京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2

《中国塑料》编辑部 ©2008-2024 版权所有

地址:北京市海淀区阜成路11号 邮编:100048

编辑部:010-68985541 联系信箱:cp@plaschina.com.cn

广告部/发行部:010-68985253 本系统由北京玛格泰克科技发展有限公司设计开发

中国塑料 ›› 2024, Vol. 38 ›› Issue (8): 100-105.DOI: 10.19491/j.issn.1001-9278.2024.08.016

• 塑料与环境 • 上一篇

收稿日期:2023-11-27

出版日期:2024-08-26

发布日期:2024-08-19

通讯作者:

江伟(1983—),男,博士,教授级高级工程师,从事塑料污染控制与资源化研究,jiangwei@nju.edu.cn

ZHU Chenxi1, CHEN Chenhui1, HU Guoming1, ZHANG Lei2, JIANG Wei1( )

)

Received:2023-11-27

Online:2024-08-26

Published:2024-08-19

Contact:

JIANG Wei

E-mail:jiangwei@nju.edu.cn

摘要:

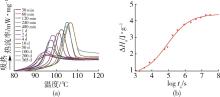

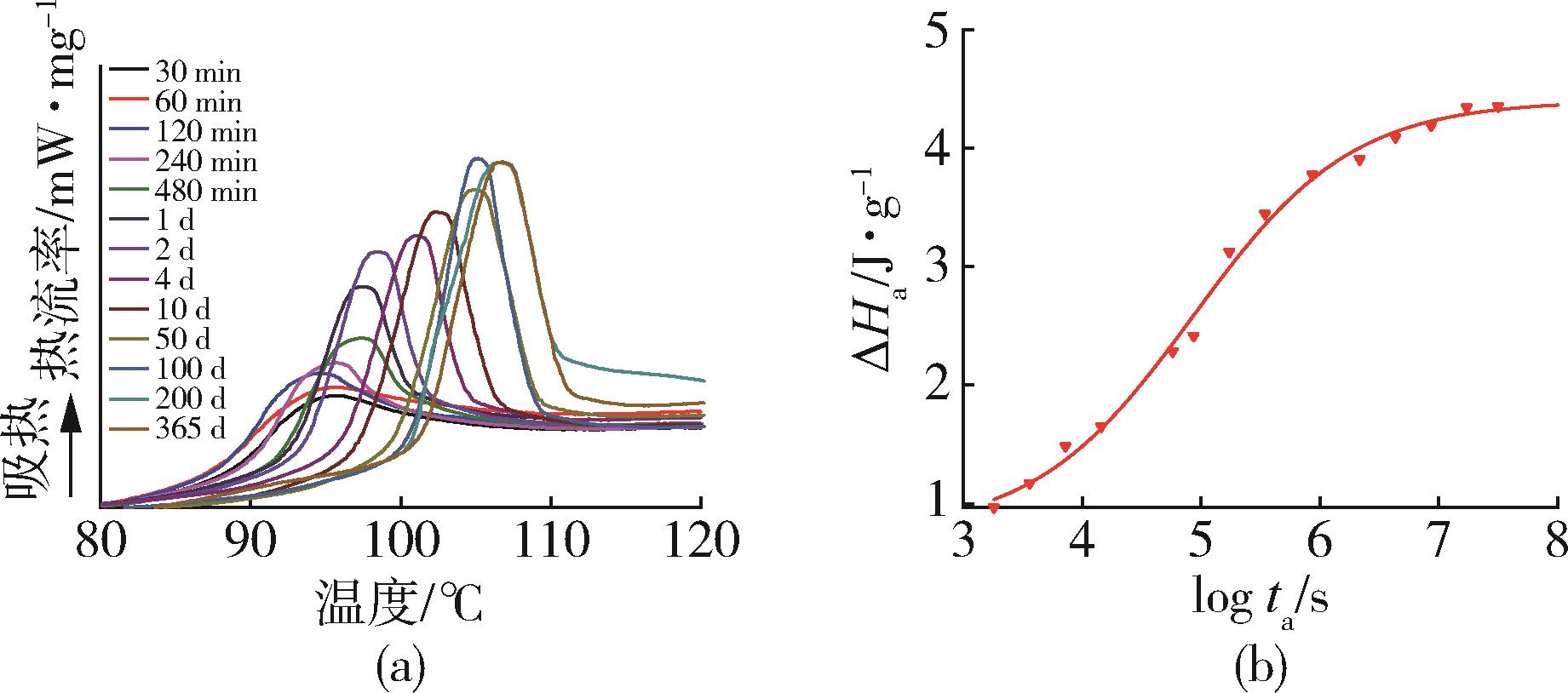

模拟了废弃聚苯乙烯(PS)在垃圾填埋场环境下的光热老化,首先对老化样品前后的分子结构进行了表征;并通过X射线衍射、差示扫描量热仪测试以及纳拉扬斯瓦米⁃莫伊尼汉(TNM)模型和全原子分子动力学计算(MD)对PS老化过程中的焓松弛过程进行研究。结果表明,PS在光老化后会断链,分子量从112 200下降至13 000左右,并产生聚苯乙烯低聚物、苯甲酸酐、苯乙酮和苯甲酸甲酯等物质;此外,老化会导致PS结晶度和玻璃化转变温度的降低,其焓松弛的变化在老化初期较为迅速,随着老化的进行趋于平缓,平衡时对应的焓值为4.2 J/g。

中图分类号:

朱晨曦, 陈辰慧, 胡国明, 张蕾, 江伟. 填埋场废弃聚苯乙烯老化机制研究[J]. 中国塑料, 2024, 38(8): 100-105.

ZHU Chenxi, CHEN Chenhui, HU Guoming, ZHANG Lei, JIANG Wei. Study on aging mechanism of waste polystyrene in landfill[J]. China Plastics, 2024, 38(8): 100-105.

| 老化天数/d | 数均分子量/g·mol-1 | 重均分子量/g·mol-1 | 分子量分布 |

|---|---|---|---|

| 0 | 112 200 | 261 400 | 2.330 |

| 5 | 34 900 | 176 300 | 5.040 |

| 10 | 31 600 | 162 800 | 5.147 |

| 20 | 19 800 | 107 700 | 5.416 |

| 30 | 17 700 | 87 000 | 4.905 |

| 40 | 13 700 | 63 100 | 4.606 |

| 50 | 13 400 | 73 100 | 5.439 |

| 60 | 13 000 | 60 100 | 4.609 |

| 70 | 13 000 | 55 600 | 4.270 |

| 80 | 12 900 | 45 600 | 3.518 |

| 老化天数/d | 数均分子量/g·mol-1 | 重均分子量/g·mol-1 | 分子量分布 |

|---|---|---|---|

| 0 | 112 200 | 261 400 | 2.330 |

| 5 | 34 900 | 176 300 | 5.040 |

| 10 | 31 600 | 162 800 | 5.147 |

| 20 | 19 800 | 107 700 | 5.416 |

| 30 | 17 700 | 87 000 | 4.905 |

| 40 | 13 700 | 63 100 | 4.606 |

| 50 | 13 400 | 73 100 | 5.439 |

| 60 | 13 000 | 60 100 | 4.609 |

| 70 | 13 000 | 55 600 | 4.270 |

| 80 | 12 900 | 45 600 | 3.518 |

| 1 | 刁晓倩, 翁云宣, 宋鑫宇, 等. 国内外生物降解塑料产业发展现状[J]. 中国塑料,2020, 34 (5):123⁃135. |

| DIAO X Q, WENG Y X, SONG X Y,et al. Current development situation of biodegradable plastic industry In China and abroad[J]. China Plastics, 2020, 34 (5):123⁃135. | |

| 2 | Sundqvist⁃Andberg H, Akerman M. Sustainability governance and contested plastic food packaging e an integrative review[J]. Journal of Cleaner Production, 2021, 306:127111. |

| 3 | Chen Y, Awasthi A K, Wei F,et al. Single⁃use plastics: production, usage, disposal, and adverse impacts[J]. Science of the Total Environment, 2021, 752:141772. |

| 4 | Qi R, Jones D L, Li Z, et al.Behavior of microplastics and plastic film residues in the soil environment: A critical review[J]. Science of the Total Environment, 2020, 703:134772. |

| 5 | Jiang H, Zhang Y, Wang H. Surface reactions in selective modification: The prerequisite for plastic flotation[J]. Environmental Science & Technology, 2020, 54 (16): 9 742⁃9 756. |

| 6 | Taghavi N, Udugama I A, Zhuang WQ, et al. Challenges in biodegradation of non⁃degradable thermoplastic waste: From environmental impact to operational readiness[J]. Biotechnology Advances, 2021, 49:107731. |

| 7 | Liang K, Liu L, Wang W, et al. Conversion of waste plastic into ordered mesoporous carbon for electrochemical applications[J]. Journal of Materials Research, 2019, 34 (6): 941⁃949. |

| 8 | Ren Z, Gui X, Wei Y, et al. Chemical and photo⁃initiated aging enhances transport risk of microplastics in saturated soils: Key factors, mechanisms, and modeling[J]. Water Research, 2021, 202:117407. |

| 9 | Ito T, Hiraki A. Aging phenomena of light⁃emitting porous silicon[J]. Journal of Luminescence, 1993, 57 (1/6): 331⁃339. |

| 10 | Jang B N, Wilkie C A. The thermal degradation of polystyrene nanocomposite[J]. Polymer, 2005, 46 (9): 2 933⁃2 942. |

| 11 | Mao R, Lang M, Yu X, et al. Aging mechanism of microplastics with UV irradiation and its effects on the adsorption of heavy metals[J]. Journal of Hazardous Materials, 2020, 393:122515. |

| 12 | Song Y K, Hong S H, Jang M, et al. Combined effects of UV exposure duration and mechanical abrasion on microplastic fragmentation by polymer type[J]. Environmental Science & Technology, 2017, 51 (8):4 368⁃4 376. |

| 13 | Liu X, Sun P, Qu G, et al. Insight into the characteristics and sorption behaviors of aged polystyrene microplastics through three type of accelerated oxidation processes[J]. Journal of Hazardous Materials, 2021, 407:124836. |

| 14 | Zhang L K, Chen W Y, Wang H M, et al. Growth factors regional patterned and photoimmobilized scaffold applied to bone tissue regeneration[J]. Journal of Materials Chemistry B, 2020, 8 (48):10 990⁃11 000. |

| 15 | Lang M, Yu X, Liu J, et al. Fenton aging signi ficantly affects the heavy metal adsorption capacity of polystyrene microplastics[J]. Science of the Total Environment, 2020, 722:137762. |

| 16 | Narayanaswamy S. A model of structural relaxation in glass[J]. Journal of The American Ceramic Society⁃Narayanaswamy, 1971, 54:491⁃498. |

| 17 | Koh Y P, Simon S L. Enthalpy recovery of polystyrene: Does a long⁃term aging plateau exist? [J]. Macromolecules, 2013, 46 (14):5 815⁃5 821. |

| 18 | Cangialosi D, Boucher V M, Alegria A, et al. Direct evidence of two equilibration mechanisms in glassy polymers. Physical Review Letters, 2013, 111 (9):095701. |

| 19 | Weyer S, Huth H, Schick C. Application of an extended Tool⁃Narayanaswamy⁃Moynihan model. Part 2. Frequency and cooling rate dependence of glass transition from temperature modulated DSC[J]. Polymer, 2005, 46 (26):12 240⁃12 246. |

| 20 | Salomon⁃Ferrer R, Case D A, Walker R C. An overview of the amber biomolecular simulation package[J]. WIREs Computational Molecular Science, 2013, 3 (2):198⁃210. |

| 21 | Lü J T, Hu B Z, Hedegard P, et al. Semi⁃classical generalized Langevin equation for equilibrium and nonequilibrium molecular dynamics simulation[J]. Progress in Surface Science, 2019, 94 (1):21⁃40. |

| 22 | Pikkemaat M G, Linssen A B M, Berendsen H J C, et al. Molecular dynamics simulations as a tool for improving protein stability[J]. Protein Engineering, Design and Selection, 2002, 15 (3):185⁃192. |

| 23 | Sprenger K G, Jaeger V W, Pfaendtner J. The general amber force field (GAFF) can accurately predict thermodynamic and transport properties of many ionic liquids[J]. The Journal of Physical Chemistry B, 2015, 119 (18):5 882⁃5 895. |

| 24 | Natali M, Nastasi F, Puntoriero F, et al. Mechanistic insights into light⁃activated catalysis for water oxidation[J]. European Journal of Inorganic Chemistry, 2019, (15):2 027⁃2 039. |

| 25 | Wang C, Zhao Z, Deng X, et al. Ultrafast oxidation of emerging contaminants by novel VUV/Fe2+/PS process at wide pH range: Performance and mechanism[J]. Chemical Engineering Journal, 2021, 426:131931. |

| 26 | Wang M, Yang L, Guo C, et al. Bimetallic Fe/Ti⁃based metal⁃organic framework for persulfate⁃assisted visible light photocatalytic degradation of orange II[J]. Chemistryselect, 2018, 3 (13):3 664⁃3 674. |

| 27 | Mueller A, Becker R, Dorgerloh U, et al. The effect of polymer aging on the uptake of fuel aromatics and ethers by microplastics[J]. Environmental Pollution, 2018, 240:639⁃646. |

| 28 | Xiong Y, Zhao J, Li L, et al. Interfacial interaction between micro/nanoplastics and typical PPCPs and nanoplastics removal via electrosorption from an aqueous solution[J]. Water Research, 2020, 184:116110. |

| 29 | Wang H, Liu P, Wang M, et al. Enhanced phototransformation of atorvastatin by polystyrene microplastics: Critical role of aging[J]. Journal of Hazardous Materials, 2021, 408:124756. |

| 30 | Zhu K, Jia H, Zhao S, et al. Formation of environmentally persistent free radicals on microplastics under light irradiation[J]. Environmental Science & Technology, 2019, 53 (14): 8 177⁃8 186. |

| 31 | Bottino F A, Cinquegrani A R, Di Pasquale G, et al. Chemical modifications, mechanical properties and surface photo⁃oxidation of films of polystyrene (PS) [J]. Polymer Testing, 2004, 23 (4):405⁃411. |

| [1] | 段凯歌, 陈小蝶, 倪佳, 梅振威, 周朝锡, 叶小平, 朱辉, 于东明. 紫外交联高密度聚乙烯材料的制备及性能研究[J]. 中国塑料, 2024, 38(5): 24-27. |

| [2] | 严成, 李露露, 陈天欢, 郭帅, 俞科静. 超高分子量聚乙烯纤维表面纳米ZnO可控生长及其界面性能研究[J]. 中国塑料, 2024, 38(5): 47-54. |

| [3] | 张春波, 刘宣伯, 姚雪容, 苏萃, 施红伟, 张龙贵, 张韬毅. 共聚焦拉曼成像技术研究PE⁃LD/EVOH共混物的三维相结构[J]. 中国塑料, 2024, 38(4): 1-5. |

| [4] | 蒲强, 何霞, 王国荣, 胡刚. 点载荷作用下聚乙烯燃气管道的损伤分析[J]. 中国塑料, 2024, 38(3): 67-72. |

| [5] | 罗冠群, 赵乐, 潘雅琪. 废弃PE与PET共热解特性与动力学特性研究[J]. 中国塑料, 2024, 38(3): 86-93. |

| [6] | 陈清江, 董志聪, 李红发, 吴毅江, 高松, 聂文翔, 罗应文. 改性纳米氧化镁交联聚乙烯复合材料的制备及其电气性能研究[J]. 中国塑料, 2024, 38(2): 20-25. |

| [7] | 白皛, 乔亮, 范峻铭, 闻炯明, 张毅. Ⅳ型储氢气瓶塑料内胆氢渗透特性及失效分析研究进展[J]. 中国塑料, 2024, 38(1): 62-78. |

| [8] | 赵晓波, 王国泰, 梁淑君. 聚硅氧烷包覆改性聚磷酸铵及其阻燃聚乙烯性能的研究[J]. 中国塑料, 2024, 38(1): 86-91. |

| [9] | 武立文, 乔亮, 范峻铭, 闻炯明, 李兆璞, 张毅. 聚乙烯管道寿命预测研究进展[J]. 中国塑料, 2023, 37(11): 149-162. |

| [10] | 万艳红. 氯化聚乙烯及专用料的研究进展[J]. 中国塑料, 2023, 37(11): 35-45. |

| [11] | 王斌, 王振超, 何安淇, 程德宝, 王娅茹, 赵晓颖, 项爱民. 聚乙烯/炭黑复合材料电熔焊接研究[J]. 中国塑料, 2023, 37(10): 111-116. |

| [12] | 杨喜英, 张文才, 赵志新. 纳米碳酸钙/废旧聚乙烯功能化复合改性沥青性能影响及机理研究[J]. 中国塑料, 2023, 37(10): 85-92. |

| [13] | 段凯歌, 朱辉, 倪佳, 泮豪, 周朝锡, 陈小蝶, 梅振威, 于东明. 热塑性交联聚乙烯(TPEXa)管材的制备及性能研究[J]. 中国塑料, 2023, 37(1): 8-12. |

| [14] | 李守超, 房迎春, 唐新强. 聚乙烯粉料粒径分布对熔体质量流动速率的影响[J]. 中国塑料, 2023, 37(1): 26-30. |

| [15] | 张兆阳, 唐敢, 柯雪, 王鑫, 江学良, 刘仿军, 游峰. 硫酸钙晶须改性聚乙烯/聚酰胺6复合材料的热性能与力学性能研究[J]. 中国塑料, 2022, 36(11): 35-40. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2