京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2

《中国塑料》编辑部 ©2008-2024 版权所有

地址:北京市海淀区阜成路11号 邮编:100048

编辑部:010-68985541 联系信箱:cp@plaschina.com.cn

广告部/发行部:010-68985253 本系统由北京玛格泰克科技发展有限公司设计开发

中国塑料 ›› 2023, Vol. 37 ›› Issue (12): 124-134.DOI: 10.19491/j.issn.1001-9278.2023.12.018

收稿日期:2023-10-05

出版日期:2023-12-26

发布日期:2023-12-26

通讯作者:

杨彪,教授,从事生物降解材料的改性及加工,ybiao@btbu.edu.cn基金资助:Received:2023-10-05

Online:2023-12-26

Published:2023-12-26

Contact:

YANG Biao

E-mail:ybiao@btbu.edu.cn

摘要:

从增强阻隔性的策略角度,分别就共聚、共混、填充复合、多层复合和构建表面阻隔涂层等5个方面,对可生物降解阻隔材料的相关研究进行了综述,并对未来的研发思路及其可行性进行了分析,以期为生物降解阻隔材料的开发提供有益的参考。

中图分类号:

王梓丞, 杨彪. 生物降解阻隔材料的研究进展[J]. 中国塑料, 2023, 37(12): 124-134.

WANG Zicheng, YANG Biao. Advances in biodegradable barrier materials[J]. China Plastics, 2023, 37(12): 124-134.

| 品种 | 熔点/℃ | 玻璃化转变 温度/℃ | 结晶度/ % | 断裂伸长率/ % |

|---|---|---|---|---|

| PLA | 176 | 60~65 | 10~40 | 4~10 |

| PGA | 220~240 | 35~40 | 46~52 | 16 |

| PVA | 230 | 75~85 | 30 | 77 |

| PPC | — | 25~45 | — | 837 |

| PBS | 115 | -30 | 35 | 150 |

| PBAT | 130 | -29.3 | 30 | 700 |

| PCL | 62 | -60 | 45 | 844 |

| PHB | 165~185 | 4~9 | 50~80 | 1 |

| PHBV | 175 | 3 | 57 | 4 |

| PHBH | 127 | -1 | 27 | 400 |

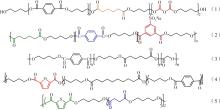

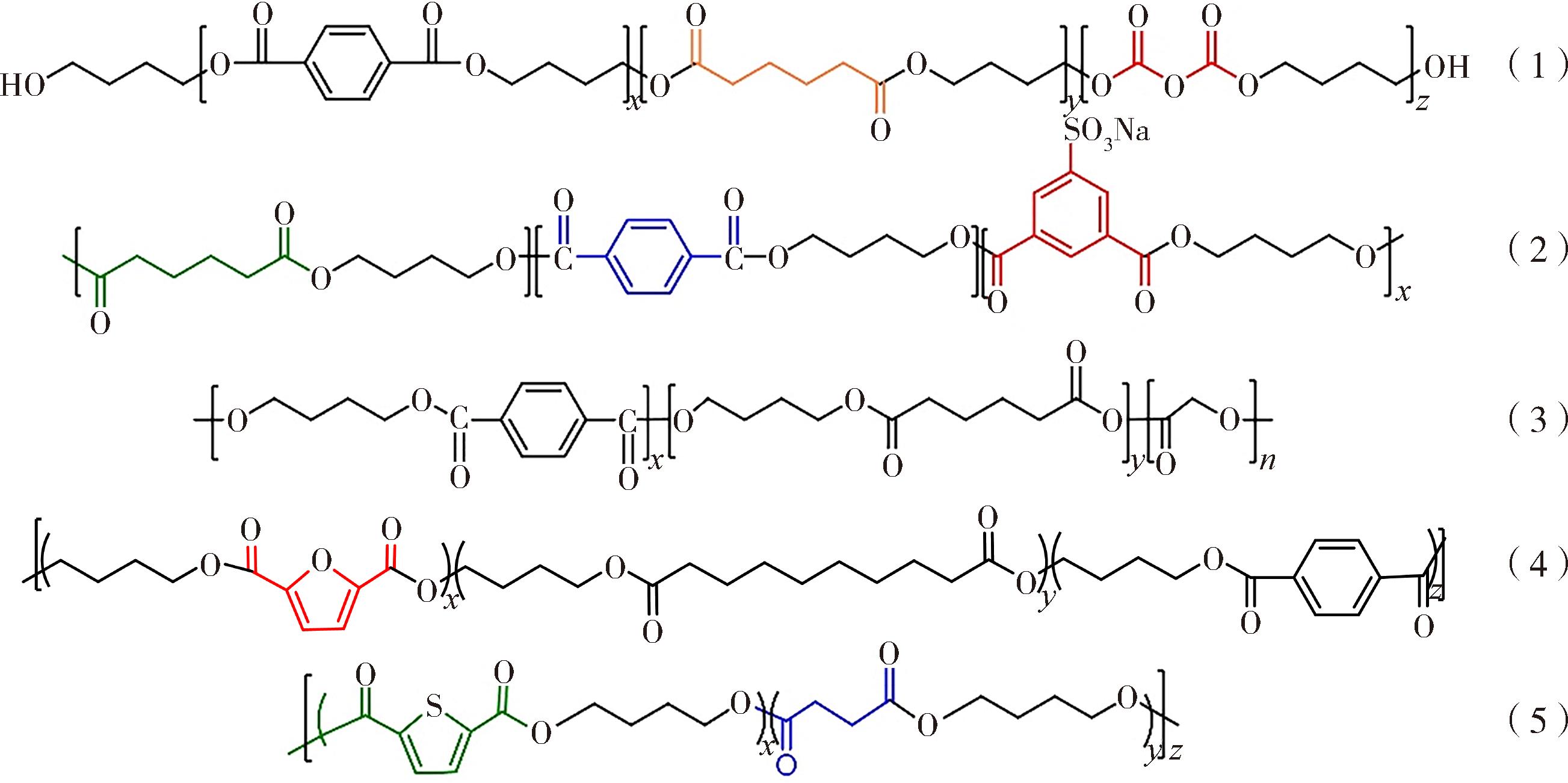

| 品种 | 熔点/℃ | 玻璃化转变 温度/℃ | 结晶度/ % | 断裂伸长率/ % |

|---|---|---|---|---|

| PLA | 176 | 60~65 | 10~40 | 4~10 |

| PGA | 220~240 | 35~40 | 46~52 | 16 |

| PVA | 230 | 75~85 | 30 | 77 |

| PPC | — | 25~45 | — | 837 |

| PBS | 115 | -30 | 35 | 150 |

| PBAT | 130 | -29.3 | 30 | 700 |

| PCL | 62 | -60 | 45 | 844 |

| PHB | 165~185 | 4~9 | 50~80 | 1 |

| PHBV | 175 | 3 | 57 | 4 |

| PHBH | 127 | -1 | 27 | 400 |

| 分类 | 品种 | 氧透过率(OTR)/ cm3·m-2·d-1·Pa-1 | 水蒸气透过率(WVTR)/ g·m-2·d-1 |

|---|---|---|---|

| 生物降解材料 | 纤维素 | 4×10⁃3[ | 8×103 [ |

| 壳聚糖 | 5.97×10⁃3[ | 275 [ | |

| 淀粉 | 394.48[ | 592 [ | |

| PLA | 180[ | 35.5 [ | |

| PGA | 1[ | 10 [ | |

| PVA | 1.83×10⁃5[ | 190 [ | |

| PPC | 20[ | 68.8 [ | |

| PBS | 490[ | 175 [ | |

| PBAT | 375.2[ | 884.08 [ | |

| PCL | 1 100[ | 783 [ | |

| PHB | 301.2[ | 298.7 [ | |

| PHBV | 420[ | 310 [ | |

| PHBH | 35[ | 38 [ | |

| 常规塑料 | PET | 1.54×10⁃4[ | 4.2 [ |

| PA 6 | 4.3×10⁃4[ | 530 [ | |

| PVC | 0.94×10⁃4[ | 5.2 [ | |

| PP | 2.8×10⁃2[ | 3 [ | |

| PE | 5.3×10⁃2[ | 11.4 [ |

| 分类 | 品种 | 氧透过率(OTR)/ cm3·m-2·d-1·Pa-1 | 水蒸气透过率(WVTR)/ g·m-2·d-1 |

|---|---|---|---|

| 生物降解材料 | 纤维素 | 4×10⁃3[ | 8×103 [ |

| 壳聚糖 | 5.97×10⁃3[ | 275 [ | |

| 淀粉 | 394.48[ | 592 [ | |

| PLA | 180[ | 35.5 [ | |

| PGA | 1[ | 10 [ | |

| PVA | 1.83×10⁃5[ | 190 [ | |

| PPC | 20[ | 68.8 [ | |

| PBS | 490[ | 175 [ | |

| PBAT | 375.2[ | 884.08 [ | |

| PCL | 1 100[ | 783 [ | |

| PHB | 301.2[ | 298.7 [ | |

| PHBV | 420[ | 310 [ | |

| PHBH | 35[ | 38 [ | |

| 常规塑料 | PET | 1.54×10⁃4[ | 4.2 [ |

| PA 6 | 4.3×10⁃4[ | 530 [ | |

| PVC | 0.94×10⁃4[ | 5.2 [ | |

| PP | 2.8×10⁃2[ | 3 [ | |

| PE | 5.3×10⁃2[ | 11.4 [ |

| 分类 | 集体 | 填料 | 氧气透过率/氧气渗透系数* | 气透过率/水蒸气渗透系数* | 参考文献 |

|---|---|---|---|---|---|

| 天然矿物 | 壳聚糖 | 有机蒙脱土(5 %) | 1.12×10-16 m3/(s·m·Pa)* | 1.24×10-11 g/(s·m·Pa)* | [ |

| 玉米淀粉 | 纳米蒙脱土(1 %) | 12.31 g·mm/(m·h·kPa)* | [ | ||

| PBS | 纳米黏土(3 %) | 119.87 g/(m2·d) | [ | ||

| PLA | 纳米黏土(4 %) | 0.192 g·cm/(m2·d) | [ | ||

| PBAT | 有机蒙脱土(13 %) | 7.1×10-12 g·m/(Pa·s·m2)* | [ | ||

| PBAT | 云母(2 %) | 119.87 g/(m2·d) | [ | ||

| 生物基纳米材料 | PVA | 纤维素纳米晶体(10 %) | 104.9 g/(m2·d) | [ | |

| 橙子废料 | 纤维素纳米纤维(6 %) | 1.02×10-7 g/(Pa·h·m)* | [ | ||

| 玉米淀粉 | 纤维素纳米纤维(15 %) | 501.4 g/(m2·d) | [ | ||

| PBS | 甲壳素纳米晶体(5 %) | 23.8 cm3/(m2·d) | 30.8 g/(m2·d) | [ | |

| PBS | 香蕉淀粉纳米晶体(5 %) | 60 cm3/(m2·d) | 259 g/(m2·d) | [ | |

| 碳基 | 树胶 | 氧化石墨烯(1 %) | 1.37×10-4 cm3/(m2·d·Pa) | [ | |

| PLA | 氧化石墨烯(2 %) | 2.18×10-18 kg·m/(m2 s Pa)* | 12.31 g·mm/(m·h·kPa)* | [ | |

| 无机氧化物 | PBAT/PLA | 纳米二氧化硅(0.5 %) | 5.179×10-3 cm3/(m2·d·Pa) | 187 g/(m2·d) | [ |

| PLA/PBS | 氧化硅基Janus纳米片(0.5 %) | 0.63×10-15 cm3·cm/(cm2·s·Pa)* | [ | ||

| PVA | 改性纳米二氧化硅(4 %) | 0.21 g·mm/(m·d·kPa)* | [ | ||

| PBS | 纳米氧化锌(4 %) | 41.8 cm3/(m2·d) | 49.75 g/(m2·d) | [ | |

| 壳聚糖 | 纳米二氧化钛(0.3 %) | 2.31 cm3/(m2·d) | 1.64×103 g/(m2·d) | [ | |

| PBAT/PLA | 纳米二氧化硅(0.5 %) | 5.179×10-3 cm3/(m2·d·Pa) | 187 g/(m2·d) | [ |

| 分类 | 集体 | 填料 | 氧气透过率/氧气渗透系数* | 气透过率/水蒸气渗透系数* | 参考文献 |

|---|---|---|---|---|---|

| 天然矿物 | 壳聚糖 | 有机蒙脱土(5 %) | 1.12×10-16 m3/(s·m·Pa)* | 1.24×10-11 g/(s·m·Pa)* | [ |

| 玉米淀粉 | 纳米蒙脱土(1 %) | 12.31 g·mm/(m·h·kPa)* | [ | ||

| PBS | 纳米黏土(3 %) | 119.87 g/(m2·d) | [ | ||

| PLA | 纳米黏土(4 %) | 0.192 g·cm/(m2·d) | [ | ||

| PBAT | 有机蒙脱土(13 %) | 7.1×10-12 g·m/(Pa·s·m2)* | [ | ||

| PBAT | 云母(2 %) | 119.87 g/(m2·d) | [ | ||

| 生物基纳米材料 | PVA | 纤维素纳米晶体(10 %) | 104.9 g/(m2·d) | [ | |

| 橙子废料 | 纤维素纳米纤维(6 %) | 1.02×10-7 g/(Pa·h·m)* | [ | ||

| 玉米淀粉 | 纤维素纳米纤维(15 %) | 501.4 g/(m2·d) | [ | ||

| PBS | 甲壳素纳米晶体(5 %) | 23.8 cm3/(m2·d) | 30.8 g/(m2·d) | [ | |

| PBS | 香蕉淀粉纳米晶体(5 %) | 60 cm3/(m2·d) | 259 g/(m2·d) | [ | |

| 碳基 | 树胶 | 氧化石墨烯(1 %) | 1.37×10-4 cm3/(m2·d·Pa) | [ | |

| PLA | 氧化石墨烯(2 %) | 2.18×10-18 kg·m/(m2 s Pa)* | 12.31 g·mm/(m·h·kPa)* | [ | |

| 无机氧化物 | PBAT/PLA | 纳米二氧化硅(0.5 %) | 5.179×10-3 cm3/(m2·d·Pa) | 187 g/(m2·d) | [ |

| PLA/PBS | 氧化硅基Janus纳米片(0.5 %) | 0.63×10-15 cm3·cm/(cm2·s·Pa)* | [ | ||

| PVA | 改性纳米二氧化硅(4 %) | 0.21 g·mm/(m·d·kPa)* | [ | ||

| PBS | 纳米氧化锌(4 %) | 41.8 cm3/(m2·d) | 49.75 g/(m2·d) | [ | |

| 壳聚糖 | 纳米二氧化钛(0.3 %) | 2.31 cm3/(m2·d) | 1.64×103 g/(m2·d) | [ | |

| PBAT/PLA | 纳米二氧化硅(0.5 %) | 5.179×10-3 cm3/(m2·d·Pa) | 187 g/(m2·d) | [ |

| 1 | Zhao X Y, Cornish K, Vodovotz Y. Narrowing the gap for bioplastic use in food packaging: an update [J]. Environmental Science & Technology, 2020, 54(8): 4 712⁃4 732. |

| 2 | Conk R J, Hanna S, Shi J X, et al. Catalytic deconstruction of waste polyethylene with ethylene to form propylene [J]. Science, 2022, 377(6614): 1 561⁃1 566. |

| 3 | Haussler M, Eck M, Rothauer D, et al. Closed⁃loop recycling of polyethylene⁃like materials [J]. Nature, 2021, 590(7846): 423⁃427. |

| 4 | Sullivan K P, Werner A Z, Ramirez K J, et al. Mixed plastics waste valorization through tandem chemical oxidation and biological funneling [J]. Science, 2022, 378(6616): 207⁃211. |

| 5 | Guzman⁃Puyol S, Hierrezuelo J, Benitez J J, et al. Transparent, UV⁃blocking, and high barrier cellulose⁃based bioplastics with naringin as active food packaging materials [J]. International Journal of Biological Macromolecules, 2022, 209 (Part B): 1 985⁃1 994. |

| 6 | Zhu Q H, Tan J H, Li D D, et al. Cross⁃linked chitosan/tannin extract as a biodegradable and repulpable coating for paper with excellent oil⁃resistance, gas barrier and UV⁃shielding [J]. Progress in Organic Coatings, 2023, 176: 107 399⁃107 409. |

| 7 | Wen H T, Tang D B, Lin Y S, et al. Enhancement of water barrier and antimicrobial properties of chitosan/gelatin films by hydrophobic deep eutectic solvent [J]. Carbohydrate Polymers, 2023, 303: 120 435⁃120 445. |

| 8 | Chavan P, Sinhmar A, Sharma S, et al. Nanocomposite starch films: a new approach for biodegradable packaging materials [J]. Starch⁃Starke, 2022, 74(5⁃6): 10.1002/star.202100302. |

| 9 | Singh S, Sharanagat V S, Desai S, et al. Interaction of pulsed electric modified elephant foot yam (amorphophallus paeoniifolius) starch and polyvinyl alcohol to enhance the mechanical and barrier properties of film [J]. Starch⁃Starke, 2023, 75(5/6): 10.1002/star.202200229. |

| 10 | de Beukelaer H, Hilhorst M, Workala Y, et al. Overview of the mechanical, thermal and barrier properties of biobased and/or biodegradable thermoplastic materials [J]. Polymer Testing, 2022, 116: 107 803⁃107 811. |

| 11 | Thiyagu T T, Kumar J V S P, Gurusamy P, et al. Effect of cashew shell biomass synthesized cardanol oil green compatibilizer on flexibility, barrier, thermal, and wettability of PLA/PBAT biocomposite films [J]. Biomass Conversion and Biorefinery, 2021: 11 841⁃11 851. |

| 12 | Yamane K, Sato H, Ichikawa Y, et al. Development of an industrial production technology for high⁃molecular⁃weight polyglycolic acid [J]. Polymer Journal, 2014, 46(11): 769⁃775. |

| 13 | 朱清梅, 陈秀琼, 李东泽, 等. 食品软包装用透明高阻隔涂料:PVA涂料研究进展 [J]. 精细化工, 2022, 39(09): 1 729⁃1 738+1 746. |

| ZHU Q M, CHEN X Q, LI D Z, et al. Transparent high barrier coatings for food flexible packaging:research progress on PVA coatings[J]. Fine Chemicals, 2022, 39(9): 1 729‐1 738+1 746. | |

| 14 | Nguyen S V, Lee B K. PVA/CNC/TiO(2) nanocomposite for food⁃packaging: Improved mechanical, UV/water vapor barrier, and antimicrobial properties [J]. Carbohydrate Polymers, 2022, 298: 120 064⁃120 074. |

| 15 | Lee D Y, Kim K Y, Cho M, et al. Fabrication and Characterization of Environmentally Friendly PLA/PPC/PLA Multilayer Film [J]. Polymer⁃Korea, 2013, 37(2): 249⁃253. |

| 16 | Wang X Y, Weng Y X, Wang W, et al. Modification of poly(propylene carbonate) with chain extender ADR⁃4368 to improve its thermal, barrier, and mechanical properties [J]. Polymer Testing, 2016, 54: 301⁃307. |

| 17 | Vassallo E, Pedroni M, Aloisio M, et al. Plasma deposition to improve barrier performance of biodegradable and recyclable substrates intended for food packaging [J]. Plasma, 2022, 5(4): 451⁃461. |

| 18 | Charlon S, Follain N, Chappey C, et al. Improvement of barrier properties of bio⁃based polyester nanocomposite membranes by water⁃assisted extrusion[J]. Journal of Membrane Science, 2015, 496: 185⁃198. |

| 19 | Yang F, Zhang C L, Ma Z R, et al. In situ formation of microfibrillar PBAT in PGA films: an effective way to robust barrier and mechanical properties for fully biodegradable packaging films [J]. ACS Omega, 2022, 7(24): 21 280⁃21 290. |

| 20 | Cheng P F, Liang M, Yun X Y, et al. Biodegradable blend films of poly(epsilon⁃caprolactone)/poly(propylene carbonate) for shelf life extension of whole white button mushrooms [J]. Journal of Food Science and Technology, 2022, 59(1): 144⁃156. |

| 21 | Kakroodi A R, Kazemi Y, Rodrigue D, et al. Facile production of biodegradable PCL/PLA in situ nanofibrillar composites with unprecedented compatibility between the blend components [J]. Chemical Engineering Journal, 2018, 351: 976⁃984. |

| 22 | 张波波. 聚羟基丁酸酯/纳米纤维素复合薄膜的制备与性能研究 [D]. 南宁: 广西大学, 2019. |

| 23 | Malmir S, Montero B, Rico M, et al. Morphology, thermal and barrier properties of biodegradable films of poly (3⁃hydroxybutyrate⁃co⁃3⁃hydroxyvalerate) containing cellulose nanocrystals [J]. Composites Part A⁃Applied Science and Manufacturing, 2017, 93: 41⁃48. |

| 24 | 李潇潇, 徐晓晴, 闫 昫, 等. PEG200增塑改性ACNs/MMT/PHBH纳米复合包装膜 [J]. 包装工程, 2021, 42(7): 91⁃98. |

| LI X X, XU X Q, YAN X, et al. PEG200 plasticized mod‐ ified ACNs/MMT/PHBH nanocomposite packaging film [J]. Packaging engineering, 2021, 42(7): 91‐98. | |

| 25 | Hu Y, Wang Z C, Zhang X, et al. Development of whey protein isolate/chitosan/microcrystalline cellulose‐based bilayer films using surface‐pretreated polyethylene terephthalate substrate [J]. Journal of Food Process Engineering, 2020, 44(1): e13600. |

| 26 | Lian S Y, Zhang J T, Wang J Y, et al. A model for adsorption and diffusion in water vapor barrier films [J]. Physica Status Solidi B⁃Basic Solid State Physics, 2021, 258(6): 2000609. |

| 27 | Pramanik N K, Katamgari I, Dey A, et al. Electron beam irradiation on monolayer plastic packaging films: Studies on physico⁃mechanical and thermal properties [J]. Packaging Technology and Science, 2021, 34(8): 475⁃483. |

| 28 | Zhu A P, Cai A Y, Zhang J, et al. PMMA⁃grafted⁃silica/PVC nanocomposites: mechanical performance and barrier properties [J]. Journal of Applied Polymer Science, 2008, 108(4): 2 189⁃2 196. |

| 29 | Zheng W, Kobayashi Y, Hirata K, et al. Suppression of radiation⁃induced oxidation of polymers by sputtered silicon oxide coating [J]. Journal of Applied Polymer Science, 2002, 83(1): 186⁃190. |

| 30 | Mooninta S, Poompradub S, Prasassarakich P. Packaging film of PP/LDPE/PLA/clay composite: physical, barrier and degradable properties [J]. Journal of Polymers and the Environment, 2020, 28(12): 3 116⁃3 128. |

| 31 | Maji T, Tsimenidis K, Nagarajan R, et al. One⁃layer water vapor poly(olefin) barriers compete metal sputtering onto flexible substrates [J]. Polymer, 2020, 197: 122487. |

| 32 | 董志远, 王克俭. 高阻隔性包装材料发展综述 [J]. 塑料包装, 2018, 28(2): 1⁃4. |

| DONG Z Y, WANG K J. Areview of the development of high‐barrier packaging material [J]. Plastic Packaging, 2018,28(2):1‐4. | |

| 33 | 谢新艺, 薛华育. 高阻隔性塑料材料在食品包装中的应用 [J]. 塑料包装, 2008(1): 42⁃44. |

| Xie X Y, Xue H Y. Application of high barrier plastic materials in food packaging [J]. Plastic Packaging, 2008 (1): 42‐44. | |

| 34 | Trinh B M, Chang B P, Mekonnen T H. The barrier properties of sustainable multiphase and multicomponent packaging materials: A review [J]. Progress in Materials Science, 2023, 133: 101 071⁃101 112. |

| 35 | Tyuftin A A, Kerry J P. Gelatin films: Study review of barrier properties and implications for future studies employing biopolymer films [J]. Food Packaging and Shelf Life, 2021, 29: 100 688⁃100 698. |

| 36 | Hu H, Tian Y, Wang J G, et al. Enhanced degradation and gas barrier of PBAT through composition design of aliphatic units [J]. Polymer Degradation and Stability, 2022, 195: 109 795⁃109 805. |

| 37 | Huang F F, Wu L B, Li B G. Sulfonated biodegradable PBAT copolyesters with improved gas barrier properties and excellent water dispersibility: From synthesis to structure⁃property [J]. Polymer Degradation and Stability, 2020, 182: 109391 |

| 38 | Wang Y N, Yang H C, Li B J, et al. Poly(butylene adipate/terephthalate⁃co⁃glycolate) copolyester synthesis based on methyl glycolate with improved barrier properties: from synthesis to structure⁃property [J]. International Journal of Molecular Sciences, 2022, 23(19): 11 074⁃11 090. |

| 39 | Feng Y, Li Y C, Ye X M, et al. Synthesis and characterization of 2,5⁃furandicarboxylic acid poly(butanediol sebacate⁃butanediol) terephthalate (PBSeT) segment copolyesters with excellent water vapor barrier and good mechanical properties [J]. Journal of Materials Science, 2022, 57(24): 10 997⁃11 012. |

| 40 | Zhang X Q, Wang J G, Wang Q F, et al. New biodegradable polyesters synthesized from 2,5⁃thiophenedicarboxylic acid with excellent gas barrier properties [J]. Polymer Degradation and Stability, 2022, 205: 110 148⁃110 160. |

| 41 | 张田伟, 梁嘉欣, 岳双双, 等. 可生物降解的半芳香聚酯聚碳酸丙烯酯共聚物/聚己二酸⁃对苯二甲酸丁二酯共混物的制备及性能表征[J]. 高分子学报, 2023, 54(8): 1 144⁃1 154. |

| ZHANG T W, LIANG J X, YUE S S, et al. Preparation and characterization of biodegradable semi‐aromatic polyester polypropylene carbonate copolymer/polyadipic acid‐butylene terephthalate blend [J]. Acta Polymer Sinica, 2023, 54(8): 1 144‐1 154. | |

| 42 | Duan R T, He Q X, Dong X, et al. Renewable sugar⁃based diols with different rigid structure: comparable investigation on improving poly(butylene succinate) performance [J]. ACS Sustainable Chemistry & Engineering, 2016, 4(1): 350⁃362. |

| 43 | Guidotti G, Soccio M, Siracusa V, et al. Novel random PBS⁃based copolymers containing aliphatic side chains for sustainable flexible food packaging [J]. Polymers, 2017, 9(12): 724. |

| 44 | Ali F B, Kang D J, Kim M P, et al. Synthesis of biodegradable and flexible, polylactic acid based, thermoplastic polyurethane with high gas barrier properties [J]. Polymer International, 2014, 63(9): 1 620⁃1 626. |

| 45 | 刘庆玉, 王华平, 吉 鹏, 等. 热塑性淀粉共混改性PBAT纤维的制备及其性能研究[J]. 合成纤维工业, 2023, 46(2): 1⁃7. |

| LIU Q Y, WANG H P, JI P, et al. Preparation and prop‐ erties of thermoplastic starch blended modified PBAT fibers [J]. Synthetic Fiber Industry, 2023, 46(2): 1‐7. | |

| 46 | Wang Z P, Tian H L, Wang X Y, et al. Study on thermal, rheological, mechanical, morphological, and barrier properties of poly(butylene adipate⁃co⁃terephthalate)/thermoplastic starch/poly(propylene carbonate) biodegradable blown films [J]. Journal of Thermal Analysis and Calorimetry, 2022, 148: 1 853⁃1 865. |

| 47 | 王明明, 关二旗, 李萌萌, 等. 淀粉含量和直链与支链比例对淀粉基可降解薄膜的性能影响及土壤降解研究 [J]. 河南工业大学学报(自然科学版), 2022, 43(5): 68⁃76+101. |

| WANG M M, GUAN E Q, LI M M, et al. Effects of starch content and ratio of linear chain to branched chain on the performance of starch‐based degradable films and soil degradation [J]. Journal of Henan University of Technology(Natural Science Edition), 2022, 43(5): 68‐76+101. | |

| 48 | Akhir M A M, Zubir S A, Mariatti J. Effect of different starch contents on physical, morphological, mechanical, barrier, and biodegradation properties of tapioca starch and poly(butylene adipate⁃co⁃terephthalate) blend film [J]. Polymers for Advanced Technologies, 2022, 34: 717⁃730. |

| 49 | 徐 璐, 袁 龙, 陆 冲, 等. EVA⁃g⁃GMA的制备及其对PLA/PHBV共混物性能的影响 [J]. 材料科学与工程学报, 2017, 35(5): 768⁃774. |

| XU L, YUAN L, LU C, et al. Preparation of EVA ‐ g ‐ GMA and its effect on the properties of PLA/PHBV blends[J]. Chinese Journal of Materials Science and Engineering, 2017, 35(5): 768‐774. | |

| 50 | Gao F X, Cai Y, Liu S J, et al. High⁃performance biodegradable PBAT/PPC composite film through reactive compatibilizer [J]. Chinese Journal of Polymer Science, 2023, 41(7): 1 051⁃1 058. |

| 51 | 赵美艳, 李 立, 陈建康. 相容剂在淀粉复合膜中的研究及展望 [J]. 食品与发酵工业, 2021, 47(20): 312⁃318. |

| ZHAO M Y, LI L, CHEN J K. Research and prospect of compatibilizers in starch composite membranes [J]. Food & Fermentation Industry, 2021, 47(20): 312⁃318. | |

| 52 | Eceolaza S, Sangroniz A, del Rio J, et al. Improving the barrier character of poly(caprolactone): Transport properties and free volume of immiscible blends [J]. Journal of Applied Polymer Science, 2019, 136(40): 48 018⁃48 029. |

| 53 | Sangroniz A, Sangroniz L, Aranburu N, et al. Blends of biodegradable poly(butylene adipate⁃co⁃terephthalate) with poly (hydroxi amino ether) for packaging applications: Miscibility, rheology and transport properties [J]. European Polymer Journal, 2018, 105: 348⁃358. |

| 54 | Sangroniz A, Sangroniz L, Gonzalez A, et al. Improving the barrier properties of a biodegradable polyester for packaging applications [J]. European Polymer Journal, 2019, 115: 76⁃85. |

| 55 | 狄莹莹, 任鹏刚, 谭温珍. 纳米片层填充型高阻隔性复合薄膜研究进展 [J]. 合成纤维工业, 2018, 41(6): 59⁃63. |

| DI Y Y, REN P G, TAN W Z. Research progress of nanosheet layer filled high barrier composite films [J].Synthetic Fiber Industry, 2018, 41(6): 59⁃63. | |

| 56 | Tamer Y B. Development of citric acid crosslinked biodegradable chitosan/hydroxyethyl cellulose/organo⁃modified nanoclay composite films as sustainable food packaging materials [J]. Polymer⁃Plastics Technology and Materials, 2023, 62(9): 1 138⁃1 156. |

| 57 | Peres L G S, Malafatti J O D, Bernardi B, et al. Biodegradable starch sachets reinforced with montmorillonite for packing ZnO nanoparticles: solubility and Zn2+ ions release [J]. Journal of Polymers and the Environment, 2023, 31: 2 388⁃2 398. |

| 58 | Taleb K, Saidi⁃Besbes S, Pillin I, et al. Biodegradable poly(butylene succinate) nanocomposites based on dimeric surfactant organomodified clays with enhanced water vapor barrier and mechanical properties [J]. ACS Omega, 2022, 7(47): 43 254⁃43 264. |

| 59 | Scarfato P, Di Maio L, Milana M R, et al. Performance properties, lactic acid specific migration and swelling by simulant of biodegradable poly(lactic acid)/nanoclay multilayer films for food packaging [J]. Food Additives and Contaminants Part A⁃Chemistry Analysis Control Exposure & Risk Assessment, 2017, 34(10): 1 730⁃1 742. |

| 60 | Li J X, Lai L, Wu L B, et al. Enhancement of water vapor barrier properties of biodegradable poly(butylene adipate⁃co⁃terephthalate) films with highly oriented organomontmorillonite [J]. ACS Sustainable Chemistry & Engineering, 2018, 6(5): 6 654⁃6 662. |

| 61 | Wang Y, Liu Q, Zhen Z C, et al. Effects of mica modification with ethylene⁃vinyl acetate wax on the water vapor barrier and mechanical properties of poly⁃(butylene adipate⁃co⁃terephthalate) nanocomposite films [J]. Journal of Applied Polymer Science, 2021, 138(26): e50610. |

| 62 | Mousavi Kalajahi S E, Alizadeh A, Hamishehkar H, et al. Orange juice processing waste as a biopolymer base for biodegradable film formation reinforced with cellulose nanofiber and activated with nettle essential oil [J]. Journal of Polymers and the Environment, 2021, 30(1): 258⁃269. |

| 63 | Reichert A A, Sa M R, de Freitas T C, et al. Barrier, mechanical and morphological properties of biodegradable films based on corn starch incorporated with cellulose obtained from pineapple crowns [J]. Journal of Natural Fibers, 2022, 19(14): 8 541⁃8 554. |

| 64 | Xu J W, Manepalli P H, Zhu L J, et al. Morphological, barrier and mechanical properties of films from poly (butylene succinate) reinforced with nanocrystalline cellulose and chitin whiskers using melt extrusion [J]. Journal of Polymer Research, 2019, 26(8): 188. |

| 65 | Saeng⁃on J, Aht⁃Ong D. Compatibility of banana starch nanocrystals/poly(butylene succinate) bio⁃nanocomposite packaging films [J]. Journal of Applied Polymer Science, 2018, 135(43): 46 836⁃46 854. |

| 66 | Venkateshaiah A, Cheong J Y, Habel C, et al. Tree gum⁃graphene oxide nanocomposite films as gas barriers [J]. ACS Applied Nano Materials, 2020, 3(1): 633⁃640. |

| 67 | Ahmed J, Mulla M Z, Vahora A, et al. Morphological, barrier and thermo⁃mechanical properties of high⁃pressure treated polylactide graphene oxide reinforced composite films [J]. Food Packaging and Shelf Life, 2021, 29. |

| 68 | 何金凤, 张 明, 林勤保, 等. 纳米成分对PLA/PBAT生物可降解薄膜阻隔性能及其中爽滑剂芥酸酰胺迁移的影响 [J]. 塑料工业, 2018, 46(11): 76⁃80+94. |

| HE J F, ZHANG M, LIN Q B, et al. Effect of nanoconstituents on the barrier properties of PLA/PBAT biodegradable films and the migration of the slippery agent erucamide [J]. Plastics Industry, 2018, 46(11): 76⁃80+94. | |

| 69 | Zhang M, Jiang C, Wu Q, et al. Poly(lactic acid)/Poly(butylene succinate) (PLA/PBS) layered composite gas barrier membranes by anisotropic janus nanosheets compartibilizers [J]. ACS Macro Letters, 2022, 11(5): 657⁃662. |

| 70 | Lara B R B, de Andrade P S, Guimaraes M, et al. Novel whey protein Isolate/polyvinyl biocomposite for packaging: improvement of mechanical and water barrier properties by incorporation of nano⁃silica [J]. Journal of Polymers and the Environment, 2021, 29(8): 2 397⁃2 408. |

| 71 | Petchwattana N, Covavisaruch S, Wibooranawong S, et al. Antimicrobial food packaging prepared from poly (butylene succinate) and zinc oxide [J]. Measurement, 2016, 93: 442⁃448. |

| 72 | Perera K Y, Sharma S, Duffy B, et al. An active biodegradable layer⁃by⁃layer film based on chitosan⁃alginate⁃TiO2 for the enhanced shelf life of tomatoes [J]. Food Packaging and Shelf Life, 2022, 34: 100971. |

| 73 | 侯 婷. 玉米醇溶蛋白/纳米二氧化硅复合膜的超声波制备技术研究 [D]. 镇江: 江苏大学, 2021. |

| 74 | 黄 睿, 李小全, 卞福萍, 等. 功能化纳米纤维素复合PLA/PBAT薄膜的制备及性能 [J]. 精细化工, 2023, 40(6): 1 253⁃1 263. |

| HUANG R, LI X Q, BIAN F P, et al. Preparation and properties of functionalized nanocellulose composite PLA/PBAT films[J]. Fine Chemicals, 2023, 40(6): 1 253⁃1 263. | |

| 75 | 王爽爽. 聚乳酸基可降解多层复合膜及其在冷鲜肉包装中的应用 [D]. 呼和浩特: 内蒙古农业大学, 2015. |

| 76 | 许思兰, 许国志, 孙 辉. PBAT/PPC多层共挤薄膜的制备及其阻透性能研究 [J]. 中国塑料, 2016, 30(3): 38⁃42. |

| XU S L, XU G Z, SUN H. Preparation of PBAT/PPC multi⁃layer co⁃extrusion film and its permeability resistance [J]. China Plastics, 2016, 30(3): 38⁃42. | |

| 77 | Chang C C, Trinh B M, Mekonnen T H. Robust multiphase and multilayer starch/polymer (TPS/PBAT) film with simultaneous oxygen/moisture barrier properties [J]. Journal of Colloid and Interface Science, 2021, 593: 290⁃303. |

| 78 | Rhim J W, Mohanty K A, Singh S P, et al. Preparation and properties of biodegradable multilayer films based on soy protein isolate and poly(lactide) [J]. Industrial & Engineering Chemistry Research, 2006, 45(9): 3 059⁃3 066. |

| 79 | Gao Y Q, Picot O T, Tu W, et al. Multilayer coextrusion of graphene polymer nanocomposites with enhanced structural organization and properties [J]. Journal of Applied Polymer Science, 2018, 135(13): 46 041⁃46 052. |

| 80 | Thellen C, Cheney S, Ratto J A. Melt processing and characterization of polyvinyl alcohol and polyhydroxyalkanoate multilayer films [J]. Journal of Applied Polymer Science, 2013, 127(3): 2 314⁃2 324. |

| 81 | Hamdani S S, Li Z, Rolland E, et al. Barrier and mechanical properties of biodegradable paper bilayer⁃coated with plasticized starch and zein [J]. Journal of Applied Polymer Science, 2023, 140(8): e53440. |

| 82 | Jing X, Li X, Jiang Y F, et al. Degradable collagen/sodium alginate/polyvinyl butyral high barrier coating with water/oil⁃resistant in a facile and effective approach [J]. Carbohydrate Polymers, 2022, 278: 118 962⁃118 972. |

| 83 | Chi K, He J, Lin W S, et al. Electrostatically complexed natural polysaccharides as aqueous barrier coatings for sustainable and recyclable fiber⁃based packaging [J]. ACS Applied Materials&Interfaces, 2023, 15(9): 12 248⁃12 260. |

| 84 | Zhang T, Yu Q Y, Fang L L, et al. y All⁃organic multilayer coatings for advanced poly(lactic acid) films with high oxygen barrier and excellent antifogging properties [J]. ACS Applied Polymer Materials, 2019, 1(12): 3 470⁃3 476. |

| 85 | Song S X, Wang Y, Liang M, et al. Mechanical and gas barrier properties of poly(l⁃lactic acid) by plasma⁃enhanced chemical vapor deposition of SiOx [J]. Polymer⁃Plastics Technology and Engineering, 2018, 57(6): 581⁃590. |

| 86 | Hirvikorpi T, Vaha⁃Nissi M, Mustonen T, et al. Atomic layer deposited aluminum oxide barrier coatings for packaging materials [J]. Thin Solid Films, 2010, 518(10): 2 654⁃2 658. |

| 87 | Zhu J, Kumar A, Hu P, et al. Layering⁃triggered delayering with exfoliated high⁃aspect ratio layered silicate for enhanced gas barrier, mechanical properties, and degradability of biodegradable polymers [J]. Global Challenges, 2020, 4(9): 2000030⁃2000039. |

| 88 | 徐岩岩, 张永红, 尹宗杰, 等. 氧化石墨烯/聚乳酸自组装薄膜的制备及阻隔性能研究 [J]. 化工新型材料, 2023, 51(4): 96⁃101. |

| XU Y Y, ZHANG Y H, YIN Z J, et al. Preparation and barrier properties of graphene oxide/polylactic acid self‐assembled films [J]. New Chemical Materials, 2023, 51(4): 96‐101. | |

| 89 | Thakur S, Misra M, Mohanty A K. Sustainable hydrophobic and,moisture⁃resistant coating derived from downstream corn oil [J]. ACS Sustainable Chemistry & Engineering, 2019, 7(9): 8 766⁃8 774. |

| 90 | 郑闪闪, 杭建忠, 孙小英, 等. 苯基三甲氧基硅烷改性纳米纤维素纸基阻隔涂层的制备及性能 [J]. 高分子材料科学与工程, 2020, 36(3): 120⁃125. |

| ZHENG S S, HANG J Z, SUN X Y, et al. Preparation and properties of phenyltrimethoxysilane modified nanocellulose paper⁃based barrier coating [J] Polymer Materials Science and Engineering, 2020, 36(3): 120⁃125. | |

| 91 | Weizman O, Dotan A, Nir Y, et al. Modified whey protein coatings for improved gas barrier properties of biodegradable films [J]. Polymers for Advanced Technologies, 2017, 28(2): 261⁃270. |

| 92 | 吴新磊. 壳聚糖基纳米复合涂料流变性及涂层阻隔性的研究 [D]. 南京: 南京林业大学, 2016. |

| 93 | 敬 兴, 黄海洋, 骆华英, 等. 环保型PLA/CNF应用于纸张阻隔性涂布的研究 [J]. 中国造纸学报, 2022, 37(3): 86⁃93. |

| JING X, HUANG H Y, LUO H Y, et al. Environmentallyfriendly PLA/CNF is used in research on barrier coating of paper [J]. Journal of Chinese Journal of Papermaking, 22, 37(3): 86⁃93. | |

| 94 | 张 玲, 陈 寿, 孙耀明, 等. FGO⁃WPUPA光固化阻隔涂料的制备及其对PLA薄膜阻氧性能的影响 [J]. 中国塑料, 2017, 31(8): 35⁃40. |

| ZHANG L, CHEN S, SUN Y M, et al. Preparation of the oxygen barrier properties of PLA films [J]. China Plastics, 2017, 31(8): 35⁃40. | |

| 95 | Ma M L, Mao Y, Gupta M, et al. Superhydrophobic fabrics produced by electrospinning and chemical vapor deposition [J]. Macromolecules, 2005, 38(23): 9 742⁃9 748. |

| [1] | 孙颖, 白林, 刘明昊, 翁云宣, 陈礼平. 生物聚酯保鲜膜的制备及其保鲜效果比较[J]. 中国塑料, 2023, 37(10): 93-100. |

| [2] | 李毅, 樊桂琪, 吴天宇, 叶海木. 石墨微片对聚三氟氯乙烯结晶及性能的影响[J]. 中国塑料, 2023, 37(1): 18-25. |

| [3] | 熊一鸣, 宋季岭, 秦舒浩, 龙雪彬, 鲁显睿. 改性热塑性淀粉的制备及其与PBAT复合薄膜的性能[J]. 中国塑料, 2022, 36(8): 69-72. |

| [4] | 孙滔, 杨青, 胡健, 王洋样, 刘博, 云雪艳, 董同力嘎. 聚(乳酸⁃乙醇酸)薄膜制备及其性能研究[J]. 中国塑料, 2022, 36(2): 33-40. |

| [5] | 祝文亲, 张丽洋, 崔亮, 王仪森, 张凤波, 朱凯歌, 高克京, 荔栓红. 微纳层叠聚合物复合材料研究进展[J]. 中国塑料, 2022, 36(11): 158-163. |

| [6] | 李玉竹, 姚利辉, 叶世强, 吕国永, 刘盼盼, 徐龙飞, 仇丹. 生物降解材料在水环境中降解性能的研究进展[J]. 中国塑料, 2021, 35(7): 103-114. |

| [7] | 杨小龙, 李永青, 闫晓堃, 陈文静, 马秀清. 聚合物/石墨烯阻气型复合材料的研究进展[J]. 中国塑料, 2021, 35(12): 145-153. |

| [8] | 冯申, 温亮, 孙朝阳, 计扬. PGA/PBAT复合材料的性能及应用研究[J]. 中国塑料, 2020, 34(11): 36-40. |

| [9] | 卞其波, 田华峰, 王娅茹, 刘茜, 项爱民. 聚乙烯醇/淀粉纳米晶复合膜的制备及表征[J]. 中国塑料, 2015, 29(03): 95-99 . |

| [10] | 王竹 许国志 孙辉. 聚碳酸亚丙酯/有机水滑石复合材料的制备及性能研究[J]. 中国塑料, 2014, 28(03): 65-70 . |

| [11] | 田 华, 杨 彪, 许国志, 林 毅. 淀粉基生物降解材料的制备及其力学性能的研究[J]. 中国塑料, 2009, 23(02): 51-53 . |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2