北京玛格泰克科技发展有限公司设计开发

中国塑料 ›› 2022, Vol. 36 ›› Issue (12): 167-174.DOI: 10.19491/j.issn.1001-9278.2022.12.022

• 综述 • 上一篇

收稿日期:2022-08-18

出版日期:2022-12-26

发布日期:2022-12-20

作者简介:孙永涛(1979-),男,中海油田服务股份有限公司油田生产事业部副总经理,博士研究生,从事完井工艺技术研究, sunyt5@cosl.com.cn基金资助:

SUN Yongtao1( ), LU Daosheng1, LIU Lian2, ZHANG Hailong3, LIU Mingtai1

), LU Daosheng1, LIU Lian2, ZHANG Hailong3, LIU Mingtai1

Received:2022-08-18

Online:2022-12-26

Published:2022-12-20

摘要:

简述了橡胶纳米复合材料疲劳失效机理和对包括了硅藻土、纳米氧化锌、凹凸棒土、二氧化铈、石墨烯和碳纳米管在内的纳米填料填充改性氟橡胶的研究进展。

中图分类号:

孙永涛, 卢道胜, 刘练, 张海龙, 刘明泰. 氟橡胶纳米复合材料的应用研究进展[J]. 中国塑料, 2022, 36(12): 167-174.

SUN Yongtao, LU Daosheng, LIU Lian, ZHANG Hailong, LIU Mingtai. Research progress in applications of fluororubber nanocomposites[J]. China Plastics, 2022, 36(12): 167-174.

| 样品 | 表面是否存在缺陷 | 表面是否存在裂纹 | 膨胀率/ % | 氟流失(质量分数)/% |

|---|---|---|---|---|

| FE⁃OBD | 是 | 是 | -15.7 | 32.0 |

| CNT/FE⁃OBD | 否 | 否 | 5.7 | 10.3 |

| ACNT/FE⁃OBD | 否 | 否 | 4.1 | - |

| BCNT/FE⁃OBD | 否 | 否 | 2.8 | 7.3 |

| 样品 | 表面是否存在缺陷 | 表面是否存在裂纹 | 膨胀率/ % | 氟流失(质量分数)/% |

|---|---|---|---|---|

| FE⁃OBD | 是 | 是 | -15.7 | 32.0 |

| CNT/FE⁃OBD | 否 | 否 | 5.7 | 10.3 |

| ACNT/FE⁃OBD | 否 | 否 | 4.1 | - |

| BCNT/FE⁃OBD | 否 | 否 | 2.8 | 7.3 |

| 1 | 李 强, 李文涛, 邹思源, 等. 钻完井工具橡胶密封件材料优选[J]. 石化技术, 2021,28(07): 35⁃36. |

| LI Q, LI W T, ZOU S Y, et al.Optimization of rubber seal materials for drilling and completion tools[J]. Petrochemical Technology, 2021,28(07): 35⁃36. | |

| 2 | 曹鸿璋, 刘杰民, 张玉玺, 等. 氟橡胶改性技术研究进展[J]. 橡胶工业, 2014,61(03): 187⁃191. |

| 3 | 张立群, 吴友平, 王益庆, 等. 橡胶的纳米增强及纳米复合技术[J]. 合成橡胶工业, 2000(02): 71⁃77. |

| ZHANG L Q, WU Y P, WNAG Y Q. The nanp⁃reinforcing and nano⁃compounding technique of rubber[J]. China Synthetic Rubber Industry, 2000(02): 71⁃77. | |

| 4 | 董 月, 周 睿, 辛振祥. 橡胶动态疲劳失效机理的研究进展[J]. 特种橡胶制品, 2017,38(05): 69⁃74. |

| DONG Y, ZHOU R, XIN Z X. Research progress of fatigue mechanism of rubber[J]. Special Purpose Rubber Products, 2017,38(05): 69⁃74. | |

| 5 | 张松波. 不同维度纳米填料/橡胶复合材料疲劳性能的研究[D]. 北京:北京化工大学, 2018. |

| 6 | 李昂. 橡胶的老化现象及其老化机理[J]. 特种橡胶制品, 2009,30(05): 56⁃67. |

| 7 | 俞进涛. 天然橡胶疲劳失效机理研究[D]. 南昌:南昌航空大学, 2016. |

| 8 | DIANI J, FAYOLLE B, GILORMINI P. A review on the mullins effect[J]. European Polymer Journal, 2009,45(3): 601⁃612. |

| 9 | SRIVASTAVA S, MISHRA Y. Nanocarbon reinforced rubber nanocomposites: detailed insights about mechanical, dynamical mechanical properties, payne, and mullin effects[J]. Nanomaterials, 2018,8(11): 945. |

| 10 | 武卫莉, 李 响. 改性氟橡胶复合材料的研究进展[J]. 弹性体, 2020,30(06): 79⁃83. |

| WU W L, LI X. Research progress of modified fluorine rubber composites[J]. China Elastomerics,2020,30(06): 79⁃83. | |

| 11 | WU W, CONG S. Modified diatomite forms in the rubber nanocomposites[J]. Journal of Thermoplastic Composite Materials, 2020,33(5): 659⁃672. |

| 12 | WU W, CONG S. Silica⁃ and diatomite⁃modified fluorine rubber nanocomposites[J]. Bulletin of Materials Science, 2019,42(4): 1⁃6. |

| 13 | 谢 强, 魏 刚, 刘 燕, 等. 硅藻土/nano⁃MoS2复合改性氟橡胶的摩擦磨损性能研究[J]. 塑料工业, 2021,49(01): 49⁃54. |

| XIE Q, WEI G, LIU Y. Research on friction and wear properties of fluorine rubber modified by diatomite/nano⁃MoS2 [J]. China Plastics Industry, 2021,49(01): 49⁃54. | |

| 14 | QIN X, XU H, ZHANG G, et al. Enhancing the performance of rubber with Nano ZnO as activators[J]. ACS Applied Materials & Interfaces, 2020,12(42):48 007⁃48 015. |

| 15 | 亓 明, 贾现召, 石建永, 等. 不同填料氟橡胶复合材料高温性能研究[J]. 润滑与密封, 2021,46(02): 106⁃113. |

| QI M, JIA X Z, SHI J Y. Study on high temperature properties of fluorine rubber composites with different fillers[J]. Lubrication Engineering, 2021,46(02): 106⁃113. | |

| 16 | NING M, LI K, YAN C, et al. Study on mechanical and tribological properties of ternary fluororubber filled with four needles of zinc oxide[J]. Polymer Composites, 2021,42(6): 3 064⁃3 076. |

| 17 | 马玉恒, 方卫民, 马小杰. 凹凸棒土研究与应用进展[J]. 材料导报, 2006(09): 43⁃46. MA Y H, FANG W M, MA X J. Advances in attapulgite research and application[J]. Materials Reports., 2006,20(09): 43⁃46. |

| 18 | 闫普选, 王玉峰, 卢江荣, 等. 凹凸棒/石墨协同改性氟橡胶复合材料摩擦磨损性能[J]. 润滑与密封, 2017,42(08): 110⁃114. |

| YAN P X, WANG Y F, LU J R,et al. Fricyion and wear properties of fluororubber nanocompsite modified by attapulgite and graphite[J]. Lubrication Engineering, 2017,42(08): 110⁃114. | |

| 19 | 代宏武, 王玉峰, 闫普选, 等. 维生素C⁃稀土配合物改性氟橡胶复合材料的制备与表征[J]. 合成橡胶工业, 2018,41(06): 470⁃474. |

| DAI H W, WANG Y F, YAN P X, et al. Preparation and characterization of fluorine rubber composite modified with vitamin C⁃rare earth complex[J]. China Synthetic Rubber Industry, 2018,41(06): 470⁃474. | |

| 20 | HAN J, LI Z, XU Z, et al. Study on high temperature composite properties of ternary fluor rubber filled with nano⁃cerium oxide[J]. Journal of Polymer Research, 2021,28(12):487. |

| 21 | KANG Q, LI A, ZHANG X, et al. Study on mechanical and tribological properties of cerium oxide/fluorine rubber composites[J]. Materials Today Communications, 2021,28: 102596. |

| 22 | LIU X, WANG L, ZHAO L, et al. Research progress of graphene⁃based rubber nanocomposites[J]. Polymer Composites, 2016,39(4):1 006⁃1 022. |

| 23 | 崔小明. 石墨烯在合成橡胶中的应用研究进展[J]. 橡胶科技, 2022,20(03): 109⁃116. |

| CUI X M. Research progress on application of graphene in synthetic rubber[J]. Rubber Science and Technology, 2022,20(03): 109⁃116. | |

| 24 | LIU M, CATALDI P, YOUNG R J, et al. High⁃performance fluoroelastomer⁃graphene nanocomposites for advanced sealing applications[J]. Composites Science and Technology, 2021,202: 108592. |

| 25 | MONI G, JOSE T, RAJEEVAN S, et al. Influence of exfoliated graphite inclusion on the thermal, mechanical, dielectric and solvent transport characteristics of fluoroelastomer nanocomposites[J]. Journal of Polymer Research, 2020,27(3):72. |

| 26 | 刘雅琼, 王广克, 李文鹏, 等. 氧化石墨烯/氟橡胶复合材料的制备及性能研究[J]. 橡胶工业, 2022,69(03): 187⁃191. |

| LIU Y Q, WANG G K, LI W P. Prepartion and properties of graphene oxide/fluororubber composites[J]. China Rubber Industry, 2022,69(03): 187⁃191. | |

| 27 | WEI J, JACOB S, QIU J. Graphene oxide⁃integrated high⁃temperature durable fluoroelastomer for petroleum oil sealing[J]. Composites Science and Technology, 2014,92: 126⁃133. |

| 28 | DARVISHI S, AFSHARPOUR M, HEIDARIAN J. Siligraphen/g⁃C3N4 nanocomposites as the novel nanofillers for improving the thermal and mechanical properties of fluoroelastomer[J]. Composites Science and Technology, 2021,213: 108885. |

| 29 | BAKOŠOVÁ D, BAKOŠOVÁ A. Testing of rubber composites reinforced with carbon nanotubes[J]. Polymers, 2022,14(15):3 039. |

| 30 | ZHOU H, LI S, ZHANG Z, et al. Preparation of fluororubber/carbon nanotube composites and the effect of carbon nanotubes on aging resistance and solvent resistance of fluororubber[J]. Journal of Macromolecular Science, Part A, 2022,59(10):689⁃697. |

| 31 | SEMENTSOV Y, YANG W, IVANENKO K, et al. Modification of rubber compositions by carbon nanotubes[J]. Applied Nanoscience, 2021,12:621⁃628. |

| 32 | DANAFAR F, KALANTARI M. A review of natural rubber nanocomposites based on carbon nanotubes[J]. Journal of Rubber Research, 2018,21:293⁃310. |

| 33 | 包巧云. 碳纳米管/聚合物复合材料的力学性能综述[J]. 化工管理, 2014(20): 91⁃92. |

| 34 | 王 双, 田晨晨, 宁南英, 等. 碳纳米管/橡胶复合材料的界面性能:碳纳米管的比表面积的影响[J]. 复合材料学报, 2021,38(02): 601⁃611. |

| WANG S, TIAN C C, NING N Y. Interfacial properties of carbon nanotubes/rubber composites: Effects of specific surface area of carbon nanotubes[J].Acta Materiae Compositae Sinica, 2021,38(02): 601⁃611. | |

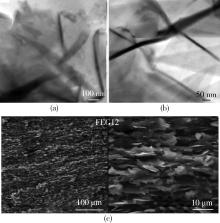

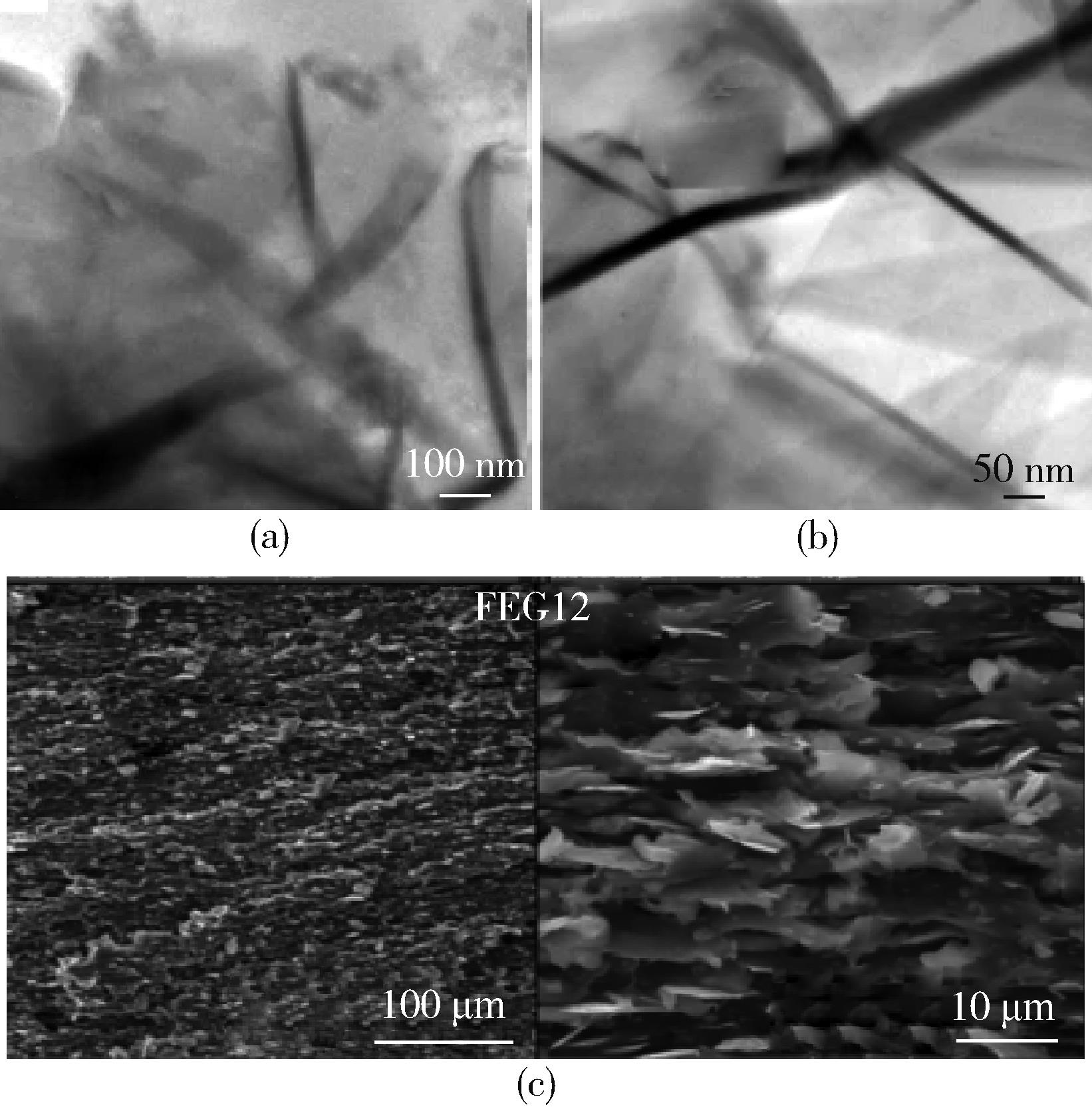

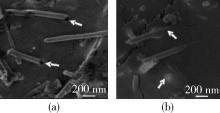

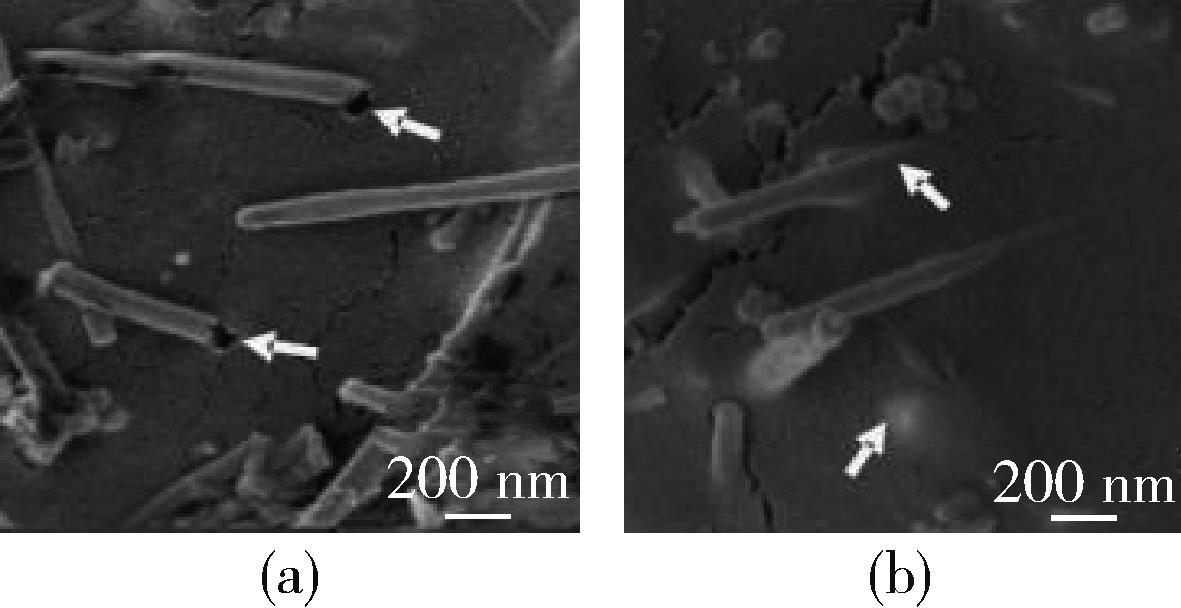

| 35 | ENDO M, NOGUCHI T, ITO M, et al. Extreme⁃performance rubber nanocomposites for probing and excavating deep oil resources using multi⁃walled carbon nanotubes[J]. Advanced Functional Materials, 2008,18(21): 3 403⁃3 409. |

| 36 | HEIDARIAN J, HASSAN A. Microstructural and thermal properties of fluoroelastomer/acidic surface modified carbon nanotube nanocomposites[J]. Polymer Composites, 2016,37(12): 3 341⁃3 353. |

| 37 | 逄见光, 李晓鹏, 薛海恩, 等. 钛酸钾晶须与碳纳米管对氟橡胶的协同补强性能研究[J]. 橡胶工业, 2020,67(09): 677⁃682. |

| PANHG J G, LI X P, XUE H E. Study on synergistic reinforcement of FKM with PTWs and CNTs[J]. China Rubber Industry, 2020,67(09): 677⁃682. | |

| 38 | GAO W, GUO J, XIONG J, et al. Improving thermal, electrical and mechanical properties of fluoroelastomer/amino⁃functionalized multi⁃walled carbon nanotube composites by constructing dual crosslinking networks[J]. Composites Science and Technology, 2018,162: 49⁃57. |

| 39 | HEIDARIAN J, HASSAN A. Characterization and comparison of fluoroelastomer unfilled, filled with carbon nanotube (unmodified, acid or base surface modified) and carbon black using TGA⁃GCMS[J]. Journal of Elastomers & Plastics, 2021,53(7): 861⁃885. |

| 40 | HEIDARIAN J. Acid surface modified carbon nanotube⁃filled fluoroelastomers aging test in oil⁃based drilling fluids[J]. Journal of Elastomers & Plastics, 2017,49(8): 706⁃737. |

| 41 | HEIDARIAN J. OH⁃functionalized carbon nanotube filled fluoroelastomers aging test in oil based drilling fluids[J]. Journal of Petroleum Science and Engineering, 2017,158: 11⁃28. |

| [1] | 陈淑花, 任子萌, 孙婷婷. 壳聚糖/壳聚糖接枝氧化石墨烯复合气凝胶的制备及性能研究[J]. 中国塑料, 2022, 36(9): 32-37. |

| [2] | 李亚飞, 孙小杰, 任月庆, 张寅灵. 阻燃抗静电聚烯烃板材的制备与性能研究[J]. 中国塑料, 2022, 36(8): 23-27. |

| [3] | 杜青, 何祎, 余坦竟, 蓝艳姣, 赵彦芝, 周菊英. 取向PAN/MWCNTs与热塑性聚烯烃复合材料的制备及表征[J]. 中国塑料, 2022, 36(8): 49-55. |

| [4] | 李凯泽, 辛勇. 改性碳纳米管增强热塑性聚氨酯复合材料的性能研究[J]. 中国塑料, 2022, 36(6): 1-5. |

| [5] | 杨小龙, 陈文静, 李永青, 闫晓堃, 王修磊, 谢鹏程, 马秀清. 导电型聚合物/石墨烯复合材料的研究进展[J]. 中国塑料, 2022, 36(6): 165-173. |

| [6] | 王帅, 张玉迪, 杨富凯, 徐新宇. 聚酰亚胺/多壁碳纳米管泡沫材料的制备及性能研究[J]. 中国塑料, 2022, 36(6): 39-45. |

| [7] | 李梦琪, 陈雅君. 纳米材料阻燃聚乳酸的研究进展[J]. 中国塑料, 2022, 36(4): 102-114. |

| [8] | 彭博, 肖运彬, 顾家宝, 陈梓钧, 唐雁煌, 朱刚, 徐焕翔. 聚合物/石墨烯复合材料制备与性能研究进展[J]. 中国塑料, 2022, 36(4): 190-197. |

| [9] | 宋仁达, 武高健, 陈俊翔, 张有忱, 杨卫民, 谢鹏程. 微孔发泡PP/PET/CNTs复合材料的制备及其电磁屏蔽效能研究[J]. 中国塑料, 2022, 36(2): 1-7. |

| [10] | 何明峰, 王珂, 王启扬, 杨肖, 郭红, 胡泊洋, 李保安. 聚偏氟乙烯/类基体基团修饰石墨烯导热复合材料研究[J]. 中国塑料, 2022, 36(2): 41-48. |

| [11] | 李波, 龚军, 金学义, 孟晓宇. 碳纳米管改性方法对聚酰胺11性能影响研究[J]. 中国塑料, 2022, 36(2): 61-66. |

| [12] | 周丹砚, 黄汉雄. 基于导电涂层微结构TPU柔性传感器的制备和性能[J]. 中国塑料, 2022, 36(11): 1-6. |

| [13] | 李文婷, 李明鹏, 陈季荷, 苑之童, 程海涛. 加捻植物纤维增强聚氨酯复合材料的力学特性与疲劳性能[J]. 中国塑料, 2022, 36(11): 41-50. |

| [14] | 王启扬, 杨肖, 陈吉奂, 何悦星, 杨冬梅, 胡泊洋, 郭红, 李保安. 双隔离结构聚乙烯/石墨烯导热复合材料的研究[J]. 中国塑料, 2022, 36(1): 32-41. |

| [15] | 彭凡畅, 陈小随, 张爱清, 周洪福. 超支化聚磷酰胺包覆碳纳米管的可控制备及阻燃应用[J]. 中国塑料, 2021, 35(9): 55-63. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2