京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2

《中国塑料》编辑部 ©2008-2024 版权所有

地址:北京市海淀区阜成路11号 邮编:100048

编辑部:010-68985541 联系信箱:cp@plaschina.com.cn

广告部/发行部:010-68985253 本系统由北京玛格泰克科技发展有限公司设计开发

中国塑料 ›› 2025, Vol. 39 ›› Issue (3): 19-24.DOI: 10.19491/j.issn.1001-9278.2025.03.004

收稿日期:2024-09-04

出版日期:2025-03-26

发布日期:2025-03-24

通讯作者:

侯丹丹(1981-),女,高级工程师,从事高分子材料与精细化学品的研究工作,houdd.bjhy@sinopec.com作者简介:邓静倩(1995-),女,博士,工程师,从事多孔材料的制备工作,dengjq.bjhy@sinopec.com

DENG Jingqian1( ), KONG Peng2, HOU Dandan1(

), KONG Peng2, HOU Dandan1( )

)

Received:2024-09-04

Online:2025-03-26

Published:2025-03-24

Contact:

HOU Dandan

E-mail:dengjq.bjhy@sinopec.com;houdd.bjhy@sinopec.com

摘要:

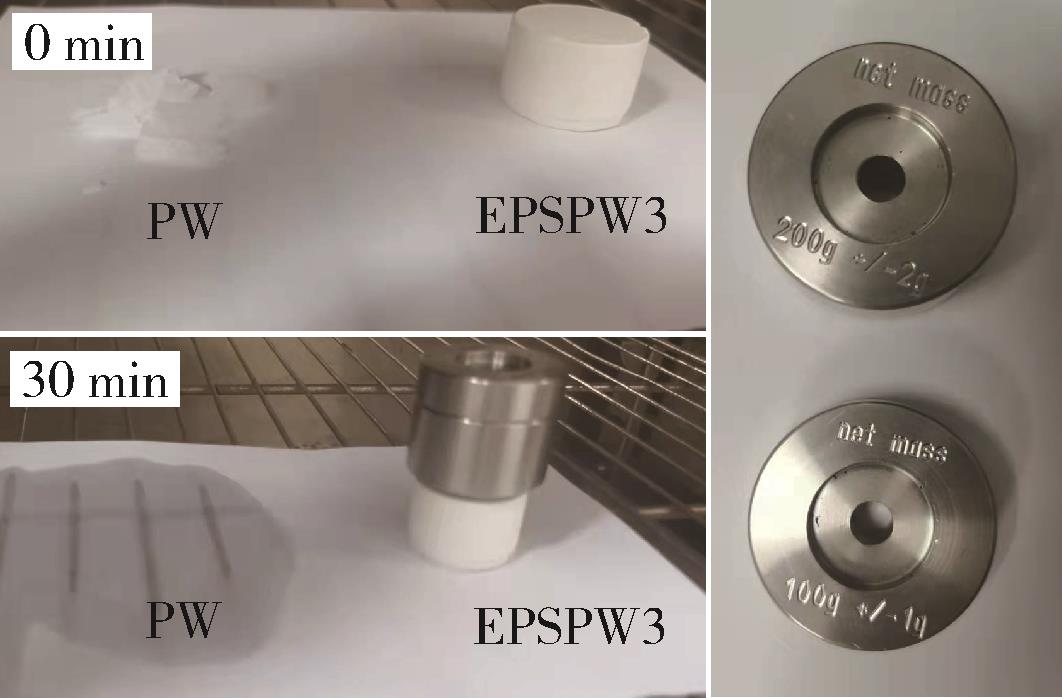

采用乳液模板法制备了聚苯乙烯/石蜡复合相变泡沫材料(EPSPW),其中石蜡被包封在泡沫材料的孔隙中。结果表明,EPSPW的孔隙率为85 %~92 %(体积分数,下同),孔径介于3.5~10 μm,分布较窄;当石蜡含量为30 %(质量分数,下同)时,EPSPW在33倍自身质量的载荷下表现出优异的形状稳定性,且无石蜡泄露;浸出测试显示,在高于石蜡熔点的温度下样品中的质量损失率仅为3%;EPSPW的熔融焓达到32 J/g,远远高于直接发泡的相变泡沫材料的相变焓(大多在15~20 J/g之间);此外,EPSPW在50次加热/冷却循环中表现出良好的循环稳定性。

中图分类号:

邓静倩, 孔鹏, 侯丹丹. 乳液模板法制备相变泡沫材料及其储热性能增强研究[J]. 中国塑料, 2025, 39(3): 19-24.

DENG Jingqian, KONG Peng, HOU Dandan. Fabrication of foamy phase change materials with enhanced thermal performance by emulsion⁃templating method[J]. China Plastics, 2025, 39(3): 19-24.

| 样品 | 质量比 | 石蜡 质量 分数/% | ||||

|---|---|---|---|---|---|---|

| St | DVB | Span80 | 石蜡 | 石蜡 乳化剂 | ||

| EPS | 4 | 4 | 2 | 0 | 0 | 0 |

| EPSPW1 | 6 | 6 | 3 | 4.00 | 1 | 20.0 |

| EPSPW2 | 4 | 4 | 2 | 4.00 | 1 | 26.7 |

| EPSPW3 | 10 | 10 | 5 | 12.00 | 3 | 30.0 |

| PW | 0 | 0 | 0 | 10.00 | 0 | 100.0 |

| PS/20wt%PW | 6 | 6 | 3 | 3.75 | 0 | 20.0 |

| 样品 | 质量比 | 石蜡 质量 分数/% | ||||

|---|---|---|---|---|---|---|

| St | DVB | Span80 | 石蜡 | 石蜡 乳化剂 | ||

| EPS | 4 | 4 | 2 | 0 | 0 | 0 |

| EPSPW1 | 6 | 6 | 3 | 4.00 | 1 | 20.0 |

| EPSPW2 | 4 | 4 | 2 | 4.00 | 1 | 26.7 |

| EPSPW3 | 10 | 10 | 5 | 12.00 | 3 | 30.0 |

| PW | 0 | 0 | 0 | 10.00 | 0 | 100.0 |

| PS/20wt%PW | 6 | 6 | 3 | 3.75 | 0 | 20.0 |

| 样品 | 密度/g·cm-3 | 孔隙率/% |

|---|---|---|

| EPS | 0.055 | 93.9 |

| EPSPW1 | 0.090 | 91.2 |

| EPSPW2 | 0.130 | 87.1 |

| EPSPW3 | 0.150 | 85.1 |

| 样品 | 密度/g·cm-3 | 孔隙率/% |

|---|---|---|

| EPS | 0.055 | 93.9 |

| EPSPW1 | 0.090 | 91.2 |

| EPSPW2 | 0.130 | 87.1 |

| EPSPW3 | 0.150 | 85.1 |

| 样品 | Tcpeak/ ℃ | ΔHc/ J·g-1 | Tmpeak/ ℃ | ΔHm/ J·g-1 | Xrelative/ % |

|---|---|---|---|---|---|

| PW | 45.2 | 138.5 | 55.9 | 134.1 | 100.0 |

| PS/20wt%PW | 45.2 | 27.7 | 55.9 | 26.8 | 100.0 |

| EPSPW1 | 46.1 | 18.2 | 53.4 | 17.6 | 65.6 |

| EPSPW2 | 45.3 | 28.5 | 54.0 | 27.9 | 78.5 |

| EPSPW3 | 45.7 | 33.0 | 53.4 | 32.0 | 79.5 |

| EPSPW3⁃经过50个循环 | 45.7 | 32.8 | 53.4 | 31.9 | - |

| 样品 | Tcpeak/ ℃ | ΔHc/ J·g-1 | Tmpeak/ ℃ | ΔHm/ J·g-1 | Xrelative/ % |

|---|---|---|---|---|---|

| PW | 45.2 | 138.5 | 55.9 | 134.1 | 100.0 |

| PS/20wt%PW | 45.2 | 27.7 | 55.9 | 26.8 | 100.0 |

| EPSPW1 | 46.1 | 18.2 | 53.4 | 17.6 | 65.6 |

| EPSPW2 | 45.3 | 28.5 | 54.0 | 27.9 | 78.5 |

| EPSPW3 | 45.7 | 33.0 | 53.4 | 32.0 | 79.5 |

| EPSPW3⁃经过50个循环 | 45.7 | 32.8 | 53.4 | 31.9 | - |

| 1 | Wang Y, Zhang S, Wang D, et al. Experimental study on the influence of temperature and humidity on the thermal conductivity of building insulation materials[J]. Energy and Built Environment, 2023, 4(4): 386⁃398. |

| 2 | Liu K, Niu H, Wang Y. Moisture absorption and desorption characteristics and prediction model analysis of building thermal insulation materials[J]. Applied Thermal Engineering, 2024, 248: 123196. |

| 3 | Chang L, Lu Z, Hou X, et al. Preparation of flame retardant and thermal insulation polystyrene foams via high internal phase emulsion template[J]. Polymers for Advanced Technologies, 2024, 35(2): e6292. |

| 4 | Marques DV, Barcelos RL, Silva HR, et al. Recycled polyethylene terephthalate⁃based boards for thermal⁃acoustic insulation[J]. Journal of Cleaner Production, 2018, 189:251⁃262. |

| 5 | Naldzhiev D, Mumovic D, Strlic M. Polyurethane insulation and household products⁃a systematic review of their impact on indoor environmental quality[J]. Building and Environment, 2020,169:106559. |

| 6 | Lee Y, Choi S, Choe K, et al. Physical and mechanical characteristics of polyurethane foam insulators blown by HFC[C]. InISOPE International Ocean and Polar Engineering Conference, 2005, 19 (pp. ISOPE⁃I). ISOPE. |

| 7 | Serrano A, Borreguero A M, Garrido I, et al. The role of microstructure on the mechanical properties of polyurethane foams containing thermoregulating microcapsules[J]. Polymer Testing, 2017, 60:274⁃282. |

| 8 | Amaral C, Pinto SC, Silva T, et al. Development of polyurethane foam incorporating phase change material for thermal energy storage[J]. Journal of Energy Storage, 2020, 28:101177. |

| 9 | Sobolčiak P, Mrlik M, Popelka A, et al. Foamed phase change materials based on recycled polyethylene/paraffin wax blends[J]. Polymers, 2021, 13(12):1 987. |

| 10 | Ramli Sulong N H, Mustapa S A, Abdul Rashid M K. Application of expanded polystyrene (EPS) in buildings and constructions: A review[J]. Journal of Applied Polymer Science, 2019, 136(20):47529. |

| 11 | Mochane M J, Luyt A S. Preparation and properties of polystyrene encapsulated paraffin wax as possible phase change material in a polypropylene matrix[J]. Thermochimica acta, 2012, 544:63⁃70. |

| 12 | Amaral C, Vicente R, Eisenblätter J, et al. Thermal characterization of polyurethane foams with phase change material[J]. Ciência & Tecnologia dos Materiais, 2017, 29(2):1⁃7. |

| 13 | Qu L, Li A, Gu J, Zhang C. Thermal energy storage capability of polyurethane foams incorporated with microencapsulated phase change material[J]. ChemistrySelect, 2018, 3(11):3 180⁃3 186. |

| 14 | Wu H Y, Li S T, Shao Y W, et al. Melamine foam/reduced graphene oxide supported form⁃stable phase change materials with simultaneous shape memory property and light⁃to⁃thermal energy storage capability[J]. Chemical Engineering Journal, 2020, 379:122373. |

| 15 | Xue F, Lu Y, Qi XD, et al. Melamine foam⁃templated graphene nanoplatelet framework toward phase change materials with multiple energy conversion abilities[J]. Chemical Engineering Journal, 2019, 365:20⁃29. |

| 16 | Chen T, Liu C, Mu P, et al. Fatty amines/graphene sponge form⁃stable phase change material composites with exceptionally high loading rates and energy density for thermal energy storage[J]. Chemical Engineering Journal, 202, 382:122831. |

| 17 | Sarier N, Onder E. Thermal characteristics of polyurethane foams incorporated with phase change materials[J]. Thermochimica acta, 2007, 454(2):90⁃98. |

| 18 | Kausar A. Polyurethane composite foams in high⁃performance applications: A review[J]. Polymer⁃Plastics Technology and Engineering, 2018, 57(4):346⁃369. |

| 19 | Qu L, Li A, Gu J, Zhang C. Thermal energy storage capability of polyurethane foams incorporated with microencapsulated phase change material[J]. ChemistrySelect, 2018, 3(11):3 180⁃3 186. |

| 20 | Chen P, Gao X, Wang Y, et al. Metal foam embedded in SEBS/paraffin/HDPE form⁃stable PCMs for thermal energy storage[J]. Solar Energy Materials and Solar Cells, 2016, 149:60⁃65. |

| 21 | Qiu X, Lu L. Microencapsulated paraffin as a phase change material with polyurea/polyurethane/poly (lauryl methacrylate) hybrid shells for thermal energy storage applications[J]. Journal of Renewable and Sustainable Energy, 2021, 13(1). |

| 22 | Krupa I, Nógellová Z, Špitalský Z, et al. Phase change materials based on high⁃density polyethylene filled with microencapsulated paraffin wax[J]. Energy conversion and management, 2014, 87:400⁃409. |

| 23 | 林 捷,张 茜,魏信义,等.相变微胶囊填充改性聚乙二醇/酚醛泡沫的制备[J].林业工程学报,2023,8(04):102⁃109.DOI:10.13360/j.issn.2096-1359.202211007 . |

| LIN J, ZHANG Q, WEI X, et al. Preparation and characterization of modified polyethylene glycol/phenolic foam filled with phase change microcapsules[J]. Journal of Forestry Engineering, 2023,8(04):102⁃109.DOI:10.13360/j.issn.2096-1359.202211007 . | |

| 24 | Yuan L, Li X, Ge L, et al. Emulsion template method for the fabrication of gelatin⁃based scaffold with a controllable pore structure[J]. ACS applied materials & interfaces, 2018, 11(1):269⁃277. |

| 25 | Zhang Z, Zhang Z, Chang T, et al. Phase change material microcapsules with melamine resin shell via cellulose nanocrystal stabilized Pickering emulsion in⁃situ polymerization[J]. Chemical Engineering Journal, 2022, 428:131164. |

| 26 | Shang Y, Zhang D. Preparation and characterization of three⁃dimensional graphene network encapsulating 1⁃hexadecanol composite[J]. Applied Thermal Engineering, 2017, 111:353⁃357. |

| 27 | Wibawa P J, Saim H, Agam M A, et al. Design, preparation and characterization of polystyrene nanospheres based⁃porous structure towards UV⁃vis and infrared light absorption[J]. Physics Procedia, 2011, 22: 524⁃531. |

| 28 | Cao L, Tang F, Fang G. Synthesis and characterization of microencapsulated paraffin with titanium dioxide shell as shape⁃stabilized thermal energy storage materials in buildings[J]. Energy and Buildings, 2014, 72: 31⁃37. |

| 29 | Chae D W, Kim B C. Characterization on polystyrene/zinc oxide nanocomposites prepared from solution mixing[J]. Polymers for advanced technologies, 2005, 16(11/12): 846⁃850. |

| 30 | Brezny R, Green D J. The effect of cell size on the mechanical behavior of cellular materials[J]. Acta metallurgica et materialia, 1990, 38(12): 2 517⁃2 526. |

| 31 | Yang S, Zeng L, Li Z C, et al. Tailoring the morphology of emulsion⁃based (glycidylmethacrylate⁃divinylbenzene) monoliths[J]. European polymer journal, 2014, 57: 127⁃136. |

| 32 | Sobolčiak P, Abdelrazeq H, Ouederni M, et al. The stabilizing effect of expanded graphite on the artificial aging of shape stabilized phase change materials[J]. Polymer Testing, 2015, 46: 65⁃71. |

| 33 | Sobolciak P, Mrlík M, AlMaadeed M A, et al. Calorimetric and dynamic mechanical behavior of phase change materials based on paraffin wax supported by expanded graphite[J]. Thermochimica acta, 2015, 617: 111⁃119. |

| 34 | Tang Q, Sun J, Yu S, et al. Improving thermal conductivity and decreasing supercooling of paraffin phase change materials by n⁃octadecylamine⁃functionalized multi⁃walled carbon nanotubes[J]. RSC advances, 2014, 4(69): 36 584⁃36 590. |

| 35 | McClements D J, Dungan S R, German J B, et al. Droplet size and emulsifier type affect crystallization and melting of hydrocarbon⁃in⁃water emulsions[J]. Journal of food science, 1993, 58(5): 1 148⁃1 151. |

| 36 | Wu D, Ni B, Liu Y, et al. Preparation and characterization of side⁃chain liquid crystal polymer/paraffin composites as form⁃stable phase change materials[J]. Journal of materials chemistry A, 2015, 3(18): 9 645⁃9 657. |

| 37 | Freiberg S, Zhu X X. Polymer microspheres for controlled drug release[J]. International journal of pharmaceutics, 2004, 282(1/2): 1⁃18. |

| [1] | 唐波, 相利学, 代旭明, 王二轲, 姜涛, 王瑛, 吴新锋. 金刚石导热复合材料的研究进展[J]. 中国塑料, 2024, 38(8): 125-131. |

| [2] | 代瑞, 潘威, 黄士争, 朱家威, 曾宪奎, 杨卫民, 鉴冉冉. 场协同扭转螺杆热输运性能的研究[J]. 中国塑料, 2024, 38(3): 109-115. |

| [3] | 佟亚轩, 高海南, 陈礼平, 翁云宣. 生物基气凝胶的改性及功能化研究进展[J]. 中国塑料, 2024, 38(2): 87-94. |

| [4] | 张之琪, 李润焘, 杨瑞程, 代云良, 章晓娟, 温变英. 片状FeSiAl/Al2O3共填充聚偏氟乙烯复合材料的吸波导热性能研究[J]. 中国塑料, 2023, 37(9): 44-50. |

| [5] | 贾子辰 马辰俣 汪毅 汪贵梅 彭万 黄琦睿 潘丽静 韩敏 胡一鸣 宇平. 基于大体积芴侧基热固性聚酰亚胺的合成及性能研究[J]. , 2023, 37(7): 22-26. |

| [6] | 李凯 曹宁 蒋岳航 李建华 崔雪梅 连慧琴 汪晓东 崔秀国. 膨胀石墨/黑磷阻燃硬质聚氨酯泡沫的制备及性能研究[J]. , 2023, 37(6): 21-30. |

| [7] | 沈一蕊, 周文斌, 张菁菁, 赵承仲, 高华坤, 沈曙光, 刘德开, 蒋平平. 中长碳链氯化石蜡在聚氯乙烯制品中的应用及性能研究[J]. 中国塑料, 2023, 37(1): 31-37. |

| [8] | 董佑邦, 张泽祺, 杨荣杰. 氨丙基低聚硅倍半氧烷及其酰胺化产物的合成与表征[J]. 中国塑料, 2022, 36(8): 1-9. |

| [9] | 李凯泽, 辛勇. 改性碳纳米管增强热塑性聚氨酯复合材料的性能研究[J]. 中国塑料, 2022, 36(6): 1-5. |

| [10] | 张云峰, 钟威, 张璐, 兰志兴, 董志博. 液体石蜡/聚砜树脂/纳米SiO2复合相变材料的制备及性能表征[J]. 中国塑料, 2022, 36(6): 32-38. |

| [11] | 蒋森, 王立岩, 陈延明, 张乐, 翟桂法. MPO改性PBS共聚酯的合成及其热性能研究[J]. 中国塑料, 2022, 36(4): 24-29. |

| [12] | 衡月, 薛南翔, 陈壮鑫, 雷彩红, 徐睿杰. 聚乙烯/石蜡油共混体系动态流变行为和相容性[J]. 中国塑料, 2022, 36(2): 13-18. |

| [13] | 何明峰, 王珂, 王启扬, 杨肖, 郭红, 胡泊洋, 李保安. 聚偏氟乙烯/类基体基团修饰石墨烯导热复合材料研究[J]. 中国塑料, 2022, 36(2): 41-48. |

| [14] | 王芳, 李言, 郭新涛, 窦鹏. 含双酚芴三元共聚聚砜的合成与性能[J]. 中国塑料, 2022, 36(11): 24-29. |

| [15] | 王启扬, 杨肖, 陈吉奂, 何悦星, 杨冬梅, 胡泊洋, 郭红, 李保安. 双隔离结构聚乙烯/石墨烯导热复合材料的研究[J]. 中国塑料, 2022, 36(1): 32-41. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802034965号

京ICP备13020181号-2

京公网安备11010802034965号

京ICP备13020181号-2