京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2

《中国塑料》编辑部 ©2008-2024 版权所有

地址:北京市海淀区阜成路11号 邮编:100048

编辑部:010-68985541 联系信箱:cp@plaschina.com.cn

广告部/发行部:010-68985253 本系统由北京玛格泰克科技发展有限公司设计开发

中国塑料 ›› 2023, Vol. 37 ›› Issue (10): 70-76.DOI: 10.19491/j.issn.1001-9278.2023.10.010

收稿日期:2023-03-20

出版日期:2023-10-26

发布日期:2023-10-23

通讯作者:

郝建薇(1957-),女,博士,教授,主要从事阻燃复合材料的研究,hjw@bit.edu.cn作者简介:王芳(1986-),女,博士,主要从事消防科技与火灾调查工作,2295201770@qq.com

Received:2023-03-20

Online:2023-10-26

Published:2023-10-23

Contact:

HAO Jianwei

E-mail:2295201770@qq.com;hjw@bit.edu.cn

摘要:

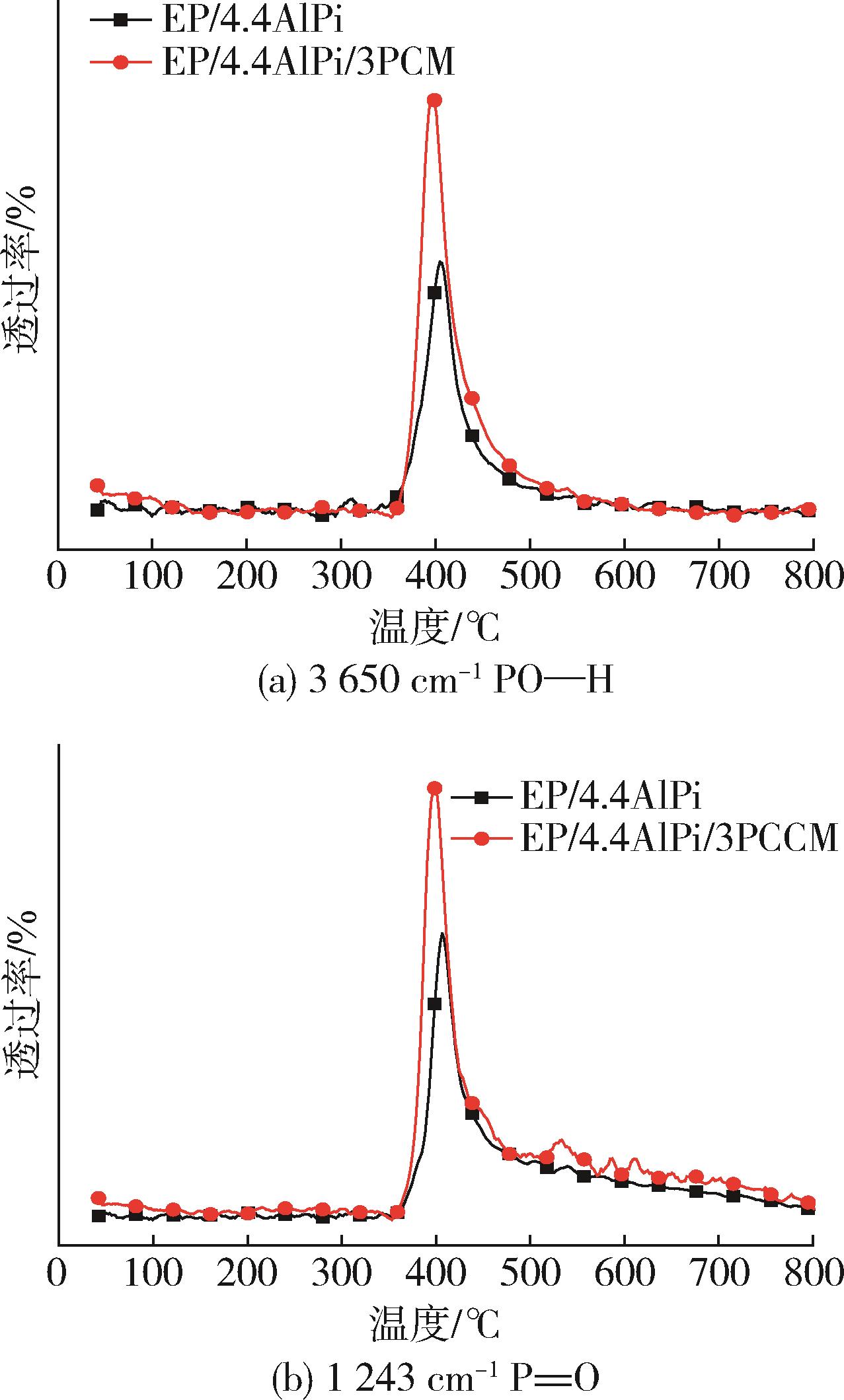

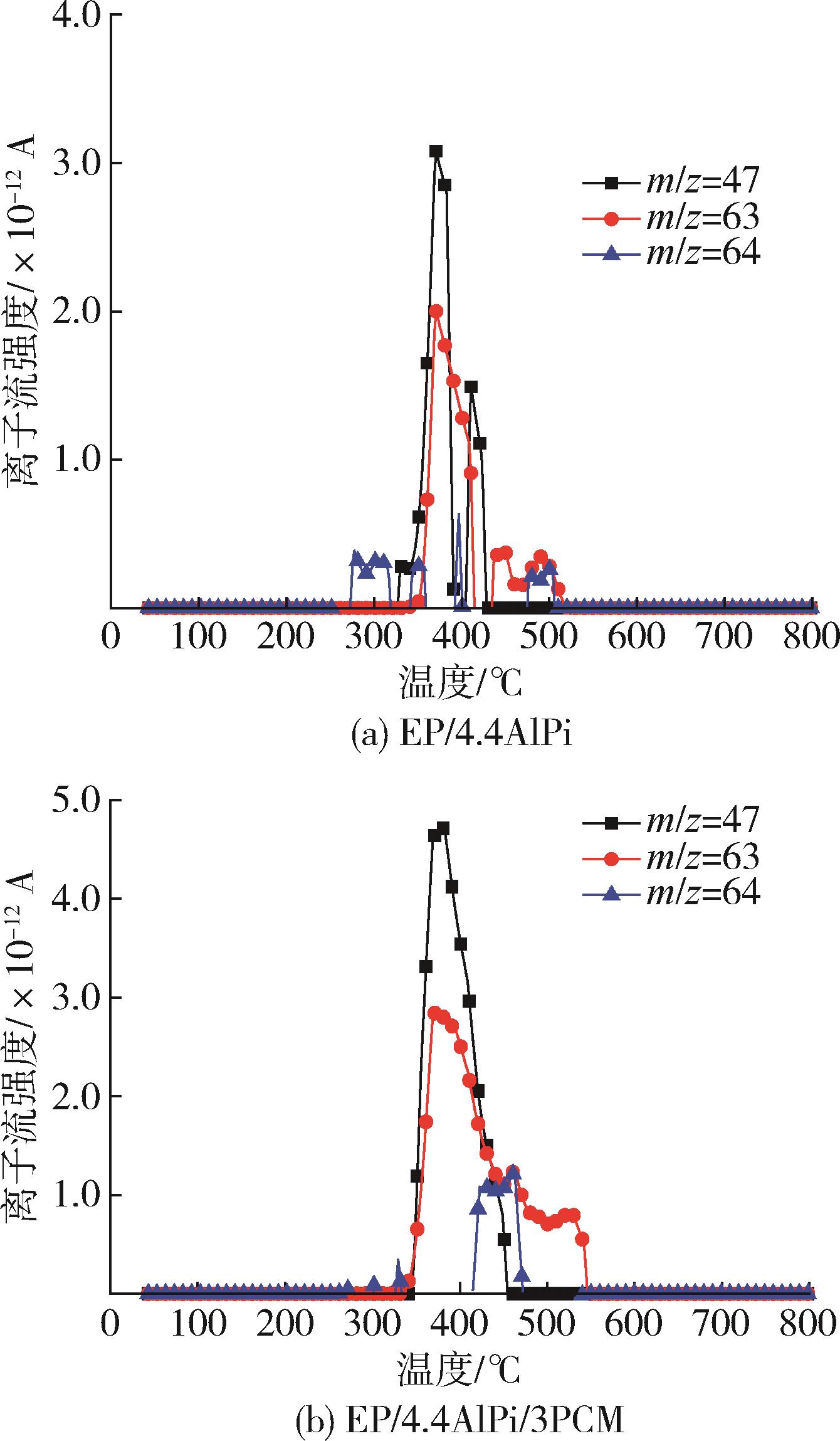

利用可再生资源为协效剂,将竹基多孔碳(PCM)与二乙基次膦酸铝(AlPi)添加于环氧树脂(EP),研究了PCM协同AlPi催化阻燃EP复合材料性能及作用机理。结果表明,PCM(3 %)与AlPi(4.4 %)复合于EP后,复合材料的极限氧指数(LOI)由纯EP的24.6 %提高到42.6 %,UL 94测试达到V⁃0级,热释放速率峰值降低60.7 %,PCM协同AlPi催化阻燃EP的效果显著。热失重⁃红外光谱联用、热失重⁃质谱联用、X射线光电子能谱及拉曼光谱研究揭示,PCM具有催化AlPi在气相释放二乙基次膦酸捕捉自由基,在凝聚相形成氧化铝、磷酸铝和焦磷酸铝,提高炭层的耐热氧化能力及促进类石墨炭层形成的作用。

中图分类号:

王芳, 郝建薇. 竹基多孔碳协同二乙基次膦酸铝催化阻燃环氧树脂及作用机理研究[J]. 中国塑料, 2023, 37(10): 70-76.

WANG Fang, HAO Jianwei. Study on flame⁃retardant epoxy resins and mechanism based on catalysis of bamboo⁃based porous carbon and aluminum diethylphosphinate[J]. China Plastics, 2023, 37(10): 70-76.

| 样品 | AlPi 含量/% | P* 含量/% | PCM 含量/% | EP 含量/% |

|---|---|---|---|---|

| EP | - | - | - | 100 |

| EP/4.4AlPi | 4.4 | 1.0 | - | 95.6 |

| EP/1PCM | - | - | 1.0 | 99.0 |

| EP/3PCM | - | - | 3.0 | 97.0 |

| EP/5PCM | - | - | 5.0 | 95.0 |

| EP/4.4AlPi/1PCM | 4.4 | 1.0 | 1.0 | 94.6 |

| EP/4.4AlPi/3PCM | 4.4 | 1.0 | 3.0 | 92.6 |

| EP/4.4AlPi/5PCM | 4.4 | 1.0 | 5.0 | 90.6 |

| EP/2.2AlPi/1.5PCM | 2.2 | 0.5 | 1.5 | 96.3 |

| 样品 | AlPi 含量/% | P* 含量/% | PCM 含量/% | EP 含量/% |

|---|---|---|---|---|

| EP | - | - | - | 100 |

| EP/4.4AlPi | 4.4 | 1.0 | - | 95.6 |

| EP/1PCM | - | - | 1.0 | 99.0 |

| EP/3PCM | - | - | 3.0 | 97.0 |

| EP/5PCM | - | - | 5.0 | 95.0 |

| EP/4.4AlPi/1PCM | 4.4 | 1.0 | 1.0 | 94.6 |

| EP/4.4AlPi/3PCM | 4.4 | 1.0 | 3.0 | 92.6 |

| EP/4.4AlPi/5PCM | 4.4 | 1.0 | 5.0 | 90.6 |

| EP/2.2AlPi/1.5PCM | 2.2 | 0.5 | 1.5 | 96.3 |

| 样品 | UL 94垂直燃烧测试 | ΔLOIc)/% | |||||

|---|---|---|---|---|---|---|---|

| 第一次有焰燃烧时间/s | 第二次有焰燃烧时间/s | 熔融滴落 | 垂直燃烧级别 | ||||

| EP | 火焰燃至夹具 | 火焰燃至夹具 | 是 | 无级别 | 24.6 | ⁃⁃ | ⁃⁃ |

| EP/2.2AlPi | 10.4 | 5.8 | 否 | V⁃1 | 35.1 | ⁃⁃ | ⁃⁃ |

| EP/4.4AlPi | 2.8 | 2.0 | 否 | V⁃0 | 38.0 | ⁃⁃ | ⁃⁃ |

| EP/1PCM | >60 | ⁃⁃ | 否 | 无级别 | 24.7 | ⁃⁃ | ⁃⁃ |

| EP/1.5PCM | >60 | ⁃⁃ | 否 | 无级别 | 25.9 | ⁃⁃ | ⁃⁃ |

| EP/3PCM | >60 | ⁃⁃ | 否 | 无级别 | 27.6 | ⁃⁃ | ⁃⁃ |

| EP/5PCM | 火焰燃至夹具 | 火焰燃至夹具 | 否 | 无级别 | 29.7 | ⁃⁃ | ⁃⁃ |

| EP/4.4AlPi/1PCM | 2.3 | 1.8 | 否 | V⁃0 | 39.5 | 38.1 | 1.4 |

| EP/4.4AlPi/3PCM | 0.8 | 1.1 | 否 | V⁃0 | 42.6 | 41.0 | 1.6 |

| EP/4.4AlPi/5PCM | 5.4 | 3.2 | 否 | V⁃0 | 42.5 | 43.1 | -0.6 |

| EP/2.2AlPi/1.5PCM | 6.4 | 3.2 | 否 | V⁃0 | 39.2 | 36.4 | 2.8 |

| 样品 | UL 94垂直燃烧测试 | ΔLOIc)/% | |||||

|---|---|---|---|---|---|---|---|

| 第一次有焰燃烧时间/s | 第二次有焰燃烧时间/s | 熔融滴落 | 垂直燃烧级别 | ||||

| EP | 火焰燃至夹具 | 火焰燃至夹具 | 是 | 无级别 | 24.6 | ⁃⁃ | ⁃⁃ |

| EP/2.2AlPi | 10.4 | 5.8 | 否 | V⁃1 | 35.1 | ⁃⁃ | ⁃⁃ |

| EP/4.4AlPi | 2.8 | 2.0 | 否 | V⁃0 | 38.0 | ⁃⁃ | ⁃⁃ |

| EP/1PCM | >60 | ⁃⁃ | 否 | 无级别 | 24.7 | ⁃⁃ | ⁃⁃ |

| EP/1.5PCM | >60 | ⁃⁃ | 否 | 无级别 | 25.9 | ⁃⁃ | ⁃⁃ |

| EP/3PCM | >60 | ⁃⁃ | 否 | 无级别 | 27.6 | ⁃⁃ | ⁃⁃ |

| EP/5PCM | 火焰燃至夹具 | 火焰燃至夹具 | 否 | 无级别 | 29.7 | ⁃⁃ | ⁃⁃ |

| EP/4.4AlPi/1PCM | 2.3 | 1.8 | 否 | V⁃0 | 39.5 | 38.1 | 1.4 |

| EP/4.4AlPi/3PCM | 0.8 | 1.1 | 否 | V⁃0 | 42.6 | 41.0 | 1.6 |

| EP/4.4AlPi/5PCM | 5.4 | 3.2 | 否 | V⁃0 | 42.5 | 43.1 | -0.6 |

| EP/2.2AlPi/1.5PCM | 6.4 | 3.2 | 否 | V⁃0 | 39.2 | 36.4 | 2.8 |

| 样品 | TTI/s | pk⁃HRR/ W·m-2 | THR /MJ·m-2 | CO产率(COY)/ kg·kg-1 | EHC/ MJ·kg-1 | MLR/ g·s-1 | pk⁃HRR/TTI/ kW·(m-2·s-1) | THE/TML /MJ·(m-2·g-1) |

|---|---|---|---|---|---|---|---|---|

| EP | 95 | 1357 | 68.0 | 0.07 | 35.1 | 20.9 | 14.3 | 2.95 |

| EP/3PCM | 69 | 1401 | 69.4 | 0.09 | 33.5 | 12.5 | 20.3 | 3.03 |

| EP/4.4AlPi | 68 | 765 | 45.1 | 0.14 | 26.0 | 13.4 | 11.3 | 2.74 |

| EP/4.4AlPi/3PCM | 67 | 533 | 40.2 | 0.15 | 24.2 | 10.2 | 8.0 | 2.20 |

| 样品 | TTI/s | pk⁃HRR/ W·m-2 | THR /MJ·m-2 | CO产率(COY)/ kg·kg-1 | EHC/ MJ·kg-1 | MLR/ g·s-1 | pk⁃HRR/TTI/ kW·(m-2·s-1) | THE/TML /MJ·(m-2·g-1) |

|---|---|---|---|---|---|---|---|---|

| EP | 95 | 1357 | 68.0 | 0.07 | 35.1 | 20.9 | 14.3 | 2.95 |

| EP/3PCM | 69 | 1401 | 69.4 | 0.09 | 33.5 | 12.5 | 20.3 | 3.03 |

| EP/4.4AlPi | 68 | 765 | 45.1 | 0.14 | 26.0 | 13.4 | 11.3 | 2.74 |

| EP/4.4AlPi/3PCM | 67 | 533 | 40.2 | 0.15 | 24.2 | 10.2 | 8.0 | 2.20 |

| 1 | 杨 晨, 唐晓东, 李晶晶, 等. 双酚A型环氧树脂合成技术进展 [J]. 中国塑料, 2023, 37(2): 106⁃112. |

| YANG C, TANG X D, LI J J, et al. Research progress in synthetic technology of bisphenol⁃a epoxy resin [J]. China Plastics, 2023, 37(2): 106⁃112. | |

| 2 | 姜思雨, 娄春华, 周永丽. 环氧树脂/棕榈酰氯改性玉米秸秆复合材料力学性能研究[J]. 中国塑料, 2022, 36(12): 44⁃49. |

| JIANG S Y, LOU C H, ZHOU Y L. Modification and applications of renewable biomass materials [J]. China Plastics, 2022, 36(12): 44⁃49. | |

| 3 | Zhuang J W, Lin Y F, An G P, et al. Steady superlubricity achieved by epoxy resin composite coatings containing polydimethylsiloxane [J]. Progress in Organic Coatings, 2023, 175: 107361. |

| 4 | Li Y, Bai Y S, Chen H, et al. Fabrication and evaluation of epoxy resin film adhesive with excellent heat resistance and potential flame retardance [J]. International Journal of Adhesion & Adhesives, 2023, 121: 103318. |

| 5 | Lee W J, Cha S H, Kim D H. Preparation and characterization of cardanol⁃based flame retardant for enhancing the flame retardancy of epoxy adhesives [J]. Polymers, 2022, 14: 5205. |

| 6 | Aljamal A, Szolnoki B, Marosi G. Improving thermal and flame retardant properties of sorbitol⁃based bioepoxy systems by phosphorus⁃based flame retardants [J]. Fire and Materials, 2022, 46: 605⁃614. |

| 7 | Lau S, Gonchikzhapov M, Kasper T, et al. Aluminum diethylphosphinate as a flame retardant for polyethylene: investigation of the pyrolysis and combustion behavior of PE/AlPi⁃mixtures [J]. Combustion and Flame, 2022, 240: 112006. |

| 8 | Tomiak F, Schoeffel A, Rathberger K. Expandable graphite, aluminum diethylphospinate and melamine polyphosphate as flame retarding system in glass fiber⁃reinforced PA6 [J]. Polymers, 2022, 14: 1 263. |

| 9 | Yuan Z, Wen H, Liu Y, et al. Synergy between piperazine pyrophosphate and aluminum diethylphosphinate in flame retarded acrylonitrile⁃butadiene⁃styrene copolymer [J]. Polymer Degradation and Stability, 2021, 190: 109639. |

| 10 | Si M M, Feng J, Hao J W, et al. Synergistic flame retardant effects and mechanisms of nano⁃Sb2O3 in combination with aluminum phosphinate in poly(ethylene terephthalate) [J]. Polymer Degradation and Stability, 2014, 100: 70⁃78. |

| 11 | Tomiak F, Schoeffel A, Rathberger K. A synergistic flame retardant system based on expandable graphite, aluminum (diethyl⁃)polyphospinate and melamine polyphosphate for polyamide 6 [J].Polymers, 2021, 13: 2 712. |

| 12 | Peng H, Zhou Y, Li Z S, et al. Percolation and catalysis effect of bamboo based active carbon on the thermal and flame retardancy properties of ethylene vinyl⁃acetate [J]. Journal of Applied Polymer Science, 2015, 132(34): 42 414. |

| 13 | 王 芳, 郝建薇, 李茁实, 等. 竹基多孔碳材料的制备及其协同阻燃环氧树脂研究[J]. 高分子学报, 2015(8): 897⁃905. |

| WANG F, HAO J W, LI Z S, et al. Preparation of bamboo⁃based porous carbon materials and their synergistic flame⁃retardant effect for epoxy resin [J]. Acta Polymerica Sinica, 2015(8): 897⁃905. | |

| 14 | Gu L Q, Qiu C, Qiu J H, et al. Preparation and characterization of DOPO⁃functionalized MWCNT and its high flame⁃retardant performance in epoxy nanocomposites [J]. Polymers, 2020, 12: 613. |

| 15 | Liu C, Li P, Xu Y J, et al. Nickel alginate⁃enhanced fire safety of aluminum diethylphosphinate on epoxy resin [J]. Journal of Applied Polymer Science, 2023, 140: 53 552. |

| 16 | Liu J Q, Xin Z X. Effect of sepiolite on properties of silicone rubber/melamine/starch/sepiolite flame retardant composites [J]. Journal of Applied Polymer Science, 2023, 140: 53 538. |

| 17 | 王 芳, 郝建薇, 李茁实, 等. 碳材料表面特性及形貌对阻燃环氧树脂燃烧和热解行为的影响[J]. 高分子学报, 2016(7): 860⁃870. |

| WANG F, HAO J W, Li Z S, et al. Effects of surface characteristics and morphology of carbon materials on combustion and thermal decomposition of flame retardant epoxy resin [J]. Acta Polymerica. Sinica, 2016(7): 860⁃870. | |

| 18 | Usta N J. Investigation of fire behavior of rigid polyurethane foams containing fly ash and intumescent flame retardant by using a cone calorimeter [J]. Journal of Applied Polymer Science, 2012, 124: 3 372⁃3 382. |

| 19 | Petrella R V. The assessment of full⁃scale fire hazards from cone calorimeter data [J]. Journal of Fire Sciences, 1994, 12: 14⁃43. |

| 20 | Lu S K, Liu J B, Zeng L J, et al. Preparation and characterization of cyclodextrin coated red phosphorus double⁃shell microcapsules and its application in flame retardant polyamide6 [J]. Polymers, 2022, 14:4 101. |

| 21 | Doğan M, Bayramli E. The flame retardant effect of aluminum phosphinate in combination with zinc borate, borophosphate, and nanoclay in polyamide-6 [J]. Fire Mater, 2014, 38: 92⁃99. |

| 22 | Xu B, Shao L S, Wang J Y, et al. Enhancement of the intumescent flame retardant efficiency in polypropylene by synergistic charring effect of a hypophosphite/cyclotetrasiloxane bi⁃group compound [J]. Polymer Degradation and Stability, 2020, 181: 109281. |

| 23 | 王建琪, 吴文辉, 冯大明. 电子能谱学(XPS/XAES/UPS)引论[M]. 北京: 国防工业出版社. 1992: 544, 546. |

| 24 | Biniak S, Szymański G, Siedlewski J, et al. The characterization of activated carbons with oxygen and nitrogen surface groups [J]. Carbon, 1997, 35(12): 1 799⁃1 810. |

| 25 | Ma C, Wang J L, Yuan Y, et al. An insight into gas phase flame retardant mechanisms of AHP versus AlPi in PBT: Online pyrolysis vacuum ultraviolet photoionization time⁃of⁃flight mass spectrometry [J]. Combustion and Flame, 2019, 209: 467⁃477. |

| 26 | Zhu P B, Xu M J, Li S, et al. Preparation and investigation of efficient flame retardant TPE composites with piperazine pyrophosphate/aluminum diethylphosphinate system [J]. Journal of Applied Polymer Science, 2020, 137: 47711. |

| 27 | Li H X, Ning N Y, Zhang L Q, et al. Different flame retardancy effects and mechanisms of aluminium phosphinate in PPO, TPU and PP [J]. Polymer Degradation and Stability, 2014, 105: 86⁃95. |

| 28 | Lau S, Atakan B. Isothermal pyrolysis investigation of aluminum diethylphosphinate mixed as a flame retardant additive into ultra⁃high molecular weight polyethylene [J]. Combustion and Flame, 2020, 222: 272⁃284. |

| [1] | 金清平 陈东哲. 纤维增强复合材料/混凝土组合梁界面连接与性能研究进展[J]. , 2023, 37(3): 64-70. |

| [2] | 杨晨, 唐晓东, 李晶晶, 冯雪峰, 曹晔飞, 高志强. 双酚A型环氧树脂合成技术进展[J]. 中国塑料, 2023, 37(2): 106-112. |

| [3] | 王芳 郝建薇. 竹基多孔碳协同二乙基次膦酸铝催化阻燃环氧树脂及作用机理研究[J]. , 2023, 37(10): 70-76. |

| [4] | 刘昊育, 辛菲, 杜家盈, 樊晓玲. 无卤阻燃聚酯复合材料研究进展[J]. 中国塑料, 2023, 37(1): 133-143. |

| [5] | 杨金, 陈鹏然, 高培鑫. DIDOPO与POSS/EG协同阻燃环氧树脂泡沫及机理研究[J]. 中国塑料, 2022, 36(9): 38-45. |

| [6] | 谭立钦, 刘伟区, 梁利岩, 王硕, 冯志强, 林家明. 含巯基聚硅氧烷改性环氧树脂的制备及性能[J]. 中国塑料, 2022, 36(7): 21-29. |

| [7] | 徐杰, 钟进福, 童晓茜, 李广富, 付栋梁, 李城城. 端羧基修饰单宁酸/没食子酸环氧树脂复合材料的制备与性能研究[J]. 中国塑料, 2022, 36(7): 44-50. |

| [8] | 衣惠君, 汤明, 张清怡, 摆音娜. 3D打印用光固化树脂产品性能研究[J]. 中国塑料, 2022, 36(5): 43-46. |

| [9] | 徐伟华, 郑宇, 沈向阳, 张炎, 刘桔文, 严石静. 不同POSS对磷⁃硅协同阻燃环氧树脂性能的影响[J]. 中国塑料, 2022, 36(4): 115-120. |

| [10] | 张祥凯, 王智敏, 谢建强. 生物质环氧树脂固化剂的研究进展[J]. 中国塑料, 2022, 36(2): 111-124. |

| [11] | 田保政. 烷基次膦酸盐阻燃剂复配体系的研究进展[J]. 中国塑料, 2022, 36(2): 197-208. |

| [12] | 刘振, 余云, 张孟航, 尹浏烨, 段雨霏, 侯桂香. 没食子酸环氧树脂/蓖麻油酸多胺体系固化动力学及性能[J]. 中国塑料, 2022, 36(2): 75-81. |

| [13] | 丁丁, 徐文总, 闫弘毅. 壳聚糖/ZIF⁃67杂化物的制备及其对环氧树脂阻燃抑烟性能的影响[J]. 中国塑料, 2022, 36(12): 31-37. |

| [14] | 姜思雨, 娄春华, 周永丽. 环氧树脂/棕榈酰氯改性玉米秸秆复合材料力学性能研究[J]. 中国塑料, 2022, 36(12): 44-49. |

| [15] | 张克宏, 褚承祥, 刘孝龙. 环氧树脂/纳米纤维素复合材料的制备与性能研究[J]. 中国塑料, 2022, 36(11): 67-72. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2